2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2024-01-17 18:53

Ntau hom plastics muab sijhawm txaus los tsim qee yam qauv thiab qhov chaw. Nws tsis yog coincidence uas cov ntsiab lus no tau siv nyob rau hauv ntau yam: los ntawm mechanical engineering thiab xov tooj cua engineering mus rau tshuaj thiab kev ua liaj ua teb. Cov kav dej, tshuab qhov chaw, cov ntaub ntawv rwb thaiv tsev, cov khoom siv, thiab cov khoom siv hauv tsev tsuas yog qee yam ntawm ntau yam yas tuaj yeem tsim.

ntau yam tseem ceeb

Hom yas thiab lawv daim ntawv thov yog nyob ntawm seb cov polymers yog ntuj lossis hluavtaws. Lawv raug cua sov, siab, tom qab uas lawv yog molded khoom ntawm txawv complexity. Qhov loj tshaj plaws yog tias thaum lub sij hawm no manipulations cov duab ntawm cov khoom tiav yog khaws cia. Tag nrho cov yas yog thermoplastic, uas yog, thim rov qab, thiab thermoset (irreversible).

Reversible ua yas nyob rau hauv lub zog ntawm cua sov thiab ntxiv siab, thaum lub hauv paus kev hloov nyob rau hauv muaj pes tsawg leeg yog tsistshwm sim. Ib yam khoom uas twb tau nias thiab twb dhau los lawm yuav tsum tau softened thiab muab ib tug tej yam zoo li. Xws li hom yas (thermoplastic) li polyethylene thiab polystyrene paub. Thawj yog resistant rau corrosion thiab dielectric zog. Raws li nws, cov kav dej, cov yeeb yaj kiab, cov nplooj ntawv raug tsim tawm, nws tau dav siv los ua cov khoom siv insulating.

Los ntawm styrene rau polystyrene

Vim li cas ntawm cov polymerization ntawm styrene, polystyrene tau txais. Los ntawm nws, ntau qhov chaw yog tom qab tsim los ntawm casting los yog nias. Cov hom yas no tau siv dav rau kev tsim cov khoom loj thiab cov khoom, xws li cov khoom siv rau cov tub yees lossis chav dej. Ntawm cov thermosetting plastics, feem ntau siv yog xovxwm hmoov, laminates, fibers, uas tuaj yeem ua tiav ntxiv kom tau txais ntau qhov chaw.

Yas yog cov khoom siv yooj yim heev, raws li koj tuaj yeem tsim ntau yam khoom. Raws li cov khoom siv thermal, cov kev ua cov yas hauv qab no yog qhov txawv:

- nias. Qhov no yog txoj kev nrov tshaj plaws los tsim cov khoom los ntawm cov khoom siv thermosetting. Moulding yog nqa tawm hauv cov pwm tshwj xeeb hauv qhov kub thiab txias.

- Txhaj tshuaj molding. Txoj kev no ua rau nws muaj peev xwm tsim cov khoom ntawm ntau yam duab. Ua li no, cov thawv tshwj xeeb tau ntim nrog cov yas molten. Cov txheej txheem nws tus kheej yog cov khoom tsim tau thiab kev lag luam.

- Extrusion. Los ntawm kev ua haujlwm notau txais ntau yam khoom yas, xws li cov kav dej, xov, hlua, zaj duab xis rau ntau lub hom phiaj.

- tshuab tawm. Txoj kev no yog lub sijhawm zoo tshaj plaws los tsim cov khoom peb-seem uas yuav muaj cov seam ntawm qhov kaw ntawm pwm.

- stamping. Txoj kev no tsim cov khoom los ntawm cov ntawv yas thiab daim hlau siv cov duab tshwj xeeb.

