2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Ntoo nyob rau hauv daim ntawv ntawm cov ntoo tiav, plywood thiab particle board tseem yog ib qho yooj yim consumable raw khoom rau ntau industries thiab kev tsim kho. Nws ib puag ncig tus phooj ywg thiab yoog raws hauv kev ua haujlwm tso cai rau nws los sib tw txawm tias siv high-tech fiberglass. Nyob rau tib lub sijhawm, kuj tseem muaj qhov tsis zoo ntawm cov khoom siv, vim tsis muaj zog thiab rhiab heev rau kev tawm tsam. Lawv tuaj yeem txo qis los ntawm kev kho tshwj xeeb ua ntej. Tshwj xeeb, chamber ziab ntawm ntoo nrog thermal ua haujlwm yog ib txoj hauv kev zoo tshaj plaws los txhim kho nws cov khoom siv thiab lub cev.

Khoom siv siv

Muaj ntau hom tshuab ziab khaub ncaws, cov ntsiab lus dav dav uas muab rau cov dej hloov pauv cua sov. Los ntawm lawv, cov kwj dej kub tau muab faib rau saum npoo ntawm cov khoom siv. Lub hauv paus kev faib tawm distinguishes drying chambers ntawm dielectric thiab convective hom. Dielectric qauv tsim thermal zog nyob rau hauv cov txheej txheem ntawm kev hloov siab zaus tam sim no.

Thiab, convective units tso cua sov ntws mus rau lub lumber los ntawm preheated cua, uastxhawb kev tshem tawm cov dej noo. Tus neeg saib xyuas kom qhuav nyob rau hauv xws li kev ua haujlwm yog rhuab ua ke nrog dej vapor. Tom qab ntawd cov sib tov yog circulated nyob rau hauv lub tshav kub exchanger. Lub chamber convective rau ziab ntoo tuaj yeem siv hluav taws-tub, chav dej, thiab induction nqa khoom ua haujlwm (cov khoom siv hluav taws xob). Qee zaum cov chav roj kuj tseem siv tau, uas tso tawm ntau lub zog thermal. Ob qho tib si dielectric thiab convective qauv ntawm cov tshuab ziab khaub ncaws tuaj yeem ua haujlwm hauv lub tshuab nqus tsev, uas yog, ntawm qhov tsis tshua muaj siab.

khoom npaj

Qhov kev ziab kom zoo yog nyob ntawm seb cov pawg tau npaj tau li cas - lub npe hu ua pob khoom nrog ntoo, uas tau tsim tshwj xeeb rau kev tso rau hauv lub chamber. Piv txwv li, kev ziab tsis sib xws thiab deformation ntawm cov ntu ntawm cov laug cam yuav tsuas yog qhov tshwm sim ntawm kev ntim khoom tsis raug.

Feem ntau siv ob txoj kev ntawm kev npaj hom no:

- ib pawg;

- batch bookmarking.

Hauv thawj rooj plaub, ib pawg suav nrog ob peb lub rooj sib txoos ua ke hauv tib qho kev teeb tsa. Batch nteg xav tias cov ntoo yuav raug muab tso rau hauv ob peb lub pob npaj txhij. Lub platform nruj nrog lub tiaj tiaj yog siv los ua lub hauv paus rau pawg. Nws tuaj yeem yog lub tsheb ciav hlau tsim los ntawm tus kheej lem.

Txhawm rau kom lub tshuab ziab khaub ncaws ntawm cov ntoo yuav tsum tau nqa tawm yam tsis muaj qhov cuam tshuam los ntawm tus neeg saib xyuas cua sov, tsis tso cai rau kev thauj khoom ntawm pawg. Nws yuav tsum tau sau tag nrho nrog cov laug cam ntawm tib qhov ntev, los yoglumber ntawm ntau qhov sib txawv hauv kab. Nyob nruab nrab ntawm cov rooj sib txoos, ib lossis ntau txheej txheej yog muab.

