2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

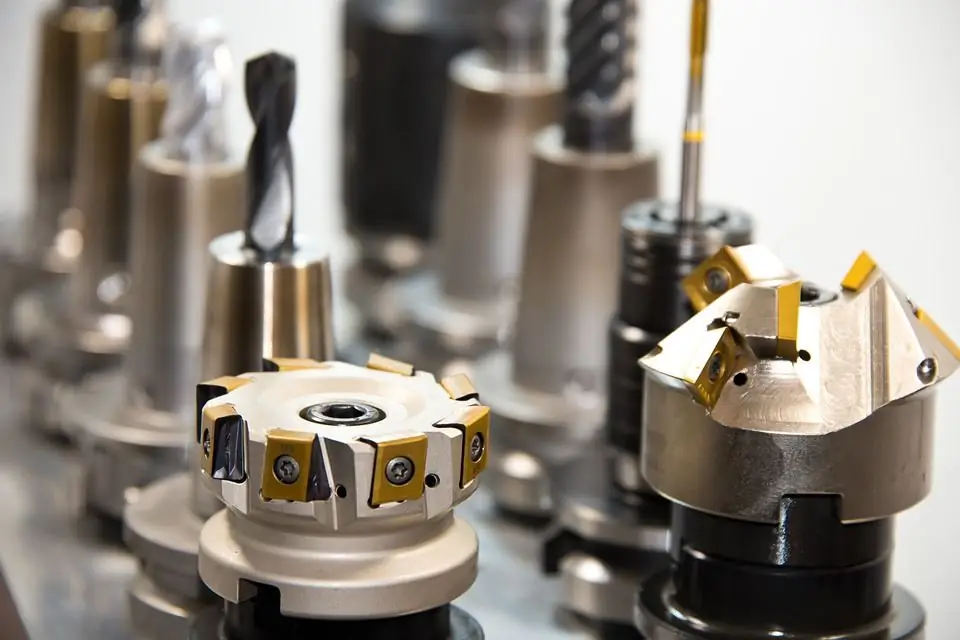

Machining yog nqa tawm los ntawm kev txiav ib zawj, dav hlau, tiaj tus (qab). Hauv qhov no, lub cuab yeej txiav hu ua milling cutter yog siv. Li no lub npe - milling. Lub cutter txav rotationally, thaum lub workpiece txav mus rau pem hauv ntej.

Tus kws tshaj lij Askiv Askiv Eli Whitney tau suav tias yog tus tsim lub tshuab milling. Nws tau txais patent rau lub tshuab milling xyoo 1818.

instrumental yog dab tsi?

Ua ntej yuav mus rau qhov kev piav qhia ntawm cutters, kev faib tawm thiab lub hom phiaj, nws tsim nyog nkag siab tias txhua lub cuab yeej yog dab tsi. Nws muaj cov hniav, tig lub cev thiab cov hniav.

Qhov txiav yog ua los ntawm carbide, cermet, ntxhia ceramic, pob zeb diamond, khoom xaim xaim lossis cov hlau kub ceev. Cov qauv tuaj yeem ua los ntawm ib qho khoom siv (khoom), lossis nws tuaj yeem ua tau prefabricated (cov ntsiab lus sib txawv yog txuas rau ib leeg siv tus qauv fasteners, xws li cov ntsia hlau, cov npoo, txiv ntseej, bolts).

Teem faib cov cutters nrog cov ntsiab lus brazed rau kev txiav. Cov cuab yeej no hu ua soldered. Welded milling cutters suav nrog tus Tsov tus tw thiab txiav qhov chaw ntawm ntau yam ntaub ntawv, uas txuas nrog vuam.

Tsis tas li ntawd, muaj milling taub hau, uas tseem hu ua mechanical. Qhov no yog ib hom tshwj xeeb ntawm cutter. Kev faib tawm ntawm cutters implies ib tug loj tus naj npawb ntawm cov cuab yeej siv nyob ntawm seb cov khoom ntawm lub workpiece. Cov no suav nrog cov cuab yeej uas muaj kev kub ceev steel thiab cov khoom siv hloov pauv tau (nyuaj alloys). Cais, lub taub hau (tsis muaj hniav) hu ua lub cev.

