2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Kev ua haujlwm ntawm machining workpieces ntawm lathes tsis tshua dhau los ua qhov kawg hauv cov txheej txheem thev naus laus zis. Tsim qhov yog qhov tseem ceeb hauv kev tau txais cov duab uas xav tau ntawm ib feem. Tab sis feem ntau nws yog ua raws los ntawm kev hloov kho theem. Ib feem, cov no yog cov kev kho kom tiav, tab sis qee zaum cov txheej txheem ntawm kev hloov pauv hauv cov kev txiav ua tiav kuj tau siv. Cov kev ua haujlwm zoo li no suav nrog countersinking thiab reaming ntawm qhov, vim tias tus neeg teb xov tooj tau txais cov khoom ua haujlwm zoo tshaj plaws ntawm cov yam ntxwv. Ua ntej, qhov chaw ua si npaj tau txais qhov loj me, thiab qhov thib ob, nws cov npoo thiab qhov chaw raug ntxuav ntawm cov burrs thiab chips ntau dhau.

Cov teeb meem dab tsi daws daws tau?

Qhov sib txawv ntawm cov hauv paus chiv keeb tau tso cai rau cov txheej txheem countersinking. Cov no tuaj yeem raug cam khwb cia, stamped lossis drilled niches, uas tus tswv reaming yuav ua haujlwm yav tom ntej. Dab tsi yog qhov tseem ceeb ntawm txoj haujlwm no? Nws yuav muaj ob lub hom phiaj. Yam tsawg kawg nkaus, kev tu lub qhov ntawm qhov chaw yuav ua kom ntseeg tau. Qhov no yog ib qho tseem ceeb tshwj xeeb tshaj yog nyob rau hauv cov rooj plaub uas ntxhib drilling thiab reaming ntawm lub qhov ua ntej ua ntej, cov npoo uas yuav tsum tau ua kom tiav. Nyob ntawm qhov zooQhov tsim, semi-tiav lossis xov countersinking tuaj yeem siv. Yog li ntawd, cov degree ntawm smoothing ntawm qhov chaw ua hauj lwm kuj hloov. Lub luag haujlwm ntawm calibration yog lub luag haujlwm ntau dua. Nyob rau hauv rooj plaub no, tus tswv tsis txwv rau kev tu thiab kho qhov tsis sib xws ntawm lub qhov, xws li qhov tob thiab tuab. Qhov xav tau rau qhov kev ua no tshwm sim yog tias qhov pib tau txais qhov tsis haum rau lub hom phiaj stud, ntsia hlau lossis lwm yam fastener. Tom qab reaming, threading tsuas yog ua raws li qhov ntev ntawm lub hardware.

Yuav ua li cas yog lub txee?

