2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

tinned tooj liab yog dab tsi? Cia peb pib nrog qhov tseeb tias tam sim no cov hlau no tau siv dav hauv ntau yam lag luam. Ntawm cov yam ntxwv tshwj xeeb ntawm cov hlau, uas piav qhia qhov kev thov rau nws, ib tus tuaj yeem nco ntsoov nws cov kev tiv thaiv rau sab nraud: nag lossis daus, kub hloov.

Tsis tas li, tooj liab sib piv nrog rau lwm cov hlau los ntawm nws cov thermal thiab hluav taws xob conductivity.

Distinguishing parameters

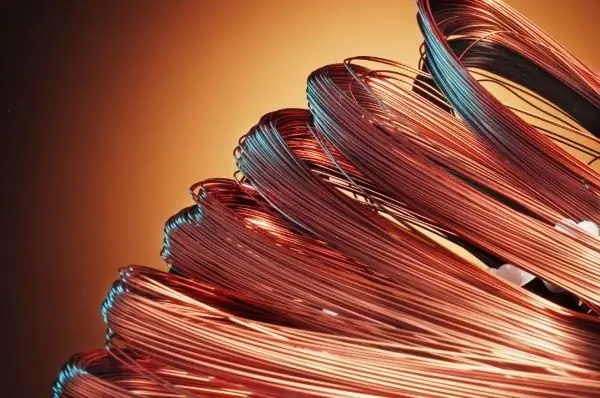

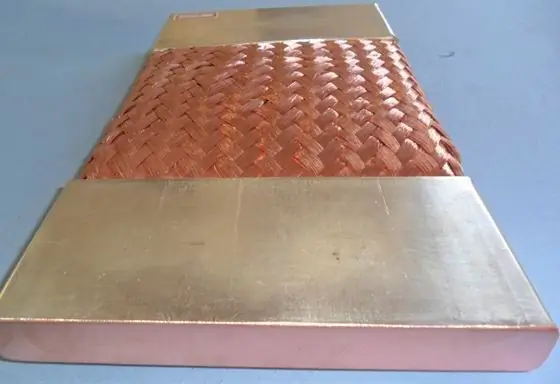

Tinned tooj liab muaj ductility siab thiab zoo heev machinability. Nws yog cov khoom siv no siv hauv hluav taws xob engineering rau kev tsim cov khoom siv hluav taws xob ntawm cov tooj liab cables, braids rau cov tub rog thiab cov khoom siv pej xeem.

Cia sim nrhiav seb qhov sib txawv ntawm tinned thiab untinned tooj liab. Thawj qhov kev xaiv yog kev tiv thaiv ntau dua los ntawm kev cuam tshuam sab nraud, txij li cov hlau yog npog nrog ib txheej ntawm tin. Cov hlau no tiv thaiv cov xov hlau los ntawm ib qho kev tshwm sim ntawm corrosion, muab cov khoom muaj zog tensile zog. Tinned tooj liab yuav tsis tawg thaum khoov.

Tau txais

Ua galvanized tinning. Nws ua rau nws muaj peev xwm siv tau nyias, txawm tias tin txheej (los ntawm 1 txog 20 microns) ntawm tooj liab. Lub thickness ntawm txheej thoob plaws hauv cov hlau yog tib yam, yog li tsis muaj "ob txoj kab uas hla" ntawm cov hlau.

Tinned tooj liab tam sim no muaj nyob rau hauv ob hom:

- tooj liab mos tinned hlau (MML);

- khoom tinned tooj liab hlau (MTL)

Ntse

Lub ntsiab qhov txawv ntawm lawv yog lub peev xwm khoov. Txoj kab uas hla ntawm tinned tooj liab nrog txhuas tuaj yeem sib txawv heev. Feem ntau siv hlau, nws txoj kab uas hla yog nyob rau hauv thaj tsam ntawm 0.02-9.42 hli.

Ua kom nws, siv cov tooj liab zoo tib yam rau ntawm lub kauj, ua rau nws ua rau galvanic tinning. Cov khoom yog dhau los ntawm ib tug tin da dej uas muaj molten tin. Yog li ntawd nws tsis nkag mus rau hauv oxidation nrog atmospheric oxygen, saum npoo ntawm da dej yog them nrog cov khoom uas tsis muaj peev xwm mus dhau huab cua. Tshwj xeeb, charcoal tuaj yeem yog cov khoom zoo li no.

Yuav kom nkag siab tias tinned tooj liab txhais li cas, cia peb ua tib zoo saib cov theem tseem ceeb ntawm cov txheej txheem txuas ntxiv mus. Ua ntej, cov hlau tooj liab, uas yog mounted rau ib tug tshwj xeeb feeder, yog ntxuav. Cov ntsiab lus ntawm cov txheej txheem yog dhau los ntawm cov txhuam tshwj xeeb txhuam moistened nrog cov tshuaj zinc chloride (cov ntsev no tau los ntawm reacting granulated zinc nrog hydrochloric acid).

