2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

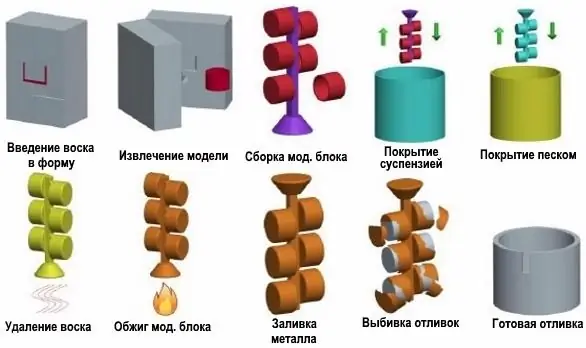

Kev siv cov qauv peev yog ib txoj hauv kev nrov ntawm kev tsim khoom tsim. Cov txheej txheem yog qhov txawv los ntawm qhov nyuaj ntawm cov txheej txheem thev naus laus zis thiab cov nqi ua haujlwm siab rau cov txheej txheem npaj. Yog li ntawd, nws yog siv nyob qhov twg nws yog tsim nyog los soj ntsuam qhov ntev thiab xyuas kom meej qhov zoo ntawm qhov chaw ntawm qhov chaw. Qhov no yog li cas turbine hniav thiab cov cuab yeej ua tau zoo, cov hniav cuav thiab cov hniav nyiaj hniav kub raug cam, nrog rau cov duab puab ntawm kev teeb tsa nyuaj. Lub ntsiab lus ntawm ploj-wax casting yog tias cov pwm rau casting yog ib-thooj, cov qauv ntawm cov ntaub ntawv uas tsis muaj melting tsis raug tshem tawm thaum molding, tab sis yog melted. Qhov no ua kom ceev faj ua raws li qhov loj me thiab nyem. Hlau yog poured rau hauv kab noj hniav seem ntawm tus qauv. Thaum ua tiav cov cua txias, cov pwm raug rhuav tshem thiab cov khoom raug tshem tawm. Thaum casting loj series, tus nqi ntawm cov khoom raug txo.

Txoj kev txiaj ntsig

Qhov txiaj ntsig tseem ceeb ntawm kev nqis peev casting yog qhov tseeb ntawm cov pwm hloov pauv thiab tsis tshua muaj qhov roughness. Tsis tas li ntawd, muaj lwm yam txiaj ntsig:

- Kev tsim cov khoom siv sib xyaw ua ke muaj.

- Txo qhov xav tau rau kev ua haujlwm ntxiv.

- Cov khoom pov tseg uas txwv tsis pub yuav tsum tau ua hauv qhov chaw thiab sib sau ua ke.

- Nrog cov koob loj, txo qis ntawm kev siv zog tshwj xeeb (ib yam khoom) thiab nws cov nqi tau ua tiav.

- Muaj peev xwm ntawm kev siv tshuab thiab ib nrab automation ntawm kev npaj ua haujlwm ntawm qhov casting nws tus kheej.

Cov txiaj ntsig no ua rau txoj hauv kev yog ib qho ntawm cov neeg nyiam tshaj plaws thiab siv nyob rau hauv niaj hnub metallurgy, tshwj xeeb tshaj yog ua ke nrog cov txheej txheem niaj hnub niaj hnub.

Qhov tsis zoo ntawm kev nqis peev casting

Qhov zoo tsis txaus ntseeg ntawm txoj kev, nws yuav zoo li, yuav tsum tau ua kom nws txoj kev tswj hwm ntawm lwm txoj hauv kev. Txawm li cas los xij, txawm tias muaj koob meej ntawm kev nqis peev casting txoj kev, qhov tsis zoo tau tiv thaiv nws txoj kev saws loj. Lub ntsiab tsis zoo yog qhov nyuaj ntawm cov txheej txheem ntau theem. Nws xav tau cov cuab yeej siv thev naus laus zis nyuaj heev thiab kim heev rau cov theem kev npaj. Rau cov khoom siv yooj yim tsim hauv cov khoom me me, txoj kev no muaj tus nqi siab dua.

