2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

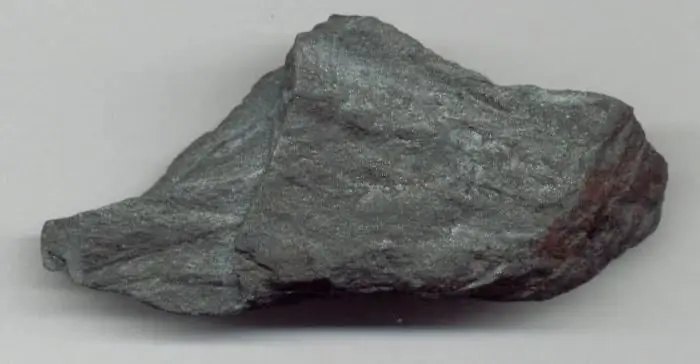

Thawj chiv keeb, thev naus laus zis ntawm cov hlau casting yog thawj zaug hauv Suav teb xyoo pua 10th, tom qab ntawd nws tau nthuav dav mus rau lwm lub tebchaws hauv ntiaj teb. Lub hauv paus ntawm cam khwb cia hlau yog cov hlau alloy nrog carbon thiab lwm yam khoom. Ib tug txawv feature yog hais tias nyob rau hauv nws muaj pes tsawg leeg cam khwb cia hlau muaj ntau tshaj 2% carbon nyob rau hauv daim ntawv ntawm cementite, uas tsis pom nyob rau hauv lwm yam hlau. Tus neeg sawv cev tseem ceeb ntawm cov hlau no yog cov hlau cam dawb, uas yog siv rau hauv kev tsim kho tshuab rau kev tsim khoom, hauv kev lag luam thiab hauv lub neej txhua hnub.

Zoo

Cov hlau muaj xim dawb ntawm qhov tawg thiab cov yam ntxwv ntawm cov hlau nplaum. Cov qauv ntawm cov hlau cam dawb yog nplua-grained.

Properties

Piv nrog rau lwm yam hlau, hlau-carbon alloy muaj cov yam ntxwv thiab cov khoom nram qab no:

- siab brittleness;

- nce hardness;

- siab resistivity;

- qis casting zog;

- qis machinability;

- zoo tshav kub;

- loj shrinkage (txog 2%) thiab cov pwm tsis zoo;

- tsis tshua muaj kev cuam tshuam;

- siab hnav tsis kam.

Hlau loj muaj qhov zoo corrosion kuj hauv hydrochloric lossis nitric acid. Yog tias muaj cov carbide dawb hauv cov qauv, ces corrosion yuav tshwm sim thaum cam khwb cia hlau muab tso rau hauv sulfuric acid.

Cov cam khwb cia dawb, uas muaj feem pua ntawm cov pa roj carbon tsawg, suav tias yog cov hlau tiv taus ntau dua rau qhov kub thiab txias. Vim tias muaj zog txhua yam muaj zog thiab tawv tawv uas tshwm sim thaum raug kub hnyiab, kev tsim cov kab nrib pleb hauv castings raug txo kom tsawg.

Composition

Hlau-carbon alloy yog suav tias pheej yig dua li cov hlau. Dawb cam khwb cia hlau muaj hlau thiab carbon, uas yog nyob rau hauv ib tug chemically khi lub xeev. Cov pa roj carbon ntau, uas tsis muaj nyob rau hauv cov khoom sib tov ntawm hlau, muaj nyob rau hauv lub xeev ua ke nyob rau hauv daim ntawv ntawm hlau carbides (cementite), thiab nyob rau hauv alloyed cam khwb cia hlau nyob rau hauv daim ntawv ntawm tshwj xeeb carbides.

Views

Nyob ntawm tus nqi ntawm cov ntsiab lus carbon hauv cov hlau cam dawb, nws tau muab faib ua hom hauv qab no:

- Hyotectic tuav los ntawm 2.14% mus rau 4.3% carbon thiab tom qab ua tiav txias tau txais cov qauv ntawm perlite, theem nrab cementite thiab ledeburite.

- Eutectic muaj 4.3% carbon thiab muaj cov qauv nyob rau hauv daim ntawv ntawm lub teeb tom qab ntawm cementite, uas yog dotted nrog tsaus grains ntawm perlite.

- Hyotectic muaj los ntawm 4.3% mus rau 6.67% carbon hauv nws cov muaj pes tsawg leeg.

