2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Fretting corrosion yog raws li lub cev thiab tshuaj txheej txheem tshwm sim ntawm qib molecular. Thaum thawj theem, electrochemical kev puas tsuaj predominates. Nyob rau hauv cheeb tsam kev sib cuag ntawm cov hlau (los yog hlau uas tsis yog-hlau), oxides yog tsim, vim hais tias txhua yam hnav yog qhib. Ob txheej txheem no muaj kev sib raug zoo thiab cuam tshuam rau cov yam ntxwv ntawm lub zog ntawm cov rooj sib txoos. Qhov tshwm sim ntawm fretting tau kawm los ntawm cov kws tshawb fawb tau ntau tshaj li ib puas xyoo, tab sis nws qhov kev kwv yees tseem tsis zoo.

Kev piav qhia

Fretting corrosion yog ib qho ntawm ntau hom kev puas tsuaj ntawm cov hlau. Cov txheej txheem no tshwm sim ntawm qhov sib cuam tshuam ntawm kev sib cuag nrog cov hlau-hlau lossis hlau-nonmetal khub. Nws cov yam ntxwv feature yog lub xub ntiag ntawm oscillatory txav ntawm me amplitude. Fretting corrosion cuam tshuam tsis tsuas yog carbon steels, tab sis kuj corrosion-resistant steels.

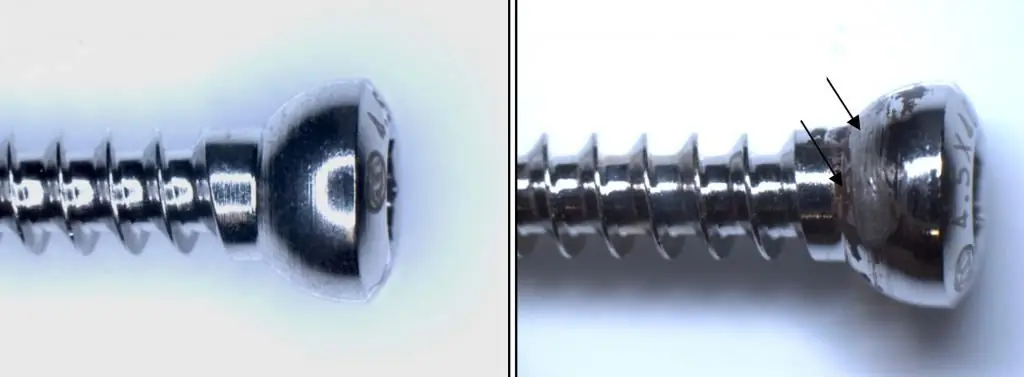

Rau qhov tshwm sim ntawm qhov tshwm sim no, lub voj voog loj ntawm tsuas yog 0.025 microns txaus. Nws tus nqi siab tshaj plaws tuaj yeem yog 200-300 microns. Sab nraud, kev puas tsuaj yog tshwm sim nyob rau hauv cov tsos ntawm me me ulcers, rubbing, tearing,xim pob zeb, hmoov deposits ntawm qhov chaw tiv tauj.

Oxide-zoo li corrosion khoom ntawm steel qhov chaw muaj xim sib txawv - los ntawm reddish mus rau tsaus xim av. Nws nyob ntawm hom khoom siv thiab kev ua haujlwm. Lawv tsis tuaj yeem tawm ntawm thaj chaw sib cuag vim yog qhov me me ntawm qhov oscillations ntawm kev sib nrig sib txav ntawm qhov chaw, vim tias lawv cov nyhuv abrasive tau txhim kho.

Qhov tsis zoo tshaj plaws ntawm qhov tshwm sim no yog qhov qaug zog tsis ua haujlwm ntawm qhov chaw. Lub peev xwm los nkag siab txog cov loads cyclic hauv cov nodes yog txo mus txog 5 zaug.

