2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Nyob rau hauv txhua lub tshuab uas siv shafts los actuate, yeej ib txwm muaj kev sib txuas thiab hu ua iav txuas.

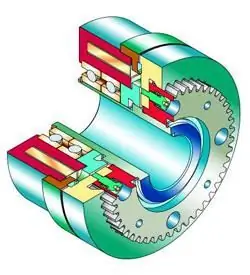

Yog tias muaj ob lub shafts uas yuav tsum tau txuas nrog tib lub axis lossis ntawm lub kaum sab xis rau ib leeg, ces txoj hauv kev zoo tshaj plaws los hloov cov khoom thauj thiab quab yuam yog ib qho kev sib txuas ib nrab uas siv lub iav txuas. Ib qho kev sib txuas ib leeg yog ntsia rau ntawm qhov xwm txheej uas tsuas yog kev hloov pauv angular tau tso cai nyob nruab nrab ntawm cov ncej. Yog tias muaj kev xav tau los them nyiaj rau radial lossis axial hloov pauv, ces ob qhov txuas ib leeg raug teeb tsa. Cov iav coupling tau nce kev ntseeg tau thiab muaj peev xwm zoo, vim nws tau nruab nrog ntau cov hniav. Xws li couplings ua haujlwm zoo hauv cov txheej txheem nrog kev sib hloov ceev (cranes, khoom siv conveyor).

Couplings ua tiav cov txiaj ntsig zoo rau radial, angular thiab axial hloov chaw ntawm cov ncej, vim tias muaj cov kev tshem tawm sab nraud hauv kev sib koom tes thiab ntawm cov hniav ntawm tus kheej bushings. Txhua qhov chaw uas tsim cov coupling yog ua los ntawm cov hlau: rau ib tug ncej nrog ib txoj kab uas hla mus txog 140 mm - forged, thiab rau loj diameters - cam khwb cia. Txhawm rau kom hnav tsis kam ntawm cov hniav, lawv raug kho kom sov, thiab hauvlub clutch yog txhaj nrog cov roj khov.

Hauv paus ntsiab lus, lub iav clutch muaj ntau yam sib xws nrog kev sib kis ntawm cardan, txawm hais tias nws muab kev them nyiaj rau kev hloov pauv me me, tab sis nws muaj ntau lub zog rau ib chav tsev ntim.

Gear Coupling Features

Cov iav txuas muaj ob lub txuas txuas txuas nrog cov bolts thiab ob lub bushings tso rau hauv lub nruas tawb. Nruab nrab ntawm lawv tus kheej, lawv koom nrog cov hniav ntawm ib tug kheej kheej. Xws li couplings yog standardized raws li GOST 5006-55 rau shafts nrog diameters ntawm 40 mus rau 560 mm. Kuj tseem muaj lwm cov qauv rau cov iav txuas uas siv rau kev sib koom ua ke hauv txhua lub tebchaws CIS, nyob ntawm qhov torque, piv txwv li, GOST R 50895-96 (Russia), DSTU 2742-94 (Ukraine).

Kev siv ntau yam thiab ntau yam uas yuav tsum tau siv rau cov couplings tau ua rau lub fact tias niaj hnub no couplings tau muab faib ua ob peb pawg raws li lawv tsim nta.

Yog li, raws li lub hauv paus ntsiab lus ntawm kev ua haujlwm, cov clutches tau muab faib ua ntu zus, sib txuas thiab tswj tus kheej, thiab raws li qhov ua haujlwm ntawm kev ua haujlwm - nruj thiab elastic.

Raws li kev ua tiav, muaj cov sib txuas nrog lub tawb sib cais (cov iav txuas GOST 5006-55-MZ), nrog rau ib lub tawb thiab nrog cov ncej nruab nrab (GOST 5006-55 - MZP).

Rau qhov luv luv ntawm ncej, bushings yog tsim rau kev sib txuas raws li GOST 12080 nrog lub qhov cylindrical, thiab raws li GOST 12081 - nrog conical qhov.

Kuj iav txuas tuaj yeem tsim tau raws li cov neeg siv khoom tshwj xeeb. Yog tias tus neeg siv khoom xav tau ib qho tshwj xeeb iav coupling, daim duab kos yuav tsum raug qhia txhua qhov tsim nyogparameters.

Thaum mounting couplings, qee qhov kev txiav txim siab tshwj xeeb yuav tsum tau soj ntsuam, tshwj xeeb, mounting ntawm ncej yuav tsum tau nqa tawm nrog cua sov me ntsis.

Tsis ntev los no, iav couplings ua los ntawm cov khoom siv polymer (kapron, caprolon) tau nquag siv. Ua kom elasticity thiab muaj peev xwm ua kom sib npaug sib npaug ntawm cov khoom thauj ntawm cov hniav, muab tso rau ntawm ib qho sib npaug nrog cov hlau. Tsis tas li ntawd, polymer couplings yog cov khoom siv hluav taws xob ntau dua thiab raug nqi zoo.

Pom zoo:

Autoclaved aerated qhob: ntau lawm, Scope, khoom nta

Hom pob zeb no tau ntev tau nyob rau hauv cov npe ntawm thawj cov khoom siv hauv tsev. Yog li ntawd, ntau lub Hoobkas thiab tuam txhab lag luam tau koom nrog nws cov khoom siv. Nrog rau kev txhim kho thev naus laus zis, koj tuaj yeem pom autoclaved aerated qhob hauv ntau yam duab, qhov ntau thiab tsawg thiab xim

Robotization ntawm ntau lawm nyob rau hauv lub ntiaj teb no: Scope, piv txwv, pros thiab cons

Txhim kho, tib neeg ib txwm ua kom yooj yim rau nws tus kheej, hloov mus rau kev txawj ntse. Robotization ntawm kev tsim khoom ua rau nws muaj peev xwm tshem tawm ntau txoj haujlwm, piv txwv li, kev pabcuam xov tooj niaj hnub no tsuas yog ua los ntawm cov khoom siv hluav taws xob, txawm tias thaum pib ntawm lub xyoo pua xeem, poj niam xov tooj txuas nrog ob tus neeg siv khoom. Niaj hnub no, kev vam meej tau nce mus ntxiv, thiab tib neeg tau pib tsim cov cav tov tiag tiag uas muaj peev xwm ua tau qee yam kev ua haujlwm - robots

Hom pob zeb crushed: piav qhia, yam ntxwv, Scope thiab keeb kwm

Pob zeb crushed yog ib lub pob zeb crushed thiab muab faib ua feem raws li nws loj. Cov yam ntxwv xws li flakiness, ceev, Frost tsis kam, feem, radioactivity cuam tshuam rau thaj tsam ntawm kev siv gravel thiab nws cov nqi

Carbon yog Carbon: piav qhia, Scope, nta thiab tshuaj xyuas

Carbon yog cov khoom siv niaj hnub siv hauv ntau yam kev lag luam thiab lwm qhov chaw ntawm tib neeg lub neej. Peb yuav tham txog cov khoom lag luam nthuav dav tshaj plaws hauv kev nthuav dav ntau li ntau tau hauv kab lus

Flange plugs: Scope thiab tsim nta

Flange plugs yog cov qauv tsim tsim los npog txhua yam ntawm qhov kawg qhib ntawm cov kav dej thiab txoj kev loj