2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Kub vuam yog ib qho ntawm cov txheej txheem sib dhos uas siv hauv kev tsim kho thiab kev lag luam. Nws yog siv ob qho tib si hauv kev ua haujlwm siab rau kev sib dhos ntawm cov cuab yeej siv, thiab hauv kev ua haujlwm yooj yim tshaj plaws thaum txuas cov khoom siv thauj khoom. Nyob rau hauv txhua rooj plaub, nws tus kheej welding txheej txheem yog siv, uas yog optimally haum rau kev ua hauj lwm tsis, ua hauj lwm tej yam kev mob thiab yuav tsum tau rau qhov tshwm sim.

YVim yog dabtsi?

Hauv kev pom classical, vuam yog cov thev naus laus zis ntawm kev tsim cov pob qij txha mus tas li los ntawm kev tsim cov qauv sib txuas sib txuas tiv thaiv keeb kwm yav dhau los ntawm thermal raug. Nyob rau hauv lwm yam lus, nyob rau hauv lub kub kub, yas deformation ntawm lub workpieces yog guaranteed thiab tom qab kev sib hloov ntawm hais nruab nrab ntawm lawv, uas ua rau lub tsim ntawm ib tug sib koom ua ke tom qab cov ntaub ntawv txias. Cov txheej txheem vuam nws tus kheej tsuas yog muab cov xwm txheej tsim nyog rau kev nqa cov hlau mus rau hauvxav tau lub xeev. Nyob rau hauv ib txwm kub tej yam kev mob, cov hlau yog ib tug qauv ntawm cov khoom crystalline hais, tab sis thaum ncav cuag ib tug tej yam cua sov Performance index, cov khoom softens. Nyob rau tib lub sijhawm, nws yuav tsum tau hais qhia tias qhov cuam tshuam ntawm qhov kub thiab txias tsis yog tsuas yog muaj txiaj ntsig zoo los ntawm qhov pom ntawm qhov muaj peev xwm mounting. Oxidation ntawm cov hlau kuj tshwm sim, tsim cov kab nrib pleb hauv qhov chaw tsis tsim nyog vim muaj kev ntxhov siab sab hauv, kev sib tsoo thiab deformation tshwm sim. Nws yog ib qho ua tau kom tshem tawm thiab txo qhov tshwm sim tsuas yog los ntawm kev xaiv cov khoom siv thiab kev koom tes ntawm cov txheej txheem vuam.

Welds thiab pob qij txha

Txhawm rau nkag siab cov hom phiaj ntawm cov hlau yas deformation, nws yog ib qho tsim nyog los txiav txim siab seb cov haujlwm twg yog qhov kev ua haujlwm vuam ua haujlwm. Feem ntau, nws yog ib qho tsim nyog kom tau txais kev sib txuas ntawm ob lub workpieces lossis cov qauv nrog cov khoom. Kev sib txuas configurations txawv - angular, taub qab, tee, thiab lwm yam. Los ntawm qhov pom ntawm qhov tsim ntawm cov npoo, cov txheej txheem vuam seam tso cai rau kev tsim cov pob qij txha tsis muaj bevels, nrog flanges, nrog rau bevels nyob rau hauv ntau yam duab. Ib qho nyuaj tshaj plaws bevels yog suav tias yog X-puab, nyob rau hauv uas ob ncaj los yog nkhaus npoo yog mated. Txawm hais tias ib qho ntawm cov kev cai tseem ceeb rau kev sib koom ua ke yog nruj, qee zaum muaj cov haujlwm meej meej rau kev tsim cov qhov hauv qhov sib koom ua ke. Piv txwv li, thaum txuas cov ntsiab lus los ntawm kev sib tshooj thiab tsis muaj ntug bevel, lub qhov elongated tuaj yeem tsim tau, uas yog tom qab siv rau lwm yam kev ua haujlwm.