Mos

Muaj peb hom kev ziab:

- thawj qeb yog hom zoo, nqa tawm ntawm qhov kub ntawm +60 + 70 ° C. Hom no tso cai rau koj kom qhuav cov khoom mus rau cov dej noo ntawm 6-8%. Cov khoom uas tau txais nyob rau hauv txoj kev ua no yog txawv los ntawm high technical thiab ua hauj lwm ntsuas, uas ua rau nws muaj peev xwm mus siv cov khoom nyob rau hauv ntsuas thiab mechanical engineering, nyob rau hauv load-bearing lub tsev qauv, nyob rau hauv zus tau tej cov engineering khoom ntsiab, thiab lwm yam.

- qeb thib ob muab hom nrog nqa cov av noo mus txog 8-10%. Rau cov hom phiaj no, cov tshuab ziab khaub ncaws ua haujlwm ntawm qhov kub txog + 75 ° C yog siv. Lub hom phiaj ntawm kev siv cov ntaub ntawv ua tiav hauv hom no yog cov rooj tog tsim khoom, nrog rau kev tsim cov khoom siv thiab cov khoom siv hauv tsev.

- Qhov thib peb ntawm kev ziab tso cai rau koj kom tau txais cov ntoo zoo nruab nrab, cov dej noo tuaj yeem ncav cuag li 15%. Los ntawm cov ntoo, ntim khoom, moldings thiab cov khoom siv pheej yig tom qab tsim tawm.

kub ntoo

Cov cua sov hauv paus yuav tsum tau tiv thaiv cov txheej txheem kev ntxhov siab hauv cov qauv sab hauv ntawm cov ntoo thaum lub ntsiab kom qhuav. Kev mob siab, tab sis luv luv thermal nyhuv yog tsim, thaum lub sij hawm uas ya raws tsis evaporate. Nyob rau hauv parallel nrog kev kho cua sov, saturated chav xa mus rau hauv lub chamber. Txoj haujlwm no yog ua los ntawm ib pawg kiv cua nrog cov cua sov. Cov txheej txheem evaporationya raws thoob plaws hauv cov thickness ntawm cov khoom yuav pib tsuas yog tom qab tas ntawm thermal raug.

Dua, kom lub tshuab ziab khaub ncaws ntawm ntoo tsis ua rau nws cov qauv, twb yog thawj theem ntawm cua sov, qhov sib npaug ntawm cov tswj kub thiab tus nqi ntawm noo noo yog tswj. Yog tias qhov nyiaj tshuav no cuam tshuam, muaj kev pheej hmoo ntawm kev tawg. Lub sijhawm ntawm cov txheej txheem no yog txiav txim siab los ntawm cov xwm txheej sab nraud thiab cov yam ntxwv ntawm cov ntoo - qhov nruab nrab ntawm 1 txog 2 teev.

theem tseem ceeb

Tom qab pib ua kom sov, ziab sai sai. Tab sis qhov kev hloov pauv yuav tsum tau maj mam, uas yog pom nyob rau hauv qeeb qhib ntawm huab cua pauv dampers uas tshem tawm cov dej noo. Nyob rau tib lub sijhawm, qhov kev pom zoo ntawm cov cua sov fluxes raug teeb tsa. Qhov kub tswj hwm, nyob rau hauv lem, yog tswj los ntawm theem ntawm qhib lub shutters ntawm lub chamber. Yog hais tias nws yuav tsum tau ua kom cov saturation ntawm tus neeg sawv cev, cov kav dej yuav raug kaw tag.

Tsis tas li, qhov ntsuas ntawm qhov saturation ntawm cov nyhuv thermal tuaj yeem hloov kho los ntawm kev pib lub tshuab hluav taws xob. Txawm li cas los xij, thaum lub hood qhib, lub tshuab txhaj tshuaj tsis tuaj yeem txuas nrog. Nyob rau hauv tus txheej txheem ntawm kev ua haujlwm, chamber ziab ntawm ntoo yog tswj los ntawm cov yam ntxwv ntawm qhov kub thiab txias thiab nws qhov kev ua yuam kev. Hauv kev tsim khoom, cov txiaj ntsig no feem ntau yog teev txhua teev.

