2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Plastics, lossis tsuas yog cov yas, yog cov khoom sib xyaw ua ke uas ua los ntawm cov khoom ntuj lossis hluavtaws. Lub ntsiab feature ntawm xws li tshuaj yog muaj peev xwm ntawm kev hloov mus rau ib lub xeev yas nyob rau hauv tus ntawm ob yam - kub thiab siab. Tsis tas li ntawd, nws tseem ceeb heev uas tom qab ntawd cov huab hwm coj tuaj yeem tswj tau cov duab muab rau nws.

Kev piav qhia dav dav ntawm plastics

Plastic pawg pib tsim tawm txog 50-60 xyoo dhau los. Txog rau tam sim no, cov khoom lag luam no tau dhau los ua ntau yam hauv lub neej txhua hnub thiab hauv kev lag luam thiab lwm ceg ntawm tib neeg kev ua haujlwm. Tsis tas li ntawd, tam sim no, yas tuaj yeem hloov pauv ntoo, iav thiab txawm tias hlau hauv qee kis. Nws yog tsim nyog sau cia tias kev lag luam xws li mechanical engineering, xov tooj cua engineering, hluav taws xob engineering, thiab kev lag luam tshuaj tsis tuaj yeem ua yam tsis muaj cov khoom zoo li no lawm.

Cov khoom siv yas tuaj yeem ua ke lub zog ntawm cov khoom siv hlau,thaum muaj qhov hnyav ntawm ntoo thiab pob tshab ntawm iav. Nrog rau tag nrho cov kev zoo no, cov tshuaj no tsis muaj qhov tsis zoo nyob rau hauv tag nrho cov ntaub ntawv no. Lawv tsis corrode zoo li hlau, rot zoo li ntoo, thiab tsis tuaj yeem tawg zoo li iav.

Cov ntaub ntawv siv dav dav

Cov khoom siv yas tuaj yeem siv los tsim cov ntaub ntawv zaj duab xis. Lawv, nyob rau hauv lem, yog nquag siv thaum lub sij hawm cultivation ntawm zaub, piv txwv li. Zoo rau kev tsim thaj chaw tiv thaiv hauv av, kom loj hlob berries, paj thiab ntau dua.

Tsis tas li ntawd, cov thawv ntim yas, cov thawv ntim khoom thiab lwm lub thawv kuj tseem tuav ib qho ntawm cov chaw ua haujlwm hauv kev xav tau thauj cov tshuaj tua kab, chiv, khoom ua liaj ua teb. Txog rau tam sim no, kev tsim cov khoom siv roj-pauv zaj duab xis tau ua tiav. Xws li daim nyias nyias yuav raug siv los khaws cov khoom hauv ib puag ncig uas tswj tau cov pa roj. Rau kev ua ub ua no nyob deb nroog, cov yeeb yaj kiab tseem tab tom raug tsim los ua cov av.

Kev sib txuas yooj yim

Yog tias peb muab cov ntaub ntawv dav dav txog cov yas, peb tuaj yeem hais cov hauv qab no: lub hauv paus muaj cov khoom siv molecular siab lossis tsuas yog cov polymer, nrog rau ntuj (pitch, asph alt) lossis cov khoom siv hluavtaws. Txog niaj hnub no, qhov dav thiab qhov tseem ceeb tshaj plaws yog cov khoom siv hluavtaws, uas tau txais los ntawm polymerization lossis polycondensation.

Cov txheej txheem ntawm polymerization ntawm cov yas yog cov tshuaj tiv thaiv ntawm kev sib txuas cov molecules zoo tib yam uashu ua monomers. Hauv qhov no, tsis muaj cov tshuaj yooj yim tso tawm. Thiab qhov tshwm sim polymer yuav muaj qhov hnyav molecular sib npaug rau qhov loj ntawm ob lub ntsiab lus uas tsim nws. Nws yuav tsum raug sau tseg tias ob peb lub monomers tuaj yeem koom nrog hauv cov tshuab tsim khoom yas tib lub sijhawm. Hauv qhov no, cov txheej txheem yuav raug hu ua copolymerization.

Yog tias peb tham txog polycondensation, tom qab ntawd cov polymer yuav tau txais los ntawm kev sib txuas ntau pawg ua haujlwm ntawm cov khoom sib txawv. Hauv qhov no, qee cov tshuaj yooj yim yuav raug tso tawm. Raws li qhov no, nws tau pom tseeb tias tag nrho qhov hnyav molecular ntawm cov polymer tiav yuav tsis sib npaug rau tag nrho cov khoom ntawm cov monomers koom nrog hauv kev tsim.

