2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Machining yog ib txheej txheem thaum lub sij hawm qhov ntev thiab configuration ntawm workpieces thiab qhov chaw hloov. Yog tias peb tham txog cov khoom siv hlau, ces cov cuab yeej txiav tshwj xeeb yog siv rau lawv cov kev ua, xws li cutters, broaches, xyaum, kais, cutters, thiab lwm yam. Tag nrho cov kev khiav hauj lwm yog ua los ntawm cov hlau-txiav tshuab raws li daim ntawv qhia technologies. Hauv tsab xov xwm no, peb yuav pom dab tsi yog txoj hauv kev thiab hom kev ua haujlwm hlau.

txheej txheem txheej txheem

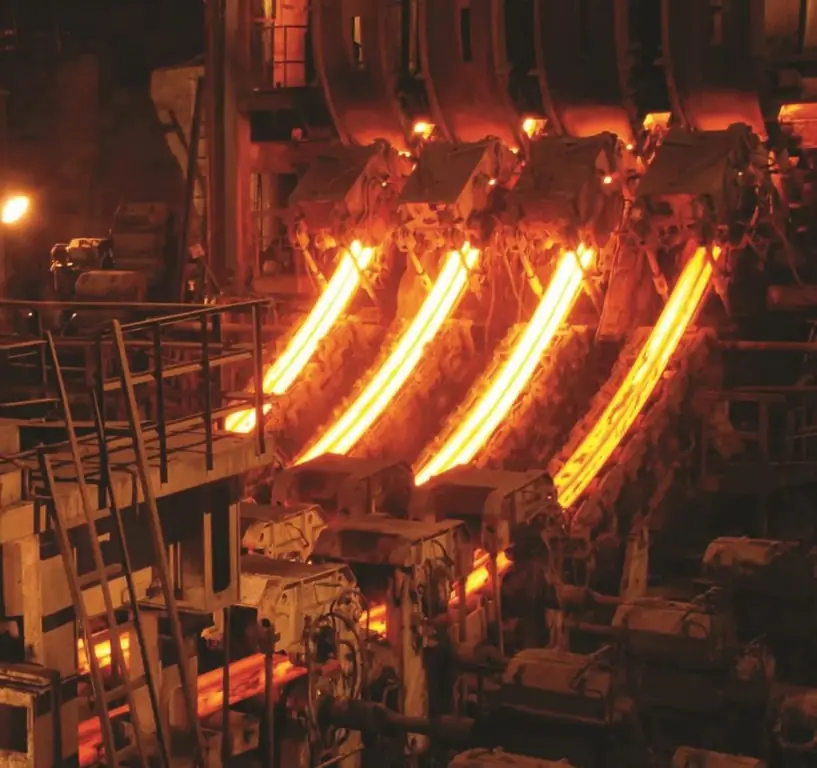

Machining muab faib ua ob pawg loj. Thawj suav nrog kev ua haujlwm uas tshwm sim yam tsis tau tshem tawm cov hlau. Cov no suav nrog forging, stamping, nias, dov. Qhov no yog lub npe hu ua mechanical processing nrog kev pab ntawm lub siab los yog kev cuam tshuam. Nws yog siv los muab cov duab uas xav tau rau lub workpiece. Rau cov hlau tsis-ferrous, forging feem ntau yog siv, thiab rau cov hlau ferrous, stamping.

Pab pawg thib ob suav nrog kev ua haujlwm thaum lub sijhawm cov hlau raug tshem tawm ntawm qhov chaw ua haujlwm. Qhov no yog qhov tsim nyog los muab nws qhov loj me. Xws li kev ua haujlwm ntawm cov hlau yog hu ua txiav thiab ua tiav siv cov tshuab txiav hlau. Cov txheej txheem machining feem ntau yog tig, drilling, countersinking, sib tsoo, milling, reaming, chiselling, npaj thiab broaching.