Tom ntej no, cov xaim tau qis rau hauvtinning da dej, qhov twg tin nyob rau hauv daim ntawv molten, yog li ntawd, tinned tooj liab yog tau. Daim duab ntawm cov khoom tiav qhia txog qhov sib xws ntawm txheej txheej.

Nws yog ib qho tseem ceeb nyob rau theem no txhawm rau tiv thaiv qhov tshwm sim ntawm "sagging" ntawm cov hlau, vim lawv ua rau tsis lees paub ntau vim qhov sib txawv ntawm txoj kab uas tau tshaj tawm.

Nyob rau theem tom ntej ntawm kev tsim cov tinned hlau, cov khoom siv tau dhau los ntawm cov roj hmab txhuam (lawv txoj kab uas hla yuav tsum tsis pub tshaj 0.14 hli) lossis los ntawm kev kos duab nrog pob zeb diamond discs. Ib txoj kev zoo sib xws yog yuav tsum tau muab cov hlau saum npoo zoo ib yam.

Cov khoom yog txias los ntawm kev hla lub thawv dej txias. Cov xaim txias yog rov qab los ntawm kev kos duab nrog cov pob zeb diamond discs, tshem tawm cov seem "sagging".

Lub sijhawm kawg yog xaim pub rau lub tshuab txais. Ntawm no nws yog tsau rau ntawm ib tug tshwj xeeb kauj. Tau dhau los ntawm tag nrho cov saw hlau, cov hlau yog kiag li npaj txhij rau kev muag khoom lossis rau kev tsim tom ntej ntawm ib lub cable ntawm ntau ntu. Ua ntej cov tinned hlau xa mus rau cov neeg siv khoom, nws yuav tsum tau mus dhau cov txheej txheem tswj. Nws lub ntsiab yog ua kom tiav ntau yam haujlwm uas yuav ua pov thawj nws ua raws li TU 16-505.850-75.

Ntawm cov hlau nplaum

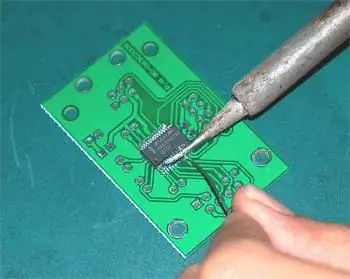

Lub ntsiab ntawm tinning yog los npog cov tooj liab nrog ib txheej nyias ntawm tin, uas tiv thaiv cov khoom los ntawm cov txheej txheem corrosive. Kev kho hlau soldering muaj qee qhov tshwj xeeb.

Ua ntej, nws yog ib qho tseem ceeb los npaj qhov chaw ua haujlwm. cojtshiab soldering hlau, sharpen lub ntsis ntawm lub cuab yeej. Ua li no, lub sting yog rub tawm, armed nrog ib tug soldering hlau los yog lub tshuab hluav taws xob, ntawm ib lub kaum sab xis ntawm txog 400, ces sharpening yog nqa tawm. Yog tias cov hlau nplaum tau npaj ua haujlwm nrog cov xov tooj cua me me, nws yuav tsum yog conical.

Pros pom zoo tias qhov dav ntawm lub ntsej muag ntse tsis tsawg tshaj li ib millimeter. Yog tias cov duab ntawm sting thov los ntawm cov chaw tsim khoom haum rau cov neeg siv khoom, koj tuaj yeem hla cov kauj ruam no. Txij li cov pas nrig hlau yog coated ntawm lub Hoobkas nrog patina - ntsuab tooj liab oxide, nws yog ib qho tseem ceeb kom tshem tawm cov txheej nrog abrasive khoom (sandpaper) ua ntej tinning. Tom ntej no, cov lus qhia rov qab mus rau lub cuab yeej, cov hlau soldering txuas nrog cov khoom siv hluav taws xob. Koj yuav tsum tau tos rau qhov chaw ntawm qhov sting kom sov kom sib npaug, thiab tom qab ntawd mus rau tinning.

Technology

Thaum lub sijhawm ua haujlwm, tooj liab thiab nws cov alloys muaj peev xwm tsim cov oxides nrog cov pa hauv huab cua. Txhawm rau tiv thaiv cov xwm txheej zoo li no, tooj liab yog tinned nrog tin. Txhawm rau ua cov txheej txheem no hauv tsev, koj yuav xav tau solder, soldering hlau, rosin lossis flux. Yuav kom tin lub tooj liab hlau zoo, nws yog ib qho tseem ceeb kom sov li cov hlau soldering zoo. Tus neeg xyuas pib yog ua ntej ntxuav ntawm rwb thaiv tsev, tshem tawm (nyob ntawm qhov xav tau) rwb thaiv tsev. Thaum ua hauj lwm nrog stranded hlau, twist nws ua ntej tinning.