Kev piav qhia ntawm macromolecular compounds

Kev ua cov khoom sib xyaw no yog ua los ntawm kev raug kub thiab siab. Thaum npaj, xws li cov tebchaw yuav nyob rau hauv daim ntawv ntawm cov kua nplaum los yog ib qho khoom. Tsis tas li ntawd, nws tsim nyog hais tias cov polymers tau muab faib ua peb pawg loj - raws li cov qauv tshuaj ntawm cov monomer siv los tsim.

khoom noj khoom haus

Tus qauv thiab lub hom phiaj ntawm cov yas nyob ntawm lawv cov khoom. Yog li ntawd, nws tsim nyog hais tias muaj cov additives tshwj xeeb uas tuaj yeem hloov qee qhov kev coj ua zoo.

Qee cov khoom tiav yog tsim los ntawm 100% polymers - cov no yog polyethylene lossis polyamides. Lwm tus muaj cov polymers nkaus xwb rau 20-60%, thiab cov seem ntawm pawg yog nyob los ntawmtshwj xeeb fillers. Lub hom phiaj tseem ceeb ntawm fillers yog hloov ntau yam khoom: ua kom muaj hluav taws kub, ua kom muaj zog, nce hardness thiab mechanical zog. Piv txwv li, ib tug muab tub lim xws li carbon dub ntxiv rau roj hmab.

Lwm cov khoom ntxiv pom muaj nyob hauv cov thawv yas, piv txwv li, thiab hauv ntau lwm cov thawv ntim khoom, yog cov yas yas. Txawm li cas los xij, qhov ntau plasticizer ntxiv, qhov ntau dua yuav yog cov coefficient ntawm plasticity. Yog li, nws tuaj yeem tau txais cov khoom siv ruaj khov, tab sis cov khoom siv yas.

Lwm yam tseem ceeb yog lub stabilizer. Nws yog ntxiv rau cov muaj pes tsawg leeg nyob rau hauv thiaj li yuav zam lub decomposition ntawm cov khoom tiav nyob rau hauv tus ntawm cov kub kub, tshav ntuj thiab lwm yam sab nraud yam. Qee zaum, cov xim me ntsis ntxiv yog tias koj xav hloov xim ntawm cov khoom.

Kev piav qhia ntawm cov tshuaj

Lub thev naus laus zis rau kev tsim cov khoom sib xyaw no txhais tau tias muaj lwm yam khoom, uas yog hu ua IUD.

Navy yog qhov tseem ceeb tshaj plaws additives uas tuav ntau yam sib txawv ua ke, thiab kuj muab plasticity. Tsis tas li ntawd, HMS kuj txhawb kev moldability, hluav taws xob rwb thaiv tsev thiab kev tiv thaiv corrosion. Yog tias peb tham txog kev faib tawm dav dav ntawm cov yas, ces lawv tuaj yeem ua tsis tau thiab puv.

thawj pab pawg yog pawg ntawm cov polymer ntshiab, lossis nrog cov tshuaj ntxiv me me. Cov pab pawg thib ob, ntawm qhov tsis sib xws, muaj ob qho tib si polymers thiabntau ntau yam additives uas sib npaug zos rau hauv lub binder, feem ntau yog nyob rau hauv resin.

Raws li tau hais ua ntej, cov khoom ntim tau qhia los hloov lossis txhim kho qhov zoo tshaj plaws. Los ntawm lawv tus kheej, cov khoom no tuaj yeem yog cov organic lossis ntxhia sib xyaw. Lawv tuaj yeem nthuav tawm nyob rau hauv daim ntawv ntawm cov hmoov fillers - ntoo hmoov, mica los yog quartz hmoov, thiab lwm yam. Thiab lawv tuaj yeem sawv cev los ntawm cov ntsiab lus fibrous, piv txwv li, paj rwb. Qhov kawg ntawm cov khoom ntim yog canvas (daim ntawv, mica thiab lwm yam).

