2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

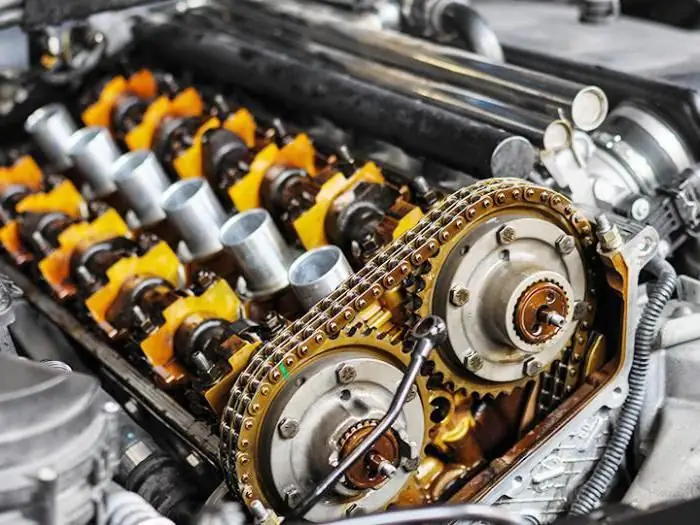

Cov txheej txheem ntawm kev ua haujlwm ntawm cov cuab yeej cuab tam, tshuab thiab ib pawg ntawm cov cuab yeej tseem ceeb yog inevitably nrog hnav. Kev sib nrig sib cuam tshuam ntawm cov khoom ntawm ib leeg nrog ntau qib ntawm kev siv zog ua rau puas tsuaj ntawm lawv qhov chaw thiab kev puas tsuaj ntawm cov qauv sab hauv. Tsis tas li ntawd, ib puag ncig feem ntau muaj qhov zoo sib xws hauv daim ntawv ntawm kev yaig thiab cavitation. Yog li ntawd, muaj kev poob ntawm cov cuab yeej ua haujlwm lossis tsawg kawg yog qhov txo qis hauv kev ua haujlwm. Cov kev tshuaj xyuas hauv qab no ntawm cov hmoov txhuam thiab cov khoom siv los tiv thaiv kev sib txhuam yuav pab koj nkag siab txog txoj hauv kev kom txo qis kev sib txhuam tsis zoo. Cov ntaub ntawv zoo li no tau pom zoo siv rau hauv cov khoom siv hauv tsev thiab cov khoom siv hauv tsev, nrog rau cov cuab yeej tsim kho.

Qhov sib txawv ntawm kev sib txhuam thiab cov khoom siv tiv thaiv kev sib txhuam

Kev txiav txim siab ntawm cov ntaub ntawv no hauv ib lub ntsiab lus yog vim qhov tseeb tias lawv txoj haujlwm muaj feem cuam tshuam rau cov yam ntxwv ntawm kev ua haujlwm ntawm cov txheej txheem - cov coefficient ntawm kev sib txhuam. Tab sis yog hais tias antifriction ntsiab thiab additives yog lub luag hauj lwm rau txo tus nqi no, ces kev sib txhuam ntsiab, ntawm qhov tsis tooj, nce nws. Nyob rau hauv cov ntaub ntawv no, piv txwv li, hmoov alloys nrog ncecoefficient ntawm kev sib txhuam muab kev hnav tsis kam thiab kev siv lub zog ntawm lub hom phiaj ua haujlwm. Txhawm rau kom ua tiav cov txiaj ntsig zoo li no, cov khoom siv hluav taws xob refractory oxides, boron, silicon carbides, thiab lwm yam yog nkag mus rau hauv cov khoom sib txhuam raw khoom, tsis zoo li cov khoom siv tiv thaiv kev sib txhuam, kev sib txhuam cov ntsiab lus feem ntau sawv cev rau tag nrho cov khoom siv hauv lub cev hauv cov txheej txheem. Qhov no, tshwj xeeb, tuaj yeem yog brakes thiab clutches.