Dab tsi txiav txim siab hom kev ua haujlwm

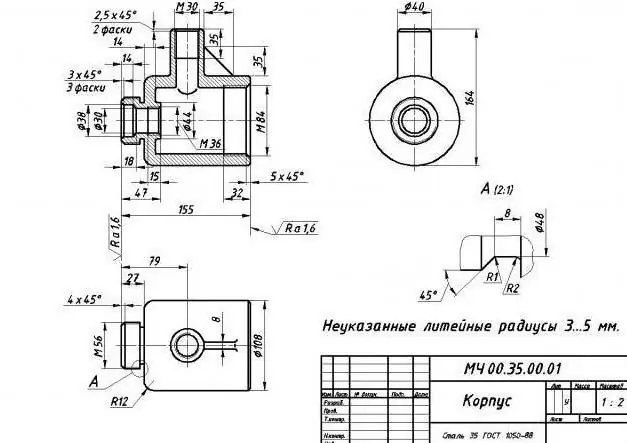

Kev tsim cov hlau los ntawm daim hlau yog ib lub sijhawm siv sijhawm thiab cov txheej txheem nyuaj. Nws suav nrog ntau yam haujlwm sib txawv. Ib tug ntawm lawv yog cov neeg kho tshuab ua hlau. Ua ntej pib nrog nws, lawv kos ib daim ntawv qhia kev siv tshuab thiab ua ib daim duab ntawm qhov ua tiav uas qhia txog txhua qhov tsim nyog qhov ntev thiab cov chav kawm raug. Qee zaum, ib qho kev kos duab cais kuj tau npaj rau kev ua haujlwm nruab nrab.

Ntxiv rau, muaj ntxhib, semi-tiav thiab tiav machining ntawm hlau. Rau txhua tus ntawm lawv, kev suav ntawm kev txiav thiab cov nyiaj pub dawb yog ua. Hom kev ua hlau tag nrho yog nyob ntawm qhov chaw yuav tsum tau kho, chav kawm raug, qhov roughness tsis thiab qhov ntev ntawm qhov. Piv txwv li, kom tau txais ib lub qhov nyob rau hauv qib H11, ntxhib drilling yog siv nrog ib tug xyaum, thiab rau ib tug ib nrab huv si reaming rau 3rd qhov tseeb, koj muaj peev xwm siv ib tug reamer los yog countersink. Tom ntej no, peb yuav kawm txog cov txheej txheem ntawm machining hlau kom ntxaws.