Rau qhov kev siv nyiaj txiag zoo ntawm kev nqis peev casting, qhov zoo thiab qhov tsis zoo ntawm txoj kev raug muab piv, kev txiav txim siab ntawmnws qhov kev xaiv yog coj los ntawm qhov kev ntsuam xyuas ntawm tus nqi / qhov zoo. Yog li ntawd, nws yog tsuas yog siv rau cov khoom tseem ceeb tshaj plaws thiab kim kim uas yog qhov nyuaj kom tau txais lwm txoj hauv kev, xws li turbine blades, sculptures, high-speed cov cuab yeej, thiab lwm yam. Lwm qhov chaw ntawm daim ntawv thov yog loj-scale castings, hauv uas cov nyhuv nplai ua rau nws ua tau kom txo tau tus nqi tseem ceeb.

Technology

Kev nqis peev casting thev naus laus zis yog txheej txheem kev tsim khoom ntau theem uas yog siv zog ua haujlwm. Nyob rau hauv thawj theem, tus tswv qauv tsim, nws yuav dhau los ua tus qauv rau kev tsim cov qauv ua haujlwm tom qab dhau los ntawm txhua theem ntawm cov khoom kawg. Rau kev tsim cov qauv tsim, ob qho tib si qauv tsim tshwj xeeb thiab cov tsoos - gypsum lossis ntoo - yog siv. Cov khoom ntawm tus qauv tus qauv yuav tsum sib txuas lub zog thiab yooj yim ntawm kev ua.

Ntxiv mus, peev casting tshuab muab rau kev tsim pwm rau hauv uas txhua tus qauv ua haujlwm yuav raug nrum. Pwm yog ua los ntawm gypsum, roj hmab, silicone, tsis tshua muaj hlau. Structurely, nws yuav tsum tau detachable thiab tsim rau rov siv dua. Cov pwm yog ntim nrog cov qauv tsim, tom qab nws tau hardened, nws yog disassembled thiab tom ntej no ua hauj lwm qauv raug tshem tawm.

Thaum tsim cov khoom tshwj xeeb lossis kev khiav me me, cov theem ntawm kev tsim cov qauv tsim thiab pwm raug hla, thiab cov txheej txheem (lossis ob peb) yog tsim los ntawm molding cov khoom manually.

kauj ruam tom ntej hauv kev nqis peev casting yogtsim nyob ib ncig ntawm qhov layout (los yog thaiv ntawm layouts) ntawm cov pwm casting. Cov matrices no yog cov txheej txheem twb tsis sib cais thiab pov tseg, uas ua rau nws muaj peev xwm ua tau zoo ua raws li qhov ntev thiab qhov ntxhib ntawm cov khoom. Hauv kev lag luam niaj hnub no, ob hom pwm yog siv - cov khoom siv xuab zeb-av nplaum pwm rau hauv av thiab plhaub pwm - rau kev tsim cov khoom zoo thiab kim.

Tom qab pwm ua tiav, tus qauv yog smelted los ntawm nws los ntawm cua sov los yog tshuab nrog superheated chav. Cov ntaub ntawv plhaub tau ntxiv dag zog los ntawm cua sov txog 1000 ˚С.

theem kawg ntawm cov txheej txheem suav nrog qhov tseeb casting ntawm cov khoom, nws txias nyob rau hauv tej yam ntuj tso tej yam kev mob los yog los ntawm ib tug tshwj xeeb txoj kev nyob rau hauv ib tug thermostat, kev puas tsuaj ntawm pwm thiab ntxuav cov khoom. Txoj kev tso cai rau kom tau txais cov khoom zoo tshaj plaws uas hnyav los ntawm ob peb grams mus rau kaum kilograms.

Model Lineups

Cov khoom siv rau kev tsim cov txheej txheem yuav tsum muaj qee yam khoom. Nws yuav tsum muaj cov khoom xws li:

- Plasticity nyob rau theem khoom. Nws yog ib qho tsim nyog yuav tsum tau ua kom raug cov duab ntawm cov khoom yav tom ntej thiab kho nws yog tias tsim nyog.

