2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Lo lus "shavings" yog lub tswv yim tshaj plaws rau cov lus Lavxias. Tab sis hom chips hauv kev nkag siab ntawm tib neeg yog txawv. Qee tus txawm hais tias tsim lub ntsiab lus rau cov shavings. Tom qab tag nrho, lawv hais txog tus thawj coj nruj uas nws tshem cov shavings ntawm nws cov subordinates. Tib lub sijhawm, lawv txhais tau tias nws cem cov neeg ua haujlwm rau qhov ua tsis ncaj ncees, coj tus cwj pwm tsis zoo rau kev ua haujlwm, sim tshem tawm cov kev coj phem.

Ib yam dab tsi zoo sib xws tshwm sim hauv kev tsim cov khoom: ib txheej ntxiv raug tshem tawm ntawm lub workpiece, tau txais cov khoom tsim nyog. Thiab shavings, nws yog shavings - ib txwm muaj pov tseg. Nws tau sau thiab xa mus rau rov ua dua.

shavings yog dab tsi?

Shaving yog ib feem me me ntawm txhua yam khoom siv, suav nrog ntoo, yas, hlau, uas yog txheej nqaim nqaim tshem tawm ntawm qhov chaw ua haujlwm los ntawm kev npaj cov cuab yeej,riam lossis lwm yam cuab yeej. Hauv kev tsim cov hlau, shavings yog cov khoom lag luam. Nws pov tseg yuav tsum. Tsis tsim nyog offcuts ntawm non-ferrous, ferrous thiab txawm precious hlau yog tsim los ntawm machining ntawm drilling, milling thiab tig tshuab. Raws li txoj cai, cov qauv nti khaws nws tus kheej nrog cov khoom siv tswj hwm. Hauv qhov tshwj xeeb, qhov sib xyaw ntawm cov alloys sib txawv hauv cov tshuaj muaj pes tsawg leeg pom. Qhov no yog ua tau tom qab vuam, soldering thiab zoo sib xws manipulations.

Tim cov chips

Cov txheej txheem ntawm kev txiav hlau (OMP) yog ua raws li cov kev txwv tsis pub siv cov cuab yeej thiab cov khoom siv nrog cov khoom sib txawv. Nyob ntawm qhov no, lub zog tshwm sim hauv cheeb tsam txiav uas cuam tshuam rau kev ua haujlwm zoo thiab kev tsim cov nti. Tus xibfwb-tus kws tshawb fawb I. A. Lub Sijhawm tau txheeb xyuas cov hom tseem ceeb hauv qab no:

- tawg chips - yam ntxwv ntawm kev ua cov hlau cam khwb cia, muaj cov khoom me me-cov nplej;

- drain chips - du, curled, feem ntau tsim thaum lub sij hawm ua tooj liab;

- chips ntawm chipping (cleavage) - cov khoom tawg ntawm cov khoom seem ntawm cov hlau ua haujlwm ntawm cov hlau tawv thiab yeej.

Los ntawm hom thiab xim ntawm cov chips, ib tus tuaj yeem txiav txim siab qhov zoo ntawm qhov chaw tau txais los ntawm MMP thiab kev tsim khoom ntawm cov txheej txheem tag nrho.

Tig Parts

Txoj kev feem ntau ntawm OMP, uas tso cai rau koj kom tau txais ib feem ntawm qhov xav tau kev teeb tsa thiab kev ntxhib los mos, tig. essencemuaj nyob rau hauv kev txiav tawm ib tug tsis tsim nyog txheej ntawm hlau los ntawm ib tug dawb paug los yog dawb paug. Ua ntawm txheej yuav raug tshem tawm los ntawm pem hauv ntej nto, lub cutter deforms nws. Raws li cov hlau compression, nws cov khoom compressed yog chipped thiab dislocated los ntawm pem hauv ntej nto ntawm lub cuab tam upwards. Tom qab ntawd cov algorithm rov ua dua: cov chips yog chipped, sib cais thiab curled rau hauv zoo nkauj springs.

Yuav ua li cas cov chips tsis pom nyob rau hauv kev tig. Cov hauv qab no cuam tshuam:

- degree ntawm kev sib txuas ntawm cov khoom hlau sib txuas ua ntu zus thaum ua tiav (drain chips, tawg thiab chipping);

- txiav tej yam kev mob: spindle ceev, caliper pub tus nqi, qhov tob ntawm txiav;

- daim ntawv txiav cov kua dej.

Chip temper color

Nyob rau hauv mechanical engineering, tshwj xeeb yog hlau txiav, muaj xws li tint xim. Nws tuaj yeem muab piv, piv txwv li, nrog iridescent stains ntawm roj av ntawm qhov chaw ntawm lub pas dej tom qab los nag hnyav. Nws hloov tawm tias los ntawm cov xim ntawm cov xim thiab qhov txawv txav ntawm cov chips, cov neeg paub txog lub tshuab ua haujlwm tau yooj yim txiav txim siab cov cua sov hauv cheeb tsam txiav thiab nkag siab tias qee yam tau ploj mus: tej zaum lub tshuab txiav tau ua npub, uas yuav tsum tau ua. yuav tsum ceev kom sharpened los yog hloov.

Qhov xwm txheej ntawm qhov tshwm sim ntawm cov hlau kub yog tsim los ntawm txheej nyias - zaj duab xis ntawm tint xim. Dab tsi yog qhov degree ntawm incandescence ntawm cov chips, xws li cov xim ntawm zaj duab xis. Cov qauv xim txawv ntawmme ntsis daj ntawm 200 0 C, hla ntshav thiab xiav tsaus ntawm 270-290 ℃, rau lub teeb grey, yuav luag dawb ntawm 400 0 S.

