2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Kev Txhim Kho yog ib qho qauv uas muaj cov hlau nplaum uas muaj ntau yam duab thiab ntau thiab tsawg. Nws lub luag haujlwm tseem ceeb yog rov faib cov compressive thiab tensile stresses nyob rau hauv cov khoom siv. Raws li, cov kev xav tau nce ntxiv yog tsim los ntawm kev nruj ntawm cov qauv zoo li no. Lub zog index, nyob rau hauv lem, yog txiav txim los ntawm qhov zoo ntawm qhov kev sib txuas ntawm lub zog los ntawm vuam. Tam sim no, ntau txoj kev vuam siv tau. Peb yuav xav txog cov yam ntxwv ntawm qee qhov ntawm lawv hauv kab lus.

Rebar vuam: GOST 14098–91

Cov hom kev sib txuas feem ntau yog:

- electroslag semi-automatic;

- bath-suture;

- electric arc phau ntawv;

- contact;

- bathroom.

GOST txhais cov qauv tsim, geometric tsis, hom pob qij txha tau los ntawm hluav taws xob arc thiab tsis kam vuam ntawm qhov cuab lub zog.

Cov kev cai ntawm tus qauv siv rau cov pas nrig nrog ntu ntu tsis tshaj 30, tab sis tsis tsawg dua 4 hli, thiabhlau hlau nrog hla ntu ntau tshaj mm.

hom kev sib txuas

GOST txhais peb hom:

- lapped;

- pob;

- T-shaped.

Kev siv zog sib tshooj welding yog ua los ntawm 2 lub pob nyem thiab seams (hluav taws xob arc phau ntawv qhia txoj kev). Lub tee kev twb kev txuas yog ua nyob rau hauv daim ntawv teev cov khoom (siv ib tug electrode nyob rau hauv lub da dej), submerged (nyob rau hauv cov ntaub ntawv no, muab tub lim tsis siv), mechanized, manually, hu (los ntawm nruam melting ntawm cov khoom nrog kuj).

Butt vuam ntawm qhov cuab lub zog yog ua nyob rau hauv ntau txoj kev. Feem ntau yog:

- Nyob rau hauv cov kabmob sib xyaw thiab tsim cov khoom ntawm ntxaib tuav nrog ib tus pas nrig.

- Mechanized siv hluav taws xob arc thiab hlau (hmoov ntxiv).

- In inventory form.

- Handmade arc thiab ntau txheej seams.

chav dej vuam fittings

Txoj kev no feem ntau yog siv los txuas:

- Txhim kho cov khoom loj ntawm txoj kab uas hla (2-10 cm).

- Kev sib koom ua ke ntawm cov kab teeb tsa hauv ob peb kab hauv cov pob zeb ua kom muaj zog.

- Flange pob qij txha ua los ntawm steel strips nrog ib ntu loj.

Txoj kev no yog qhov zoo tshaj plaws rau kev siv vuam siv lub hauv paus thiab lwm yam khoom siv pob zeb loj, cov thav duab nyuaj hauv kev tsim kho ntawm ntau lub tsev. Nws ua kom muaj kev khaws cia ntawm lub zog ntawm qhov tsis sib xws thiab rigidity ntawm cov qauv raws li tag nrho ntev. Hom vuam zoo li notso cai rau koj los tsim ib lub zog thav duab.

Kev sib txuas tuaj yeem ua tau ob qho tib si kab rov tav thiab ntsug. Bathtub welding ntawm kem qhov cuab lub zog thiab lwm yam khoom ntsug tuaj yeem nqa tawm yam tsis txav lawv thiab nqa mus rau txoj haujlwm kab rov tav.

Lwm qhov zoo dua yog cov qauv siv tau los ua kev sib txuas, xws li hauv arc vuam.

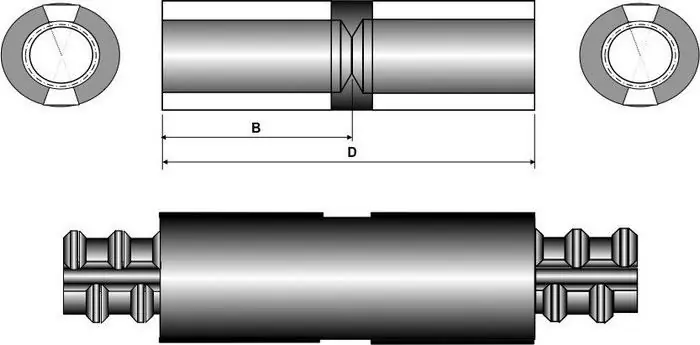

lub sijhawm tseem ceeb

Cov xwm txheej tseem ceeb rau kev tau txais cov pob qij txha zoo hauv lub dab da dej ntawm cov rebar yog qhov pom tseeb ntawm cov tuav. Nws yog ib qho tsim nyog los xyuas kom meej tias cov axes ntawm cov pas nrig tsis hloov los ntawm ntau tshaj ib nrab ntawm lawv cov seem txheeb ze rau ib leeg.