- Txoj kev. Tus qauv yuav tsum tiv taus yam tsis muaj deformation txheej txheem ntawm kev tsim ib puag ncig nws.

- Fusible. Kev ua qauv yuav tsum tsis txhob siv sijhawm ntau thiab lub zog.

- Molten fluidity. Cov muaj pes tsawg leeg yuav tsum yooj yim nkag mus rau hauv tag nrho cov recesses thiab cov ntsiab lus ntawm lub nyem, raws nraim rov hais dua cov txheej txheem ntawm yav tom ntej nthuav dav.

- Kev lag luam. Tshwj xeeb yog qhov tseem ceeb rau kev tsim khoom loj.

Rau cov qauv tsim, feem ntau yog siv cov tshuaj stearin thiab paraffin. Cov ntaub ntawv no tau ua tiav cov txiaj ntsig ntawm ib leeg, them nyiaj rau qhov tsis txaus melting point ntawm paraffin thiab cov viscosity ntau dhau ntawm stearin.

Cov khoom sib xyaw ua raws li cov khoom siv lignite tsis tshua muaj neeg nyiam hauv kev lag luam. Nws cov khoom tseem ceeb yog dej tsis kam, lub zog thiab lub peev xwm los tsim cov txheej txheem du, uas yog tshwj xeeb tshaj yog muaj txiaj ntsig rau kev tsim qauv khoom.

Cov tshuaj muaj cov sib xyaw ntawm cov xim av coal wax, paraffin thiab stearin kuj siv.

moulding

Rau cov khoom lag luam tshwj xeeb, kev teeb tsa tau npaj los ntawm kev txiav tawm ib daim qauv ntawm cov khoom siv manually lossis raws li cov qauv. Cov qauv nyob rau hauv daim ntawv ntawm lub cev ntawm lub kiv puag ncig kuj yog ua nyob rau hauv lub lathes. Tsis ntev los no, txoj kev ntawm 3D luam ntawv ntawm cov qauv tau dhau los ua ntau thiab ntau dua. Nws yog haum rau ob qho tib si layouts thiab me me series.

Tus nqi ntawm lub tshuab luam ntawv 3D niaj hnub no tseem siab, tab sis vim qhov yooj yim ntawm kev teeb tsa los ntawm ib qho khoom mus rau lwm qhov, nws tuaj yeem dhau los ua cov qauv tsim cov cuab yeej zoo nyob rau hauv rooj plaub ntawm ntau ntau ntawm cov kev txiav txim me me.

Txhawm rau ua kom muaj ntau qhov zoo ib yam, lub matrix yog ua los ntawm plaster, roj hmab, silicone lossis hlau. Ua hauj lwm layouts yog tsim, nyob rau hauv lem, casting rau hauv ib tug matrix. Los ntawm kev tsim, cov pwm yuav tsum yog collapsible kom ntseeg tau tias muaj peev xwm ntawm kev tsim ntau tus qauv. Cov khoom xaiv yuav tsum tau muab lub sijhawm zoo li no, yog li ntawd, cov kev xav tau no raug yuam rau nws raws li lub zog, qhov ntom ntom, tsis tshua muaj roughness, thiab tshuaj lom neeg inertness nyob rau hauv kev sib raug zoo rau cov txheej txheem. Cov khoom pwm kuj tseem yuav tsum muaj qhov adhesion tsawg heev rau qhov mock-up kom paub meej tias cov mock-ups tiav tuaj yeem tshem tawm tau yooj yim thiab qhov ntev ua raws li. Cov cuab yeej tseem ceeb ntawm pwm yog nws lub zog thiab hnav tsis kam, tshwj xeeb tshaj yog rau cov koob loj.