Tom qab ntawd cov tub ntxhais tooj liab yog them nrog rosin, rhuab thoob plaws hauv lub ntim nrog cov hlau soldering. Tin tau muab tso rau ntawm qhov cua sov, nws muab faib rau tag nrho cov seem ntawm cov hlau, pre-kho nrog rosin.

Nyob hauv lub mloog pob ntseg, vim muaj kev ntxhov siab ntawm cov neeg kho tshuab, cov neeg siv hluav taws xob tsawg feem ntau tawg. Txij li thaum lawv muaj ib txoj kab uas hla me me, ib qho kev sib txawv me ntsis yog siv rau tinning. Siv ib tug soldering hlau nrog ib tug nyias ntsis, rosin, solder hlau. Ua ntej solder tawg xov hlau, ces mus rau solder ib tug tshiab hlau. Cov xov hlau yog them nrog ib txheej ntawm cov kua roj vanish (kom muab rwb thaiv tsev), yog li nws yog thawj zaug muab tshem tawm nrog ib tug rhuab soldering hlau thiab rosin. Tom qab ntawd lawv tau npog nrog ib txheej ntawm cov tin, uas ua kom yooj yim rau tom qab soldering.

Pom zoo:

CVG steel: muaj pes tsawg leeg, daim ntawv thov thiab cov yam ntxwv

Kawm metallurgy thiab tag nrho nws cov subtleties, koj tsis yeem pib muaj kev xav tsis thoob kom tau txais cov ntaub ntawv muaj txiaj ntsig ntau npaum li qhov ua tau thiab siv sijhawm me ntsis thiab siv zog li sai tau. Nyob rau hauv cov ntaub ntawv no, kab lus no tshwm sim. Nws muaj tag nrho cov ntaub ntawv tseem ceeb tshaj plaws ntsig txog CVG steel: txiav txim siab lub cim, kawm txog kev muaj pes tsawg leeg, kev siv cov hlau no, nrog rau kev mus ncig luv luv rau hauv cov hlau hloov pauv thiab txawv teb chaws analogues. Txhua yam koj xav tau nyob rau hauv ib qho chaw rau txhua tus neeg yooj yim

Rip-nres ntaub: nws yog dab tsi, muaj pes tsawg leeg, yam ntxwv, weaving threads thiab daim ntawv thov

Rip-stop ntaub - yog dab tsi? Qhov no yog cov khoom siv muaj zog uas muaj cov qauv sib xyaw ua ke nrog cov xov paj muaj zog. Nws muaj ntau yam kev hloov kho. Rip-stop ntaub yog siv los xaws txhua yam ntawm cov khaub ncaws thiab khoom siv rau kev ua si thiab kev ua kis las, expeditions thiab hiking, nuv ntses thiab yos hav zoov, zuag qhia tag nrho. Xav txog seb nws muaj pes tsawg leeg, nws muaj dab tsi

Polymer cement mortar: muaj pes tsawg leeg, cov yam ntxwv, kev ua raws li GOST cov cai, lub hom phiaj thiab daim ntawv thov

Polymer cement mortar yog ib qho kev hloov kho ntawm cov pa xuab zeb-cement mortar. Polymers kuj tuaj yeem muab ntxiv rau cov khoom sib tov uas siv thaum tso plaster thiab lwm yam khoom siv. Qhov sib ntxiv ntawm cov tshuaj no rau cov muaj pes tsawg leeg pab txhim kho nws cov yam ntxwv

Solder rau soldering tooj liab, txhuas, tooj dag, hlau, stainless hlau. Solder muaj pes tsawg leeg rau soldering. Hom solders rau soldering

Thaum nws yuav tsum tau ua kom ruaj khov ntau yam khoom sib txuas ua ke, soldering feem ntau xaiv rau qhov no. Cov txheej txheem no tau nthuav dav hauv ntau lub lag luam. Peb yuav tsum tau solder thiab tsev craftsmen

Pob zeb sib xyaw: cov khoom, muaj pes tsawg leeg, hom, qib ntawm pob zeb, yam ntxwv, ua raws li GOST cov qauv thiab daim ntawv thov

Ntawm cov khoom tseem ceeb ntawm cov pob zeb sib tov, uas tseem hu ua hydrotechnical pob zeb, nws yog ib qho tsim nyog los qhia txog qhov ua kom muaj dej ntau ntxiv. Cov vaj tse raug tsim los ntawm cov khoom siv no los siv rau hauv thaj chaw swampy lossis hauv cheeb tsam uas muaj dej nyab