Hnav nta

Fretting corrosion muaj qhov sib txawv hauv qab no los ntawm lwm hom kev hnav thiab tsim kua muag:

- hlau puas tshwm sim nyob rau hauv reciprocating motion.

- Localization ntawm kev puas tsuaj - tsuas yog nyob rau hauv kev sib cuag ntawm qhov chaw.

- Tsawg mus ncig ceev hauv ob khub.

- Kev puas tsuaj ntawm cov yeeb yaj kiab oxide tshwm sim vim yog tangential (tangential) rog.

- Kev tawg ntawm vuam txuas hniav thaum lub sij hawm teeb tsa ntawm qhov chaw ua rau detachment ntawm atoms thiab cov tsos ntawm qaug zog tawg.

- Teared tawm hlau hais sai sai oxidize hauv huab cua.

- Cov khoom lag luam Corrosion tau koom nrog hauv cov txheej txheem hnav ntxiv.

Cas thiab mechanism ntawm qhov tshwm sim

Simplistically, cov txheej txheem ntawm fretting corrosion tuaj yeem sawv cev raws li hauv qab no:

- Tsiv thiab deform nto.

- Hlau oxidation.

- Kev puas tsuaj ntawm oxidemovies.

- Discovery ntawm ntshiab hlau.

- Nws tuav nrog qhov chaw tiv tauj.

- Kev rhuav tshem choj.

- Npaj oxygen concentration hauv qhov chaw qhib.

- Kev rov ua dua ntawm lub voj voog corrosion, maj mam nce hauv qhov tsua.

Raws li qhov tshwm sim ntawm kev ua haujlwm abrasive ntawm cov khoom sib cais, qhov kub thiab txias hauv thaj chaw tiv tauj kuj tseem nce siab (qee zaum txog 700 ° C). Ib txheej dawb yog tsim, muaj cov qauv hlau hloov pauv.

Cov laj thawj tseem ceeb hauv qab no ntawm fretting corrosion raug txheeb xyuas:

- Tsawg amplitude dynamic loads hauv kev sib txuas ruaj khov.

- Nkauj sab nraud ib puag ncig.

- ntsuas kub.

Qhov xwm txheej ntawm cov txheej txheem corrosion nyob ntawm seb nws nyob ntawm theem twg. Thaum pib, qhov tseem ceeb ntawm cov tshuaj tiv thaiv oxidative vim electrochemical kev sib cuam tshuam tau raug kaw. Cov txheej txheem no yog qeeb los ntawm kev siv tshuaj lom neeg muaj pes tsawg leeg uas ua rau tsis muaj zog ntawm kev ua phem rau ib puag ncig. Peb yuav tham txog dab tsi corrosion inhibitors hauv qab no.

Lub xeev kev ntxhov siab ntawm cov khoom siv muaj peb yam - lub zog compressive coj mus rau qhov chaw sib cuag, hloov cov kev ntxhov siab thiab kev sib txhuam. Hnav thaum fretting corrosion muaj tus yam ntxwv ntawm qaug zog tsis ua hauj lwm. Cov kab nrib pleb me me sib koom ua ke thaum lub sijhawm thiab cov hlau tawg tawm.

Khoom tsim

Fretting corrosion yam ntxwv ntawm cov khoom sib dhos,nominally immovable. Feem ntau, kev puas tsuaj ntawm cov hlau yog pom nyob rau hauv cov nram qab no hom pob qij txha:

- Bolted.

- Riveting.

- Slotted.

- Hu rau hluav taws xob.

- Castle.

- Toothed Hirth.

- Flanged.

- Squeeze haum (bearings, discs, log, ncej txuas, qag thiab log hubs).

- Caij nplooj ntoos hlav bearing nto thiab lwm yam.