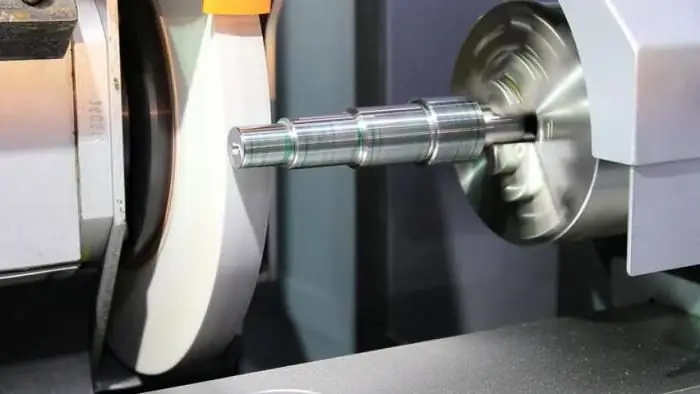

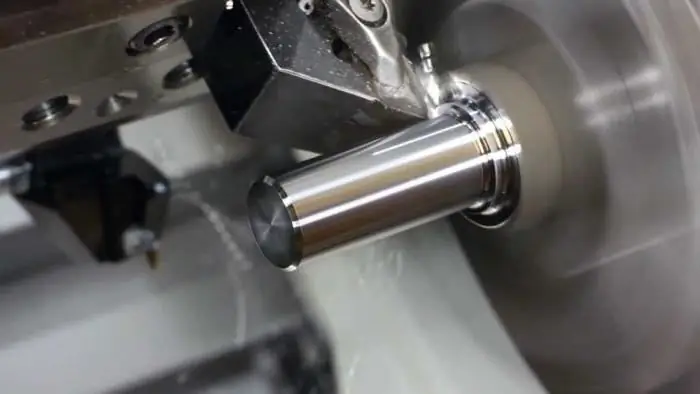

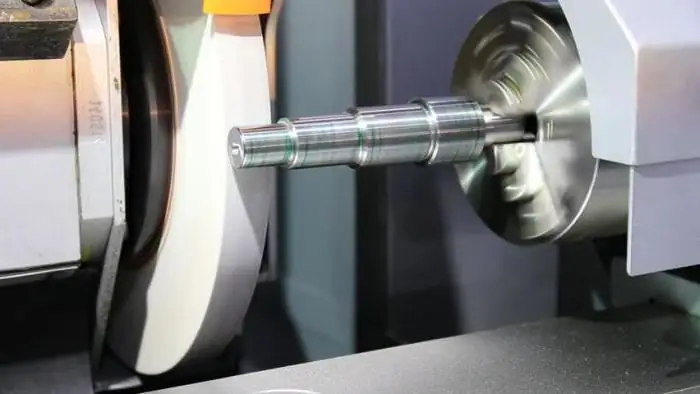

Tigua ntawm lathes ntawm pab pawg nrog kev pab los ntawm cutters. Lub workpiece yog txuas mus rau spindle, uas rotates ntawm ib tug ceev ceev. Thiab lub cutter, tsau nyob rau hauv lub caliper, ua longitudinal-transverse txav. Hauv cov tshuab CNC tshiab, tag nrho cov kev ntsuas no tau nkag mus rau hauv lub computer, thiab lub cuab yeej nws tus kheej ua haujlwm tsim nyog. Hauv cov qauv qub, piv txwv li, 16K20, longitudinal thiab transverse txav tau ua manually. Ntawm lathes nws muaj peev xwm tig zoo li tus, conical thiab cylindrical nto.

Drilling yog ib qho kev ua haujlwm uas tau ua kom tau qhov. Cov cuab yeej ua haujlwm tseem ceeb yog lub laum. Raws li txoj cai, drilling tsis muab cov chav kawm siab ntawm qhov tseeb thiab yog qhov ntxhib lossis semi-tiav. Txhawm rau kom tau txais ib lub qhov nrog qhov zoo hauv qab H8, reaming, reaming, tho txawv thiab countersinking yog siv. Tsis tas li ntawd, tom qab drilling, internal threading kuj tuaj yeem ua tau. Xws li machining ntawm cov hlau yog ua los ntawm cov kais dej thiab qee hom cutters.

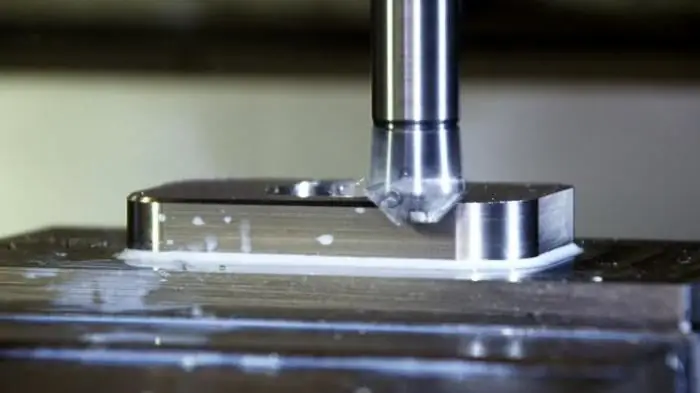

Milling yog ib txoj hauv kev zoo tshaj plaws los ua cov hlau. Qhov kev ua haujlwm no yog ua los ntawm kev siv ntau yam cutters ntawm cov tshuab milling. Muaj qhov kawg, zoo li tus, kawg thiab peripheral ua. Milling tuaj yeem yog ob qho tib si ntxhib thiab semi-finishing, thiab tiav. Qhov qis tshaj plaws ntawm qhov tseeb tau txais thaum lub sijhawm ua tiav yog 6. Nrog kev pab ntawm milling cutters, ntau yam yuam sij, grooves, qhov dej, undercuts yog machined, profiles yog milled.