Ua raws li cov xwm txheej no, cov neeg siv hluav taws xob ntau yam siv. Nyob rau hauv lawv, cov geometric tsis thiab qhov chaw ntawm cov tuav thaum lub sij hawm welding ntawm reinforcement tseem unchanged.

Lub ntsiab ntawm txoj kev

Ua ntej welding ncaj, ib lub pwm hlau txuas (welded) rau cov tuav. Nws tsim ib da dej nrog cov khoom molten. Rau qhov no, hluav taws xob arc yog siv. Qhov kawg ntawm cov tuav tuav hauv qhov kub siab. Qhov no ua rau ib lub pas dej ntawm cov khoom siv vuam.

Ua ntej welding qhov cuab lub zog, qhov kawg thiab qhov chaw ntawm cov tuav raug ntxuav. Lawv tshem tawm nplai, corrosion, av. Ua li no, siv cov txhuam tawv tawv nrog cov txhuam hniav.

Tom qab tu, cov tuav tau muab tso rau coaxially. Yuav tsum muaj qhov sib txawv ntawm qhov kawg. Nws qhov loj me yog tsawg dua 1.5 pas nrig diameters.

Thaum welding lub zog ntawm txhua kab, cov ntawv hlau ua raws li cov khoom tsimstamped daim ntawv. Nws txuas nrog rau hauv qab los ntawm vuam yam tsis siv cov khoom siv ntxiv. Fusion ntawm kev sib koom ua ke thoob plaws cheeb tsam cross-sectional yog ua los ntawm kev ua oscillatory maj mam txav ntawm cov electrode. Nrog rau cov axes ntawm cov tuav, cov kev txav no yog ua rau perpendicular.

Cov slag ntau dhau raug tshem tawm nrog rab diav. Tom qab ntawd qhov kawg ntawm tus pas nrig sab saud txuas mus rau qhov kawg ntawm qhov qis, tom qab ntawd cov hlau xa mus rau hauv pwm.

Slag raug tso tawm los ntawm cov pwm los ntawm lub qhov tshwj xeeb, uas tau hlawv nrog cov electrode. Tom qab kev sib txuas ntawm cov pas nrig ua tiav, nws yog brewed.

chav dej welding xaiv

Hauv kev xyaum, peb txoj kev siv:

- Semi-automatic (hauv daim ntawv ceramic).

- Ib zaug, peb-theem hluav taws xob arc siv steel clip (kev xaiv phau ntawv).

- Tsis siv neeg slag da dej (tooj liab pwm).

Kev lag luam tshaj plaws yog qhov kev xaiv uas cov ntaub qhwv tsis siv thaum txuas cov pas nrig. Qhov tseeb yog tias rau lawv cov chaw tsim khoom nws yog ib qho tsim nyog yuav tsum siv sijhawm thiab hlau. Tsis muaj escutcheons, kev sib txuas sib txuas kuj tau ua kom ntseeg tau.

Nuances

Vuam hauv da dej yog ua ntawm cov dej ntws siab. Nws tuaj yeem yog 450 amps yog 5-6 hli electrodes siv.

Thaum koom nrog cov khoom ntawm qhov kub qis, kwv yees li 10% siab dua li tus qauv tam sim no yog siv. Cov kws tshaj lij pom zoo siv UONI-13/55 rods.

Thaum siv peb-theem vuamtawm ntawm qhov sib txawv 1.5-2 cm loj dua li txoj kab uas hla ntawm electrode. Qhov Performance index ntawm misalignment ntawm lub axes ntawm lub zog tuav yuav tsum tsis txhob ntau tshaj 5% ntawm qhov chaw hla ntawm cov electrodes. Cov kws tshaj lij pom zoo muab "rov qab deflection" rau cov tuav yog tias lawv ntev dua.

tshem tawm slag

Ntau zaus, qhov kawg ntawm cov pas nrig yog slagged thaum ua da dej welded sib koom ua ke. Qhov no yog vim lub tshav kub sai sai. Yog li ntawd, kev ntseeg siab ntawm kev sib txuas yog txo qis. Koj tuaj yeem txo qhov kev pheej hmoo ntawm slagging:

- Cua qhov kawg ua ntej vuam.