Fretting corrosion ntawm bolted pob qij txha yog tshwm sim los ntawm hnav ntawm threaded ib feem thiab cov tsos ntawm leaks nyob rau hauv qhov sib txawv. Qhov no yog yooj yim los ntawm kev txo qis thaum lub sijhawm ua haujlwm, nws tus kheej unscrewing ntawm pob qij txha vim kev co loads. Txawm li cas los xij, qhov nce ntawm qhov nruj torque tsis yog ib qho kev lav phib xaub ntawm kev txo qis hauv corrosion, txij li qhov no tsis kam vuam ntawm qhov chaw yuav tshwm sim. Raws li qhov tshwm sim, kev ua haujlwm ntawm cov xov txuas yuav tshwm sim hauv cov xwm txheej tsis zoo ntawm tensile stresses.

Fracture intensity

Tus nqi ntawm fretting corrosion nyob ntawm ntau lub kaum os yam. Qhov tseem ceeb tshaj plaws yog:

- Ambient cua (corrosion sai dua hauv huab cua). Qhov tshwm sim no kuj pom nyob rau hauv lub tshuab nqus tsev, nitrogen thiab helium.

- Amplitude thiab zaus ntawm oscillatory txav (kev sib txhuam nrawm). Kev sib raug zoo ntawm tus nqi tawg thiab amplitude yog yuav luag linear.

- Siab (load) hauv thaj chaw tiv tauj thiab lwm yam kev ua haujlwm. Nrog rau kev thauj khoom loj, qhov tob ntawm kev puas tsuaj nce.

- Hardness ntawm lub hauv paus hlau thiab tiv thaiv txheej ntawm qhov chaw, roughness ntawm kev sib cuagnto.

- Technological yam tseem ceeb (txoj kev tau txais lub workpiece, residual stresses, machining raug thiab rigidity ntawm lub assembled los ua ke).

- Cov khoom ntawm cov khoom oxide tshwm sim los ntawm hnav.

- Kub. Feem ntau, nws cov txiaj ntsig tsis zoo ua rau muaj kev cuam tshuam ntau dua. Qhov ntsuas kub zoo cuam tshuam rau kev ua haujlwm ntawm chav tsev tsuas yog mus txog rau qee qhov tseem ceeb. Thaum overheated, tus nqi ntawm kev puas tsuaj nce.

- Abrasion tsis kam ntawm cov khoom hnav.

Txoj kev tawm tsam

Txoj kev zoo tshaj los daws qhov tshwm sim no tsis muaj nyob. Txhawm rau txo nws, cov kev ntsuas hauv qab no tau ua:

- Txo cov txheeb ze hloov chaw los ntawm kev ua kom muaj kev sib txhuam. Nce roughness, siab los yog hloov cov configuration ntawm qhov chaw. Thawj txoj kev yog qhov ua tau zoo tshaj plaws yog tias ib qho ntawm cov ntsiab lus tsis yog hlau. Kev sib txhuam kuj tuaj yeem nce los ntawm electroplating nrog tooj liab, tin lossis cadmium.

- Yog tias qhov kev tshem tawm ntawm kev co tsis tuaj yeem ua tsis tau, tom qab ntawd txoj kev rov qab yuav tsum tau - txo qhov kev sib txhuam quab yuam los ntawm kev siv phosphate, txhuas lossis indium coatings, nrog rau kev qhia cov roj nplua nyeem. Raws li ib feem ntawm tom kawg, nws raug pom zoo kom siv cov tshuaj tiv thaiv corrosion. Txoj kev no hloov cov swb mus rau qhov chaw nruab nrab.

- Ua kom lub zog ntawm ib qho ntawm cov khoom (kub kho, kho tshuab hardening). Qhov kev ntsuas no txo qhov kev sib nrig sib adhesionmating nto thiab txo hnav.

Roj thiab roj raws li lubricants zoo txo qhov hnav. Feem ntau, lawv cov hom zoo ib yam yog siv - cov khoom uas, ntawm qhov kub ntawm 25 ° C, yog cov khoom tuab, zoo li tshuaj pleev. Phosphate thiab anodic hlau coatings pab txhawb rau nws tuav ntawm qhov chaw.