Muab cov dej num ntawm kev sib txhuam, lawv ib txhij ua cov haujlwm tshwj xeeb. Nyob rau tib lub sijhawm, ob qho tib si kev sib txhuam thiab cov khoom siv los tiv thaiv kev sib txhuam tau raug kuaj xyuas nruj ua ntej siv. Tib yam alloys rau brakes tau txais kev ntsuas tag nrho thiab lub rooj ntev zaum, thaum lub sijhawm ua tiav ntawm lawv daim ntawv thov hauv kev xyaum yog txiav txim siab. Cov khoom siv thev naus laus zis tshaj plaws los ntawm cov khoom siv polymers niaj hnub no yog tsim los ntawm ntau txoj hauv kev. Yog li, rau cov txheej txheem ntawm cov pab pawg nres, cov txheej txheem nias yog siv - blocks, daim hlau thiab cov sectors yog ua nyob rau hauv cov ntaub ntawv. Cov ntaub ntawv kab xev yog tsim los ntawm cov txheej txheem woven, thiab overlays yog tsim los ntawm dov.

Cov khoom ntawm cov khoom tiv thaiv kev sib txhuam

Txuas nrog kev tiv thaiv kev sib txhuam yuav tsum ua tau raws li ntau yam kev xav tau uas txiav txim siab lawv qhov kev ua tau zoo. Ua ntej tshaj plaws, cov khoom siv yuav tsum sib haum nrog ob qho tib si mating thiab qhov chaw ua haujlwm. Nyob rau hauv tej yam kev mob ntawm compatibility ua ntej thiab tom qab khiav nyob rau hauv, cov khoom muab qhov yuav tsum tau degree ntawm kev sib txhuam txo. Ntawm no nws yog ib qho tsim nyog yuav tsum nco ntsoov qhov khiav-hauv xws li. Cov cuab yeej no txhais lub ntsiab lub peev xwm los kho qhov chaw geometry.nyob rau hauv qhov kev pom zoo, uas yog tsim rau ib qho chaw ua haujlwm. Hauv lwm lo lus, ib qho qauv ntxiv nrog microroughnesses raug tshem tawm los ntawm ib feem, tom qab ntawd qhov kev khiav-hauv yuav muab kev ua haujlwm nrog cov khoom siv tsawg heev.

Hnav tiv thaiv kuj yog ib qho khoom tseem ceeb uas muaj los ntawm cov ntaub ntawv no. Cov khoom tiv thaiv kev sib txhuam yuav tsum muaj cov qauv uas muab kev tiv thaiv rau ntau hom kev hnav. Nyob rau tib lub sijhawm, ib feem yuav tsum tsis txhob nruj heev thiab nyuaj, vim qhov no yuav ua rau muaj kev pheej hmoo ntawm kev txeeb, uas yog qhov tsis zoo rau cov khoom siv los tiv thaiv kev sib txhuam. Ntxiv mus, technologists ib leeg tawm xws li cov cuab yeej xws li kev nqus ntawm cov khoom siv. Qhov tseeb yog tias kev sib txhuam ntawm qhov sib txawv tuaj yeem ua rau kev tso tawm ntawm cov khoom me me - feem ntau yog hlau. Nyob rau hauv lem, lub anti-kev sib txhuam nto muaj peev xwm "nias" xws li hais rau hauv nws tus kheej, tshem tawm lawv los ntawm qhov chaw ua hauj lwm.

