2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Hlau band saw yog cov cuab yeej ua haujlwm siab ua haujlwm rau ntau yam haujlwm, xws li txiav cov hlau thiab txiav ntau yam khoom muaj zog thiab muaj zog. Cov khoom siv no yog siv tau zoo heev ob qho tib si hauv kev tsim cov qauv hlau thiab hauv kev tsim kho kev lag luam kom txiav cov khoom sai sai. Los ntawm kev siv ntawm lub kaw nyias steel band ua raws li kev txiav ntawm band pom, lub workpiece yog sawn los ntawm txoj kab ncaj.

Ntaus Ntaus

Yog tias peb xav txog phau ntawv txhais tes pom rau cov hlau kom ntxaws, ces nws zoo ib yam li jigsaw, txij li lub tswv yim ntawm lawv txoj haujlwm zoo sib xws. Tsuas muaj ib qhov sib txawv - ib daim ntaub kaw, txuas los ntawm vuam rau hauv ib lub nplhaib, tsis reciprocate, tab sis nyob rau hauv lub contour ntawm ob lub pulleys nyob rau hauv ib qho kev taw qhia. Cov qauv kev txav no tso cai rau lub neej ntev ntawm cov saw saw thiab tseem tiv thaiv cov saw tsis txhob npub sai heev. Qhov no yog vim li cas band saws ua npubtsis ntev heev, uas yog, lawv tsis tas yuav hloov ntau zaus. Qhov qis roughness ntawm lub dav hlau txiav tshem tawm qhov xav tau ntawm qhov chaw tiav.

Yog tias koj siv phau ntawv qhia band saw tshuab rau hlau, ces txiav cov khoom dov, profiles thiab cov kav dej yuav zoo tshaj plaws. Ua tsaug rau kev tsim tshwj xeeb ntawm cov cuab yeej siv, nws muaj peev xwm txo qis kev siv hluav taws xob hluav taws xob, nrog rau kev txo qis ntawm cov khoom kim heev. Qhov no yog ua tiav vim qhov tseeb hais tias hlau txiav nyob rau hauv cov ntaub ntawv no yog nqa tawm nrog ib tug tsawg kawg nkaus kerf dav. Tias yog vim li cas cov tshuab no tau siv ntau zuj zus nyob rau qhov chaw ua haujlwm cuam tshuam txog kev txiav cov hlau kim thiab cov hlau, nrog rau cov khoom nrog cov phab ntsa nyias.

Kev ua haujlwm ntawm cov khoom siv band pom

Yog tias koj xav tau cov saw hlau rau cov hlau, ces koj yuav tsum paub tias kev ua lag luam tam sim no muaj cov khoom siv uas tswj tau hauv phau ntawv, tsis siv neeg thiab semi-automatic hom. Kev tuav cov cav tov yog ib qho yooj yim rau kev khiav lag luam, txhim khu kev qha raws li qhov ua tau, txij li lawv cov qauv tsim tsis muaj lub nra hnyav nrog cov khoom siv hluav taws xob uas feem ntau ua tsis tiav. Lawv txoj haujlwm yog ua tiav nrog kev siv zog thiab nrawm, teem ua ntej.

Lub ntiajteb txawj nqus

Cov khoom siv no tau txais lawv lub npe vim qhov tseeb tias kev txiav cov hlau tsis muaj hlau yog ua los ntawm lawv vim qhov hnyav ntawm lub console ntawm cov khoom ua tiav. Hydraulic cylinders thiab throttle li qub yog lub luag haujlwm rau kev kho qhov nrawm ntawm kev ua haujlwm. Band sawing txawvkuj dag nyob rau hauv qhov tseeb hais tias lub suab ntawm cov hniav ntawm cov hniav nyob ntawm qhov profile raug txiav.

Kev ua haujlwm ntawm cov cuab yeej siv kab xev tuaj yeem sib txawv. Qhov kev ntsuas no tso cai rau koj los qhia qee hom tshuab.

Cantilever hlau txiav tshuab. Nyob rau hauv rooj plaub no, lub saw ncej (console) txav los ntawm pob khawm. Cov qauv no yog siv rau kev txiav cov raj, profiles, ntu thiab cov khib nyiab.

Ib-kem, ob-kem thiab portal. Thawj hom yog tus cwj pwm los ntawm kab rov tav saw thav duab uas nqis los ntawm cov khib nyiab. Nyob rau hauv ob-kab, ncej txav raws li ob kab. Lawv tsuas yog siv rau miter sawing thiab complex ua. Gantry machines yog tsim nyob rau hauv daim ntawv ntawm ib lub rooj nyob ruaj ruaj nrog lub portal movable. Cov cuab yeej no yog siv rau hauv kev ua haujlwm nrog cov ntaub ntawv uas nyuaj rau kev ua haujlwm.