Ntau yam ntawm cov txheej txheem vuam

Txoj hauv kev mus rau lub koom haum kev lag luam ntawm vuam tuaj yeem sib txawv ntawm qhov tsis ua haujlwm ntawm qhov chaw ua haujlwm thiab hauv kev siv tshuab ntawm qhov cuam tshuam rau cov khoom siv. Cov txheej txheem vuam nrov tshaj plaws suav nrog cov hauv qab no:

- Arc vuam. Ib qho hluav taws xob arc yog tsim los ntawm qhov chaw ntawm cov qauv los yog ib feem yuav tsum tau welded, cov nyhuv thermal uas ua rau lub melting ntawm cov khoom. Txoj kev no tuaj yeem yog phau ntawv, tshuab lossis tsis siv neeg. Piv txwv li, cov txheej txheem arc vuam tsis siv neeg suav nrog kev pub cov hlau electrode nrog cov cuab yeej tshwj xeeb, tso tus neeg teb xov tooj txhais tes.

- Gas welding. Yog hais tias nyob rau hauv cov ntaub ntawv dhau los lub tshav kub qhov hluav taws xob yog hluav taws xob, cov roj welding siv ib tug oxy-fuel nplaim taws kub ntawm 3,200 ° C. Nyob rau tib lub sijhawm, kev sib xyaw ua ke yuav tsum tsis txhob tsis meej pem nrog cov qauv no, uas cov roj sib tov kuj siv tau, tab sis tsis yog los ntawm qhov kub thiab txias, tab sis cais lub pas dej ua ke.

- Electroslag vuam. Qhov cuam tshuam ntawm cov khoom yog muab los ntawm hluav taws xob tam sim no, thiab molten slag ua raws li tus neeg xyuas pib thiab lub zog hloov pauv.

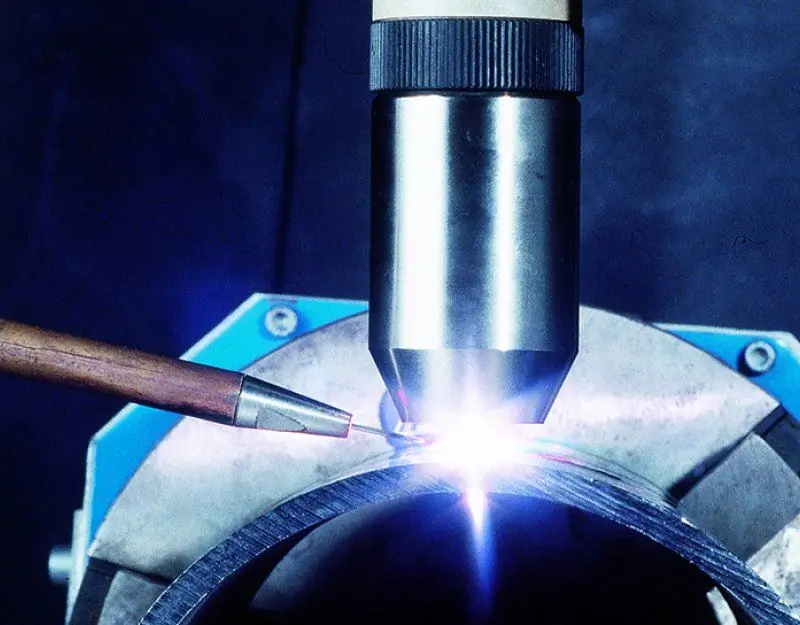

- Plasma vuam. Txoj kev vuam kub kub uas siv lub dav hlau plasma-arc nrog thermal zog txog 10,000 °C.

- Laser vuam. Cov txheej txheem yog raws li kev siv lub zog photoelectronic. Lub melting ntawm qhov chaw tshwm sim nyob rau hauv lub zog ntawm lub teeb beam emitted los ntawm lub laser.