Kev faib tawm

Muaj ntau hom kev txiav cov cuab yeej. Kev faib tawm ntawm cov cutters nyob ntawm ntau yam khoom.

hom tsiaj:

1. Kaum. Hom kev txiav cov cuab yeej no feem ntau yog siv hauv groove milling. Lawv yog:

- asymmetrical biangular (ncaj thiab helical grooves);

- symmetric ob-lub kaum sab xis (grooves ntawm ib tug zoo li tus txiav);

- ib lub kaum ntse ntse (ncaj flutes).

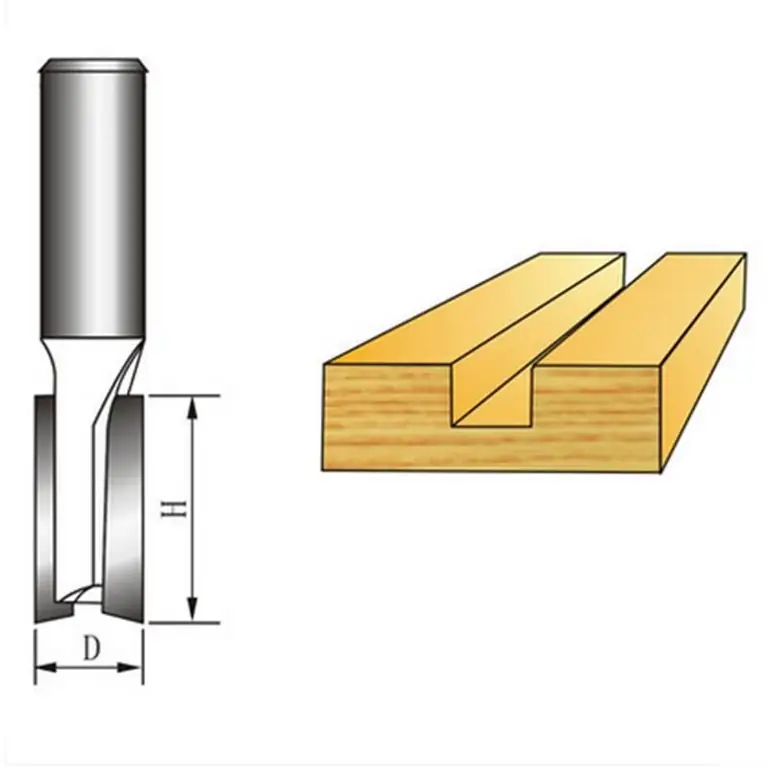

2. Nrog lub tiaj kawg. Kuv siv ntau yam no hauv kev faib cov cutters rau kev txiav, roughing thiab sampling. Thaum kawg, lub cuab yeej muaj cov duab ntawm tsab ntawv "P", thiab lub shank nyob rau hauv txoj kab uas hla yog tsawg kawg yog 0.2 hli. Chip evacuation coils yuav muaj ntau cov lus qhia:

- hybrid;

- left;

- ncig;

- yog.

Qhov chaw siv nws txawv nyob ntawm seb tus naj npawb ntawm cov hniav.

- 1 hniav - txiav, dub tiav;

- 2 hniav - ib nrab tiav thiab txiav;

- 3 thiab ntau dua - sampling, tiavkev ua ntawm ntau hom hlau, mos hlau.

3. Nrog spherical kawg. Cov cuab yeej zoo li no yog siv rau hauv kev ua haujlwm hlau hauv kev tsim cov khoom ntawm cov duab nyuaj: pwm, turbine hniav, tuag. Lawv tsuas yog tsim nyob rau hauv ib thooj, txawm hais tias kuj muaj cutters nrog interchangeable inserts. Thaum ua cov ntoo, nws yog siv los tsim cov khoom 3D. Txawm hais tias cheeb tsam no yog dominated los ntawm kev siv cov conical cutters nrog ib tug spherical kawg.