Vertical band saw rau hlau. Nrog nws, koj tuaj yeem txiav cov hlau raws txhua txoj kab, ncaj los yog nkhaus. Nyob rau hauv cov ntaub ntawv no, lub workpiece yog pub rau hauv qhov chaw ua hauj lwm manually, thiab cov saw ncej tseem tsau.

Rotary kab rov tav hlau txiav tshuab. Nyob rau hauv cov ntaub ntawv no, lub thav duab yog tig ib ncig ntawm lub axis nyob rau hauv ib los yog ob qho kev qhia nrog rau lub kaum sab xis ntawm lub axis. Qhov kev tsim no tso cai rau kev txiav ntau lub kaum sab xis nrog rau kev hloov kho tam sim ntawm lub kaum sab xis.

Ntaus Ntaus

Cov qhab pom rau hlau muaj ntau yam zoo dua piv rau yav dhau los tso tawmcov kwv tij, obsolete morally. Qhov tseeb ntawm cov cuab yeej zoo li no yog siab npaum li qhov ua tau, thiab qhov tshwm sim saum npoo yog qhov zoo heev. Yog li ntawd, cov chaw tsim khoom tau txais cov khoom siv tseem ceeb, thiab koj tuaj yeem hnov qab txog qhov muaj burrs thiab nicks ntawm qhov chaw txiav. Cov txheej txheem ntawm hom piav qhia tso cai rau kev ua cov blanks hauv batch. Nrog nws cov kev pab, koj tuaj yeem txiav ob qho tib si cov khoom siv tubular thiab cov khoom siv hlau. Band pom rau hlau yog tus cwj pwm los ntawm kev xav zoo tsim, vim tias qhov kev sib tw ntawm cov hniav thiab kev kub ceev ntawm tus neeg teb xov tooj yog guaranteed. Lub tshuab ua haujlwm tau ntev heev vim muaj lub tshuab ua kom txias.

Txoj Cai Ua Haujlwm

Nyob rau hauv txhua yam khoom siv ntawm pawg no, tib lub hauv paus ntsiab lus ntawm kev ua haujlwm yog siv: tus neeg teb xov tooj manually installs lub workpiece ntawm lub tshuab, tom qab uas nws yog pub rau nres, thiab ces tag nrho lub voj voog tshwm sim nyob rau hauv tsis siv neeg hom, xws li clamping cov khoom, nqa lub saw ncej thiab nws pub, nyem. Cov cuab yeej no yog tus cwj pwm los ntawm kev tsim khoom siab tshaj plaws, nrog rau kev muaj peev xwm ua haujlwm hauv cov khoom siv ncaj ncees hauv cov khoom me me lossis ib qho khoom siv. Raws li kev txiav ib feem ntawm cov cav tov, ib daim kab xev steel ntawm me me thickness yog siv. Ntawm ib qho ntawm nws cov npoo muaj cov hniav, thiab nws yog hu ua txiav, lossis pem hauv ntej, thiab thib ob - rov qab.

Lub hom phiaj ntawm cov tshuab

Cov tshuab ua haujlwm nrog cov hlau tsis muaj hlau yog siv ntau heev hauv kev ua haujlwm ntawm cov tshuab tshuab. Lawv pab rautxiav cov hlau tsis-ferrous, zoo li tus profiles, cov kav dej kom loj, nrog rau cov khoom dov khoom. Ntawm lawv qhov zoo yog qhov tseeb dua ntawm kev ua haujlwm, kev tsim khoom siab, txo kev siv cov khoom siv. Band saws rau hlau, tus nqi ntawm uas yog siab heev thiab rau cov qauv me me pib los ntawm 28 txhiab rubles, tso cai rau koj kom tau txais cov khoom loj ntawm cov khoom tsim tawm, nrog rau lav qhov hnav tsis kam ntawm cov saws yog tias lawv raug xaiv kom raug. cov khoom raug ua tiav.

txiaj ntsig ntawm kev siv

Muaj ntau yam txiaj ntsig rau kev ua haujlwm nrog cov saw saw:

- siab precision txiav;

- qhov zoo ntawm qhov txiav tawm;

- qhov tsawg kawg nkaus qhov dav ntawm kev txiav, vim tias cov khoom siv tau txais txiaj ntsig zoo heev;

- txiav blanks hauv batch.

