2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Cov kev ua haujlwm ntawm cov ntaub ntawv hauv ib puag ncig hnyav inevitably yuam cov neeg siv xav txog kev tiv thaiv tshwj xeeb ntawm lub hom phiaj cov khoom thiab cov qauv. Cov no tuaj yeem yog kev tsim kho, kev lag luam, nrog rau kev siv hauv tsev thiab lwm qhov chaw uas yuav tsum tau muaj kev tiv thaiv kev tawm tsam. Ib txoj hauv kev zoo tshaj los daws qhov teeb meem no yog cladding. Qhov no yog ib qho ntawm cov txheej txheem ntawm txheej txheej sab nraud ntawm qhov chaw thiab cov qauv, uas nyob rau hauv peb lub sij hawm tab tom ntsib ib puag ncig tshiab ntawm kev loj hlob.

Technology overview

Lub hom phiaj tseem ceeb ntawm cladding yog los tsim cov txheej txheem ntawm qhov chaw ua haujlwm uas tuaj yeem muab cov haujlwm tiv thaiv tau teev tseg los ntawm qhov project. Ntawm cov tom kawg, hluav taws tsis kam, lom ruaj khov, Frost tsis kam, thiab lwm yam tuaj yeem hais tau. Qee zaum, cov khoom tshiab tau ntxiv, xws li insulatingzoo los yog nce hluav taws xob thiab thermal conductivity. Dab tsi yog cladding nyob rau hauv cov nqe lus ntawm kev siv tswv yim?

Qhov no yog txheej txheem ntawm kev tsim cov txheej txheem tshiab thiab cov txheej txheem ua haujlwm ntawm qhov chaw, uas tuaj yeem ua tau ntau yam. Peb tuaj yeem tham txog cov txheej txheem ncaj qha lossis overlay, tab sis nws yog cov txheej txheem ntawm kev tsim cov txheej txheem uas muaj qhov sib txawv. Classical txoj hauv kev rau cladding koom nrog thermomechanical tsim ntawm lub plhaub tiv thaiv, tab sis niaj hnub no, nrog rau qhov tshwm sim ntawm cov ntaub ntawv tshiab, cov txheej txheem ntawm cov txheej txheem ntawm kev tiv thaiv txheej kuj hloov.

Kev Npaj Ua Haujlwm

Txhawm rau tsim cov txheej txheem ua haujlwm ntawm qhov chaw ntawm cov khoom lag luam, cov xim zoo ib yam nrog ib lossis lwm cov khoom siv kuj tso cai. Cladding, ntawm qhov tod tes, hais txog kev tiv thaiv sab nraud uas cuam tshuam txog kev nkag mus rau hauv cov qauv ntawm lub hom phiaj nto. Cov nyhuv no ntawm kev sib xyaw ua ke ntawm cov txheej txheem ua haujlwm thiab cov khoom siv hauv paus tsuas yog ua tiav los ntawm kev ua haujlwm thermal, uas tuaj yeem nthuav tawm hauv ntau hom. Vim li no, cladding ntawm hlau nto yog feem ntau nrog kub-lub sij hawm vuam, ua raws li los ntawm deformation ntawm lub workpiece.

Lwm yam tseem ceeb ntawm cladding yog nws ntau txheej xwm. Cov qauv tsim tsis yog homogeneous txheej ntawm ib lossis lwm cov khoom siv tiv thaiv, tab sis los ntawm ob peb txheej heterogeneous uas muaj cov kev taw qhia sib txawv. Tsis tas li ntawd, qee qhov ntawm cov khaubncaws sab nraud povtseg yuav muaj lub hom phiaj ua haujlwm dav dav (kev tiv thaiv hluav taws kub, tiv thaiv kub, biosecurity), thiab lwm qhov ua haujlwm tshwj xeeb hauv cov qauv.txheej, piv txwv li, tsim cov nplaum nplaum rau cov txheej txheem ntawm cladding.