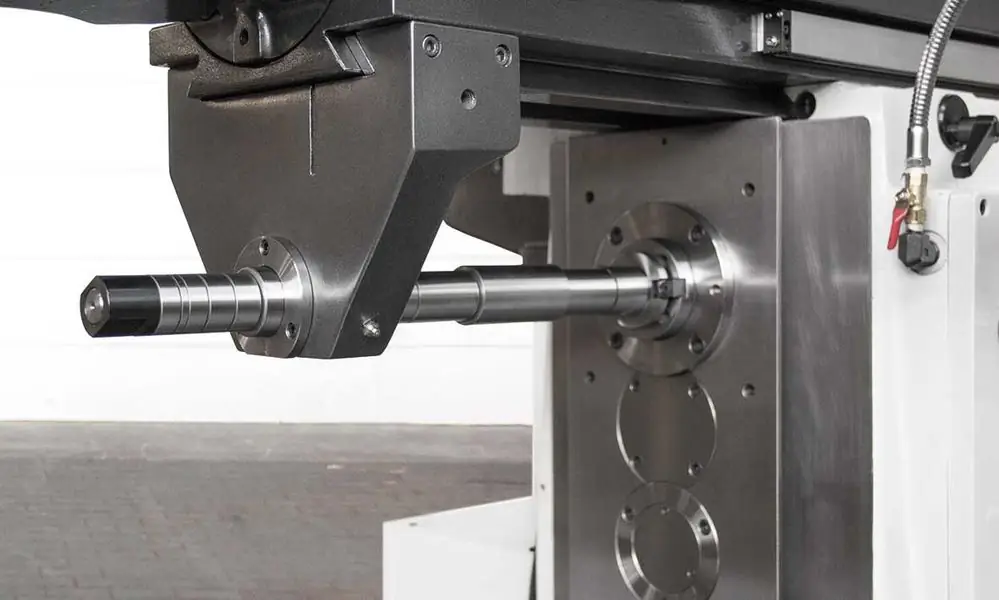

4. Xaus. Nws yog siv rau industrial milling tshuab. Tsis zoo li kev xyaum, ib yam khoom tuaj yeem ua haujlwm rau txhua qhov kev qhia, tsis yog nyob rau hauv ib qho kev taw qhia axial xwb. End mills yog mounted nyob rau hauv lub tshuab spindle nrog tus Tsov tus tw nyob rau hauv daim ntawv ntawm lub khob hliav qab los yog lub tog raj kheej. Muaj ntau ntau hom kawg mills nyob ntawm cov khoom:

- tungsten carbide crowns thiab ntsia hlau hniav;

- tungsten carbide;

- keyway nrog lub tog raj kheej lossis lub khob hliav qab;

- rau segment keys.

5. Disk. Hauv kev faib cov cutters, cov cuab yeej disk siv rau kev txiav, txiav thiab lwm yam kev ua uas cuam tshuam nrog kev ua haujlwm ntxhib ntawm cov hlau lossis cov hlau tsis yog hlau. Muab faib ua 3 pawg:

- Spline (keyway) - muaj cov hniav nkaus xwb ntawm qhov chaw cylindrical.

- Peb-sab - hniav ntawm ob qho kawg.

- ob-sab - hniav ntawm qhov kawg.

Yog tias koj cov cutters muaj carbide inserts, lawv tuaj yeem hloov kho raws li txoj haujlwm ntawm daim cartridge. Qhov no hloov qhov dav ntawm grooves. Feem ntau, lawv profile ntoo qhov chaw rau rooj tog facades, ntoo euro-qhov rais,euro plinth, qhov rooj glazing hlaws, vaj huam sib luag, qhov rooj ncej, thiab lwm yam.

Muab cov cutters raws li cov khoom ua tiav

Kev faib tawm ntawm cov cuab yeej no thiab lawv lub hom phiaj yog nyob ntawm cov khoom siv los ua tiav. Piv txwv li:

- Cast iron.

- Copper.

- Graphite.

- Teeb.

- Hardened thiab stainless hlau.

- Aluminium.

Technological nta

Tsis tas li ntawd, cov cuab yeej raug cais los ntawm cov khoom uas tso cai ua ntau yam ntaub ntawv:

- Lub cev tig;

- Rau cov khoom txiav;

- xov thiab iav.

Tsim nta

1. Kev taw qhia hniav:

- ncig;

- ntsej;

- oblique;

- cutters nrog ntau txoj kev cov hniav.

2. Kev faib tawm ntawm cov cutters los ntawm kev tsim:

- solid;

- nrog lub taub hau sib tsoo;

- compound;

- Insert tool.