Ua qauv thiab thaiv

Ib txoj kev siv dav ntawm kev tsim cov qauv peev yog muab lawv nyob rau hauv qis qis rau hauv pwm. Kev txhaj tshuaj ntawm cov kua sib tov yog nqa tawm ob qho tib si manually, siv piston syringes, thiab txhua yam, hydraulic lossis pneumatic superchargers. Nyob rau hauv cov ntaub ntawv ntawm kev siv cov xim av coal wax, nws yog ib qhov tsim nyog los ua kom sov cov kav dej rau kev muab cov muaj pes tsawg leeg vim nws cov viscosity siab. nthuav polystyrene qauv yog tsim los ntawm extrusion ntawm automated molding tshuab.

Txhawm rau kom muaj txiaj ntsig kev lag luam thiab txo qis kev siv zog hauv cov ntaub ntawv ntawm kev tsim cov khoom me me, lawv cov layouts tau ua ke rau hauv cov blocks. Gating systems yog tsim los saum toj no cov blocks los ntawm kev txuas ib tug neeg layouts rau lub sprues siv tes soldering hlau. Nyob rau hauv cov ntaub ntawv ntawm ib tug castings los yog me me series, cov qauv yog tsim los ntawm tes.

Thaum tsim lub rooj vag kaw lus, nws yog qhov tsim nyog los xyuas kom meej tias tsis muaj cua nkag ntawm cov yaj, sib sau ua ke ntawm tag nrho cov ntsiab lus ntawm matrix. Thaum muab ib daim ntawv los ntawm PGS, koj yuav tsum tau saib xyuas cov ntawv sau tag nrhoqhib nruab nrab ntawm sprues thiab tiv thaiv kev puas tsuaj.

Muaj pwm

Nyob rau hauv txoj kev peev casting raws li kev xav, muaj ob lub ntsiab ntawm pwm:

- Sand-av nplaum sib tov (SGM).

- Shell.

Flued wax casting pwm yog siv los tsim cov khoom me me uas tsis tas yuav muaj qhov raug siab heev. Cov txheej txheem ntawm lawv cov chaw tsim khoom yog heev siv zog thiab yuav tsum tau siab thiab feem ntau tshwj xeeb kev txawj ntawm modelers thiab molders. Ib feem mechanization qiv nws tus kheej rau qee yam haujlwm, xws li npaj thiab sau cov xuab zeb molding, nws tamping.

Plhaub pwm, ntawm qhov tod tes, yog siv los tsim cov khoom uas xav tau kev tsim tshwj xeeb. Cov txheej txheem ntawm lawv cov chaw tsim khoom yog qhov nyuaj thiab ntev, tab sis nws qiv nws tus kheej zoo dua rau kev siv tshuab.

av casting

Nov yog txoj kev ntxov tshaj plaws ntawm kev ua hlau ua tiav los ntawm noob neej. Nws tau ua tiav los ntawm peb cov poj koob yawm txwv ib txhij nrog kev pib siv cov khoom siv hlau ua riam phom, cuab yeej lossis khoom siv, uas yog, txog 5 txhiab xyoo dhau los. Molten hlau yog poured rau hauv ib tug npaj matrix los ntawm ib tug sib tov ntawm xuab zeb thiab av nplaum. Qhov chaw ntxov tshaj plaws rau kev ua hlau tsuas yog tshwm sim qhov chaw tso nyiaj ntawm cov hlau nyob rau hauv daim ntawv ntawm nuggets thiab placers nyob ze. Ib qho piv txwv yog Kasli cog hauv Urals, ntiaj teb nto moo rau nws cov hlau lace casting.

Txoj kev peev casting yog siv rau kev tsim cov khoom hlau - ob qho tib si ferrous thiabxim. Thiab tsuas yog rau cov hlau uas nthuav tawm qhov kev xav tau ntau dua rau cov kua theem (xws li titanium), nws yog qhov tsim nyog los ua cov matrices los ntawm lwm cov khoom xyaw.

Cov txheej txheem tsim khoom ntawm casting hauv PGS muaj cov theem hauv qab no:

- qauv tsim;

- npaj lub khob;

- filling thiab compaction ntawm qhov sib tov hauv lub khob;

- hlau casting;

- tshem tawm thiab ntxuav lub casting.