Yog tias qhov kev tsim khoom uas twb muaj lawm xav tau kev hloov kho lossis kev txhim kho, ces qhov kev xaiv yog xaiv semi-automatic band saws.

khoom siv tsis siv neeg

qeb no yog tus yam ntxwv los ntawm qhov tsawg kawg nkaus kev koom tes ntawm tus neeg teb xov tooj hauv cov txheej txheem ntawm kev ua haujlwm, uas pab txhawb kev ua haujlwm zoo heev. Txhawm rau tswj cov cuab yeej siv, CNC system yog siv, uas nws tus kheej suav tag nrho cov haujlwm tsim nyog ntawm cov txheej txheem. Hauv kev tsim khoom loj, lub tshuab hlau tsis siv neeg pom ua tau zoo tshaj plaws. Lub zog thiab kev ntseeg siab ntawm qhov chaw, nce qhov tseeb ntawm kev ua haujlwm thiab kev ua haujlwm siab ntawm kev txiav ua kom nws ua tau raws li qhov nyuaj tshaj plaws.cov haujlwm.

Semi-automatic ob-kem tshuab

Cov khoom siv no yog cov khoom tsim tau zoo, thiab nws yog siv los ua haujlwm nrog cov hlau sib txawv thiab cov alloys. Tshwj xeeb, lawv tau siv los txiav cov hlau nrog cov khoom dov khoom, nrog rau cov khoom uas nws txoj kab uas hla loj heev. Lawv yog siv rau cov ntaub ntawv nyias-walled: profiles, kav dej thiab lwm yam.

Txoj haujlwm ntawm kev ua haujlwm

Hnyav-duty cam khwb cia hlau castings ua haujlwm raws li qhov chaw thauj khoom rau ob-kem band saws. Lawv tau tsim los tiv thaiv cov ntaub ntawv ua tiav los ntawm kev vibrations me ntsis, nrog rau los ntawm kev muaj zog thiab kev poob siab. Qhov kev txav ntawm lub bracket yog nqa tawm ntawm plaub tus lej qhia. Cov khoom no yog tus cwj pwm los ntawm kev muaj peev xwm ntxiv, uas muab lawv lub peev xwm ua haujlwm zoo nrog forgings, qhov loj, nrog rau lwm yam. Kev ua haujlwm ntawm cov khoom siv nyob rau hauv ib lub voj voog semi-automatic yog ua kom ntseeg tau los ntawm qhov tshwj xeeb hydraulic system, tus cwj pwm los ntawm kev tswj hluav taws xob.

Semi-automatic Ob Chav Kab Square Txiav Tshuab

hom khoom siv no yog tus cwj pwm los ntawm kev muaj cov saw hlau tso rau kab rov tav. Thaum lub luag haujlwm tau teeb tsa los ntawm tus neeg teb xov tooj tau ua tiav, lub caij no txav ntawm ib khub ntawm racks nyob hauv vertically. Lub saw thav duab nrog lub txaj yog txuas nrog ib qho kev sib txuas uas txav tau. Nws rigidity, ua ke nrog kev ntseeg siab ntawm cov khoom siv, tso cai rau koj los tsim kev kub siab ntawm lub workpiece, uas yog qhia.kom meej meej li sai tau.

Cov tshuab hnyav rau txiav cov khoom loj

Qhov kev nruj nruj ntawm cov tshuab no tso cai rau lawv siv los txiav cov khoom loj thiab cov ntaub ntawv uas nyuaj rau kev ua haujlwm. Cov khoom siv no yog siv hauv cov nroj tsuag metallurgical. Thiab kuj nyob rau hauv warehouses uas yog siv los khaws cov hlau. Tsis tas li ntawd, lawv tuaj yeem siv rau hauv kev cob qhia, ntawm qhov chaw yuav khoom ntawm ntau hom kev lag luam high-tech, qhov chaw ua haujlwm puv ntoob xav tau cov khoom tsim tau siab tshaj plaws rau ib qho khoom siv.

Txoj haujlwm ntawm cov tshuab

Ua haujlwm ntawm phau ntawv hlaws saws yog txheej txheem nyuaj thiab siv sijhawm, txij li txhua qhov haujlwm, tshwj xeeb, clamping thiab pub khoom siv rau hauv cheeb tsam txiav, tig, txo qis thiab tsa cov saw saw, tensioning saw, thiab lwm yam.., yog ua los ntawm tus neeg ua haujlwm nws tus kheej. Yog li ntawd, lawv feem ntau yog siv nyob rau hauv me me thiab ib-thooj ntau lawm, uas yog yus muaj los ntawm ib tug me me ntim ntawm cov khoom. Saws rau band tshuab nyob rau hauv cov ntaub ntawv no kuj siv thawj.