3. Hniav tsim:

- cutters nrog cov hniav thim rov qab (profile txiav ntug yog muab nrog kev sib xws thaum rov ua kom ntse dua rau pem hauv ntej);

- taw tes.

4. Kev faib tawm ntawm cov cutters raws li txoj kev ntawm kev teeb tsa ntawm lub tshuab:

- overhanging (milling cutter nrog qhov);

- cuab yeej nrog lub khob lossis lub tog raj kheej shank;

- end (tail).

Teeb

Kev xaiv cov cuab yeej tshwj xeeb los ntawm kev faib tawm ntawm cov ntoo txiav yog nyob ntawm qhov chaw los ua machined.

Cov ntoo tuaj yeem siv rau:

- koom kev sib tw los ntawm kev sib tw;

- ua qhov chaw so rau kev txhim kho cov hlua khi thiab lwm yam khoom siv;

- kho kom zoo nkauj, uas yog ua los ntawm kev siv lub tshuab txiav.

Cov cuab yeej siv feem ntau yog 6-12 hli inch. Nyob rau hauv cov ntaub ntawv no, ib tug nti collet thiab ib tug millimeter tail yuav tsum tsis txhob siv nyob rau hauv ua hauj lwm. Qhov no tuaj yeem ua rau tawg ntawm cov txiav, thiab qhov phem tshaj plaws, ua rau raug mob rau tus neeg ua haujlwm.

Cov khoom lag luam muab rau qee qhov kev hloov kho. Nws yog ib qho ua tau los siv lub tshuab txiav txiav. Nws cov cuab yeej tsim los ua cov yas thiab hlau, nrog rau ntoo.

hom ntoo ua haujlwm

- Grooves yog tsim, recesses yog tsim siv kawg cutters.

- Cylindrical cuab tam grooving.

- Kev siv cov duab snaps rau curly recesses, uas ua rau cov khoom tshwj xeeb thiab inimitable.

- Kev tsim khoom raws li cov qauv tshwm sim siv kev tsim kho ntawm ntug thiab cov kabmob.

Tsis tas li, tsis txhob hnov qab tias cov kabmob hauv tes zeb yuav tsum tau saib xyuas tag nrho cov cuab yeej. Lub rotating caij yog lubricated nrog ib tug nyias txheej thoob plaws hauv lub neej ntawm cov khoom.

Metal

Kev faib cov cutters rau hlau:

1. Xaus. Lawv feem ntau yog siv los ua lub dav hlau ntawm lub tshuab ntsug milling. Hom cutter no muaj qhov ua haujlwm saum cov npoo ntse ntawm cov hniav. Lub luag haujlwm tseem ceeb yog nqa tawm nrog kev pab ntawm lateral pointed edges nyob sab nraum ib feem. Thiab cov npoo kawg yog cov khoom siv ntxiv. Cov cuab yeej no ua kom muaj kev ua haujlwm zoo, vim tias lub kaum sab xis sib cuag nyob ntawm txoj kab uas hla ntawm cov khoom txiav. Lub tshuab kawg yog nruj heev thiab loj, uas tso cai rau koj kom yooj yim thiab ntseeg tau txoj haujlwm thiab ruaj ntseg txiav cov ntsiab lus, nrog rau muab lawv nrog cov alloys nyuaj. Qhov milling no ua tau zoo dua li lwm cov cuab yeej.

2. Disk. Qhov no yog cov khoom siv niaj hnub tseem ceeb tshaj plaws. Nws yog siv rau milling grooves thiab grooves, muaj peb hom. Disc cutters muaj cov khoom lag luam siab, txawm tias lawv feem ntau muaj cov hniav txiav. Nyias disc cutters, tseem hu ua saws, yog siv los txiav cov qhov thiab nqaim grooves ntawm qhov chaw. Ua li no, sharpen chamfers los ntawm qhov kawg ntawm cov khoom siv. Nws tuaj yeem txiav tawm ib nrab ntawm kev txiav ntug. Vim li no, cov hniav txiav tawm chips ntawm qhov xav tau dav, uas yuav nqaim dua li qhov dav ntawm qhov raug txiav. Yog li, kev tshem tawm nti hauv cov kab noj hniav yog txhim kho, txij li nws tau muab tso rau qhov dav li sai tau. Yog tias qhov ntev ntawm qhov txiav thiab qhov zawj yog tib yam, qhov kawg ntawm cov chips yuav pib kov rau sab ntawm qhov zawj. Yog li ntawd, yuav muaj teeb meem nyob rau hauv qhov chaw pub dawb ntawm chips, ces lub diskcutter tej zaum yuav tawg.