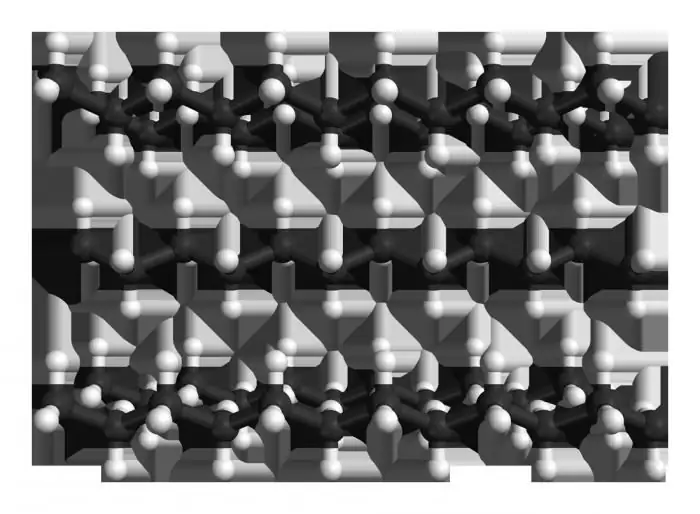

Cov yam ntxwv ntawm polymerization

Yas tuaj yeem tau txais los ntawm polymerization thiab polycondensation. Hauv thawj kis, monomer molecules khi los ua cov saw hlau polymer yam tsis tso dej thiab cawv; nyob rau hauv rooj plaub thib ob, cov khoom lag luam raug tsim uas tsis cuam tshuam nrog cov polymer. Ntau txoj hauv kev thiab hom polymerization ntawm plastics ua rau nws muaj peev xwm kom tau txais cov khoom sib txawv ntawm lawv cov khoom pib. Qhov tseeb qhov kub thiab txias ntawm cov tshuaj tiv thaiv ua lub luag haujlwm tseem ceeb hauv cov txheej txheem no kom cov khoom siv molding rau polymerize kom raug. Thaum lub sij hawm polymerization, nws yog ib qho tseem ceeb uas yuav tau xyuam xim rau cov residual monomer - qhov tsawg nws yog, qhov ntau txhim khu kev qha thiab ntev cov yas yuav ua hauj lwm.

Nyob zoo ib tsoom niam txiv kwv tij neej tsas sawv daws

Yog tias cov txheej txheem polymerization tau ua txhaum, qhov no tuaj yeem ua rau muaj qhov tsis xws luag hauv cov khoom tiav. Npuas, stains thiab muaj zog sab hauv yuav tshwm sim hauv lawv. Muaj ntau hom yas porosity:

- Gas. Nws tshwm sim vim qhov tseeb tias hom polymerization cuam tshuam, thiab benzoyl peroxide boils. Yog tias cov roj pores tsim nyob rau hauv lub thickness ntawm lub prosthesis, ces nws yuav tsum tau redone.

- Granular porosity tshwm sim vim muaj cov polymer ntau dhauhmoov, evaporation ntawm monomer los ntawm qhov chaw ntawm cov khoom, los yog tsis zoo sib xyaw ntawm cov yas compound.

- Compression porosity. Qhov tshwm sim vim qhov txo qis ntawm qhov ntim ntawm cov polymerizing huab hwm coj nyob rau hauv kev cuam tshuam ntawm lub siab tsis txaus lossis tsis muaj pwm pwm.

xav txog dab tsi?

Koj yuav tsum paub txog hom porosity plastics yog dab tsi, thiab zam qhov tsis xws luag hauv cov khoom kawg. Nws yog ib qho tsim nyog yuav tau them sai sai rau qhov zoo porosity ntawm qhov chaw ntawm lub prosthesis. Qhov no tshwm sim vim muaj ntau monomer, thiab lub porosity tsis raug rau kev sib tsoo. Yog hais tias ib qho kev ntxhov siab nyob sab hauv tsim thaum ua haujlwm nrog cov yas, cov khoom yuav tawg. Qhov xwm txheej no tshwm sim vim kev ua txhaum ntawm hom polymerization, thaum cov khoom nyob hauv dej kub npau npau ntev dhau.

Txawm li cas los xij, qhov tsis zoo ntawm cov khoom siv hluav taws xob ntawm cov khoom siv polymeric nws thiaj li ua rau lawv cov laus, thiab yog li cov cuab yeej tsim khoom yuav tsum raug soj ntsuam tag nrho.

Basic plastics - yog dab tsi?