Hais lus kom ntxaws ntxiv txog cov yas yas, lawv tuaj yeem ua tus yam ntxwv raws li hauv qab no: cov no yog cov khoom siv hluav taws xob tsawg, uas feem ntau sawv cev los ntawm qee yam kua. Lawv cov kev taw qhia rau hauv cov muaj pes tsawg leeg nce tsis tsuas elasticity. Cov khoom lag luam molded nrog kev nce hauv plasticizers hauv cov muaj pes tsawg leeg txhim kho Frost tsis kam thiab elasticity.

Muaj lwm hom additives - hardeners. Lawv cov concentration feem ntau qis heev, thiab lub luag haujlwm tseem ceeb yog hloov cov polymers rau hauv cov qauv peb sab. Qhov tseeb, qhov no ua rau qee cov yas los ua infusible.

Flaws

Nws tsim nyog sau cia qee qhov tsis txaus uas cov khoom no tseem muaj. Txhua yam ntawm cov yas muaj qhov ua kom sov qis dua li cov khoom siv hlau. Feem ntau ntawm cov khoom yas tuaj yeem ua haujlwm ntawm qhov kub tsis tshaj 150 degrees Celsius. Txawm tias lawv lub neej ua haujlwm ntev, cov khoom siv yas kujraug kev laus. Qhov teeb meem no yuav tshwm sim nws tus kheej hauv qhov tsaus ntuj ntawm cov khoom, oxidation, txo cov yam ntxwv ntawm lub zog, hardness.

Tau txais polyethylene

Koj tuaj yeem xav txog cov thev naus laus zis rau kev tsim cov yas raws li polyethylene. Qhov no yog ib qho ntawm cov khoom uas tau txais los ntawm polymerization, thiab nws yog qhov xav tau hauv kev ua lag luam.

Kom tau txais polyethylene hauv nws daim ntawv ib txwm, peb txoj kev polymerization yog siv:

- thawj txoj kev yog polymerization nyob rau hauv siab ntawm 1000-2000 atm nrog kub ntawm 180 txog 200 degrees Celsius. Ib qho me me ntawm cov pa oxygen yog siv los ua tus pib ntawm cov txheej txheem - 0.005-0.05%.

- Qhov thib ob variant ntawm polymerization, ntawm qhov tsis sib xws, tshwm sim nyob rau hauv lub zog ntawm atmospheric los yog artificially tsim siab ntawm 2-6 atm thiab ntawm ib tug kub ntawm 60-70 degrees xwb. Nyob rau hauv cov ntaub ntawv no, organometallic hydrocarbons yog siv los ua catalysts nyob rau hauv ib tug roj ib puag ncig nyob rau hauv tsis muaj ib tug me ntsis ya raws thiab oxygen.

- Yam kawg ntawm polymerization tshwm sim nyob rau hauv lub siab ntawm 20-50 atm thiab nrog kev koom tes ntawm oxide catalysts nrog kub ntawm 110-140 degrees Celsius.

Type of plastics

Thaum tsim khoom thiab kho tom ntej, ob hom yas ntxiv tuaj yeem paub qhov txawv. Lub ntsiab txawv feature yog cov kev mob ntawm hardening los yog tsis muaj nws. Raws li qhov ntsuas no, cov thermoplastic thiab thermosetting yas sawv tawm.

Raws li thawj qeb ntawm cov khoom, thaum rhuab, lawvyuav dhau los ntawm qee qhov kev hloov pauv, dhau los ntawm lub xeev ruaj khov rau cov yas, khov thiab kua dej. Cov khoom no yuav solidify rov qab thaum txias. Cov khoom siv thermoplastic suav nrog polyethylene, polystyrene, fluoroplasts thiab lwm yam.

Thermosetting yas, thaum rhuab mus rau qhov kub ntawm 150-300 degrees, yuav raug hloov pauv tsis tau. Xws li cov khoom yuav dhau los ua khoom, insoluble thiab infusible nyob rau hauv siab los yog tsis muaj nws. Lawv muaj hardeners ua ib qho ntxiv. Ib qho piv txwv yog epoxy.

Zoo hauv Russia

Ib lub tuam txhab qub thiab loj tshaj plaws rau kev tsim cov khoom no yog Nelidovsky Cog ntawm Plastics NZPM. Cov chaw tsim khoom ntawm lub tuam txhab no nyob rau sab qab teb-sab hnub poob ntawm thaj tsam Tver.

Cov nroj tsuag nyob rau ntawm 19 hectares ntawm thaj av, uas muaj 25 qhov chaw tsim khoom.