Cov khoom siv hlau tiv thaiv kev sib txhuam

Cov khoom lag luam ntawm lub hauv paus hlau ua kom muaj ntau yam ntawm cov khoom ntawm pawg tiv thaiv. Feem ntau ntawm lawv yog tsom rau kev ua haujlwm hauv cov kua dej sib txhuam, uas yog, nyob rau hauv cov xwm txheej thaum cov bearings raug cais tawm ntawm cov ncej los ntawm cov roj nyias nyias. Thiab tseem, thaum lub chav tsev nres thiab pib, lub thiaj li hu ua ciam teb kev sib txhuam hom inevitably tshwm sim, nyob rau hauv uas cov roj zaj duab xis yuav raug puas tsuaj nyob rau hauv lub siab kub. Cov khoom siv hlau siv hauv cov kabmob tuaj yeem muab faib ua ob hom: cov khoom nrog cov mos moscov qauv thiab cov khoom ntxig thiab cov alloys nrog lub hauv paus nruj thiab cov ntxig mos. Yog tias peb tham txog thawj pab pawg, ces babbits, tooj dag thiab tooj liab alloys tuaj yeem siv los ua cov ntaub ntawv tiv thaiv. Vim lawv cov qauv mos, lawv khiav nrawm thiab khaws lawv cov yeeb yaj kiab roj rau lub sijhawm ntev. Ntawm qhov tod tes, cov khoom suav nrog ua rau muaj zog hnav tsis kam hauv kev sib cuag nrog cov khoom nyob ib sab - piv txwv li, nrog tib lub ncej.

Babbits yog ib qho hlau raws li cov hlau lead lossis tin. Tsis tas li ntawd, txhawm rau txhawm rau txhim kho tus kheej zoo, cov hlau alloys tuaj yeem muab ntxiv rau cov qauv. Ntawm cov khoom txhim kho, corrosion kuj, hardness, toughness thiab lub zog tuaj yeem raug sau tseg. Qhov kev hloov ntawm ib lossis lwm tus yam ntxwv yog txiav txim siab los ntawm cov khoom siv alloying dab tsi. Kev sib txhuam babbits tuaj yeem hloov kho nrog cadmium, npib tsib xee, tooj liab, antimony, thiab lwm yam. Piv txwv li, tus qauv babbit muaj li ntawm 80% tin lossis txhuas, 10% antimony, thiab tus so yog tooj liab thiab cadmium.

Lead alloys raws li kev txo qis kev sib txhuam

Qib nkag ntawm cov hlau tiv thaiv kev sib txhuam yog cov hlau lead babbits. Affordability txiav txim siab qhov tshwj xeeb ntawm kev ua haujlwm ntawm cov khoom siv no - hauv cov haujlwm tseem ceeb tshaj plaws. Lub hauv paus hlau lead, piv nrog cov tin, muab cov babbits nrog cov khoom siv tsis zoo thiab kev tiv thaiv corrosion tsawg. Muaj tseeb, txawm nyob rau hauv xws li alloys nws tsis tuaj yeem ua yam tsis muaj tin - nws cov ntsiab lus tuaj yeem ua taumus txog 18%. Tsis tas li ntawd, cov khoom siv tooj liab kuj tseem ntxiv rau cov khoom sib xyaw, uas tiv thaiv cov txheej txheem sib cais - kev faib tsis sib xws ntawm cov hlau sib txawv hauv qhov ntim ntawm cov khoom.

Cov khoom siv lead ua yooj yim tshaj plaws nrog cov khoom tiv thaiv kev sib txhuam yog cov yam ntxwv los ntawm qib siab ntawm brittleness, yog li lawv tau siv nyob rau hauv cov xwm txheej nrog txo qis dynamic loads. Hauv particular, bearings rau cov cav tov khiav, diesel locomotives thiab hnyav engineering Cheebtsam yog lub hom phiaj niche uas cov ntaub ntawv no yog siv. Anti-kev sib txhuam alloys siv calcium tuaj yeem hu ua kev hloov kho ntawm cov hlau lead alloys. Nyob rau hauv cov ntaub ntawv no, xws li zoo li high ntom thiab tsawg thermal conductivity raug sau tseg. Lub hauv paus tseem yog txhuas, tab sis nyob rau hauv qhov tseem ceeb proportions nws kuj yog supplemented los ntawm inclusions ntawm sodium, calcium thiab antimony. Raws li cov ntsiab lus tsis muaj zog ntawm cov khoom no, lawv suav nrog oxidizability, yog li ntawd, nws tsis pom zoo kom siv nws nyob rau hauv ib puag ncig chemically active.