Cov khoom siv hauv kev txiav txim siab yog siv dav hauv kev tsim cov hauv paus rau cov hniav cuav lamellar tshem tau. Cov hom nrov tshaj plaws ntawm lub hauv paus plastics muaj lub hauv paus hluavtaws. Mass rau hauv paus, raws li txoj cai, yog kev sib xyaw ntawm hmoov thiab kua. Thaum lawv sib tov, molding compound yog tsim uas hardens thaum rhuab los yog spontaneously. Nyob ntawm qhov no, tau txais cov khoom siv kub kub los yog nws tus kheej hardening. Kub kho puag resins suav nrog:

- etacryl (AKP-15);

- Acrel;

- fluorax;

- acronil.

Cov khoom siv los tsim cov hniav tshem tawm yog cov yas elastic, uas xav tau los ua cov ntaub qhwv ntsej muag rau cov hauv paus. Lawv yuav tsum muaj kev nyab xeeb rau lub cev, ruaj khov txuas nrog lub hauv paus ntawm cov prosthesis, tuav elasticity thiab ntim tas li. Ntawm cov yas no, yuav tsum tau them nyiaj rau eladent, uas yog ib lub hauv ob sab rau tshem tawm cov hniav cuav, thiab orthoxyl, uas tau txais los ntawm siloxane resin.

khoom siv

Cov hom yas tseem ceeb yog siv nyob rau hauv ntau qhov chaw ntawm kev tsim kho, nyob ntawm seb muaj pes tsawg leeg. Cov ntsiab lus nrov tshaj plaws suav nrog cov hauv qab no:

- polymer pob zeb. Qhov no yog cov yas sib xyaw, uas yog tsim los ntawm thermosetting polymers. Qhov zoo tshaj plaws ntawm lub cev thiab cov cuab yeej cuab tam yog cov pob zeb polymer raws li epoxy resins. Lub fragility ntawm cov khoom yog compensated los ntawm fibrous fillers - asbestos, fiberglass. Polymer concretes yog siv los tsim cov qauv uas tiv taus cov tshuaj.

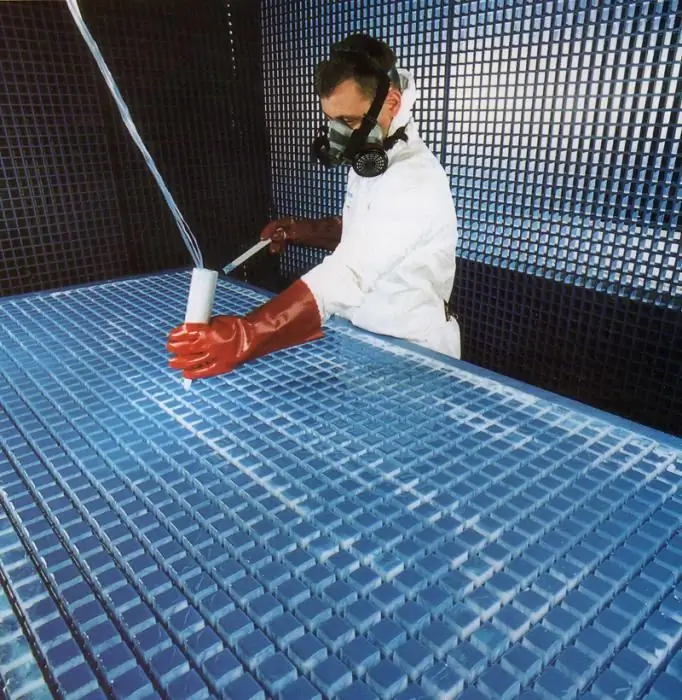

- GRPs yog hom niaj hnub ntawm lub tsev yas, uas yog cov ntaub ntawv ua los ntawm cov iav fibers, fabrics khi los ntawm ib tug polymer. Fiberglass yog tsim los ntawm oriented los yog tws fibers, nrog rau cov ntaub los yog lev.

- cov ntaub ntawv hauv pem teb. Lawv yog cov sawv cev los ntawm ntau hom yob txheej thiab cov kua-viscous compositions raws li polymers. Siv dav hauv kev tsim kholinoleum raws li polyvinyl chloride, uas muaj zoo thermal thiab suab rwb thaiv tsev. Seamless mastic pem teb tuaj yeem tsim raws li kev sib xyaw ntawm cov khoom siv raw nrog oligomers.

