2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

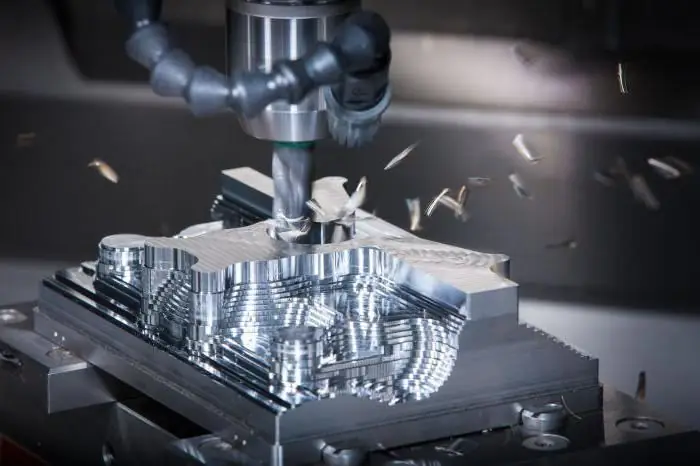

CNC tshuab rau hlau ua haujlwm yuav luag txhua lub tshuab tsim, yeeb nkab, kho cog. Niaj hnub nimno txiav txoj kev yog intensive. Cov txheej txheem tswj hwm yog nyob ntawm ib lub chaw pabcuam, uas tuaj yeem saib xyuas cov xwm txheej ntawm cov haujlwm axes thiab cov automation nyob ib puag ncig ntawm lub sijhawm. Cov ntxaij vab tshaus LCD muab cov ntaub ntawv hauv 3D duab nraaj yooj yim.

Kev tswj hwm txoj haujlwm muaj li cas?

CNC metalworking tshuab yog siv rau kev tsim cov tshuab precision, yeeb nkab threading. Tus nqi ntawm kev teeb tsa yog los ntawm ntau txhiab (tus qauv desktop) mus rau ntau lab (multi-axis machining chaw) rubles. Tus qauv tsim nyog raug xaiv raws li cov dej num ntawm ntau lawm. Tus nqi raug txo los ntawm kev xaiv cov khoom siv conveyor. Ib qhov project yog kwv yees ntawm ib qho tseem ceeb, vim tias nws yuav tsum tau tsim cov duab kos nrog yuav luagzero.

Ntawm lub plawv ntawm lub tshuab yog tus tswj uas txhais cov haujlwm hauv qab no:

- Basic anchor points.

- Txoj kev sib koom ua ke raws ib qho kev qhia raws li kev tswj hwm.

- Lub xeev ntawm analog thiab discrete sensors raug tshuaj xyuas. Cov no suav nrog kev txav, theem, siab, ntsuas kub.

- Sim qhia los ntawm lub tshuab tsav, cov tswj los ntawm cov kab sib koom tes nrog lub tshuab raug saib xyuas.

- Signals pauv nrog cov theem sab saud.

- Built-in interfaces ua teeb meem yooj yim dua.

- Qhov kev tswj hwm qhov teeb meem yuam kev ntawm tus saib. Nws yooj yim dua rau tus installer los nrhiav qhov xwm txheej ceev.

CNC tshuab rau hlau ua haujlwm tau nruab nrog cov txheej txheem kev ruaj ntseg tshiab uas txawm tias cov kws paub txog hluav taws xob tsis tuaj yeem hla. Qhov no ua rau kom muaj kev ntseeg siab, kev nyab xeeb ntawm kev ua haujlwm ntawm cov tshuab thiab khaws cov chaw tsim khoom warranty.

Txhua yam khoom

Dimensional raug yog ua tiav siv servo motors, stepper systems, rulers lossis encoders. Cov khoom seem ua tsis tau sai vim qhov chaw nruj heev hauv kev lag luam. Coolant coolant yuav tsum tau ua thaum hlau ua haujlwm ntawm cov cuab yeej siv tshuab. Yuav luag txhua qhov chaw tsim khoom ua haujlwm nrog CNC hauv Moscow. Cov neeg tsim qauv sab hnub poob tau qhia txog cov teeb liab kis tau tus mob niaj hnub nrog cov bandwidth siab. Qhov no tso cai rau koj los tsim cov khoom lag luam nrog kev siv zog txaus.

Ncua rau kev hloov pauv yuav tsis pub dhau ob peb vib nas this, uas ua rau cov khoom lag luam cov thawj coj hauv kev lag luam. Cov nqi sij hawm raug txo qis, thiab qhov no tau cuam tshuam txog tus nqi ntawm cov khoom kawg. Cov txheej txheem saw hlau tuaj yeem ua haujlwm los ntawm ib tus neeg teb xov tooj yam tsis muaj kev koom tes ntawm cov kws tshaj lij kim.