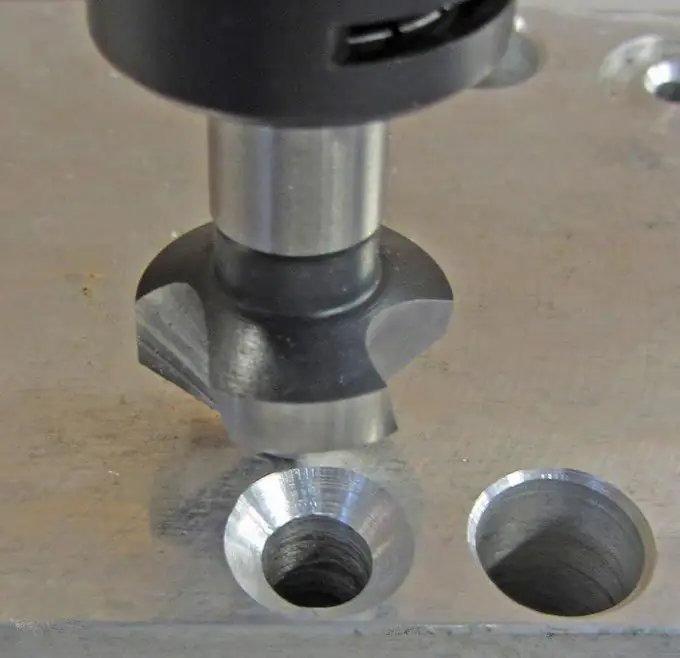

Qhov no yog cov cuab yeej txiav uas nws tsim los ntawm kev ua haujlwm ua haujlwm thiab lub shank tuav. Outwardly, qee hom countersinks zoo li kev xyaum, tab sis lawv muaj zog ntau dua. Thiab qhov tseem ceeb tshaj qhov sib txawv yog qhov muaj tsawg kawg yog peb txoj kab txiav, uas muab kev tshem tawm ntau dua ntawm cov hlau ntau dhau. Incidentally, qhov no kuj yog cov ntaub ntawv nrog reaming qhov, uas tej zaum yuav tsum intensive nti tshem tawm thiaj li yuav ua tau ib tug zoo dua workpiece zoo. Tab sis nyob rau hauv ib tug countersink, ob peb txiav ntug kuj ua nyob rau hauv ib co txoj kev raws li ib tug stabilizer. Qhov no ua kom ntseeg tau tias cov npoo tau ua tiav zoo ib yam, uas cuam tshuam rau qhov tseeb ntawm kev ua haujlwm. Txawm li cas los xij, qhov zoo ntawm qhov tshwm sim kuj tseem nyob ntawm seb hom ntsuas tau raug xaiv li cas.

Ntau yam ntawm cov txeesinks

Qhov yooj yim tshaj plaws conicalcountersink qauv muaj xws li ib tug cutter thiab ib tug shank. Lub kaum sab xis ntawm lub khob hliav qab hauv qhov chaw ua haujlwm tuaj yeem sib txawv ntawm 30 txog 120 °. Ib tug complex variation ntawm lub cuab tam yog ib tug cutter nrog kawg hniav. Tus naj npawb ntawm cov hniav nruab nrab ntawm 4 mus rau 8. Raws li, qhov ntau precisely countersinking yog yuav tsum tau, qhov me me ntawm qhov chaw ntawm lub cutter yuav tsum. Kuj tseem muaj cov khoom siv cylindrical uas muab tus pin qhia. Nws nkag mus rau hauv lub qhov tsim, yog li xyuas kom meej tias lub cylindrical recess coincides nrog lub axis ntawm lub qhov. Qhov no yog ib tug txheej txheem thoob ntiaj teb uas drilling, countersinking thiab reaming ntawm lub qhov yog ua nrog ib tug cuab yeej ntawm ib tug tsim. Yog li ntawd, lub voj voog tsim lub qhov yog yooj yim thiab qhov zoo ntawm kev ntxuav ntawm qhov chaw nyob ib sab yog txhim kho. Yuav luag txhua tus qauv ntawm cov txee yog ua los ntawm cov cuab yeej alloyed thiab carbon steels.

Tshaj tawm txheej txheem

Feem ntau, countersinking yog ua tiav ntawm cov tshuab drilling. Ib yam li kev xyaum ua haujlwm, countersinks tau nruab rau hauv cov chucks los yog clamping mechanisms. Tsis tas li ntawd, qhov hluav taws xob qhov hluav taws xob ntawm lub qhov yog ua tiav nrog conical countersinks. Cov txheej txheem no tsim conical recesses haum rau rivet hau thiab countersunk screws. Recesses rau bolts yog ua nyob rau hauv tib txoj kev, tab sis twb nrog cylindrical countersinks. Cov cuab yeej no tseem ua cov txheej txheem trimming, sampling fab thiab protrusions. Ob qho tib si countersinking thiab reaming ntawm qhov ntawm lub tshuab yog tswj los ntawm tus neeg teb xov tooj. Hauv cov qauv niaj hnub ntawm cov tshuab pneumatic thiab hluav taws xob, nws muaj peev xwm ua taunyob rau hauv semi-automatic thiab tsis siv neeg hom. CNC tshuab siv tau zoo xws li countersink chaw rau serial txij nkawm ntawm qhov chaw.

Txoj haujlwm ntawm kev xa tawm

Kev ua haujlwm reaming muaj ntau txoj hauv kev zoo ib yam li countersinking. Nws kuj yog tsim los tsim qhov zoo qhov loj me nrog qhov ua tau ntawm kev kho cov duab. Tab sis yog tias countersinks npaj qhov rau kev siv tom ntej ntawm rivets thiab bolts, ces reaming tso cai rau koj kom tau txais qhov tseeb calibrated niches rau shafts, plunger qhov chaw thiab bearings. Tsis tas li ntawd, kev xa tawm ntawm qhov tso cai rau koj kom txo qis kev sib txhuam hauv thaj chaw kho thiab muab kev sib cuag ntawm cov ntsiab lus siab. Cov hom phiaj no tau ua tiav los ntawm kev txo qhov roughness ntawm qhov chaw.