Form los ntawm ASG - siv ib zaug. Yuav kom tau txais cov khoom tiav, nws yuav tsum tau tawg. Nyob rau tib lub sijhawm, feem ntau ntawm cov sib tov muaj rau rov siv dua.

Cov ntsiab lus feem ntau ntawm cov xuab zeb quartz ntawm ntau qhov ntau thiab tsawg thiab cov av nplaum yas, cov ntsiab lus ntawm 3 txog 45 feem pua, yog siv los ua cov khoom siv rau ASG. Yog li, piv txwv li, kos duab kos duab yog tsim los ntawm kev sib xyaw nrog 10-20% av nplaum cov ntsiab lus, tshwj xeeb tshaj yog loj castings, cov av nplaum cov ntsiab lus yog hloov mus rau 25%.

Ob hom subtypes yog siv:

- Kev sib xyaws. Lawv nyob rau sab hauv ntawm cov pwm thiab cuam tshuam nrog cov hlau molten. Lawv yuav tsum muaj cua sov-resistant, muaj peev xwm tsis raug puas los ntawm qhov kub thiab txias sib txawv thiab ua rau muaj kev ntxhov siab. Cov khoom sib tov no muaj cov nplej zoo ua tib zoo qhia cov ntsiab lus ntawm qhov chaw. Lub peev xwm ntawm qhov sib tov kom dhau cov pa roj kuj tseem ceeb heev.

- Filling mixs. Lawv yog siv rau backfilling ntawm lub ntsej muag txheej thiab cov phab ntsa ntawm lub hwj. Lawv yuav tsum tiv taus qhov hnyav ntawm cov hlau nchuav, khaws cov duab ntawm cov khoom thiab pab txhawb kom lub sijhawm thiab ua tiav cov pa tawm. Ua los ntawm cov qib pheej yig dua ntawm cov xuab zeb,rov siv tau.

Yog tias cov roj hluav taws xob tsis tau khiav tawm los ntawm cov xuab zeb molding, tab sis los ntawm qhov rooj kaw, qhov tsis xws luag tshwm sim hauv qhov casting, ua rau kev sib yuav.

Cov cuab yeej siv thev naus laus zis ntawm kev pov rau hauv av yog qhia meej hauv A. Tarkovsky zaj duab xis "Andrei Rublev". Hauv zaj dab neeg luv luv "Lub Tswb", tus tub hluas Boriska, tus tub ntawm tus tswv uas tuag lawm, ua tus thawj coj ntawm lub tsev teev ntuj thiab tsa lub tswb nrov.

Shell casting

Txoj kev peev casting hauv plhaub pwm yog tus cwj pwm los ntawm qhov zoo tshaj plaws hloov khoom ntawm qhov ntev thiab tsis tshua muaj roughness. Tus qauv yog tsim los ntawm fusible compounds, xws li xim av coal wax. Foundries kuj dav siv cov muaj pes tsawg leeg ntawm paraffin-stearin nyob rau hauv sib npaug proportions. Nyob rau hauv cov ntaub ntawv ntawm castings ntawm loj qhov ntau thiab tsawg, cov ntsev muaj nyob rau hauv cov qauv khoom siv los tiv thaiv tus qauv ntawm deformation. Los ntawm dipping rau hauv cov tshuaj, tus qauv yog them rau hauv 6-10 txheej nrog ib tug high-temperature suspension.

Hydrolyzed silicates ua raws li kev khi, electrocorundum lossis quartz crystals yog coj los ua cov tshuaj tiv thaiv tshav kub. Plhaub pwm cov ntaub ntawv yog cov yam ntxwv ntawm lub zog siab, tsis tshua muaj hygroscopicity thiab zoo heev gas permeability.

Cov txheej txheem yog ziab hauv qhov chaw ntawm cov pa roj ammonia. Nyob rau theem tom ntej, pwm yog rhuab mus rau 120 ˚C kom tshem tawm cov qauv paraffin. Cov seem ntawm cov sib tov yog muab tshem tawm nrog superheated chav nyob rau hauv siab siab. Tom ntej no, cov pwm yog calcined ntawm qhov kub txog li 1000 ˚С, uas ua rau nws qhov kawg fixation thiab tshem tawm cov khoom,uas tej zaum yuav raug tso tawm raws li gases thaum lub sij hawm casting txheej txheem.