Clading technique

Kev ua haujlwm cladding tuaj yeem ua tau ob qho tib si hauv ib qho kev sib cais thiab ua ib feem ntawm cov txheej txheem thev naus laus zis ntawm kev tsim khoom lossis kev ua haujlwm ntawm ib feem. Nyob rau hauv ob qho tib si, txoj kev yooj yim ntawm kev siv thev naus laus zis suav nrog txheej txheej los ntawm txheej txheej ntawm cov alloys ntawm lub hom phiaj nto. Nyob rau hauv rooj plaub ntawm cov hlau, qhov kev ua haujlwm no yog nqa tawm thaum kub dov, kos duab lossis nias. Nyob rau theem ntawm seam kev twb kev txuas, lub cladding technology muab rau thermal deformation, uas tsim tej yam kev mob rau lub diffusion ntawm ib tug kub billet.

Nyob rau hauv txoj kev no, tag nrho pawg ntawm cov hlau tuaj yeem raug superimposed thiab fused, suav nrog steel, tooj liab, aluminium, corrosion-resistant alloys, thiab lwm yam. Nyob rau theem tam sim no ntawm kev txhim kho thev naus laus zis, nws kuj tau xyaum ua kom muaj cov txheej txheem polymer ywj siab. thiab kev hloov kho uas txhim kho tus kheej cov khoom siv txheej.

Kev siv daim kab xev nplaum

txhawm rau txhawm rau txhim kho cov txheej txheem thev naus laus zis ntawm cladding, lub tswv yim ntawm kev tso cov txheej txheej tiav tiav tau tsim. Nws yog sawv cev los ntawm ib tug bimetallic sawb, uas muaj nyob rau hauv nws cov qauv ob peb heterogeneous khaubncaws sab nraud povtseg tau los ntawm txias dov. Lub hauv paus ntawm lub workpiece no yog tsim los ntawm ob qho tib si ferrous hlau thiab cov ntaub ntawv sib xyaw, uas yog siv rau hauv daim ntawv ntshiab hauv tshuab-tsev, hluav taws xob, khoom noj khoom haus, tshuaj thiabLwm yam kev lag luam.

Cov pa roj carbon tsawg yog yuav luag siv los ua lub hauv paus rau daim kab xev, ua tsaug rau cov txheej txheem cladding tseem ceeb - qhov no yog ib hom kev sib txuas nruab nrab, cov yaj uas txuas cov khoom ua haujlwm thiab cov txheej txheem ua haujlwm. ntawm daim kab xev. Los ntawm txoj kev, qhov sib txawv ntawm multilayer tapes ntawm hom no tsis txwv rau txoj hauv kev rau cov txheej txheem ntawm cov cuab yeej txheej thiab npog cov spectrum ntawm cov dej num ntawm cov txheej txheem tshiab. Ntawm lub plhaub cladding, cov chav ua haujlwm thiab cov khoom xws li cov khoom siv tam sim no, cov lus qhia, kev sib cuag bimetallic, txiav riam, hluav taws xob clamps, thiab lwm yam tuaj yeem muab tso rau hauv.

YLaser cladding technique

Kev cog lus kev coj ua ntawm kev siv cladding nrog cov hauv paus ntsiab lus ntawm cov roj vuam. Raws li lub thermal qhov chaw, ib tug laser beam yog siv, uas ua kom lub xeev ntawm cov yaj ntawm lub workpiece thiab cov active khoom. Cov khoom siv raw rau laser cladding feem ntau yog hmoov, uas tuaj yeem muab piv rau cov flux siv hauv cov roj vuam. Qhov no yog lub hauv paus ntawm cov yaj, uas tsim ib txheej nyias ua haujlwm raws li qhov tshwm sim ntawm laser raug. Raws li cov roj sib tov, lawv cov khoom siv ua lub luag haujlwm pabcuam hauv kev tiv thaiv thaj chaw ua haujlwm los ntawm qhov tsis zoo ntawm cov pa oxygen.