Hais lus dav dav txog babbits, peb tuaj yeem hais tias qhov no yog deb ntawm qhov kev daws teeb meem zoo tshaj plaws rau kev txo qis kev sib txhuam, tab sis hais txog kev sib xyaw ua ke ntawm cov khoom zoo, nws hloov tawm los ntawm qhov pom ntawm kev ua haujlwm. Cov no yog cov ntaub ntawv uas nws antifriction zog yuav leveled los ntawm txo qaug zog tsis kam, uas ua phem rau cov kev kawm ntawm lub caij. Txawm li cas los xij, qee zaum, qhov tsis muaj zog tau them nyiaj los ntawm kev suav nrog cov hlau lossis cov hlau cam hauv qhov tsim.

Txheej txheem ntawm bronze tiv thaiv kev sib txhuam alloys

Lub cev thiab tshuaj lom neeg ntawm bronzeyog organically ua ke nrog cov kev cai rau kev sib txhuam alloys. Cov hlau no, tshwj xeeb tshaj yog, muab cov ntsuas txaus ntawm qhov tshwj xeeb siab, muaj peev xwm ua haujlwm hauv kev poob siab loads, siab bearing rotation ceev, thiab lwm yam. Tab sis kuj qhov kev xaiv ntawm bronze rau tej lub zog yuav nyob ntawm seb nws hom. Tib hom ntawv rau kev ua haujlwm ntawm cov kab hauv qab kev poob siab yog siv tau rau BrOS30 hom, tab sis tsis pom zoo rau BrAZh. Kuj tseem muaj qhov sib txawv hauv chav kawm ntawm cov khoom siv tooj liab nyob rau hauv cov nqe lus ntawm cov khoom siv kho tshuab. Cov pab pawg zoo no yuav nyob ntawm qhov xwm txheej ntawm qhov sib cuam tshuam nrog cov shafts hardened thiab ntawm kev siv lub trunnion, uas tej zaum yuav muaj hardening ntxiv. Thiab dua, nws yog tsis yooj yim sua los tham txog lub solidity ntawm lub alloy qauv.

Bronze khoom kuj tseem muaj xws li cov tin, tooj dag, txhuas. Nyob rau tib lub sijhawm, yog tias tag nrho cov npe ntawm cov hlau tuaj yeem siv los ua lub hauv paus ntawm babbitt, cov khoom siv tooj liab los tiv thaiv kev sib txhuam yog siv tsis tshua muaj. Hauv qhov no, cov khoom siv tooj liab feem ntau ua raws li tib qho ntxiv nrog cov ntsiab lus piv ntawm 2-3%. Tin-lead ua ke ntawm kev suav nrog yog suav tias yog qhov zoo tshaj plaws. Lawv muab kev ua tau zoo txaus ntawm cov hlau ua ib qho kev tiv thaiv kev sib txhuam, txawm hais tias lawv poob rau lwm qhov sib xyaw ntawm cov khoom siv dag zog. Cov khoom siv tooj liab sib xyaw yog siv rau hauv kev tsim cov khoom bearings rau hluav taws xob motors, turbines, compressor units thiab lwm chav nyob uas ua haujlwm ntawm kev kub siab thiab qis zawv zawg ceev.

PowderCov ntaub ntawv sib txhuam

Cov ntaub ntawv zoo li no yog siv rau hauv cov khoom sib xyaw uas npaj rau kev sib kis thiab nres ntawm cov kab ntsig tsheb, tsheb, cov cuab yeej siv tshuab, cov cuab yeej siv hauv tsev, thiab lwm yam. Nyob rau tib lub sijhawm, cov ntaub ntawv pib rau cov tshuaj tiv thaiv cov hmoov hlau yog tsim los ntawm tib lub npe xws li cov khoom sib txhuam - hlau thiab tooj liab feem ntau yog siv, tab sis lwm yam kev sib txuas muaj nyob.