Kev kho cua sov

Qhov no kuj yog ib hom theem nruab nrab uas tsim tshwj xeeb ib puag ncig: nws yuav tsum muaj kev siv siab ntawm kev tshem tawm noo noo thiabruaj khov kub. Ib puag ncig zoo li no yog tsim los ntawm kev txhaj tshuaj tib yam nrog lub tshuab ua kom sov. Cov kiv cua thiab cov pa tso pa tawm tuaj yeem koom nrog kev cai. Qhov ntsuas kub zoo tshaj plaws rau hom kev ua haujlwm no yuav tsum yog 6-7 ° C siab tshaj qhov nruab nrab hauv lub ntsiab kom qhuav, tab sis tib lub sijhawm yuav qis dua +100 ° C.

Nws yog ib qho tseem ceeb uas yuav tsum tau hais qhia tias kev kho cov dej noo-kub tsis siv rau txhua hom ntoo. Piv txwv li, thev naus laus zis rau kev tsim cov ntoo qhuav muab rau kev siv qhov kev ua haujlwm no rau cov ntoo sawn los ntawm cedar, ntoo thuv, linden, lub thickness ntawm ntau tshaj 60 hli. Thick workpieces tuaj yeem ntub-rhuab ob peb zaug kom npog tag nrho cov qauv sab hauv.

Tsawg txheej txheem

Tom qab ziab, kev kho cua txias yog ua tiav, lub hom phiaj ntawm kev sib npaug ntawm cov dej noo thiab cov qauv ntawm cov khoom. Los ntawm txoj kev humidifiers thiab cua sov, ib qho chaw tshwj xeeb yog tsim nyob rau hauv uas overdried thaj chaw ntawm lumber yog moistened, thiab insufficiently qhuav sawv daws yuav qhuav tawm. Nyob rau lub sijhawm, kev ua haujlwm zoo li no kav ntev li ob peb teev - lub sijhawm tshwj xeeb nyob ntawm qhov ntim ntawm cov ntawv cim thiab cov khoom siv.

Cov ntsiab lus ntawm cov dej noo ntawm cov ntoo tom qab ziab nrog cov kev kho cua txias kuj txawv ntawm 6 mus rau 15% nyob ntawm seb hom siv. Tsis tas li ntawd, tom qab pre-txias, cov pawg yog unloaded los ntawm lub chamber. Yog tias tsim nyog, kev ua haujlwm ntxiv ntawm kev yuam kom txias nrog qhov cua tuaj yeem qhib tau.

Pros of thev naus laus zis

Chambers nrog kub thiab av noo kev kho mob tso cai rau cov txheej txheem ziab nrog tag nrho kev khaws cia ntawm ib puag ncig tus phooj ywg ntawm cov khoom. Feem ntau, cov txheej txheem ua haujlwm zoo li no tsis tas yuav siv cov tshuaj nquag uas ua kom cov txheej txheem ua haujlwm tau zoo. Qhov zoo ntawm qhov tshwm sim kuj tau sau tseg. Yog tias tus neeg teb xov tooj tsis ua yuam kev thaum npaj cov txheej txheem, tom qab ntawd cov teeb pom kev zoo yuav tau txais lub zog siab thiab kev tiv thaiv zoo.

Ntau tus neeg kuj taw tes rau cov khoom lag luam siab ntawm chamber ziab ntawm ntoo. Pluses thiab minuses, txawm li cas los, converge nyob rau hauv no yam ntxwv. Ntawm qhov tod tes, batch processing tiag tiag ua rau nws muaj peev xwm ua haujlwm ntau ntawm cov ntoo hauv lub sijhawm luv luv. Ntawm qhov tod tes, qhov ua tsis tau zoo ntawm kev ua cov pob me me nrog kev txo qis txwv cov khoom siv li no.