- Siv cov pwm hlau ua los ntawm cov khoom siv cua sov. Raws li txoj cai, cov ntsiab lus tooj liab yog siv.

Nyob zoo ib tsoom niam txiv kwv tij neej tsas sawv daws

Nws yog siv los tiv thaiv kev sib koom ua ke hauv qab no. Lub shackle ua los ntawm cov ntawv hlau uas muaj cov ntsiab lus carbon tsawg lossis ua los ntawm cov tuav yog siv.

Lub girth tuav cov kua hlau thiab tiv thaiv kom tsis txhob ntws. Txhawm rau txhawm rau txhim kho qhov ua tau zoo, cov txwv txwv tau txuas rau ntawm cov npoo ntawm lub bracket, uas tiv thaiv kev sib kis ntawm slag raws tus pas nrig.

Tsis txhob siv nyiaj siv ua haujlwm ua los ntawm tooj liab, tooj dag, tooj liab alloys. Raws li txoj cai, lawv yog ua los ntawm cov tooj liab ntshiab. Cov khoom siv no siv tau ntev heev.

Txoj kev tiv tauj

Nws suav hais tias yog ib txoj hauv kev siv vuam ntau tshaj plaws. Qhov chaw ntawm kev sib cuag ntawm cov khoom yog melted los ntawm cua sov mus rau qhov kub ntawm deformation thiab compression. Qhov no yog ua los ntawm kev hla tam sim no los ntawm Circuit Court, cov kev sib txuas uas yog, ntawm lwm yam, cov pas nrig lawv tus kheej. Tam sim no tshwm nyob rau hauv ib tug kawsaw, thiab qhov loj tshaj kuj yog concentrated nyob rau hauv lub cheeb tsam ntawm cov tuav. Tib lub sijhawm, cov cua sov tso tawm, uas ua kom muaj cua sov siab tshaj plaws ntawm thaj chaw no.

Koj tuaj yeem txo lub sijhawm vuam los ntawm kev ua kom lub zog tam sim no rau 10, thiab qee zaum txog 20 txhiab amperes. Nyob rau hauv cov ntaub ntawv no, lub melting ntawm cov hlau tshwm sim yuav luag instantly. Raws li, lub sijhawm tam sim no dhau los ntawm Circuit Court yog txo qis.

Kev sib cuag ntawm cov khoom tuaj yeem nqa tawm hauv lub pob tw lossis taw tes. Thawj yog siv thaum kawg qhov kawg yog butted. Kev txhawb nqa qhov chaw vuam yog siv thaum cov tuav sib tshooj sib tshooj. Lawv txuas ntawm ob peb lub ntsiab lus tib lub sijhawm.

khoom siv

Ib lub cuab yeej tshaj lij yog siv los txuas cov pas nrig los ntawm kev sib cuag. Kev siv zog vuam yuav tsum tau nqa tawm ntawm qee lub zog tam sim no thiab qib ntawm compression ntawm thaj chaw tiv tauj, rau lub sijhawm teev.

Txhua yam khoom siv tau muab faib ua cov khoom txawb thiab nyob ruaj ruaj. Cov cuab yeej yooj yim tshaj plaws tuaj yeem sib sau ua ke ntawm nws tus kheej. Nws yuav tsum suav nrog 2 cov haujlwm ua haujlwm. Thawj yog cov khoom siv hluav taws xob, qhov thib ob yog cov chaw taws teeb hom electrode tuav.

Ntxhais sib koom

Nws cov thev naus laus zis yog raws li kev siv cov cua sov ntawm qhov kawg ntawm cov khoom. Cov cua sov tshwm sim vim qhov kev hla ntawm hluav taws xob tam sim no los ntawm cov cheeb tsam no. Nws yog muab tom qab lub Circuit Court raug kaw los ntawm kev sib txuas qhov kawg. Cov cua kub ua haujlwm siab tau muab.

Tom qab kev xa xov tiav thiab qhov tam sim no raug kaw,"draft" ntawm qhov chaw sov. Hom kev thauj khoom siab tam sim no yog siv los ua kom sov cov hlau hauv qhov sib koom ua ke thiab tiv thaiv kom tsis txhob muaj cua sov.