Deployment Tool

Reamers kuj yog ib qho cuab yeej zoo li xyaum. Qhov chaw ua haujlwm nyob rau hauv rooj plaub no yog muab cov hniav nyob ib ncig ntawm lub voj voog ntawm tus pas nrig. Tsis tas li ntawd, muaj kev pabcuam kev ua haujlwm ntawm lub tshuab txiav. Cov no yog cov khoom noj, calibrating thiab cylindrical qhov chaw. Kev txiav ncaj qha yog ua los ntawm cov lus qhia lub khob hliav qab, cov npoo ntawm cov khoom tshem tawm cov nyiaj pub dawb, tab sis tib lub sijhawm tiv thaiv sab saum toj ntawm cov ntug txiav los ntawm nicks. Thiab ntawm no nws yog ib qho ua tau kom cais cov txheej txheem sib txawv uas paub qhov txawv ntawm cov txheej txheem no thiab countersinking. Countersinking thiab reaming ntawm qhov converge hauv kev ua haujlwm, txawm li cas los xij, calibrating ib feem ntawm cov reamer kuj ua haujlwm.kev taw qhia thiab tshem tawm cov chips. Cov grooves tshwj xeeb yog tsim los rau qhov no, ua rau lub cuab yeej ywj pheej.

tshuab thiab tes reamers

Reaming tuaj yeem ua tau manually thiab los ntawm lub tshuab, uas yog, ntawm tib lub tshuab. Cov cuab yeej siv rau kev tuav haujlwm yog tus cwj pwm los ntawm kev ua haujlwm elongated. Txoj kab uas hla ntawm lub khob hliav qab nyob rau hauv cov ntaub ntawv no txawv ntawm 0.06 mus rau 0.1 mm nyob rau hauv nruab nrab. Rau kev sib piv, tshuab cuab yeej reamers muaj lub khob hliav qab tuab ntawm 0.05 txog 0.3 hli. Los ntawm txhais tes reaming nws yog ua tau kom tau qhov nrog ib txoj kab uas hla ntawm 3 mus rau 60 mm. Hauv qhov no, qhov ntsuas qhov tseeb yuav qis. Cov cuab yeej siv tshuab yog coj los ntawm qee qhov ntau thiab tsawg, feem ntau los ntawm kev txiav txim tshwj xeeb. Piv txwv li, reaming qhov nyob rau hauv structural qhov chaw yuav ua tau raws li cov ntaub ntawv technical rau ib qhov project. Qhov zoo ntawm txoj kev no suav nrog kev txiav cov neeg siab, zoo stripping thiab tsis muaj cov nyhuv deformation.

Kev xa tawm

Machine reaming ua raws tib lub hauv paus ntsiab lus xws li countersinking. Cov cuab yeej yog tsau rau hauv chuck, thiab tom qab ntawd xa mus rau qhov chaw machined los ntawm lub tshuab. Qhov sib txawv tsuas yog qhov xav tau ntau dua rau kev txias ntawm cov khoom siv ua haujlwm thaum lub sijhawm ua haujlwm thiab lubrication ntawm lub qhov. Cov roj ntxhia, turpentine thiab hluavtaws emulsions yog siv los ua cov roj nplua nyeem. Txwv tsis pub, phau ntawv ua ntawm qhov yog ua. Kev xa tawm xws lihom yuav pib fixation ntawm lub workpiece nyob rau hauv ib tug vise. Tom ntej no, lub hau ntawm lub reamer yog muab tso rau hauv lub qhov thiab qhov tshwm sim yog tiav los ntawm twisting lub pob qhov rooj. Ntxiv mus, koj tuaj yeem tig lub cuab yeej tsuas yog nyob rau hauv ib qho kev taw qhia - kom txog thaum tsim cov khoom tsim nyog.