Yas thiab nws daim ntawv lo

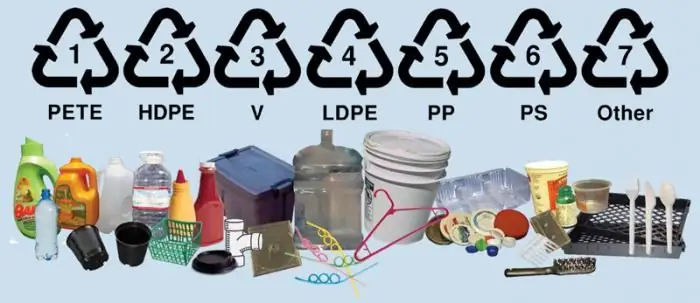

Muaj 5 hom yas uas muaj lawv tus kheej tsim:

- Polyethylene terephthalate (labeled PETE lossis PET). Nws yog kev lag luam thiab muaj ntau yam kev siv: nws yog siv los khaws ntau yam dej qab zib, roj, tshuaj pleev ib ce.

- High density polyethylene (cim li HDPE lossis PE HD). Cov khoom siv yog kev lag luam, lub teeb yuag, tiv taus qhov kub thiab txias. Siv los ua cov tais diav pov tseg, ntim khoom noj, hnab, khoom ua si.

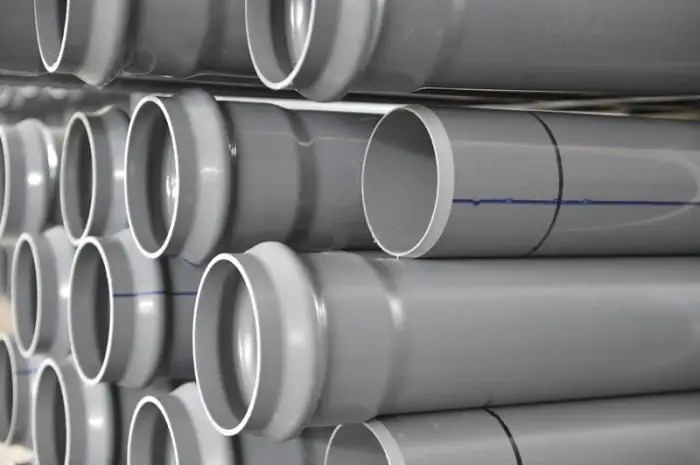

- Polyvinyl chloride (cim li PVC lossis V). Qhov rai profiles, rooj tog zaum, stretch qab nthab zaj duab xis, kav dej, pem teb npog thiab ntau yam yog tsim los ntawm cov khoom no. Vim cov ntsiab lus ntawm bisphenol A, vinyl chloride, phthalates, PVC tsis siv rau hauv kev tsim cov khoom (cov thawv, tais diav, thiab lwm yam) rau kev cia khoom noj.

- Polyethylene (LDPE lossis PEBD marking). Cov khoom pheej yig no yog siv los ua lub hnab khw, hnab khib nyiab, linoleum thiab CDs.

- Polypropylene (ntawv cim PP). Nws yog qhov ruaj khov, kub-resistant, haum rau kev tsim cov ntim khoom noj, ntim khoom noj, khoom ua si, koob txhaj tshuaj.

Cov yas nrov yog polystyrene thiab polycarbonate. Lawv tau pom daim ntawv thov dav hauv ntau yamkev lag luam.

thaj chaw thov

Ntau hom yas siv rau ntau yam kev lag luam. Nyob rau tib lub sijhawm, cov kev xav tau rau lawv yog kwv yees li qub - yooj yim ntawm kev ua haujlwm thiab kev nyab xeeb. Cia peb saib ze dua ntawm hom thermoplastic plastics thiab lawv daim ntawv thov.

| YPlastic | Scope of application |

| Polyethylene (siab thiab qis) | Kev ntim khoom, cov khoom tsis thauj khoom ntawm cov tshuab thiab khoom siv, rooj plaub, txheej, foils. |

| YPolystyrene | Kev tsim cov khoom siv, insulating films, styropian. |

| YPolypropylene | Pom dav daim ntawv thov hauv kev tsim cov kav dej, qhov chaw tsheb, cov khoom siv rau tub yees. |

| YPolyvinyl chloride (PVC) | Kev tsim cov khoom siv tshuaj, cov kav dej, ntau qhov chaw, ntim khoom, flooring. |

| YPolycarbonates | Kev tsim cov tshuab precision qhov chaw, cuab yeej, xov tooj cua thiab hluav taws xob engineering. |