vuam tshuab

Txhawm rau ua cov haujlwm vuam, ntau txoj kev siv feem ntau yog siv, suav nrog inverter, rectifier thiab transformer. Nyob rau hauv txhua rooj plaub, lub luag hauj lwm tseem ceeb ntawm lub ntsiab welding apparatus yog muab direct tam sim no. Cov khoom siv zoo tshaj plaws muab cov chaw ua haujlwm nrog cov khoom siv hluav taws xob du thiab ruaj khov. Ntawm chav kawm, qhov no siv rau hluav taws xob vuam technologies. Cov txheej txheem ntawm kev vuam nyob rau hauv gaseous media yog siv los ntawm cov burners thiab gearboxes uas tswj cov khoom ntawm cov roj sib tov los ntawm lub tog raj kheej. Tsis tas li ntawd nyob rau hauv cov ntaub ntawv ntawm plasma vuam, tshwj xeeb plasma torches yog siv uas muaj peev xwm ua hauj lwm nrog workpieces txog li 30 hli tuab. Ntxiv mus, nws yuav tsum tau hais qhia tias cov khoom siv roj thiab cov ntshav yog tsom tsis yog rau cov haujlwm ib txwm muaj ntawm kev sib txuas cov hlau, tab sis ntawm kev txiav cov khoom raws li thermal cuam tshuam.

Sew technique

Txawm hais tias lub luag haujlwm loj ntawm cov khoom siv, ntau hauv kev ua haujlwm vuam yog nyob ntawm kev txawj thiab peev xwm ntawm tus neeg teb xov tooj uas tswj tag nrho cov txheej txheem. Lub luag haujlwm ntawm tus neeg siv khoom siv yog los tswj cov khoom siv hluav taws xob thiab cov khoom siv ntawm cov khoom siv tam sim no nyob rau hauv lub pas dej ua ke uas cov seam tsim. Qhov tseem ceeb tshaj plaws yog txoj haujlwm ntawm tus neeg teb xov tooj thiab cov kev taw qhia ntawm lub seam. Cov kws tshaj lij pom zoo ua haujlwm, yog tias ua tau, nyob rau hauv txoj haujlwm qis, kom ntseeg tau tias lub vuam yog welded nrog cov hlaws dai nrog kev nthuav dav. Nws yog ntshaw kom ua tiav qhov tob tob, uas yuav ua rau cov qauv ntawm kev sib koom ua ke ntau dua thiab ruaj khov. Hauv engineeringphau ntawv vuam, theem ntawm kev ntxuav lub seam los ntawm slag thiab smudges yog qhov tseem ceeb tshwj xeeb. Yog tias qhov tsis zoo no tsis tuaj yeem tshem tawm thaum lub sijhawm tseem ceeb ntawm kev ua haujlwm, tom qab ntawd yuav tsum tau ua ib txheej txheej thib ob ntawm qhov chaw. Feem ntau cov thawj txheej tseem ceeb nce mus txog 3-4 hli hauv tuab, thiab cov tom ntej - txog li 5 hli.

Txheej txheem ntawm submerged arc thiab roj vuam

Txhawm rau kom tsis txhob tau kho cov txheej txheem vuam hauv cov txheej txheem ntawm kev ua haujlwm, nws raug nquahu kom pib xam cov thev naus laus zis nuances uas tuaj yeem txhim kho qhov txiaj ntsig zoo. Submerged arc thiab roj vuam yog qhov txawv los ntawm nws txoj kev tsom mus rau kev tiv thaiv ntawm seam los ntawm kev cuam tshuam tsis zoo ntawm ib puag ncig sab nraud thiab yaj. Piv txwv li, thaum ua cov txheej txheem roj welding nrog cov khoom ntawm argon sib tov, qhov tsis zoo ntawm cov pa oxygen, uas ua rau qhov zoo ntawm cov qauv vuam, txo qis. Raws li rau cov flux, nws suav nrog hauv thawj qhov chaw txo qis ntawm cov dej ntws tawm, thiab qhov thib ob, nws hloov kho qhov sib xyaw ntawm cov vuam los ntawm kev suav nrog cov khoom siv tshwj xeeb uas tau qhib thaum kub kub.

Parameters rau lub koom haum ntawm vuam ntau lawm

Nyob rau hauv hom kev tsim khoom ntawm kev txhim kho kev ua haujlwm vuam, ntau yam ntawm kev ua haujlwm ntawm kev ua haujlwm raug coj mus rau hauv tus account ib zaug, suav nrog cov hauv qab no:

- Qhov piv ntawm qhov nyuaj ntawm kev ua haujlwm thiab lub sijhawm tus qauv rau nws qhov kev siv.