Mechanics

Cov ntaub ntawv niaj hnub no txo cov nyhuv ntawm kev co ntawm tus ncej. Wear-resistant kinematic systems muab ib hom kev ua haujlwm tsis muaj teeb meem. Kub sensors xa cov ntaub ntawv hais txog qhov xwm txheej ntawm cov kabmob thrust, hydraulic system, lubrication thiab txias tso tsheb hlau luam. Yog tias tsis muaj cov roj ntws mus rau lub ntsiab loaded unit - spindle - cov lus malfunction yuav tshwm. Qhov no tso cai rau koj kom muaj kev ncaj ncees ntawm cov khoom kim.

Ua ntej pib ua haujlwm, lub tshuab tsis siv neeg ua kom sov cov roj lubricating. Pulse dosing ntawm cov khoom ntawm cov lus qhia yog ua los ntawm timers. Tsav tshuab tas li saib xyuas cov load ntawm cov kinematic units thaum lub sijhawm txav mus los. Tom qab qhov kev txiav tawm tam sim no dhau lawm, lub tswb nres yog muab los ntawm tus maub los. Tom qab tshem tawm qhov ua txhaum, qhov yuam kev tau lees paub los ntawm tus installer.

xaiv khoom siv

Cov neeg ua haujlwm vaj huam sib luag tuaj yeem nruab nrog lub hard drive. Nws khaws tag nrho cov ntaub ntawv ntawm cov ntaub ntawv khaws tseg, kev hloov pauv hauv cov haujlwm, kev txhim kho hauv kev txiav tshuab. Qhov kev xaiv no tso cai rau koj los nruab ib qho kev khiav hauj lwm uas ua rau lub tshuab rov sau dua luv luv. Yog li ntawd, nyob rau hauv cov kev tshwm sim ntawm ib tug tsis ua hauj lwm ntawm lub tswj board nyob rau hauv lub cim xeeb ntawm ib tug tshiabDevices hloov cov lej hauv feeb. Cov khoom siv downtime tsawg kawg nkaus, lub tuam txhab tsis raug kev puas tsuaj thaum muaj xwm txheej.

CNC tshuab ua haujlwm hlau yog nruab nrog Wi-nkaus transmitters, uas muab kev sib txuas lus wireless ntawm kab xwm txheej rau ntau pua meters. Lub server khaws cov txiaj ntsig ntawm cov khoom tiav. Raws li cov thawj coj, qhov kev kho kom zoo no pab tswj lub xeev ntawm cov txheej txheem tsim khoom yam tsis tau tawm hauv chaw ua haujlwm.

Tus neeg tsim khoom sib piv

Russian-ua CNC tshuab rau hlau ua haujlwm tsis txawv ntawm qhov zoo thiab kev ntseeg siab los ntawm cov cav tov ntawm Western cov neeg sib tw. Lub software tau nkag tau ntau dua vim nws rub tawm dawb hauv Internet kev pabcuam. Cov tuam txhab sab hnub poob tseem yog cov thawj coj vim tias muaj txiaj ntsig ntawm cov chaw tswj hwm. Cov neeg tsim qauv "ntse" cov khoom siv rau cov kev xav tau ntawm cov cuab yeej siv tam sim.

Cov thawj coj tsim qauv tsim tau ntau xyoo dhau los. Ib pab neeg ntawm cov kws tshaj lij tuaj yeem hloov kho cov tshuab ua haujlwm txhua lub hlis twg. Lavxias teb sab analogues tshwm ntau tom qab. Tab sis vim tus nqi qis ntawm kev teeb tsa, ib txwm xav tau.

Desk types

Yooj yim thiab pheej yig desktop CNC tshuab rau hlau ua haujlwm tau nrov. Kev cob qhia, kev tsim cov khoom me me lossis qhov xav tau kom nquag hloov qhov chaw ntawm lub installation yog lub hom phiaj tseem ceeb rau kev nrhiav tau ntawm cov qauv zoo li no. Compact systems yog yuav los ntawm cov tuam txhab luam tawm Circuit Board, cov khoom siv hluav taws xob.

CNC tshuab ua ke ob qho txiaj ntsig zoo:

- Tus nqi qis.

- Kev ntseeg tau thiab kev ua haujlwm mus ntev tsis nres.

Dav siv hauv kev siv tshuab txiav cov ntaub ntawv. Cov tshuab yog siv los ntawm 220 V network, uas tso cai rau koj tso ib chav ua haujlwm hauv chav nres tsheb.

Kev faib cov tshuab

CNC tshuab rau hlau ua haujlwm yog faib los ntawm qhov ntev, lub hom phiaj, hom kev txiav, kev tswj hwm txoj kev. Txhua hom yuav siv sij hawm rau hauv tus account cov yam ntxwv ntawm ib qho kev tsim khoom. Yog li, cov kav dej yuav tsum muaj ntau hom tshuab. Tag nrho cov kab ntawm cov tshuab yog concentrated nyob rau hauv ib lub lag luam, stretching rau pua pua meters.