Thermosetting hom yas (rooj)

| khoom | Scope of application |

| Phenoplasts | Siv los tsim cov khoom lag luam haberdashery (khawm, thiab lwm yam), ashtrays, plugs, sockets, xov tooj cua thiabxov tooj sets. |

| Aminoplasts | Siv rau cov kua nplaum ntoo, cov khoom siv hluav taws xob, cov khoom siv hluav taws xob, cov txheej nyias nyias rau kev kho kom zoo nkauj, cov ntaub ntawv ua npuas ncauj. |

| Fiberglass | Siv hauv kev tsim cov khoom siv hluav taws xob hluav taws xob hauv kev tsim kho tshuab, cov khoom loj loj ntawm cov duab yooj yim (lub cev tsheb, nkoj, ntsuas ntsuas, thiab lwm yam). |

| YPolyesters | Lub nkoj cawm siav, lub tsheb qhov chaw, rooj tog zaum, glider thiab helicopter hulls, corrugated ru boards, teeb ntxoov ntxoo, kav hlau txais xov masts, skis thiab ncej, nuv ntses pas nrig, kaus mom kev nyab xeeb thiab lwm yam yog tsim los ntawm polyesters. |

| Epoxy resin | Siv raws li cov khoom siv hluav taws xob hauv cov tshuab hluav taws xob, cov khoom siv hluav taws xob (raws li cov hluav taws xob hluav taws xob hluav taws xob) thiab lwm yam khoom siv, hauv kev tsim cov xov tooj fittings, hauv xov tooj cua engineering (rau kev tsim cov ntawv luam tawm). |

Siv qhov xaus

Nyob rau hauv kab lus no, peb tau saib cov hom yas thiab lawv daim ntawv thov. Thaum siv cov ntaub ntawv zoo li no, ntau yam raug coj mus rau hauv tus account, xws li lub cev thiab cov khoom siv kho tshuab rau cov yam ntxwv ntawm kev ua haujlwm. Rau tag nrho nws cov nqi-zoo, yas muaj ib theem txaus ntawm kev nyab xeeb, uas ua rau nws nthuav dav ntawm nws daim ntawv thov.

Pom zoo:

Cov ntaub ntawv xa tuaj: tus kheej xaj, daim ntawv them nqi, daim ntawv xaj, cov ntaub ntawv xa khoom thiab cov chaw xa khoom xa tuaj

Kev ua haujlwm hauv kev xa khoom yog nrov heev niaj hnub no, tshwj xeeb tshaj yog cov tub ntxhais hluas muaj siab nyiam. Tus neeg xa xov tsis yog ib tus neeg xa khoom xwb, tab sis yog tus kws tshaj lij uas muaj kev txawj ntse thiab tuaj yeem nqa parcel los yog xa mus rau qhov chaw nyob uas tau teev tseg nrog cov khoom zoo thiab sai

Daim ntawv thov rov qab los ntawm kev tuav pov hwm qiv nyiaj: piv txwv, cov cai ntawm daim ntawv thov, lub sijhawm xa tawm

Nyob rau hauv tus txheej txheem ntawm tau txais cov nyiaj qiv, cov tsev txhab nyiaj muaj peev xwm qiv nyiaj los xaus daim ntawv cog lus pov hwm. Yog tias tus neeg siv tsis tuaj yeem them cov nuj nqis, lub luag haujlwm kaw nws mus rau lub txhab nyiaj yog nrog lub tuam txhab pov hwm. Tab sis hauv kev xyaum, qhov xwm txheej tsis sib xws feem ntau tshwm sim, thiab cov neeg them nyiaj siab xav tau xav txog qhov muaj peev xwm rov qab tau txais kev pov hwm qiv nyiaj thaum them rov qab ntxov. Tab sis yuav tau txais ntau npaum li cas? Thiab leej twg yuav tsum muab cov nyiaj - tus tuav pov hwm lossis lub txhab nyiaj?

