2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Magnesium alloys muaj ntau lub cev thiab tshuaj lom neeg tshwj xeeb, lub ntsiab ntawm cov uas tsis tshua muaj zog thiab siab zog. Kev sib xyaw ua ke ntawm cov khoom zoo hauv cov ntaub ntawv nrog kev sib ntxiv ntawm magnesium ua rau nws muaj peev xwm tsim cov khoom thiab cov qauv nrog cov yam ntxwv muaj zog thiab qhov hnyav.

YMagnesium yam ntxwv

Kev lag luam tsim khoom thiab siv magnesium pib tsis ntev los no - tsuas yog kwv yees li 100 xyoo dhau los. Cov hlau no muaj qhov loj me, vim nws muaj qhov ntom ntom (1.74 g / cmᶟ), zoo tiv thaiv huab cua, alkalis, gaseous media uas muaj fluorine thiab ntxhia roj.

Nws lub ntsiab lus melting yog 650 degrees. Nws yog tus cwj pwm los ntawm cov tshuaj lom neeg ua haujlwm siab mus txog qhov tshwm sim combustion hauv huab cua. Lub zog tensile ntawm ntshiab magnesium yog 190 MPa, elastic modulus yog 4,500 MPa, thiab tus txheeb ze elongation yog 18%. Cov hlau muaj peev xwm damping siab (zoo absorbs elastic vibrations), uas muab nws nrogzoo heev poob siab kam rau ua thiab txo rhiab heev rau resonant phenomena.

Lwm cov yam ntxwv ntawm lub caij no suav nrog cov thermal conductivity zoo, muaj peev xwm tsis tshua muaj peev xwm nqus tau cov thermal neutrons thiab cuam tshuam nrog cov roj nuclear. Vim yog kev sib xyaw ua ke ntawm cov khoom no, magnesium yog cov khoom siv zoo tshaj plaws rau kev tsim hermetically kaw lub plhaub ntawm cov ntsiab lus kub ntawm nuclear reactors.

Magnesium alloys zoo nrog ntau yam hlau thiab yog ib qho ntawm cov muaj zog txo cov neeg ua haujlwm, tsis muaj cov txheej txheem metallothermic tsis yooj yim sua.

Nyob rau hauv nws daim ntawv ntshiab, nws yog tsuas yog siv los ua ib qho kev sib ntxiv ntawm cov alloys nrog txhuas, titanium thiab lwm yam tshuaj. Hauv ferrous metallurgy, magnesium yog siv rau kev sib sib zog nqus desulfurization ntawm hlau thiab cam khwb cia hlau, thiab cov khoom ntawm lub tom kawg yog txhim kho los ntawm graphite spheroidization.

YMagnesium thiab alloying additives

Cov khoom siv ntau tshaj plaws uas siv hauv magnesium-based alloys suav nrog cov khoom xws li txhuas, manganese thiab zinc. Los ntawm txhuas, cov qauv txhim kho, fluidity thiab lub zog ntawm cov khoom nce. Kev taw qhia ntawm zinc kuj ua rau nws muaj peev xwm kom tau txais cov alloys muaj zog nrog cov qoob loo txo qis. Nrog kev pab los ntawm manganese los yog zirconium, qhov corrosion kuj ntawm magnesium alloys yog nce.

Qhov sib ntxiv ntawm zinc thiab zirconium muab ntxiv zog thiab ductility ntawm cov hlau sib tov. Thiab lub xub ntiag ntawm tej yam tsawg ntiaj tebcov ntsiab lus, xws li neodymium, cerium, yttrium, thiab lwm yam, pab txhawb kom muaj kev kub ntxhov thiab ua kom muaj zog ntawm cov khoom siv magnesium alloys.

Txhawm rau tsim cov khoom siv ultra-teeb nrog qhov ntom ntawm 1.3 txog 1.6 g / mᶟ, lithium tau nkag rau hauv cov alloys. Qhov no additive ua rau nws muaj peev xwm txo tau lawv qhov hnyav los ntawm ib nrab piv rau txhuas hlau sib tov. Nyob rau tib lub sijhawm, lawv cov ntsuas ntawm plasticity, fluidity, elasticity thiab manufacturability mus txog qib siab dua.