Piv txwv li, cov ntaub ntawv ua los ntawm txhuas thiab tin bronzes, uas suav nrog graphite thiab txhuas, ua kom pom tseeb ntawm lawv tus kheej hauv kev sib txhuam ntawm qhov nrawm ntawm qhov kev txiav txim ntawm 50 m / s. Los ntawm txoj kev, thaum bearings ua hauj lwm ntawm ib tug ceev ntawm 5 m / s, hlau hmoov khoom yuav tsum tau hloov los ntawm hlau-yas raw cov ntaub ntawv. Qhov no twb yog cov khoom siv los tiv thaiv kev sib txhuam nrog cov qauv ua haujlwm hloov tau thiab txo lub zog. Qhov zoo tshaj plaws nyob rau hauv cov nqe lus ntawm kev siv nyob rau hauv tej yam kev mob ntawm nce loads yog cov ntaub ntawv uas ua los ntawm hlau thiab tooj liab. Graphite, silicon oxide los yog barium yog siv los ua additives. Kev ua haujlwm ntawm cov ntsiab lus no tuaj yeem ua tau ntawm qhov siab ntawm 300 MPa thiab zawv zawg ceev txog 60 m / s.

Cov khoom siv tshuaj tiv thaiv kab mob

Anti-kev sib txhuam cov khoom kuj yog tsim los ntawm cov hmoov raw khoom. Lawv yog cov yam ntxwv los ntawm kev hnav tsis kam, tsis tshua muaj coefficient ntawm kev sib txhuam thiab muaj peev xwm khiav ceev rau hauv lub ncej. Tsis tas li ntawd, cov khoom siv los tiv thaiv kev sib txhuam muaj ntau qhov zoo piv rau kev sib txhuam-tsawg alloys. Txaus nws hais tias lawv hnav tsis kam yog qhov nruab nrab siab dua li ntawm tib babbits. Cov qauv ntxeem tau tsim los ntawm cov hmoov hlau tso cai rau impregnation zoo nrog lubricants.

Cov neeg tsim khoom muaj lub sijhawm los tsim cov khoom kawg hauv ntau hom. Cov no tuaj yeem yog thav duab lossis matrix qhov chaw nrog cov kab noj hniav nruab nrab uas muaj lwm yam khoom siv softened. Thiab, ntawm qhov tsis sib xws, hauv qee qhov chaw, cov khoom siv tshuaj tiv thaiv hmoov av nrog lub hauv paus mos yog xav tau ntau dua. Hauv tshwj xeeb honeycombs, cov khoom sib xyaw ua ke ntawm ntau theem ntawm kev sib cais yog muab. Qhov kev ua tau zoo no yog qhov tseem ceeb ntawm qhov tseeb ntawm qhov pom ntawm qhov muaj peev xwm ntawm kev tswj cov kev txwv uas txiav txim siab qhov kev sib txhuam ntawm qhov chaw.

Cov khoom siv tiv thaiv kev sib txhuam polymer

Cov khoom siv polymer niaj hnub ua kom tau txais cov txuj ci tshiab thiab kev ua haujlwm zoo rau qhov chaw uas txo kev sib txhuam. Ob qhov sib xyaw alloys thiab hlau-yas hmoov tuaj yeem siv los ua lub hauv paus. Ib qho ntawm cov khoom tseem ceeb ntawm cov ntaub ntawv no yog lub peev xwm los faib cov khoom sib npaug thoob plaws hauv cov qauv, uas tom qab ntawd yuav ua haujlwm ntawm cov roj nplua nyeem. Graphites, sulfides, plastics thiab lwm cov tebchaw tau sau tseg hauv cov npe ntawm cov khoom no. Cov khoom ua haujlwm ntawm cov khoom siv polymeric thiab cov khoom siv tiv thaiv kev sib txhuam feem ntau sib sib zog nqus ntawm theem pib yam tsis muaj kev hloov pauv: qhov no yog qhov tsis tshua muaj coefficient ntawm kev sib txhuam, thiab tsis kam mus rau cov tshuaj lom neeg tawm, thiabmuaj peev xwm ua haujlwm nyob rau hauv ib puag ncig dej. Hais txog cov yam ntxwv tshwj xeeb, cov polymers tuaj yeem ua lawv txoj haujlwm txawm tias tsis muaj kev txhawb nqa nrog cov roj nplua nyeem tshwj xeeb.