3. Lub kaum sab xis thiab kawg mills. Cov cuab yeej lub kaum yog siv rau milling ib lub dav hlau inclined thiab lub kaum qhov. Lub kaum sab xis cutter muaj cov npoo. Lawv nyob ntawm qhov kawg thiab conical nto. Cov npoo ntawm ob lub kaum sab xis cutter yog nyob rau ntawm ob qhov chaw conical. Qhov kawg zeb yog siv thaum ua ib tug sib sib zog nqus groove nyob rau hauv lub cev qhov chaw ntawm ledges thiab contour recesses. Nyob rau hauv cov ntaub ntawv no, ib tug conical los yog cylindrical shank yog tsau nyob rau hauv lub tshuab spindle. Nrog rau cov cuab yeej no, feem ntau ntawm kev txiav ua haujlwm yog ua los ntawm cov npoo tseem ceeb ntawm qhov chaw cylindrical. Nyob rau hauv cov ntaub ntawv no, lub auxiliary npoo yog siv los ntxuav lub hauv qab ntawm qhov zawj. Cov cutters no feem ntau nruab nrog helical lossis inclined hniav.

4. Keyway cutters. Raws li tau sau tseg saum toj no, qhov no yog hom kawg zeb. Nws yog ib qho cuab yeej zoo li laum. Nws tuaj yeem plunge mus rau hauv lub workpiece thaum lub sij hawm axial feed txheej txheem, drilling ib lub qhov, thiab ces coj raws li qhov zawj. Nyob rau hauv thawj feem ntawm kev ua hauj lwm, kev txiav tshwm sim nrog kev pab los ntawm cov npoo kawg, ib tug ntawm cov uas yuav tsum yeej haum rau lub axis ntawm lub cutter. Qhov no yuav ncaj qha laum lub qhov.

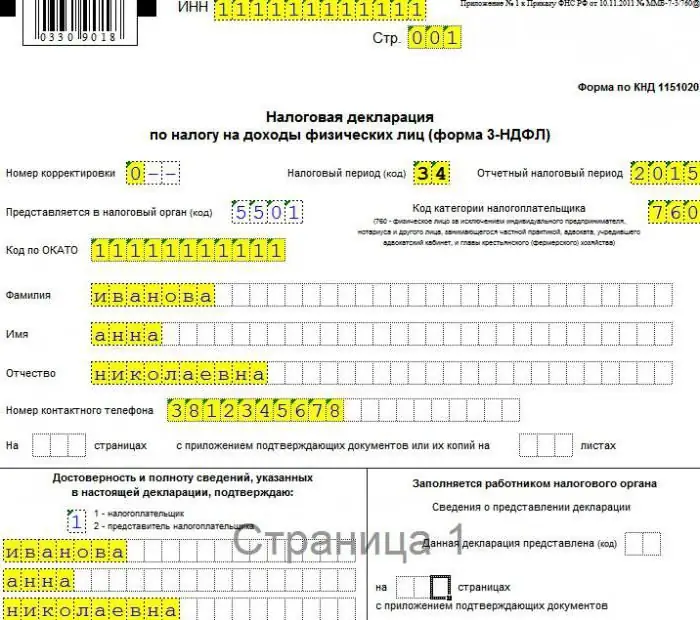

OKPD: kev faib tawm ntawm cov txiav

Qhov no yog cov ntawv luv, uas feem ntau yog deciphered li "All-Lavxias classifier ntawm cov khoom los ntawm hom kev ua haujlwm." Nws yog ib feem ntawm cov txheej txheem txheej txheem hauv Lavxias Federation.

Siv los txiav txim cov ntsiab lus ntawm kev yuav khoom pej xeem (raws li Tsoom Fwv Teb Chaws Txoj Cai "Nyob rau hauv daim ntawv cog lus"). Siv tau txij li xyoo 2008.