Kev faib tawm ntawm magnesium alloys

Magnesium alloys raug cais raws li ntau tus qauv. Nov yog:

- raws li txoj kev ua - rau casting thiab deformable;

- raws li qib ntawm rhiab heev rau kev kho cua sov - mus rau hauv tsis-hardened thiab hardened los ntawm kev kho cua sov;

- los ntawm cov khoom thiab kev siv - rau cov cua sov-tiv taus, siab-lub zog thiab cov hom phiaj dav dav;

- raws li cov txheej txheem alloying - muaj ntau pawg ntawm cov tsis-hardenable thiab kub-hardenable wrought magnesium alloys.

Casting alloys

pab pawg no suav nrog cov hlau nplaum nrog ntxiv ntawm magnesium, tsim los rau kev tsim khoom ntawm ntau yam thiab cov ntsiab lus los ntawm cov hlau casting. Lawv muaj cov khoom sib txawv, nyob ntawm seb lawv muab faib ua peb chav kawm:

- nruab nrab lub zog;

- siab zog;

- kub resistant.

Hais txog tshuaj muaj pes tsawg leeg, cov alloys kuj tau muab faib ua peb pawg:

- aluminium + magnesium + zinc;

- magnesium + zinc + zirconium;

- magnesium + rare earthcov ntsiab lus + zirconium.

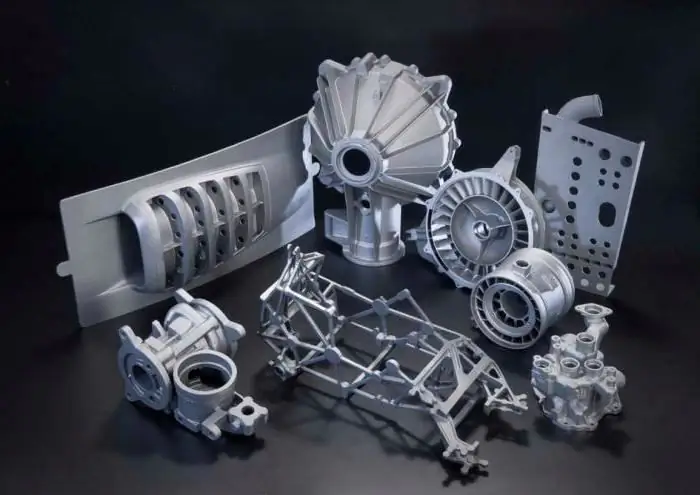

Casting zog ntawm alloys

Qhov zoo tshaj plaws casting zog ntawm cov khoom ntawm peb pawg no muaj aluminium-magnesium alloys. Lawv nyob rau hauv chav kawm ntawm cov ntaub ntawv muaj zog (txog 220 MPa), yog li lawv yog qhov kev xaiv zoo tshaj plaws rau kev tsim cov cav cav rau lub dav hlau, tsheb thiab lwm yam khoom siv ua haujlwm raws li cov khoom siv thiab cov thermal loads.

txhawm rau ua kom cov yam ntxwv muaj zog, aluminium-magnesium alloys kuj yog alloyed nrog lwm cov ntsiab lus. Tab sis lub xub ntiag ntawm hlau thiab tooj liab impurities yog undesirable, vim hais tias cov ntsiab lus no muaj kev cuam tshuam tsis zoo rau weldability thiab corrosion kuj ntawm alloys.

Cam khwb cia magnesium alloys yog npaj nyob rau hauv ntau hom melting furnaces: reverberatory furnaces, crucible furnaces nrog roj, roj los yog hluav taws xob cua sov, los yog crucible induction furnaces.

Tshwj xeeb fluxes thiab additives yog siv los tiv thaiv combustion thaum melting thiab casting. Castings yog tsim los ntawm casting hauv xuab zeb, plaster thiab plhaub pwm, nyob rau hauv siab thiab siv peev qauv.

Wrought alloys

Y Piv rau cov hlau nplaum, cov hlau nplaum hlau nplaum muaj zog dua, muaj zog dua thiab tawv dua. Lawv yog siv los tsim cov blanks los ntawm dov, nias thiab stamping. Raws li kev kho cua sov ntawm cov khoom, hardening yog siv ntawm qhov kub ntawm 350-410 degrees, ua raws li kev ua kom txias tsis muaj kev laus.