Lub plhaub tau muab tso rau hauv ib lub khob, uas yog npog nrog hlau txhaj tshuaj. Qhov no yuav pab tswj cov kev teeb tsa thaum sau cov pwm nrog yaj thiab tib lub sij hawm txhim kho cov xwm txheej kom txias lub casting. Cov yaj yog nchuav rau hauv pwm rhuab mus rau 1000 ˚С. Tom qab txias cov khoom raws li ib tug tshwj xeeb kev pab cuam nyob rau hauv ib tug thermostat, cov pwm raug puas tsuaj, lub casting raug tshem tawm thiab ntxuav.

Qhov txiaj ntsig tseem ceeb ntawm txoj kev casting no yog qhov tseeb qhov tseeb thiab qhov tsis zoo ntawm qhov tsis zoo.

Qhov zoo ntxiv ntawm txoj kev:

- Casting qhov chaw los ntawm cov alloys uas nyuaj rau tshuab.

- Ntawm cov khoom uas txwv tsis pub muab cov khoom pov tseg thiab muab rov qab ua ke.

Qhov tsis zoo ntawm qhov kev nqis peev no yog kev siv hlau tsawg thiab siv zog ua haujlwm ntxiv.

Precision casting

Precision peev casting - qhov no yog lub npe muab rau ob qho tib si thev naus laus zis thiab cov khoom kawg nws tus kheej. Lub siab raug ntawm casting yog guaranteed los ntawm qhov tseeb hais tias thaum lub sij hawm kev npaj ntawm lub pwm tsis tas yuav rho tawm cov qauv ntawm cov khoom los ntawm nws. Thaum siv cov txheej txheem ib txwm muaj, kev tsim cov txheej txheem casting yog ib qho nyuaj thiab siv sij hawm siv ntau theem. Qhov no yog tshwj xeeb tshaj yog muaj tseeb nyob rau hauv cov ntaub ntawv ntawm casting qhov chaw ntawm complex configuration, nrog recesses, depressions thiab sab hauv kab noj hniav.

Piv txwv li, thaum nrum lub cam khwb cia hlau lossis tooj liab vase nrog qhov sib txawv ntawm qhov chaw curvature, koj yuav tsum siv ntau yam kev dag. Yog lawm, ua ntejlub qis ib nrab ntawm lub hwj yog khoom, ces tus qauv raug tshem tawm, tig dua thiab sab sauv ib nrab yog rammed. Cov qauv yuav tsum tau ua kom sib xyaw, cov tes tuav ntawm lub vase yog ua los ntawm ob lub ntsiab lus, lawv tau rub tawm los ntawm cov qauv kab noj hniav hauv ob theem - thawj lub hauv paus qis, tom qab ntawd sab saud. Tag nrho cov kev tig thiab rub tawm no tsis tuaj yeem muaj txiaj ntsig zoo rau kev ncaj ncees ntawm cov pwm saum npoo thiab, thaum kawg, ntawm qhov tseeb ntawm kev tswj xyuas qhov ntev ntawm qhov casting thiab qhov zoo ntawm nws qhov chaw. Tsis tas li ntawd, tseem muaj qhov teeb meem ntawm kev sib raug zoo ntawm qhov chaw ntawm lub khob thiab ruaj ntseg txuas rau ib leeg.

Kev tsim cov peev txheej casting yog tsis muaj qhov tsis txaus, nws tsis tas yuav muaj cov qauv tsim nyog thiab txo qis kev siv zog ntawm kev ua haujlwm ua ntej casting. Qhov no yog tshwj xeeb tshaj yog pronounced nrog loj khiav ntawm castings.