Muaj ntau hom tshuab:

- milling;

- engraving;

- tig;

- sib tsoo;

- phaj dabtsi yog khoov thiab nias khoom.

Los ntawm kev tsim, lawv muab faib ua cov hauv qab no:

- portal systems;

- ntsug;

- kab rov tav.

Tsheb yuav ntau qag. Raws li cov chaw tsim khoom, txawm tias tsim cov khoom siv yooj yim, tsawg kawg yog ob lub dav hlau txav ntawm cov cuab yeej ua haujlwm yuav tsum tau ua.

hom hlau ua haujlwm

Metalworking ntawm CNC tshuab nyob rau hauv St. Petersburg yog muab tig, engraving, thermal. Tag nrho cov thev naus laus zis tau ua tiav hauv lub voj voog tsis siv neeg. Nws yuav siv sij hawm tsawg kawg nkaus kom ua tiav qhov kev txiav txim. Koj tsis tas yuav siv nyiaj rau kev hloov pauvkev siv zog ntxiv. Cov ntaub ntawv muaj cov kev pabcuam thev naus laus zis tseem ceeb, nws txaus los rub tawm cov qauv peb sab ntawm ib feem los ntawm qhov nruab nrab nqa tau.

Cov khoom kawg yog tswj hwm los ntawm lub tuam tsev tswj xyuas qhov zoo. Cov kws tshaj lij ua qhov kev soj ntsuam ntawm qhov chaw ntawm cov cuab yeej siv niaj hnub no. Qhov tseeb ntawm cov khoom tsim tau tso cai rau cov tuam txhab tuaj yeem xaj los ntawm cov tub rog thiab lub chaw haujlwm. Ntawm CNC tshuab, lawv ua tiav kev tsim cov khoom seem hauv 5D dav hlau vim yog cov axes ntxiv ntawm kev txav ntawm cov spindle sib dhos. Raws li cov tuam ntxhab, nrog rau lub sijhawm no, nws hloov tawm mus ua haujlwm tawm tag nrho cov thev naus laus zis hauv ib lub voj voog txiav.

Pom zoo:

Cov xim tsis muaj hluav taws kub rau hlau: txheej txheem cej luam, specifications, manufacturers thiab tshuaj xyuas

Cov xim tsis muaj hluav taws xob txo qhov cuam tshuam ntawm qhov kub thiab txias ntawm cov qauv, ua kom muaj hluav taws kub hnyiab, uas tuaj yeem kav ntev txog 1 teev lossis ntau dua. Feem ntau cov qauv tsim muaj kev tiv thaiv, qhov deformation uas ua rau poob ntawm lub zog thiab kev puas tsuaj ntawm lub tsev. Kev siv cov txheej txheej nyias nyias rau kev tiv thaiv yog tswj los ntawm kev tiv thaiv hluav taws ntawm kev coj ua

Lub tshuab cua sov muaj: txheej txheem cej luam, hom thiab tshuaj xyuas

Cov kab lus no mob siab rau kev lag luam cua sov. Ntau yam ntawm cov cuab yeej no, cov nuances ntawm kev xaiv thiab kev tshuaj xyuas ntawm cov tuam ntxhab raug suav hais tias

Txawb nplej tshuab ziab khaub ncaws: txheej txheem cej luam, tuam ntxhab, hom thiab tshuaj xyuas

Mobile grain dryers: piav qhia, manufacturers, hom. peculiarities. Mobile grain dryers, yam ntxwv, duab, tshuaj xyuas

Chainsaw saw sharpening tshuab - txheej txheem cej luam, nta, hom thiab tshuaj xyuas

Kev ua haujlwm hnyav nrog cov saw saws inevitably ua rau poob ntawm kev ua haujlwm zoo ntawm cov cuab yeej txiav. Nrog rau cov cuab yeej siv niaj hnub, tsuas yog cov kws ua haujlwm paub txog nrog kev ua kom zoo tuaj yeem rov qab tau cov geometry thiab cov qub sharpness ntawm cov saw ntu

Kuv puas xav tau daim ntawv teev nyiaj ntsuab rau cov neeg ua lag luam nrog cov txheej txheem se yooj yim? Yuav ua li cas rau npe thiab siv daim ntawv sau nyiaj ntsuab rau cov neeg ua lag luam nyob rau hauv cov txheej txheem se yooj yim?

Kab lus piav qhia txog cov kev xaiv rau kev ua cov nyiaj tsis muaj kev koom nrog cov ntawv sau nyiaj ntsuab (CCT)