- Tus nqi ua haujlwm yog tus nqi ntawm cov khoom lag luam uas tus neeg ua haujlwm lossis pab pawg ua haujlwm hauv 1 teev. Piv txwv li, nyob rau hauv phau ntawv arc welding txheej txheem, meters ntawm lub tiav seam los yog tus naj npawb ntawm assembled qhov chaw yuav muab rau hauv tus account.

- Unitkev pabcuam. Hauv qhov no, peb txhais tau tias qhov chaw ua haujlwm, ib qho khoom siv lossis qhov chaw rau vuam, nyob rau hauv uas cov dej num ntawm ib tug neeg ua hauj lwm los yog ib pab neeg tau koom.

Kev nyab xeeb hauv lub koom haum thiab kev tsim cov vuam

Cov txheej txheem vuam cuam tshuam nrog ntau yam kev pheej hmoo thiab kev phom sij ntawm kev hem thawj rau tib neeg kev noj qab haus huv. Vuam cov qauv kev nyab xeeb tsom rau ntau yam kev phom sij ib zaug:

- vuam hluav taws xob. Infrared hluav taws xob nrog lub ci ci tsis zoo cuam tshuam rau lub qhov muag ntawm cov welder, yog li ntawd, hauv nws cov cuab yeej siv, muaj lub ntsej muag nrog cov tsom iav tshwj xeeb tsaus nti thiab cov ntxaij lim dej yog qhov yuav tsum tau ua.

- Thermomechanical nyhuv. Tshwj xeeb tshaj yog thaum ua hauj lwm raws li txoj kev arc, splashes ntawm yaj yog txaus ntshai. Qhov tseeb, nws yog cov kua dej kub uas tuaj yeem ua rau kub hnyiab heev ntawm kev sib cuag ntawm daim tawv nqaij. Txhawm rau tiv thaiv cov nplaim taws thiab cov hlau kub, cov khaub ncaws tiv thaiv tshwj xeeb yog siv.

- Risk ntawm hluav taws. Qhov kub thiab txias ntawm cov khoom kub kub ua rau muaj kev phom sij rau hluav taws. Nws yog ib qho tsim nyog xav txog qhov no txawm tias nyob rau theem ntawm kev teeb tsa cov txheej txheem, tshem tawm cov khoom tawg ntawm qhov chaw ua haujlwm.

- tiv thaiv ua pa. Cov pa roj carbon monoxide thiab kev tso tawm ntawm lwm yam khoom muaj kev puas tsuaj thaum lub sij hawm thermal puas ntawm cov qauv hlau kuj yog ib qho tseem ceeb ntawm cov khoom phom sij. Hauv qhov no, nws tsis txaus siv lub qhov ncauj qhov ntswg thiab lub tshuab ua pa. Lub tshuab ua haujlwm yog qhov yuav tsum tau ua ua ntej rau cov txheej txheem ua haujlwm ntevQhov cua nyob hauv qhov chaw kaw thiab ua haujlwm 5-10 feeb tsis tu ncua.

Vuam yuam kev

Vim qhov nyuaj ntawm cov txheej txheem vuam, qhov kev xav ntawm kev siv thev naus laus zis tsis yog ib yam tshwj xeeb. Feem ntau ntawm cov no suav nrog cov hauv qab no:

- Arc tawg. Cov hluav taws xob thermal ua tsis tau tiav mus rau qhov kawg ntawm qhov kev npaj seam, uas yuav ua rau muaj kev nyuaj siab tawg ntawm ntug ntawm cov kab txuas.

- Kev siv zog tsis zoo nrog cov hlau nyias ntawm qhov sib koom ua ke (txiav). Ib qho tshwm sim nyob rau hauv high voltage welding cov txheej txheem. Qhov zoo tshaj plaws, kev txiav yuav tsum tsis pub ntau tshaj 1 hli sib sib zog nqus lossis ntxiv vuam yuav tsum tau.

- Point tsis muaj kev sib txuas ncaj qha hauv cov qauv ntawm cov seam ntawm cov khoom ua haujlwm. Hauv lwm lo lus, qhov seem tsis muaj kev nkag mus, uas tshwm sim vim qhov tsis raug ntawm cov electrode thaum lub sij hawm tsim cov arc, yam tsis xav txog qhov tob ntawm cov nyhuv thermal.