Butt vuam yog siv los txuas cov pas nrig nrog txoj kab uas hla tsawg kawg 14 hli. Rau kev koom nrog rebar ua los ntawm cov txheej txheem kub thiab muaj qhov profile, qhov no yog siv yog tias txoj kab uas hla ntawm cov tuav tsis tsawg dua 32 hli.

Cov yam ntxwv ntawm kev ua haujlwm

Butt vuam tshuab tau muab faib ua ob hom:

- Txoj kev txuas ntxiv mus.

- Txoj kev sib cuam tshuam.

Ua ntej yog muab rau hom thib ob. Ua ntej pib ua haujlwm, qhov kawg ntawm qhov kev txhawb nqa yog ntxuav ntawm slag formations, xim residues, thiab xeb. Rau qhov no, ib tug chisel, ib tug rauj thiab ib tug hlau txhuam yog siv. Kev huv huv ntawm qhov kawg yog qhov tseem ceeb rau qhov zoo ntawm qhov vuam.

Point txuas

Nws yog siv tsuas yog hauv kev tsim cov tawb txhawb nqa, txhawb nqa meshes los ntawm cov tuav nrog ib qho me me.

Koj tuaj yeem siv qhov chaw vuam hauv tsev, piv txwv li, thaum kho cov khoom siv hauv tsev.

Muaj ob txoj hauv kev sib txuas. Nyob rau hauv thawj rooj plaub, cov hlau nyob rau hauv qhov sib koom ua ke yog coj mus rau ib tug molten lub xeev thiab tsim ib tug cam khwb cia core. Hauv qhov thib ob, cov hlau tsuas yog cua sov.

Yog tias qhov tam sim no loj dhau ntawm kev sib tshuam ntawm cov pas nrig sib txuas, kev hloov pauv kub yuav tshwm sim hauv cheeb tsam no. Qhov no yog vim qhov tseeb tias qhov kev tiv thaiv ntawm cov khoom siv ntxiv yog siab dua li ntawm cov khoom siv tooj liab suav nrog hauv qhov thib ob.contour ntawm lub tshuab rau vuam.

Cov txheej txheem yuav tsum tau ua ntawm tus nqi siab tam sim no. Vim qhov no, tsis tsuas yog kev ua tau zoo dua, tab sis kuj yog qhov zoo ntawm kev sib txuas. Rau qhov no, cov khoom siv kim kim yog siv. Hauv tsev, koj tuaj yeem siv cov cuab yeej sib txuas, suav nrog cov khoom tsim los ntawm nws tus kheej.

Chav tseem ceeb ntawm lub cuab yeej rau qhov chaw vuam yog qhov hloov pauv. Vim nws, ib tug loj tam sim no generated. Cov cuab yeej siv tau tus qauv hom transformer OSM-1. Txawm li cas los xij, nws yuav tsum tau hloov kho me ntsis kom tau txais lub zog hluav taws xob siab dua thib ob winding.

txheej txheem kev sib txuas

Txoj haujlwm tau ua tiav hauv theem:

- Cov tuav tau muab tso rau hauv ib qho chaw thiab muab tso rau ntawm cov khoom siv hluav taws xob. Lawv raug nias nruj rau thaj tsam ntawm kev txuas yav tom ntej.

- Tam sim no siv rau thaj chaw tiv tauj; cov hlau yog rhuab mus rau lub xeev yas xav tau rau deformation. Los ntawm nias, ib txoj siv sib khi yog tsim, uas tiv thaiv cov hlau tsis txhob kis.

- Lub mem tes tam sim no yuav tsum muaj zog thiab ua neej nyob luv. Qhov no yuav ua kom cov pas nrig ua kom ruaj khov taw tes tom qab noj mov nres.

Splice

Nws suav nrog kev kho cov pas nrig ib nrab ntawm ib leeg. Thaum siv txoj kev no, cov tuav ua ib kab nrog kev sib tshooj ntawm lawv qhov ntev ntawm qhov chaw docking.

Lub ceg tawv yog siv los faib qhov ntevcompressive / tensile load rau ntawm tus pas nrig. Thaum ua haujlwm, koj yuav tsum ua raws qee cov cai:

- Kev sib tshooj tau tso cai rau hauv thaj chaw uas muaj kev ntxhov siab tsawg ntawm cov qauv.

- Cov kab sib txawv yuav tsum muab faib sib npaug. Txawm li cas los xij, nws yog qhov zoo dua los siv tib lub pas nrig.

- Kev sib tshooj vuam yog siv los txuas cov pas nrig nrog qhov hla tsis tshaj 20 hli.