Kev siv cov ntaub ntawv tiv thaiv kev sib txhuam

Feem ntau ntawm cov khoom tiv thaiv kev sib txhuam yog thawj zaug tsim los siv rau hauv pawg kabmob. Ntawm lawv yog cov khoom tsim los ua kom hnav tsis kam, thiab cov khoom siv txhim kho zawv zawg. Hauv kev tsim kho tshuab thiab tshuab cuab yeej siv lub tsev, cov khoom siv no yog siv los tsim cov cav, pistons, coupling units, turbines, thiab lwm yam. khoom siv.

Kev tsim kho kev lag luam kuj tsis tuaj yeem ua yam tsis muaj kev tiv thaiv kev sib txhuam. Nrog kev pab los ntawm cov khoom zoo li no, cov qauv tsim engineering, cov qauv mounting thiab cov ntaub ntawv masonry tau ntxiv dag zog. Nyob rau hauv kev tsim kho ntawm railways, lawv yog siv nyob rau hauv lub installation ntawm structural ntsiab ntawm dov Tshuag. Kev siv cov khoom siv polymer-based los tiv thaiv kev sib txhuam kuj yog qhov dav, uas pom lawv qhov chaw, piv txwv li, raws li cov qauv sib txuas ntawm rubeys, lub zog, siv txoj siv sia, thiab lwm yam.

Zaj lus

Txoj haujlwm ntawm kev txo kev sib txhuam tsuas yog thaum xub thawj siab ib muag yuav zoo li theem nrab thiab feem ntau xaiv tau. Kev txhim kho ntawm cov kua roj lubricating tiag tiag ua rau nws muaj peev xwm tshem tau qee cov txheej txheem los ntawm kev pabcuam kev pabcuam uas txo qhov hnav ntawm pawg ua haujlwm tseem ceeb. Ib qho kev hloov pauv txuas los ntawm classicalbabbitt mus rau kev hloov kho cov roj nplua nyeem tuaj yeem hu ua cov khoom siv los tiv thaiv kev sib txhuam, uas yog tus yam ntxwv ntawm cov qauv softer thiab versatility nyob rau hauv cov nqe lus ntawm kev ua hauj lwm. Txawm li cas los xij, kev ua haujlwm ntawm cov khoom hlau nyob rau hauv kev kub siab thiab kev cuam tshuam lub cev tseem yuav tsum tau suav nrog cov khoom hauv lub xeev los tiv thaiv kev sib txhuam. Ntxiv mus, chav kawm ntawm cov ntaub ntawv no tsis tsuas yog tsis tau dhau los ua ib qho ntawm yav dhau los, tab sis kuj tsim los ntawm kev txhim kho cov yam ntxwv ntawm lub zog, hardness thiab mechanical stability.

Pom zoo:

Siv cov txheej txheem se yooj yim: cov yam ntxwv ntawm cov txheej txheem, daim ntawv thov txheej txheem

Kab lus no tshawb txog cov yam ntxwv ntawm kev sau se nrov tshaj plaws - yooj yim. Qhov zoo thiab qhov tsis zoo ntawm qhov system, cov xwm txheej ntawm daim ntawv thov, kev hloov pauv thiab kev tshem tawm tau nthuav tawm. Cov nqi sib txawv raug txiav txim siab rau cov khoom sib txawv ntawm kev them se

Cov ntaub ntawv xa tuaj: tus kheej xaj, daim ntawv them nqi, daim ntawv xaj, cov ntaub ntawv xa khoom thiab cov chaw xa khoom xa tuaj

Kev ua haujlwm hauv kev xa khoom yog nrov heev niaj hnub no, tshwj xeeb tshaj yog cov tub ntxhais hluas muaj siab nyiam. Tus neeg xa xov tsis yog ib tus neeg xa khoom xwb, tab sis yog tus kws tshaj lij uas muaj kev txawj ntse thiab tuaj yeem nqa parcel los yog xa mus rau qhov chaw nyob uas tau teev tseg nrog cov khoom zoo thiab sai