Daim ntawv thov

Raws li cov khoom saum toj no,Nws tuaj yeem txiav txim siab tias nws ua rau tsis muaj txiaj ntsig rau kev xyaum thermal thiab kev ua haujlwm ntawm cov hlau cam dawb. Lub alloy pom nws lub ntsiab daim ntawv thov tsuas yog nyob rau hauv daim ntawv ntawm ib tug casting. Yog li ntawd, hlau cam khwb cia dawb tau txais cov khoom zoo tshaj plaws tsuas yog tias txhua yam kev ua haujlwm tau ua tiav. Txoj kev ua haujlwm no yog siv tau yog tias tsim nyog los tsim cov khoom loj uas yuav tsum muaj qhov tawv tawv siab.

Ntxiv rau, cov hlau cam dawb yog annealed, ua rau cov hlau cam tuaj yeem, uas yog siv los ua cov phab ntsa nyias nyias, piv txwv li:

- automotive qhov chaw;

- khoom noj khoom haus;

- khoom rau tsheb laij teb, sib txuas, thiab lwm yam.

Cov hlau kuj tseem siv los ua daim hlau nrog ribbed lossis du nto, thiab kuj tseem siv los tsim cov hlau thiab grey hlau.

Kev siv cov hlau cam dawb hauv kev ua liaj ua teb ua cov hlau ua qauv yog qhov txwv. Feem ntau, hlau-carbon alloy yog siv los tsim cov khoom siv rau cov tshuab hydraulic, cov xuab zeb pov tseg thiab lwm cov txheej txheem uas tuaj yeem ua haujlwm nyob rau hauv cov xwm txheej ntawm kev hnav ntau dua.

Chilled cam khwb cia hlau

Cov hlau no suav tias yog hom hlau cam dawb. Nws yog ib qho ua tau kom ua tiav qhov txias ntawm 12-30 hli los ntawm kev ua kom txias ntawm qhov chaw ntawm cov hlau-carbon alloy. Cov khoom siv: qhov saum npoo yog ua los ntawm cov dawb, grey cam khwb cia hlau hauv cov tub ntxhais. Log, pob rau mills, dov yob yog tsim los ntawm cov khoom siv zoo li no, uas tau muab tso rau hauvcov tshuab ua cov ntawv hlau.

Alloying ntsiab ntawm alloy

Tshwj xeeb tshaj tawm cov khoom siv alloying ntxiv rau cov khoom ntawm cov cam khwb cia hlau tuaj yeem muab ntau dua hnav tsis kam thiab lub zog, corrosion kuj thiab kub ua haujlwm. Nyob ntawm seb muaj pes tsawg cov khoom ntxiv, cov hom cam khwb cia hlau no txawv:

- qis-alloy alloy (txog 2.5% auxiliary tshuaj);

- nruab nrab alloyed (ntawm 2.5% mus rau 10%);

- highly alloyed (ntau dua 10%).

Alloying ntsiab tuaj yeem ntxiv rau cov hlau:

- chrome;

- sulfur;

- nickel;

- tooj;

- molybdenum;

- titanium;

- vanadium,

- silicon;

- aluminium;

- manganese.

Alloyed dawb cam khwb cia hlau tau txhim kho cov khoom thiab feem ntau yog siv rau casting turbines, hniav, mills, qhov chaw rau cement thiab pa kilns, twj siv lub tshuab hniav, thiab lwm yam. Nws tuaj yeem nqa cov khoom mus rau qee yam tshuaj muaj pes tsawg leeg:

- hauv khob;

- nyob rau hauv qhov cub hluav taws xob.

Castings ua los ntawm cov hlau cam dawb yog annealed nyob rau hauv lub cub tawg kom stabilize qhov yuav tsum tau qhov ntev thiab txo qhov kev ntxhov siab. Qhov kub ntawm annealing tuaj yeem nce mus txog 850 degrees. Cov txheej txheem cua sov thiab cua txias yuav tsum tau ua kom maj mam.

Kev kos lossis kos npe ntawm cov hlau cam dawb nrog impuritiespib nrog tsab ntawv H. Qhov twg alloying ntsiab haum nyob rau hauv muaj pes tsawg leeg ntawm cov alloy yuav txiav txim tau los ntawm cov ntawv tom ntej ntawm lub cim. Lub npe yuav muaj cov lej uas qhia qhov feem pua ntawm cov khoom ntxiv uas haum rau cov hlau cam dawb. Yog tias lub cim muaj lub npe Ш, qhov no txhais tau hais tias cov qauv ntawm cov hlau muaj kheej kheej graphite.