Txoj kev tso cai kom ncav cuag 2-5th qhov tseeb hauv chav kawm raws li GOST 26645-85. Qhov no ua rau nws muaj peev xwm cam khwb cia cov khoom lag luam siab xws li turbine hniav, cov cuab yeej txiav, suav nrog kev ua haujlwm siab milling cutters thiab xyaum, qhov tseem ceeb ntawm cov khoom siv siab, cov khoom me me ntawm cov tsheb, cov cuab yeej siv tshuab thiab lwm yam txheej txheem nyuaj.

Qhov qhov tseeb qhov tseeb thiab cov chav kawm siab saum npoo txo qis qhov xav tau rau kev ua haujlwm ntxiv ntawm cov casting, uas txuag hlau thiab txo cov nqi tsim khoom.

khoom siv

Cov cuab yeej siv peev casting yuav tsum muaj ntau yam thiab nyuaj. Cov lag luam muab lawv tso rau hauv ib qho kev sib koom tes zoo,koom ua ib qhov chaw, rhiav lossis cais ntau lawm.

Cov txheej txheem ntawm qhov nyuaj yog nyob ntawm qhov ntsuas ntawm ntau lawm, qhov loj me, kev teeb tsa thiab kev ncig ntawm castings.

Yog li, hauv kev tsim cov hniav hniav thiab cov hniav nyiaj hniav kub, cov cuab yeej yuav suav nrog:

- model table;

- muffle cub nrog ntsuas kub;

- ib txheej scalpels thiab spatulas rau kho qhov zoo ntawm tus qauv;

- forming board;

- flask;

- tanks rau khaws cia thiab npaj molding xuab zeb;

- set of sand rammer tools;

- crucible rau melting hlau;

- forceps;

- rauj tawg pwm.

Qhov kev tsim khoom no tuaj yeem yooj yim haum rau ntawm ib lub rooj thiab hauv ib lub txee. Yog tias nws tau npaj los tsim cov khoom loj, piv txwv li, aluminium castings - cov khoom siv, ces cov cuab yeej yuav tsum tau rau:

- shaping thiab pouring ceramic pwm;

- daim ntawv qhuav;

- melting tawm cov qauv khoom thiab siv cov txheej txheem kub-resistant;

- ntxuav castings los ntawm cov khoom molding.

Thiab thaum kawg, cov cuab yeej siv tiag tiag ntawm qhov chaw tsim khoom, tsim kom tau yaj thiab nchuav rau hauv pwm. Nws tuaj yeem ua cov khoom siv casting:

- nyob rau hauv qis qis;

- centrifugal;

- nyob rau hauv txoj kev nqus ib txwm.

Txhaj tshuaj molding thiab centrifugal casting tshuab yog ib qho kev sib cais thiab kev siv tshuabntau lawm complex, cais los ntawm cov huab cua ntawm lub khw. Lawv txo qis kev ua haujlwm ntawm tes thiab tib neeg raug rau cov xwm txheej tsis zoo. Lub kaw lus kaw nyob rau hauv uas cov complexes nyob rau hauv muab tag nrho capture thiab purification ntawm pa pa gases, uas ho ua rau kom ib puag ncig tus phooj ywg ntawm lub enterprise.

Post-wax casting muaj qhov muaj peev xwm loj rau kev txhim kho, tshwj xeeb tshaj yog thaum ua ke nrog cov txheej txheem pwm siab heev thiab cov txheej txheem nchuav.

Pom zoo:

Plexiglas engraving: qhov zoo thiab qhov tsis zoo, thev naus laus zis, khoom siv

Plexiglas engraving yog suav tias yog cov khoom siv kos duab. Ib tug souvenir figurine, stained-iav qhov rais los yog ib lub rooj iav, uas yog decorated nrog exquisite drawings, embody ib tug ilv artistic saj. Pickling thiab sandblasting technologies yog yav dhau los. Niaj hnub no, nrog kev pab los ntawm lub tshuab laser, txhua tus neeg tuaj yeem tsim cov qauv kom ntxaws heev