Zaj lus

Nrog rau txhua qhov kev siv thev naus laus zis ntawm kev vuam, cov txheej txheem ntawm lawv qhov kev siv tau nkag mus tau ntau dua rau tus tswv tsev zoo tib yam. Qhov no feem ntau yog vim qhov tseeb tias cov txheej txheem vuam tau dhau los ua ergonomic thiab muaj kev nyab xeeb dua. Piv txwv li, niaj hnub inverters ua kom yooj yim tswj cov kev khiav hauj lwm tseem ceeb ntawm cov txheej txheem, suav nrog cov yam ntxwv ntawm cov hlau thiab ib puag ncig. Tus neeg siv tsuas yog yuav tsum tau teeb tsa thaj chaw ua haujlwm kom raug thiab tswj cov hluav taws xob arc kom zoo thaum tsim cov seam.

Pom zoo:

Kev mus ncig ua lag luam yog dab tsi: lub tswv yim, lub ntsiab lus, cov txheej txheem kev cai lij choj, cov cai mus ncig ua lag luam thiab cov cai sau npe

Txhua tus tswv ntiav thiab cov neeg ua haujlwm yuav tsum paub tias kev mus ncig ua lag luam yog dab tsi, nrog rau kev ua tiav thiab them nyiaj li cas. Kab lus piav qhia txog cov nyiaj them twg raug xa mus rau tus neeg ua haujlwm xa mus rau kev lag luam, nrog rau cov ntaub ntawv dab tsi tau npaj los ntawm lub taub hau ntawm lub tuam txhab

Yuav hloov tus lej xov tooj li cas hauv Sberbank: txoj hauv kev yooj yim thiab yooj yim, cov txheej txheem thiab cov lus qhia kws tshaj lij

Million of Russians siv cov kev pabcuam ntawm Sberbank. Ntau tshaj 2/3 ntawm cov neeg siv khoom nyiam cov ntawv thov mobile: "Mobile Bank" thiab "Sberbank Online". Txhawm rau ua lag luam, nws txaus kom muaj daim npav Sberbank thiab siv lub smartphone. Tus neeg siv khoom lees paub tag nrho cov haujlwm nrog cov lej los ntawm SMS los ntawm lub txhab nyiaj, yog li ntawd, txhawm rau zam qhov xwm txheej tsis tau pom dua, koj yuav tsum paub yuav ua li cas hloov tus lej xov tooj hauv Sberbank

Vuam hauv qhov chaw tiv thaiv roj: ua haujlwm thev naus laus zis, txheej txheem piav qhia, cov txheej txheem ua tiav, cov khoom tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib ntus thiab cov lus qhia kws tshaj lij

Vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Versatility tau ua vuam nyob rau hauv ib puag ncig tiv thaiv roj ib qho tseem ceeb ntawm kev tsim khoom. Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv ib puag ncig tiv thaiv yog maj mam hloov cov tsoos electrode vuam

Kuv puas xav tau daim ntawv teev nyiaj ntsuab rau cov neeg ua lag luam nrog cov txheej txheem se yooj yim? Yuav ua li cas rau npe thiab siv daim ntawv sau nyiaj ntsuab rau cov neeg ua lag luam nyob rau hauv cov txheej txheem se yooj yim?

Kab lus piav qhia txog cov kev xaiv rau kev ua cov nyiaj tsis muaj kev koom nrog cov ntawv sau nyiaj ntsuab (CCT)

Kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab ntog: cov txheej txheem thiab cov txheej txheem ntawm kev kho dua tshiab, nta, txheej txheem thev naus laus zis

Vuam thiab surfacing thev naus laus zis ua rau nws ua tau zoo los kho cov hlau seem, muab cov qib siab ntawm kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom. Qhov no tau lees paub los ntawm kev xyaum siv cov txheej txheem no thaum ua haujlwm kho hauv ntau qhov chaw - los ntawm kev kho tsheb mus rau kev tsim cov hlau dov. Hauv tag nrho cov nyiaj ua haujlwm ntawm kev kho cov qauv hlau, kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam thiab surfacing yuav siv li 60-70%