Type of annealing

Rau qhov tsim ntawm cov hlau cam khwb cia dawb hauv kev lag luam, kev ua kom txias sai ntawm cov hlau yog siv. Niaj hnub no, cov hauv qab no tseem ceeb ntawm carbon alloy annealing yog nquag siv:

- softening annealing yog siv los ua kom ferrite nyob rau hauv cam khwb cia hlau muaj pes tsawg leeg;

- annealing los daws kev ntxhov siab sab hauv thiab txo qis theem hloov pauv;

- graphitizing annealing, ua rau malleable cam khwb cia hlau;

- normalization ntawm qhov kub ntawm 850-960 degrees, ua rau graphite thiab perlite, nrog rau kev hnav tsis kam thiab lub zog.

xov xwm ntxiv

Txog hnub tim, nws tau raug pov thawj tias tsis muaj kev sib raug zoo ntawm kev hnav tsis kam thiab hardness ntawm carbon alloy. Tsuas yog vim cov qauv, uas yog kev npaj ntawm carbides thiab phosphides nyob rau hauv daim ntawv ntawm ib tug tsis tu ncua daim phiaj los yog nyob rau hauv daim ntawv ntawm cov khaubncaws sab nraud povtseg, nce hnav tsis kam yog tiav.

Lub zog ntawm cov hlau cam dawb feem ntau cuam tshuam los ntawm cov pa roj carbon ntau, thiab qhov nyuaj yog nyob ntawm cov carbides. Qhov loj tshaj lub zog thiab hardness yog cov cam khwb cia hlau uasmuaj cov qauv martensitic.

Pom zoo:

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Yuav ua li cas ua noj cam khwb cia hlau los ntawm hluav taws xob vuam: ua hauj lwm technology thiab cov khoom tsim nyog

Lub ntsiab muaj pes tsawg leeg thiab hom cam khwb cia hlau. Qhov nyuaj thiab nta ntawm vuam cam khwb cia hlau cov khoom. Cam khwb cia hlau welding txoj kev. Kev npaj ua haujlwm ua ntej vuam. Yuav ua li cas ua noj cam khwb cia hlau los ntawm hluav taws xob vuam nyob rau hauv ib txoj kev txias thiab kub, nrog rau cov khoom siv roj. Cov yam ntxwv ntawm cov electrodes siv rau vuam cam khwb cia hlau. Kev ntsuas kev nyab xeeb thaum vuam

Txoj kab uas hla thiab qhov ntev ntawm cov kav dej cam khwb cia hlau. Hom thiab nta

Cov kav hlau cam tau siv niaj hnub no hauv kev tso cov kav dej tawm sab nraud thiab sab hauv. Cov khoom tuaj yeem yog channelless thiab channel. Lawv lub neej ua haujlwm tuaj yeem ncav cuag 100 xyoo. Kev sib txuas cov ntsiab lus thiab ntau yam ntawm cov kav dej phwj yog txiav txim siab los ntawm GOST 6942-98. Tom qab nyeem cov ntaub ntawv, koj yuav nkag siab tias cov kav dej yuav tsum muaj dab tsi

Alloy cam khwb cia hlau: qib, khoom thiab daim ntawv thov

Alloyed hlau yog ib yam khoom uas yog tsim los ntawm smelting nyob rau hauv blast furnaces. Nws tuaj yeem muaj cov pa roj carbon ntau sib txawv. Nyob ntawm seb muaj pes tsawg cov ntsiab lus ntawm cov khoom no, ob hom cam khwb cia hlau yog qhov txawv. Thawj yog hu ua hloov dua siab tshiab, los yog dawb, thiab lub thib ob yog grey, los yog foundry

Hom cam khwb cia hlau, kev faib tawm, muaj pes tsawg leeg, khoom, cim thiab daim ntawv thov

Cov hom cam khwb cia uas muaj nyob niaj hnub no tso cai rau ib tus neeg los tsim ntau yam khoom. Yog li ntawd, peb yuav tham txog cov ntaub ntawv no nyob rau hauv kom meej ntxiv nyob rau hauv tsab xov xwm no