Thaum cua sovcov khoom yas ntawm cov ntaub ntawv zoo li no nce, yog li ntawd, kev ua cov magnesium alloys yog nqa tawm los ntawm kev siv lub siab thiab kub. Stamping yog ua ntawm 280-480 degrees nyob rau hauv presses los ntawm kev kaw tuag. Nyob rau hauv txias dov, nquag intermediate recrystallization annealings yog nqa tawm.

Thaum vuam magnesium alloys, lub zog ntawm cov khoom seam yuav raug txo qis hauv ntu uas qhov vuam tau ua, vim qhov rhiab heev ntawm cov khoom siv rau overheating.

Teb daim ntawv thov ntawm magnesium alloys

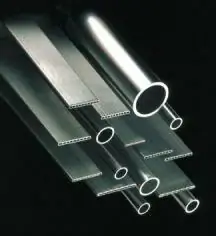

Ntau yam khoom lag luam ib nrab tiav - ingots, slabs, profiles, nplooj ntawv, forgings, thiab lwm yam yog tsim los ntawm casting, deformation thiab kev kho cua sov ntawm alloys. Cov blanks no yog siv los tsim cov ntsiab lus thiab qhov chaw ntawm cov cuab yeej siv niaj hnub no, qhov twg qhov hnyav ntawm cov qauv (qhov hnyav txo) ua lub luag haujlwm tseem ceeb thaum tswj lawv cov yam ntxwv ntawm lub zog. Piv rau txhuas, magnesium yog 1.5 npaug sib zog, thiab 4.5 npaug zog dua hlau.

Tam sim no, kev siv cov magnesium alloys tau siv dav hauv aerospace, tsheb, tub rog thiab lwm yam kev lag luam, qhov twg lawv cov nqi siab (qee qib muaj cov ntsiab lus kim heev) yog qhov ncaj ncees los ntawm kev lag luam los ntawm kev pom. muaj peev xwm tsim tau cov khoom siv ruaj khov, nrawm dua, muaj zog thiab muaj kev nyab xeeb uas tuaj yeem ua haujlwm tau zoo hauv cov xwm txheej hnyav, suav nrog thaum raug kub hnyiab.

Vim lawv lub peev xwm hluav taws xob muaj zog, cov hlau nplaum no yog cov khoom siv zoo tshaj plaws rau kev tsim cov khoom tiv thaiv electrochemical tiv thaiv cov qauv hlau, xws li cov tsheb, cov qauv hauv av, roj platforms, nkoj nkoj, thiab lwm yam, los ntawm cov txheej txheem corrosion tshwm sim. nyob rau hauv lub zog ntawm noo noo, tshiab thiab dej hiav txwv.

Alloys nrog ntxiv ntawm magnesium kuj tau siv nyob rau hauv ntau lub xov tooj cua engineering systems, uas lawv siv los ua suab ducts rau ultrasonic kab kom ncua hluav taws xob signals.

Zaj lus

Kev lag luam niaj hnub muab qhov xav tau ntau dua ntawm cov ntaub ntawv raws li lawv lub zog, hnav tsis kam, corrosion resistance thiab manufacturability. Kev siv cov magnesium alloys yog ib qho kev cog lus zoo tshaj plaws, yog li ntawd, kev tshawb fawb ntsig txog kev tshawb nrhiav cov khoom tshiab ntawm magnesium thiab qhov ua tau ntawm nws daim ntawv thov tsis nres.

Tam sim no, kev siv magnesium-based alloys hauv kev tsim ntau yam thiab cov qauv ua rau nws tuaj yeem txo lawv qhov hnyav li ntawm 30% thiab nce lub zog tensile mus txog 300 MPa, tab sis, raws li cov kws tshawb fawb, qhov no nyob deb ntawm qhov txwv rau qhov tshwj xeeb hlau no.