Zaj lus

Kev ua haujlwm ntawm cov hlau yog maj mam muab txoj hauv kev rau kev siv tshuab laser thiab thermal txoj kev. Tsis tas li ntawd, kev sib tw nrog kev txiav tsoos yog waterjet technology, uas yog tus cwj pwm los ntawm kev txiav ceev thiab raug. Tawm tsam keeb kwm yav dhau los no, dab tsi zoo tuaj yeem cuam tshuam thiab rov qab muab? Ua ntej tshaj plaws, qhov no yog qhov ua tau ntawm phau ntawv ua yam tsis muaj kev siv cov cuab yeej nyuaj hauv daim ntawv ntawm cov cuab yeej siv tshuab. Tsis tas li ntawd, tsis zoo li hydroabrasives thiab cov khoom siv thermal, cov thev naus laus zis no tsis tas yuav muaj kev sib txuas ntawm cov khoom siv ntxiv. Yog li ntawd, peb tuaj yeem tham txog qhov zoo ntawm kev lag luam, koom haum thiab ergonomic xwm. Tab sis qhov zoo ntawm kev ua thiab cov pace ntawm cov txheej txheem ntau lawm, tau kawg, yuav tsum tau txi.

Pom zoo:

Cov qauv rau kev lag luam me thiab nruab nrab. Qhov kev lag luam twg suav tias yog me me thiab qhov twg yog qhov nruab nrab

Lub xeev tsim tshwj xeeb rau kev ua haujlwm ntawm cov lag luam me thiab nruab nrab. Lawv tau txais kev tshuaj xyuas tsawg dua, them se txo qis, thiab tuaj yeem khaws cov ntaub ntawv sau nyiaj yooj yim dua. Txawm li cas los xij, tsis yog txhua lub tuam txhab tuaj yeem suav tias yog me me, txawm tias nws nyob ib puag ncig me me. Muaj cov txheej txheem tshwj xeeb rau cov lag luam me thiab nruab nrab, raws li lawv tau txiav txim los ntawm lub chaw lis haujlwm se

Kev tswj cov ntaub ntawv hluav taws xob: qhov zoo thiab qhov tsis zoo, qhov tseem ceeb ntawm qhov system, txoj hauv kev siv

Cov kab lus nthuav tawm qhov zoo ntawm kev tswj cov ntaub ntawv hluav taws xob, thiab tseem teev cov kauj ruam tseem ceeb los siv nws hauv kev ua haujlwm ntawm txhua lub lag luam. Qhov tsis txaus ntawm qhov system no tau qhia, nrog rau cov teeb meem tseem ceeb uas cov tswv ntawm cov tuam txhab yuav tsum tau ntsib

Ntiaj teb - leej twg yog qhov no Cov lus piav qhia txog haujlwm, qhov chaw ua haujlwm, qhov zoo thiab qhov tsis zoo ntawm kev ua haujlwm

Finiher yog ib qho tshwj xeeb tshaj plaws nrhiav-tom qab hauv kev tsim kho kev lag luam. Yog tsis muaj nws, nws yog tsis yooj yim sua mus nqa tawm high-zoo kho. Tsuas yog thaum xub thawj siab ib muag, txoj haujlwm no yuav zoo li yooj yim thiab tsis lees paub. Yog tias tus neeg ua tiav muaj kev paub ntau ntxiv thiab tsis ua phem rau tus cwj pwm phem, nws yuav xav tau hauv khw. Thiab qhov no suav nrog cov khoom tsim nyog nyiaj tshwj xeeb

Ntsuas kub ntawm qhov chaw ua haujlwm. Yuav ua li cas yog tias qhov kub thiab txias ntawm qhov chaw ua haujlwm siab tshaj qhov qub

Dab tsi lwm yam cuam tshuam rau cov neeg ua haujlwm ua haujlwm? Cov lus nug zoo li no, ntawm chav kawm, yuav tsum tau nug los ntawm ib tus thawj coj uas xav saib xyuas nws cov subordinates thiab nce nyiaj tau los txhua hli

Txoj haujlwm ntawm tus neeg sau xov xwm: qhov zoo thiab qhov tsis zoo, qhov tseem ceeb thiab qhov tseeb

Thaum menyuam yaus nug txog qhov nws xav ua thaum nws loj hlob, nws feem ntau teb tias: kws kho mob, kws sau ntawv, kws kos duab, tua hluav taws, neeg sau xov xwm. Ntau qhov kev cia siab rau menyuam yaus no yuav tsis muaj tseeb. Tsuas yog ob peb tus tswj kom paub lawv txoj kev npau suav thaum yau. Niaj hnub no peb xav qhia rau koj paub tias txoj haujlwm ntawm tus neeg sau xov xwm tiag tiag yog dab tsi