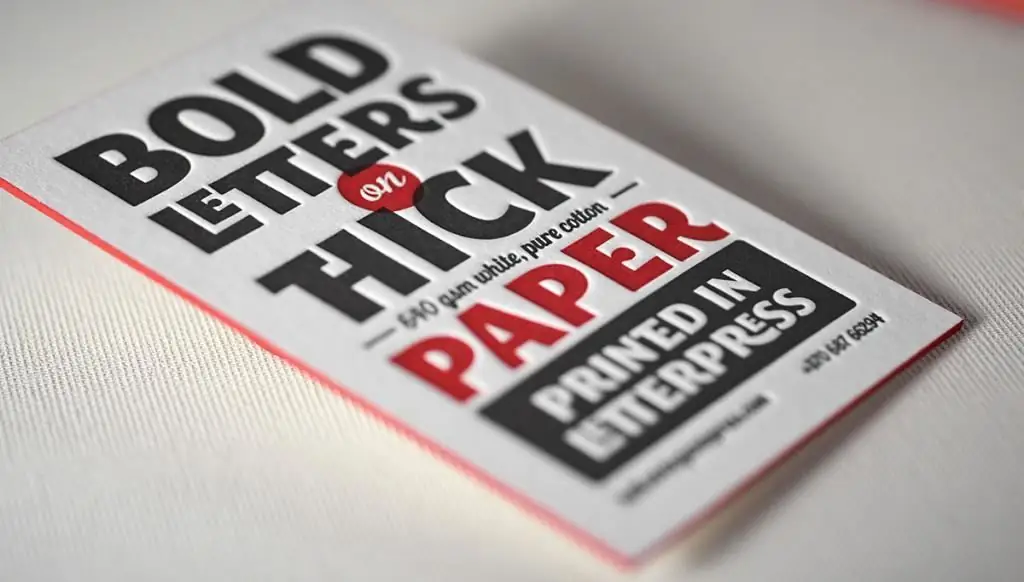

Letterpress yog Letterpress luam ntawv thev naus laus zis, theem niaj hnub ntawm kev txhim kho, cov cuab yeej tsim nyog, qhov zoo thiab qhov tsis zoo ntawm hom luam ntawv no

Letterpress yog ib txoj hauv kev siv cov ntaub ntawv siv cov matrix nyem. Cov ntsiab lus uas protrude yog them nrog xim nyob rau hauv daim ntawv ntawm ib tug muab tshuaj txhuam, thiab ces nias rau ntawm daim ntawv. Yog li, ntau yam huab hwm coj, cov phau ntawv siv, cov phau ntawv thiab cov ntawv xov xwm tau luam tawm

Ultrasonic ua: thev naus laus zis, qhov zoo thiab qhov tsis zoo

Kev lag luam hlau ua haujlwm nyob rau theem ntawm kev txhim kho no muaj peev xwm daws cov haujlwm nyuaj ntawm kev txiav thiab drilling workpieces ntawm ntau qib ntawm hardness. Qhov no tau dhau los ua tau vim yog kev txhim kho ntawm cov txheej txheem tshiab ntawm kev cuam tshuam cov khoom siv, suav nrog ntau pawg ntawm cov txheej txheem electromechanical. Ib qho ntawm cov thev naus laus zis zoo tshaj plaws ntawm hom no yog kev kho ultrasonic (UZO), raws li cov qauv ntawm electroacoustic hluav taws xob

Casting pwm: nta, thev naus laus zis, hom

Ib qho ntawm cov txheej txheem tseem ceeb tshaj plaws hauv kev lag luam yog cov txheej txheem ntawm casting ntau yam, raw khoom thiab lwm yam. Txawm li cas los xij, txhawm rau ua tiav cov khoom xav tau, nws yog qhov yuav tsum tau ua cov pwm rau nws, uas feem ntau txiav txim siab qhov txiaj ntsig kawg

Chamber ziab ntawm ntoo: thev naus laus zis, qhov zoo thiab qhov tsis zoo

Zaj lus no mob siab rau chamber ziab ntawm ntoo. Lub tshuab ziab khaub ncaws, theem thiab cov haujlwm tseem ceeb, nrog rau nws qhov zoo thiab qhov tsis zoo yog suav tias yog