Pom zoo:

Cov ntaub ntawv xa tuaj: tus kheej xaj, daim ntawv them nqi, daim ntawv xaj, cov ntaub ntawv xa khoom thiab cov chaw xa khoom xa tuaj

Kev ua haujlwm hauv kev xa khoom yog nrov heev niaj hnub no, tshwj xeeb tshaj yog cov tub ntxhais hluas muaj siab nyiam. Tus neeg xa xov tsis yog ib tus neeg xa khoom xwb, tab sis yog tus kws tshaj lij uas muaj kev txawj ntse thiab tuaj yeem nqa parcel los yog xa mus rau qhov chaw nyob uas tau teev tseg nrog cov khoom zoo thiab sai

Thermal imaging tswj ntawm cov khoom siv hluav taws xob: lub tswv yim, lub hauv paus ntsiab lus ntawm kev ua haujlwm, hom thiab kev faib tawm ntawm thermal imagers, nta ntawm daim ntawv thov thiab kev txheeb xyuas

Kev ntsuas cua sov ntawm cov khoom siv hluav taws xob yog ib txoj hauv kev zoo los txheeb xyuas qhov tsis xws ntawm cov khoom siv hluav taws xob uas kuaj pom yam tsis tau kaw lub tshuab hluav taws xob. Nyob rau hauv qhov chaw ntawm kev sib cuag tsis zoo, qhov kub thiab txias nce, uas yog lub hauv paus ntawm cov txheej txheem

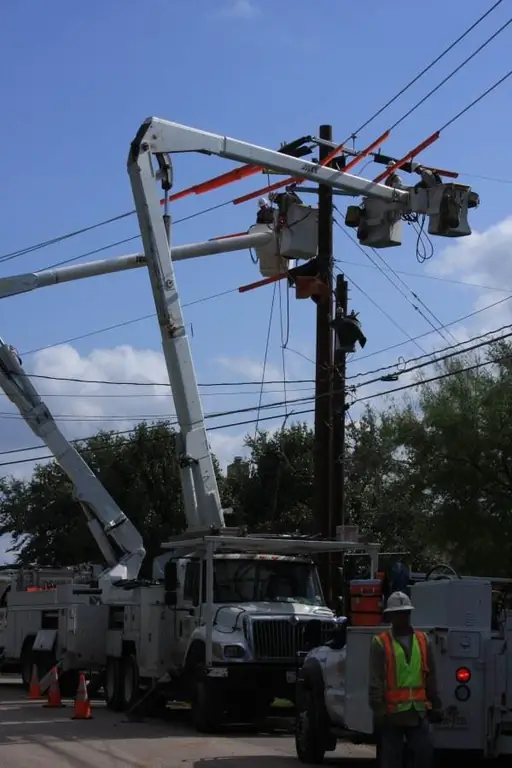

Kev faib hluav taws xob: chaw nres tsheb, khoom siv tsim nyog, kev faib khoom, daim ntawv thov, accounting thiab tswj cov cai

Txhua tus paub tias lub zog hluav taws xob tau muab rau qhov chaw ntawm nws cov khoom siv los ntawm qhov chaw ncaj qha. Txawm li cas los xij, cov peev txheej zoo li no tuaj yeem nyob ntawm qhov deb ntawm cov neeg siv khoom. Vim li no, kev faib hluav taws xob thiab nws cov khoom xa tuaj yog txheej txheem nyuaj

Cov cua kub siab qis: txhais, lub hauv paus ntawm kev ua haujlwm, cov yam ntxwv ntawm kev ua haujlwm, kev faib tawm, tsim, kev ua haujlwm nta, daim ntawv thov hauv kev lag luam

Cov cua kub siab qis (LPH) tam sim no siv heev. Muaj ob hom tseem ceeb uas yog tsim los ntawm cov nroj tsuag sib txawv. Lawm, lawv kuj txawv ntawm lawv cov kev ua tau zoo

Yam koj yuav tsum tau ua haujlwm hauv tsheb tavxij: cov ntaub ntawv tsim nyog thiab cov cai, cov cai thiab kev cai lij choj. Cov lus teb thiab cov lus qhia los ntawm cov neeg tsav tsheb tavxij, cov neeg siv khoom thiab cov neeg xa khoom

Raws li ntau tus neeg caij tsheb, txoj haujlwm ntawm tus tsav tsheb tavxij yog qhov yooj yim tshaj plaws. Koj zaum, mloog suab paj nruag zoo nkauj thiab tsav tsheb rov qab los. Thiab lawv muab nyiaj rau koj. Tab sis qhov no tsuas yog sab nraud ntawm lub npib. Qhov rov qab yog ntau dua rosy. Peb yuav tham txog nws hauv kab lus no. Thiab peb tseem yuav qhia txog yam koj xav tau ua haujlwm hauv tsheb tavxij