Qhov chaw tsim khoom loj tshaj plaws yog nyob rau ntawm qhov chaw tsim khoom Isonel polyethylene ua npuas ncauj (PPE). Thaj chaw yog 24,500 square meters. Tom ntej no los txog thaj tsam me me ntawm lub khw naj npawb 2 - 7500 square meters. meters, qhov twg extruded ntawv yas yog ua. Lub tsev kawm ntawv rau lub tshuab nqus tsev tsim khoom occupies lwm 3 txhiab square meters. meters. Tsis tas li ntawd, cov nroj tsuag tau koom nrog kev ua cov yas.

Pom zoo:

Usinskoye teb: cov yam ntxwv tseem ceeb thiab cov yam ntxwv ntawm thev naus laus zis

Usinskoye teb: thaj chaw thaj chaw, piav qhia, kwv yees hydrocarbon reserves. Nta ntawm cov roj thiab geological qauv ntawm cov deposit. Keeb kwm ntawm discovery thiab kev tshawb fawb ntawm cov deposit. Roj ntau lawm technology

Sturgeon yug me nyuam hauv RAS: cov khoom siv, kev noj haus, kev txhawb nqa thev naus laus zis, kev tsim khoom thiab cov lus qhia los ntawm cov kws kho tsiaj tshwj xeeb

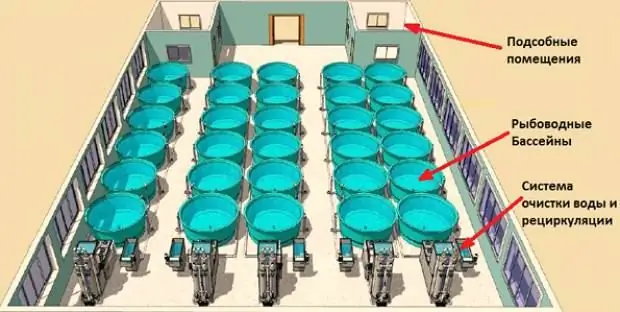

Sturgeon ua liaj ua teb yog ib lub lag luam uas cog lus tias yuav tau txais txiaj ntsig loj. Leej twg tuaj yeem ua tau, txawm lawv nyob qhov twg. Qhov no tuaj yeem ua tau vim yog kev siv cov tshuab xa dej rov qab (RAS). Thaum tsim lawv, nws tsuas yog tsim nyog los muab cov kev xav tau zoo, nrog rau thaj tsam xav tau. Nyob rau hauv cov ntaub ntawv no, cov ntses ua liaj ua teb yog tsim los ntawm hangar-hom vaj tse nyob rau hauv lub pas dej ua ke thiab ib tug purification system nyob rau hauv

Kev faib tawm ntawm cov excavators, lawv cov yam ntxwv thev naus laus zis thiab lub hom phiaj

Tam sim no, tib neeg siv ntau hom kev siv tshuab ntau yam. Cov cuab yeej no, xws li excavators, yog tam sim no nrov heev, raws li kev ua haujlwm hauv av tau nrawm nrawm thiab tsis yog xwb. Kev faib tawm ntawm excavators yog qhov dav heev thiab nws tsim nyog xav txog

Kev tsim cov khoom siv roj: cov txheej txheem thev naus laus zis, khoom siv thiab khoom siv

Hnub no, muaj ntau yam khoom siv hauv tsev uas nrov. Ib qho kev tsim kho tshiab yog kev tsim cov khoom siv roj av, uas yog cov pob zeb ntawm tes. Ntawm cov no, nws muaj txiaj ntsig tsis yog los tsim ib lub tsev ntiag tug xwb, tab sis kuj tsim khoom muag

Kev tsim cov plywood: thev naus laus zis, theem tseem ceeb ntawm cov txheej txheem thiab thaj chaw ntawm kev siv cov khoom siv

Plywood yog ib qho ntawm cov khoom siv pheej yig tshaj plaws thiab siv tau tshaj plaws. Txawm hais tias muaj ntau txheej txheej, nws yooj yim rau nruab thiab tuaj yeem ua tiav hauv tsev yam tsis muaj cov cuab yeej tshwj xeeb. Txuj kev tsim cov plywood suav nrog kev siv cov ntoo lamellas, nrog rau kev ua kom zoo uas koj tuaj yeem tau txais cov khoom tiav uas tiv taus ntau yam kev hem thawj