- Kev sib tshooj ntawm cov tuav yuav tsum ntau dua 50 cm.

Kev sib tshooj vuam ntawm cov khoom lag luam hauv qab kev thauj khoom nce ntxiv yog pom zoo siv phau ntawv arc vuam. Nws yog nqa tawm nrog ib los yog ob seams los ntawm flanks. Txhawm rau kom qhov sib koom ua ke kom ua tau zoo, qhov ntev ntawm cov seam yuav tsum tshaj li txoj kab uas hla ntawm cov tuav tsawg kawg yog 10 zaug.

Kev tuav arc vuam yog ua, raws li txoj cai, nyob rau hauv txoj hauj lwm kab rov tav ntawm cov pas nrig. Rau kev ua haujlwm, cov cuab yeej siv tau siv, uas suav nrog lub tshuab hloov pauv, lub tshuab hluav taws xob, lossis cov khoom siv nrog cov pa nruab nrab.

Pom zoo:

Kev ntsuas kev nqis peev zoo ntawm kev lag luam: cov ntsiab lus yooj yim, txoj hauv kev, cov hauv paus ntsiab lus, txoj hauv kev txhim kho

Kev nqis peev tsim khoom yog lub hauv paus ntawm txhua lub lag luam. Kev nqis peev loj loj yuav tso cai rau kev tsim lossis hloov kho cov khoom siv thiab cov txheej txheem uas twb muaj lawm, hloov lub cev lossis kev coj ncaj ncees los ntawm cov cuab yeej cuab tam, nce ntim ntawm cov dej num, mastering cov khoom tshiab, nthuav kev muag khoom, thiab lwm yam

Cov khoom siv tseem ceeb rau vuam - vuam hlau

Vuam hlau yog siv rau hauv ntau yam kev lag luam vuam, nws yog cov khoom siv tseem ceeb uas ua raws li cov khoom siv hluav taws xob, kev ua haujlwm vuam yuav tsum muaj kev paub dav dav, lub luag haujlwm rau kev xaiv cov khoom siv raw. Rau cov txheej txheem vuam, nws tsis tuaj yeem siv cov hlau tsis sib xws ntawm cov cim tsis paub thiab tsis paub muaj pes tsawg leeg

Vuam ntawm ultrasonic plastics, yas, hlau, cov ntaub ntawv polymeric, aluminium profiles. Ultrasonic vuam: tshuab, teeb meem yam

Ultrasonic vuam ntawm cov hlau yog txheej txheem thaum lub sij hawm sib koom ua ke mus tas li nyob rau hauv cov theem khoom. Kev tsim ntawm cov menyuam yaus hauv cheeb tsam (hauv cov ntawv cog lus tau tsim) thiab kev sib cuag ntawm lawv tshwm sim nyob rau hauv kev cuam tshuam ntawm cov cuab yeej tshwj xeeb

Welder's daim npog qhov ncauj yog ib txoj kev txhim khu kev qha ntawm kev tiv thaiv cov teeb meem feem ntau ntawm cov txheej txheem vuam

Tau kawg, kev vuam hlau yog ib qho txaus ntshai tshaj plaws rau tib neeg, vim tias txhua txoj haujlwm vuam yog nrog los ntawm kev tso tawm tsis tu ncua ntawm cov khoom tsis zoo thiab cov yam ntxwv. Qee qhov txaus ntshai tshaj plaws yog: hluav taws xob arc, ci ntsa iab, cov pa phem, infrared thiab ultraviolet hluav taws xob

Flux rau vuam: lub hom phiaj, hom vuam, flux muaj pes tsawg leeg, cov cai ntawm kev siv, GOST cov cai, qhov zoo thiab qhov tsis zoo ntawm daim ntawv thov

Qhov zoo ntawm cov vuam yog txiav txim siab tsis yog los ntawm lub peev xwm ntawm tus tswv los npaj lub arc kom raug, tab sis kuj los ntawm kev tiv thaiv tshwj xeeb ntawm thaj chaw ua haujlwm los ntawm kev cuam tshuam sab nraud. Tus yeeb ncuab tseem ceeb ntawm txoj hauv kev los tsim kom muaj kev sib txuas ntawm cov hlau uas muaj zog thiab ruaj khov yog cov huab cua puag ncig ntuj. Lub vuam yog cais tawm los ntawm cov pa oxygen los ntawm cov flux rau vuam, tab sis qhov no tsis yog nws txoj haujlwm xwb