Creative chips

Cov tub ntxhais kawm ntawm cov tsev kawm txuj ci engineering, uas thawj zaug tuaj rau lub rooj cob qhia rau kev xyaum, qhuas cov chips tshiab nrog kev txaus siab tiag tiag. Nab, hlaws, nplhaib, zes - dab tsi txaus siab rau cov tub ntxhais hluas tsis tuaj yeem pom hauv cov shavings.

Ntau cov duab, xim thiab intricacies ntawm shavings txhawb qee tus neeg kom muaj tswv yim. Piv txwv li, ib tug ntawm lawv coj ntau daim duab thav duab nrog zoo nkauj hlau shavings thiab hu ua lub txawv txawv gallery "Shavings, koj yog qhov chaw!". Lwm tus kws sau ntawv, Vladimir Kargin, tus hlub ntawm kev tsim cov vaj huam sib luag peb sab, ua ntau cov duab ua los ntawm ntau hom shavings. Tag nrho cov ntsiab lus ntawm nws paintings muaj feem xyuam rau xwm.

Byproduct of production

Khib ntawm txhua hom hlau shavings, suav nrog cov uas tsis yog-ferrous, yog muab pov tseg thiab xa mus rau rov ua dua. Cov txheej txheem no yog kev siv zog ntau: nws suav nrog kev txheeb cais, roj rho tawm, crushing, briquetting thiab thauj mus rau smelter. Briquetting yog tsim nyog los txo cov pov tseg thaum muab cov chips nyob rau hauv qhov cub. Chip ua machinery:

- roj extractor centrifuge;

- chip crusher;

- briquetting (baling) presses rau compaction ntawm chips.

Txhua tus tswv tshuab paub tias thaum txiav cov hlau, koj yuav tsum tiv thaiv koj ob lub qhov muag thiab tes: ua haujlwm hauvtsom iav los yog nrog cov ntaub thaiv tiv thaiv tau nruab rau ntawm cov tshuab, thiab tshem tawm cov qhov txhab thiab cov chips daig nrog tus nuv. Shavings feem ntau muaj qhov zoo nkauj zoo nkauj, tab sis lawv ib txwm txaus ntshai, vim tias lawv tuaj yeem ua tau: ntse, kub, prickly. Saib xyuas koj tus kheej.

Pom zoo:

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Daim ntawv hlau txiav: piav qhia, hom. hlau dabtsi yog khoov

Hnub no, cov ntawv hlau txiav yog ib qho ntawm cov txheej txheem thev naus laus zis uas tso cai rau koj kom tau txais qhov khoob ntawm qhov xav tau loj thiab cov duab. Txawm li cas los xij, muaj ntau txoj hauv kev los ua cov txheej txheem no thiab ntau yam khoom siv

Txiav hom rau milling. Hom cutters, xam txiav ceev

Ib txoj hauv kev los ua kom tiav cov ntaub ntawv yog milling. Nws yog siv rau kev ua cov hlau thiab cov hlau tsis yog hlau. Lub workflow yog tswj los ntawm kev txiav cov ntaub ntawv

Yam yuav muag hauv khw hauv online: tswv yim. Dab tsi yog qhov zoo dua los muag hauv khw hauv online hauv lub nroog me? Dab tsi yog txiaj ntsig los muag hauv khw hauv online thaum muaj kev kub ntxhov?

Los ntawm kab lus no koj yuav pom tias cov khoom twg koj tuaj yeem ua tau nyiaj muag hauv Is Taws Nem. Hauv nws koj yuav pom cov tswv yim tsim lub khw hauv online hauv lub nroog me thiab nkag siab tias koj tuaj yeem khwv tau nyiaj li cas thaum muaj kev kub ntxhov. Tsis tas li ntawd nyob rau hauv tsab xov xwm muaj cov tswv yim los tsim ib lub khw hauv online yam tsis muaj kev nqis peev

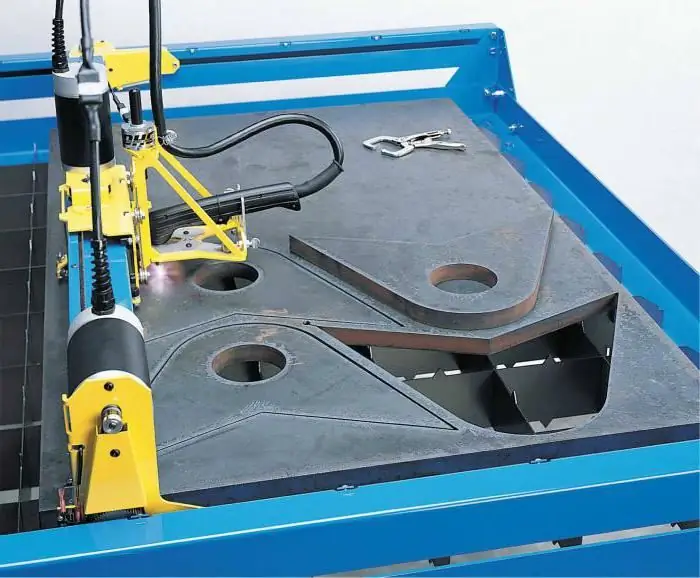

Hlau txiav tshuab. Plasma hlau txiav tshuab

Zaj lus no mob siab rau lub cuab yeej txiav hlau. Kev siv tshuab ntawm plasma txiav, nrog rau cov cuab yeej thiab cov yam ntxwv ntawm cov cuab yeej raug txiav txim siab