Cons of thev naus laus zis

Qhov kev thuam tseem ceeb ntawm cov tshuab ziab khaub ncaws no los ntawm kev pheej hmoo ntawm ntau yam tsis xws luag hauv cov ntoo thaum lub sijhawm ua haujlwm. Ib qho ntawm feem ntau ntawm cov no yog warping. Kev ua txhaum ntawm thev naus laus zis tuaj yeem ua rau ob qho tib si longitudinal thiab transverse deformations.

Feem ntau, cov txheej txheem zoo li no yog tshwm sim los ntawm kev tshem tawm cov dej tsis txaus ua ntej lub ntsiab kom qhuav. Feem ntau cov khoom tau txais qhov tsis xws luag hauv daim ntawv ntawm kev tawg ntawm qhov kawg. Cov teeb meem zoo sib xws tshwm sim yog tias lub tshuab ziab khaub ncaws tau ua haujlwm hauv hom zoo li thaum pibua kom sov. Cov thev naus laus zis xav kom cov txheej txheem no, txawm tias qhov ntsuas kub tsawg, yuav tsum tau ua nyob rau hauv cov xwm txheej ntawm softening tus qauv ntawm cov ntoo.

Zaj lus

Qhov yooj yim ntawm cov hauv paus ntsiab lus ntawm kev tswj hwm thiab kev saib xyuas cov txheej txheem ua haujlwm tau pab tsim kom muaj tag nrho cov khoom siv tsim los siv hauv tsev. Yuav ua li cas ncaj ncees yog lub koom haum ntawm koj tus kheej kab rau ziab lumber? Qhov no yuav nyob ntawm kev ua ntim.

Thiab nws tseem ceeb heev uas yuav tau xav txog tus nqi ntawm chav ziab ntawm ntoo. Tus nqi ntawm 1 m 3nruab nrab 2-3 txhiab rubles. Tau kawg, yog tias koj tsim koj tus kheej lub tsev los ntawm ib lub bar, ces cov txiaj ntsig yuav pom tseeb. Tab sis cov khoom siv nws tus kheej tsis pheej yig, tsis hais txog cov nuances ntawm kev ua haujlwm thiab kev pheej hmoo ntawm kev tau txais tib yam tsis xws luag yam tsis muaj kev txhawb nqa kev tshaj lij.

Pom zoo:

Plexiglas engraving: qhov zoo thiab qhov tsis zoo, thev naus laus zis, khoom siv

Plexiglas engraving yog suav tias yog cov khoom siv kos duab. Ib tug souvenir figurine, stained-iav qhov rais los yog ib lub rooj iav, uas yog decorated nrog exquisite drawings, embody ib tug ilv artistic saj. Pickling thiab sandblasting technologies yog yav dhau los. Niaj hnub no, nrog kev pab los ntawm lub tshuab laser, txhua tus neeg tuaj yeem tsim cov qauv kom ntxaws heev