Zaj lus

Milling cutters yog cov cuab yeej siv feem ntau siv rau kev ua haujlwm. Nws tuaj yeem muaj ntau hom hniav, txiav cov npoo thiab cov hniav ib zaug. Ib qho tshwj xeeb ntawm cov cuab yeej siv no yog ntau qhov ntau thiab tsawg, hom, profiles thiab daim ntawv thov.

Cutters, lawv hom thiab kev faib tawm txawv heev hauv lawv qhov kev teeb tsa, cov khoom thiab cov haujlwm. Txhawm rau txiav txim siab qhov tshwj xeeb, koj yuav tsum kawm cov khoom ua haujlwm.

Pom zoo:

Daim ntawv thov rov qab los ntawm kev tuav pov hwm qiv nyiaj: piv txwv, cov cai ntawm daim ntawv thov, lub sijhawm xa tawm

Nyob rau hauv tus txheej txheem ntawm tau txais cov nyiaj qiv, cov tsev txhab nyiaj muaj peev xwm qiv nyiaj los xaus daim ntawv cog lus pov hwm. Yog tias tus neeg siv tsis tuaj yeem them cov nuj nqis, lub luag haujlwm kaw nws mus rau lub txhab nyiaj yog nrog lub tuam txhab pov hwm. Tab sis hauv kev xyaum, qhov xwm txheej tsis sib xws feem ntau tshwm sim, thiab cov neeg them nyiaj siab xav tau xav txog qhov muaj peev xwm rov qab tau txais kev pov hwm qiv nyiaj thaum them rov qab ntxov. Tab sis yuav tau txais ntau npaum li cas? Thiab leej twg yuav tsum muab cov nyiaj - tus tuav pov hwm lossis lub txhab nyiaj?

Thermal imaging tswj ntawm cov khoom siv hluav taws xob: lub tswv yim, lub hauv paus ntsiab lus ntawm kev ua haujlwm, hom thiab kev faib tawm ntawm thermal imagers, nta ntawm daim ntawv thov thiab kev txheeb xyuas

Kev ntsuas cua sov ntawm cov khoom siv hluav taws xob yog ib txoj hauv kev zoo los txheeb xyuas qhov tsis xws ntawm cov khoom siv hluav taws xob uas kuaj pom yam tsis tau kaw lub tshuab hluav taws xob. Nyob rau hauv qhov chaw ntawm kev sib cuag tsis zoo, qhov kub thiab txias nce, uas yog lub hauv paus ntawm cov txheej txheem

Cov cua kub siab qis: txhais, lub hauv paus ntawm kev ua haujlwm, cov yam ntxwv ntawm kev ua haujlwm, kev faib tawm, tsim, kev ua haujlwm nta, daim ntawv thov hauv kev lag luam

Cov cua kub siab qis (LPH) tam sim no siv heev. Muaj ob hom tseem ceeb uas yog tsim los ntawm cov nroj tsuag sib txawv. Lawm, lawv kuj txawv ntawm lawv cov kev ua tau zoo

Tshaj tawm ntawm phab ntsa daim ntawv qhia hnub: hom, xaiv cov ntsiab lus ntawm daim ntawv qhia hnub, nuances ntawm kev tsim thiab luam ntawv

Daim ntawv qhia hnub yog ib qho tseem ceeb ntawm txhua qhov chaw ua haujlwm. Thiab txawm tias muaj pes tsawg tus neeg siv khoom thiab cov neeg muag khoom pub dawb rau lawv, lawv tseem ua khawv koob los ntawm lub tuam txhab cov chaw ua haujlwm uas tsis koom nrog kev sib txuas lus nrog cov neeg cog lus. Cias muab, daim ntawv qhia hnub yog qhov tseem ceeb tshaj plaws ntawm cov ntaub ntawv tshaj tawm uas ib txwm mus nrog lub suab nrov

Daim ntawv thov nyiaj rov qab ntawm cov nyiaj tau los ntawm tus kheej rau kev kawm: thaum koj tuaj yeem tau txais nws, cov cai rau kev thov rau kev txiav se tawm

Tau txais kev txiav se tawm hauv Russia yog txheej txheem yooj yim heev. Kab lus no yuav qhia rau koj txhua tus hais txog yuav ua li cas kom tau txais cov nqi kawm ntawv txiav tawm thiab thov kom rov qab tau cov nyiaj tau los