Cov khoom muag hauv lub tsev muag tshuaj: txheej txheem, cov ntaub ntawv, cov khoom sib xyaw ntawm cov khoom muag

Cov Khoom Muag yog qhov kev txheeb xyuas ntawm lub tuam txhab cov khoom muag ntawm hnub tim los ntawm kev sib piv cov ntaub ntawv tiag tiag nrog cov ntaub ntawv sib npaug. Nov yog txoj hauv kev tseem ceeb los tswj cov khoom muaj nqis. Nyeem ntxiv txog yuav ua li cas cov khoom muag tau ua thiab ua tiav hauv lub tsev muag tshuaj, nyeem rau

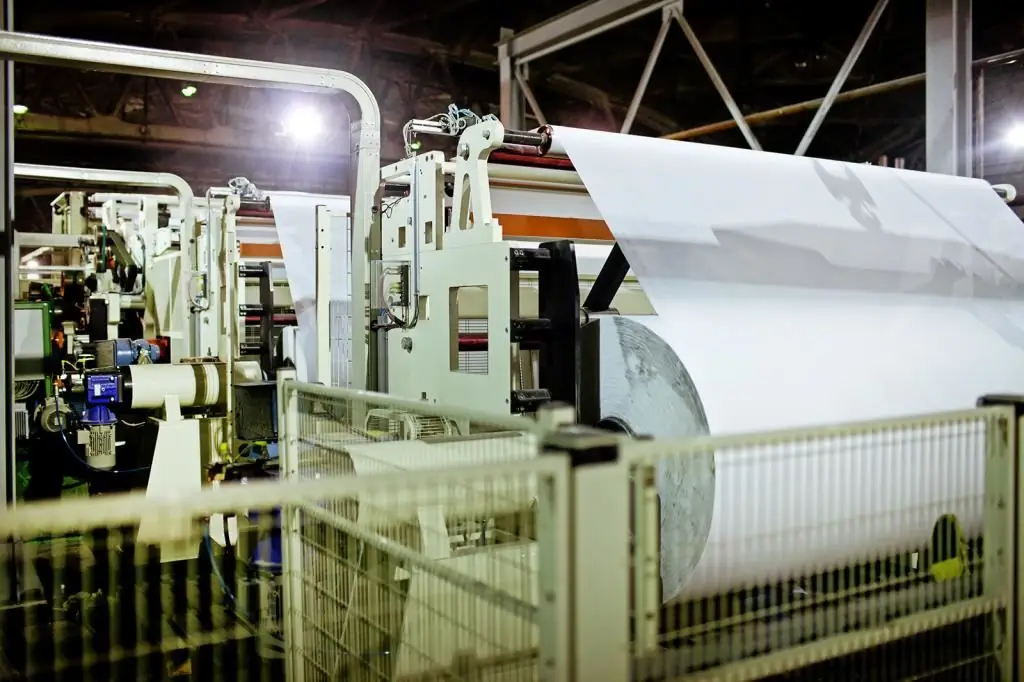

Pulp thiab ntawv zeb hauv tebchaws Russia: daim ntawv teev npe, cov yam ntxwv ntawm cov txheej txheem tsim khoom, cov khoom lag luam saib xyuas

Kev lag luam pulp thiab ntawv ntawm Lavxias Federation suav tias yog kev lag luam nyuaj. Nws yog txuam nrog cov neeg kho tshuab ua cov ntoo thiab nws cov tshuaj ua tom ntej. Qhov tshwm sim ntawm txoj haujlwm no yog kev tsim cov ntawv, duab los qhia, pulp, thiab lwm yam khoom los ntawm lawv

Kuv puas xav tau daim ntawv teev nyiaj ntsuab rau cov neeg ua lag luam nrog cov txheej txheem se yooj yim? Yuav ua li cas rau npe thiab siv daim ntawv sau nyiaj ntsuab rau cov neeg ua lag luam nyob rau hauv cov txheej txheem se yooj yim?

Kab lus piav qhia txog cov kev xaiv rau kev ua cov nyiaj tsis muaj kev koom nrog cov ntawv sau nyiaj ntsuab (CCT)