Ua haujlwm ntawm lub tshuab semi-automatic yog yooj yim dua, vim koj tsuas yog xav tau manually teeb lub workpiece hauv kev txav. Cov cuab yeej no tsim nyog siv txawm tias nyob rau hauv nruab nrab-teev ntau lawm. Yog tias peb tham txog cov tshuab tsis siv neeg, ces nws yog ib qho tseem ceeb kom nco ntsoov lawv txoj kev ywj pheej ntawm kev ua tiav tag nrho cov haujlwm. Tias yog vim li cas lawv tau nquag siv hauv kev tsim khoom loj thiab loj. Cov cav tov no yuav xav tau band saw vuam, tab sis qhov no yuav tsum tauCov khoom siv tshwj xeeb yog siv.

Siv cov txheej txheem txiav rau hlau

Txhawm rau ua tiav koj lub hom phiaj, koj yuav tsum xaiv ib pawg nrog cov hniav zoo. Qhov no coj mus rau hauv tus account ntau yam, ntawm qhov tseem ceeb tshaj plaws yog qhov profile ntawm sawn workpiece. Tsis tas li ntawd, lub sharpening ntawm band saws yuav tsum yog qhov zoo tshaj plaws. Hauv kev xyaum, cov rooj tshwj xeeb yog siv los xaiv cov canvas nrog lub suab uas xav tau. Thaum xam lub suab ntawm cov hniav, nws yog ib qho tsim nyog yuav tsum nco ntsoov tias thaum lub sij hawm txiav, 3-4 hniav yog nyob rau hauv kev sib cuag nrog cov workpieces. Thiab ntawm no nws tsis yog ib qho tseem ceeb npaum li cas band saw siv (nws tus nqi yog 10 lossis 250 txhiab rubles), nws yog qhov tsim nyog los xaiv qhov ntau thiab tsawg kom raug.

Pom zoo:

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Dav hlau niaj hnub. Thawj lub dav hlau dav hlau

Lub teb chaws xav tau niaj hnub Soviet dav hlau dav hlau, tsis qis dua, tab sis zoo dua rau qib ntiaj teb. Nyob rau xyoo 1946 parade nyob rau hauv kev hwm ntawm hnub tseem ceeb ntawm Lub Kaum Hli (Tushino), lawv yuav tsum tau qhia rau cov neeg thiab cov qhua txawv teb chaws

Daim ntawv hlau txiav: piav qhia, hom. hlau dabtsi yog khoov

Hnub no, cov ntawv hlau txiav yog ib qho ntawm cov txheej txheem thev naus laus zis uas tso cai rau koj kom tau txais qhov khoob ntawm qhov xav tau loj thiab cov duab. Txawm li cas los xij, muaj ntau txoj hauv kev los ua cov txheej txheem no thiab ntau yam khoom siv

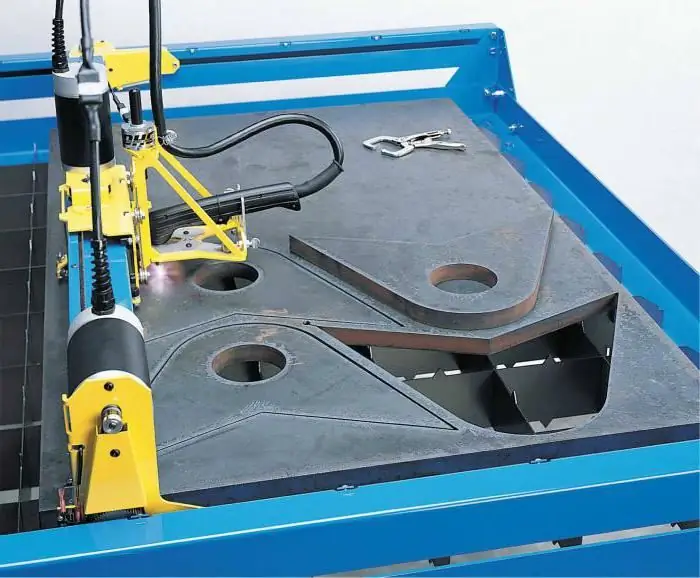

Hlau txiav tshuab. Plasma hlau txiav tshuab

Zaj lus no mob siab rau lub cuab yeej txiav hlau. Kev siv tshuab ntawm plasma txiav, nrog rau cov cuab yeej thiab cov yam ntxwv ntawm cov cuab yeej raug txiav txim siab

Ua haujlwm ua tus saib xyuas dav hlau. Lub luag haujlwm ntawm tus neeg saib xyuas dav hlau. Tus neeg saib xyuas dav hlau khwv tau npaum li cas?

Hauv paus ntsiab lus, tsis muaj ib txoj haujlwm zoo li tus neeg saib xyuas dav hlau. Nws lub npe tiag tiag yog tus tsav dav hlau. Lwm yam secrets dab tsi yog hom kev ua ub no zais, leej twg tuaj yeem thov rau qhov chaw ua haujlwm thiab cov kev cai dab tsi uas cov tuam txhab xa tawm?