Sib tsoo yog kev siv tshuab siv los txhim kho qhov zoo ntawm roughness, nrog rau tshem tawm cov txheej txheem ntau dhau ntawm cov hlau mus rau micron. Raws li txoj cai, qhov kev ua haujlwm no yog theem kawg ntawm kev tsim cov khoom, uas txhais tau tias nws yog tiav. Rau kev txiav, abrasive log yog siv, ntawm qhov chaw uas muaj ntau cov nplej nrog cov duab sib txawv ntawm kev txiav ntug. Thaum lub sij hawm ua no, ib feem yog kub heev. Txhawm rau kom cov hlau tsis txhob deformed thiab tsis chipped, txiav cov kua (LLC) yog siv. Machining ntawm cov hlau tsis yog hlau yog ua los ntawm cov cuab yeej pob zeb diamond. Qhov no tso cai rau koj los xyuas kom meej qhov zoo tshaj plaws ntawm cov khoom tsim.

Pom zoo:

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Nruam nruam ntawm cov hlau: txoj hauv kev ntawm kev ua haujlwm, cov khoom tsim nyog, qhov zoo thiab qhov tsis zoo ntawm txoj kev

Hnub no, ntau ntau yam khoom, qhov chaw, thiab lwm yam yog ua los ntawm cov hlau, Yog lawm, qhov no yuav tsum muaj ntau yam khoom siv. Yog li ntawd, cov nroj tsuag tau ntev tau siv txoj kev nruam nruam ntawm cov hlau, uas yog qhov tseem ceeb tshaj plaws feature - high productivity

Lub luag haujlwm ntawm tus neeg xyuas pib: piav qhia txoj haujlwm, txoj cai, cov cai ntawm kev ua haujlwm raws txoj kev thiab thaum lub sijhawm nres tsheb ciav hlau

Txoj haujlwm ntawm tus neeg tsav tsheb ciav hlau feem ntau xaiv los ntawm cov neeg nyiam los ntawm lub sijhawm mus ncig thiab tau txais kev paub tshiab. Thaum lub sijhawm ua haujlwm, ib tus yuav tsum tau soj ntsuam qhov kev hloov pauv tas li ntawm cov toj roob hauv pes flickering sab nraum lub qhov rais. Ua haujlwm raws li tus neeg xyuas pib yog kev sib tham tas li nrog tib neeg. Txhua qhov kev mus ncig coj cov neeg caij tsheb tshiab. Koj tsis tas yuav dhuav. Txawm li cas los xij, thaum txiav txim siab zaum kawg, koj yuav tsum nug seb tus neeg saib xyuas yuav tsum ua li cas

Hom thiab txoj kab uas hla ntawm cov kav hlau. Cov kav hlau loj ntawm txoj kab uas hla

Cov yeeb nkab steel yog lub raj cylindrical thiab yog cov khoom siv tshaj plaws hauv kev lag luam steel. Kev siv cov yeeb nkab steel tseem ceeb yog thauj cov roj, roj thiab dej mus rau qhov ntev. Hauv cov khoom siv hauv tsev, xws li cov tub yees, cov kav dej zoo tib yam yog siv, nrog rau hauv cov cua sov thiab dej

Kev sib txuas lus: hom, kev faib tawm, txoj hauv kev thiab kev tso, lub hom phiaj ntawm kev sib txuas lus

Kev sib txuas lus yog ib theem tseem ceeb tshaj plaws hauv kev tsim kho, piv txwv li, ntawm lub tsev tshiab. Txog niaj hnub no, muaj ntau ntau txoj kev sib txawv ntawm kev txhim kho kev sib txuas lus. Lawv cov yam ntxwv, nrog rau qhov zoo thiab qhov tsis zoo, tau coj mus rau qhov tseeb tias ib tus neeg txoj kev xaiv rau txhua rooj plaub