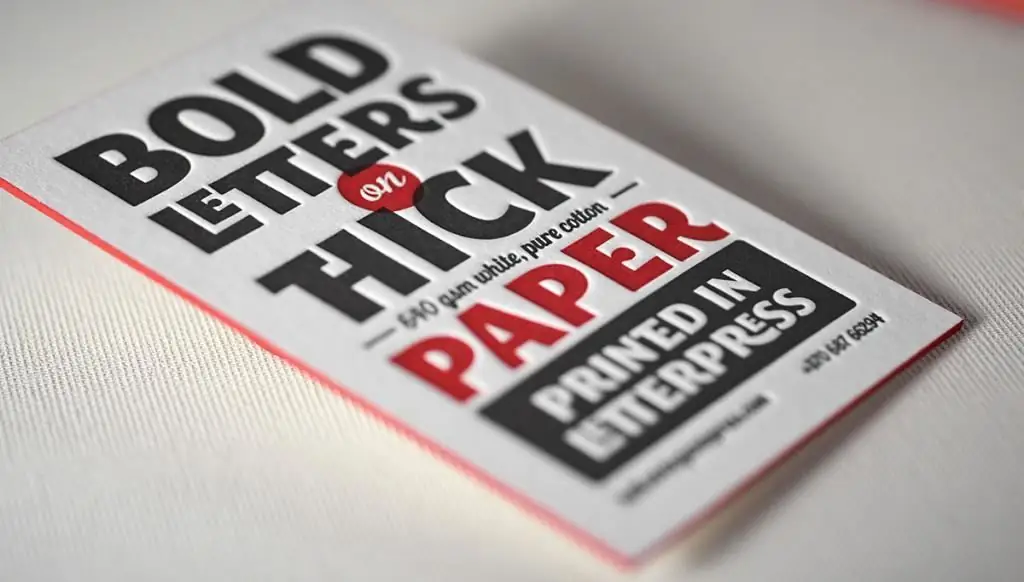

Letterpress yog Letterpress luam ntawv thev naus laus zis, theem niaj hnub ntawm kev txhim kho, cov cuab yeej tsim nyog, qhov zoo thiab qhov tsis zoo ntawm hom luam ntawv no

Letterpress yog ib txoj hauv kev siv cov ntaub ntawv siv cov matrix nyem. Cov ntsiab lus uas protrude yog them nrog xim nyob rau hauv daim ntawv ntawm ib tug muab tshuaj txhuam, thiab ces nias rau ntawm daim ntawv. Yog li, ntau yam huab hwm coj, cov phau ntawv siv, cov phau ntawv thiab cov ntawv xov xwm tau luam tawm

Ultrasonic ua: thev naus laus zis, qhov zoo thiab qhov tsis zoo

Kev lag luam hlau ua haujlwm nyob rau theem ntawm kev txhim kho no muaj peev xwm daws cov haujlwm nyuaj ntawm kev txiav thiab drilling workpieces ntawm ntau qib ntawm hardness. Qhov no tau dhau los ua tau vim yog kev txhim kho ntawm cov txheej txheem tshiab ntawm kev cuam tshuam cov khoom siv, suav nrog ntau pawg ntawm cov txheej txheem electromechanical. Ib qho ntawm cov thev naus laus zis zoo tshaj plaws ntawm hom no yog kev kho ultrasonic (UZO), raws li cov qauv ntawm electroacoustic hluav taws xob

Poob-wax casting: thev naus laus zis, qhov zoo thiab qhov tsis zoo

Kev siv cov qauv peev yog ib txoj hauv kev nrov ntawm kev tsim khoom tsim. Nws yog siv nyob qhov twg nws yog ib qho tsim nyog los saib xyuas qhov ntev thiab ua kom zoo ntawm qhov chaw ntawm qhov chaw. Qhov no yog li cas turbine hniav thiab cov cuab yeej ua tau zoo, cov hniav cuav thiab cov hniav nyiaj hniav kub raug cam, nrog rau cov duab puab ntawm kev teeb tsa nyuaj. Cov pwm rau casting yog ib-thooj, cov qauv ntawm cov ntaub ntawv uas tsis tshua muaj melting yog tsis raug tshem tawm thaum molding, tab sis yog melted tawm

Kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab ntog: cov txheej txheem thiab cov txheej txheem ntawm kev kho dua tshiab, nta, txheej txheem thev naus laus zis

Vuam thiab surfacing thev naus laus zis ua rau nws ua tau zoo los kho cov hlau seem, muab cov qib siab ntawm kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom. Qhov no tau lees paub los ntawm kev xyaum siv cov txheej txheem no thaum ua haujlwm kho hauv ntau qhov chaw - los ntawm kev kho tsheb mus rau kev tsim cov hlau dov. Hauv tag nrho cov nyiaj ua haujlwm ntawm kev kho cov qauv hlau, kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam thiab surfacing yuav siv li 60-70%