Dab tsi yog cov tshuaj tiv thaiv corrosion

Nyob rau hauv rooj plaub ntawm cov khoom puas tsuaj los ntawm hom fretting hnav, tiv tauj hom inhibitors feem ntau yog siv. Lawv ua kom qeeb corrosion nyob rau hauv ib qho kev txhoj puab heev, thiab lub hauv paus ntsiab lus ntawm lawv qhov kev ua yog raws li kev tsim ntawm sparingly soluble compounds nrog hlau ions.

Cov tshuaj tiv thaiv muaj xws li chromates, nitrites, benzoates, phosphates thiab lwm cov tebchaw. Sau qhov sib txawv nrog cov ntaub ntawv yas ntawm cov mating qhov chaw tsis tsuas yog tiv thaiv lawv los ntawm corrosion, tab sis kuj txhawb kev sib khi. Hu rau inhibitors suav nrog cov tshuaj "Vital", SIM, M-1 thiab lwm yam. Ib daim ntawv teev cov inhibitors thiab cov lus pom zoo rau lawv siv tuaj yeem pom hauv GOST 9.014-78.

Pom zoo:

Tread tiv thaiv corrosion. Txoj hauv kev tseem ceeb los tiv thaiv cov kav dej los ntawm corrosion

Kev tiv thaiv corrosion yog ib qho kev daws teeb meem thoob ntiaj teb thaum nws yuav tsum tau ua kom cov hlau tsis kam mus rau ya raws thiab lwm yam sab nraud

Corrosion ntawm aluminium thiab nws cov alloys. Cov txheej txheem rau kev sib ntaus sib tua thiab tiv thaiv aluminium los ntawm corrosion

Txhuas, tsis zoo li hlau thiab hlau, yog qhov tiv taus corrosion heev. Cov hlau no tiv thaiv los ntawm xeb los ntawm cov yeeb yaj kiab oxide tuab uas tsim los ntawm nws qhov chaw. Txawm li cas los xij, nyob rau hauv cov ntaub ntawv ntawm kev puas tsuaj ntawm lub tom kawg, cov tshuaj lom neeg kev ua si ntawm txhuas zoo heev nce

Pitting corrosion: ua rau. Txoj kev tiv thaiv cov hlau los ntawm corrosion

Thaum lub sijhawm ua haujlwm ntawm cov khoom siv hlau, lawv raug rau ntau hom kev puas tsuaj, ntawm cov pitting corrosion sawv tawm raws li qhov txaus ntshai tshaj plaws thiab tsis muaj kev cia siab

Tiv thaiv txoj cai ntawm tus neeg ua lag luam. Cov qauv thiab cov txheej txheem ntawm kev tiv thaiv cov cai ntawm cov neeg ua lag luam

Nyob rau hauv peb lub sijhawm, tsis yog txhua tus neeg ua lag luam paub txog kev tiv thaiv txoj cai ntawm tus neeg ua lag luam, tab sis qhov no yog cov ntaub ntawv tseem ceeb uas tuaj yeem siv tau ntau zaus hauv kev khiav lag luam ntawm lawv tus kheej

Kev qhia txog kev tiv thaiv kev ua haujlwm rau tus kws tshaj lij ntawm kev tiv thaiv kev ua haujlwm, khoom siv ua haujlwm

Yuav luag txhua lub lag luam loj muaj tus kws tshaj lij tiv thaiv kev ua haujlwm. Lub ntsiab lus ntawm nws txoj haujlwm yog tswj hwm cov qauv kev nyab xeeb hauv lub koom haum. Tsis muaj qhov tseem ceeb yog qhov muaj cov ntaub ntawv tshwj xeeb hu ua "Kev Tiv Thaiv Kev Ua Haujlwm". Tag nrho cov no yuav tau tham ntxiv