Yuav ua li cas kom tau nyiaj ntawm daim ntawv cog lus: kev kwv yees thiab kev tsom xam ntawm kev lag luam daim ntawv cog lus, daim ntawv cog lus yield

Yuav ua li cas kom tau nyiaj ntawm daim ntawv cog lus? Ib lo lus nug cuam tshuam rau ntau yam. Tom qab tag nrho, kev yuav daim ntawv cog lus yog suav tias yog kev nqis peev uas muaj txiaj ntsig. Txawm li cas los xij, cov neeg uas nkag siab lub ntsiab lus no tseem tsawg. Nws yuav zoo li cov lus nug ntawm yuav ua li cas kom tau nyiaj ntawm daim ntawv cog lus yuav tsum muaj cov lus teb yooj yim. Tom qab tag nrho, qhov tseeb, nws yog ib qho kev ruaj ntseg uas cov nyiaj tau los twb embedded. Tab sis nyob rau hauv kev xyaum, txhua yam hloov mus ua me ntsis nyuaj

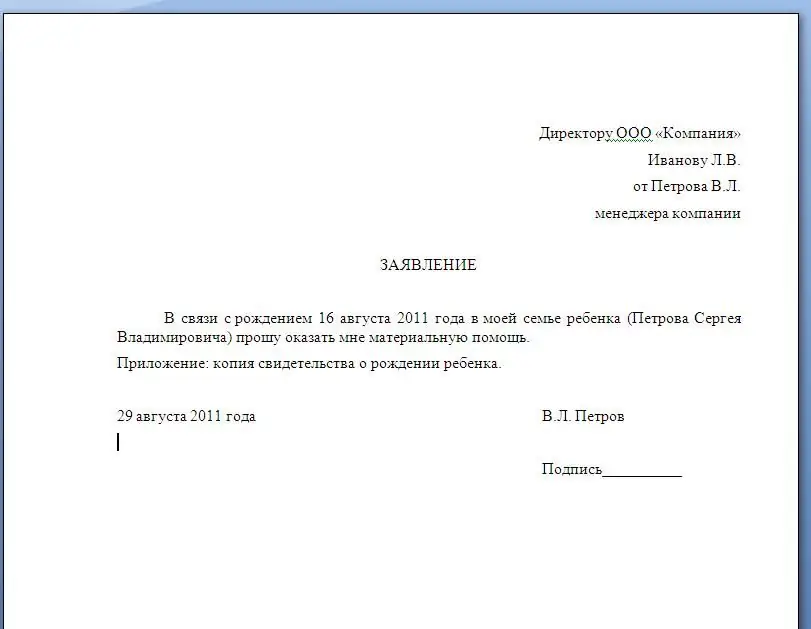

Daim ntawv thov kev pab nyiaj txiag: qauv thiab daim ntawv sau nrog piv txwv, hom kev pab nyiaj txiag

Kev pabcuam khoom siv yog muab los ntawm kev ua haujlwm rau ntau tus neeg ua haujlwm uas muaj cov xwm txheej tseem ceeb hauv lawv lub neej. Cov kab lus muab cov qauv ntawv thov rau kev pab nyiaj txiag. Piav qhia txog cov cai rau muab cov nyiaj them rau tus tswv ntiav haujlwm

Tshaj tawm ntawm phab ntsa daim ntawv qhia hnub: hom, xaiv cov ntsiab lus ntawm daim ntawv qhia hnub, nuances ntawm kev tsim thiab luam ntawv

Daim ntawv qhia hnub yog ib qho tseem ceeb ntawm txhua qhov chaw ua haujlwm. Thiab txawm tias muaj pes tsawg tus neeg siv khoom thiab cov neeg muag khoom pub dawb rau lawv, lawv tseem ua khawv koob los ntawm lub tuam txhab cov chaw ua haujlwm uas tsis koom nrog kev sib txuas lus nrog cov neeg cog lus. Cias muab, daim ntawv qhia hnub yog qhov tseem ceeb tshaj plaws ntawm cov ntaub ntawv tshaj tawm uas ib txwm mus nrog lub suab nrov