Powder cladding

Kev sib tov ntawm chromium, tungsten thiab npib tsib xee kuj tuaj yeem suav tias yog lub hauv paus ywj pheej rau cladding, tsis tas yuav cuam tshuam nrog laser yaj tshuab. Cov hmoov sib tov sib xyaw tshwj xeeb xaiv rauib qho txheej txheem ntawm kev ua haujlwm yog siv rau cov hlau los ntawm cov tshuaj cladding. Qhov no yog ib qho kev thauj mus los hauv cov tshuaj alkali-raws li ionic yaj.

Ncaj nraim, txheej txheem txheej nrog cov hmoov molten yuav siv sij hawm 30-40 feeb ntawm qhov kub ntawm li 700 ° C. Lub complexity ntawm no technology nyob rau hauv ntau lawm tej yam kev mob nyob rau hauv qhov yuav tsum tau mus cuag loj tshwj xeeb cov cuab yeej nrog crucibles thiab high-temperature furnaces.

Txhim kho cov txheej txheej cladding

Zoo li ntau lwm hom txheej txheej, lub hauv paus cladding tsoo lub sijhawm, yuav tsum tau kho dua lossis kho. Kev kho ib nrab ntawm cov txheej txheej txheej yog ua los ntawm kev siv roj-thermal, electro-thermal lossis plasma txau. Lub hauv paus rau kev txau tuaj yeem yog tib lub flux ua los ntawm cov ntaub ntawv sib xyaw lossis cov hlau alloys. Kev ntub dej rov qab cladding kuj tau nthuav dav.

Cov no yog cov qauv tshwj xeeb uas muaj cov hlau ultrafine lossis soluble hlau, lawv cov tebchaw lossis alloys. Tom qab daim ntawv thov nyob rau hauv kev cuam tshuam ntawm qee qhov kub thiab txias, cov tshuaj polymerizes, thiab tom qab ob peb teev cov txheej tshiab tuaj yeem muab tso rau hauv kev ua haujlwm tag nrho.

Zaj lus

Nyob hauv ntau thaj chaw ntawm kev lag luam hauv lub tebchaws, kev lag luam thiab kev tsim kho, kev hloov kho tshwj xeeb ntawm cov khoom siv yuav tsum tau siv, txawm li cas los xij, vim kev lag luam thiab kev tsim khotsis yog txhua txoj hauv kev los txhim kho cov yam ntxwv ntawm lub hom phiaj workpiece tuaj yeem siv. Niaj hnub nimno cladding txoj kev tseem tseem nyob tsis tau rau ntau tus neeg siv khoom siv vim yog tus nqi siab thiab kev siv thev naus laus zis nyuaj ntawm lawv qhov kev siv.

Ntawm qhov tod tes, qhov piv txwv ntawm ntau txheej kab xev qhia tau hais tias nws muaj peev xwm ua tau rau ib txhij txhim kho kev ua haujlwm ntawm cov txheej txheem thiab ua kom yooj yim rau cov txheej txheem ntawm nws tsim nyob rau saum npoo ntawm cov khoom kawg. Txawm li cas los xij, qhov kev tsim kho tshiab no tseem pom tsuas yog hauv qee qhov kev lag luam ntsig txog kev tsim cov khoom siv hluav taws xob.

Pom zoo:

Pob kws silage: cultivation, harvesting and storage technology

Pob kws silage yog ib qho khoom noj muaj txiaj ntsig uas tuaj yeem tsim lub hauv paus ntawm kev noj zaub mov ntawm ntau yam tsiaj thiab noog. Txawm li cas los xij, nws txoj kev sau qoob loo yog txheej txheem nyuaj uas yuav pab tau ntau tus neeg ua liaj ua teb kom nkag siab

Dab tsi yog qhov project technology? Kev tsim kho ntawm ib qhov project technology. Piv txwv ntawm ib qhov project technology

Raws li ib feem ntawm tsab xov xwm, peb yuav pom tias qhov project thev naus laus zis yog dab tsi, thiab tseem ua haujlwm tawm cov teeb meem ntawm nws txoj kev loj hlob

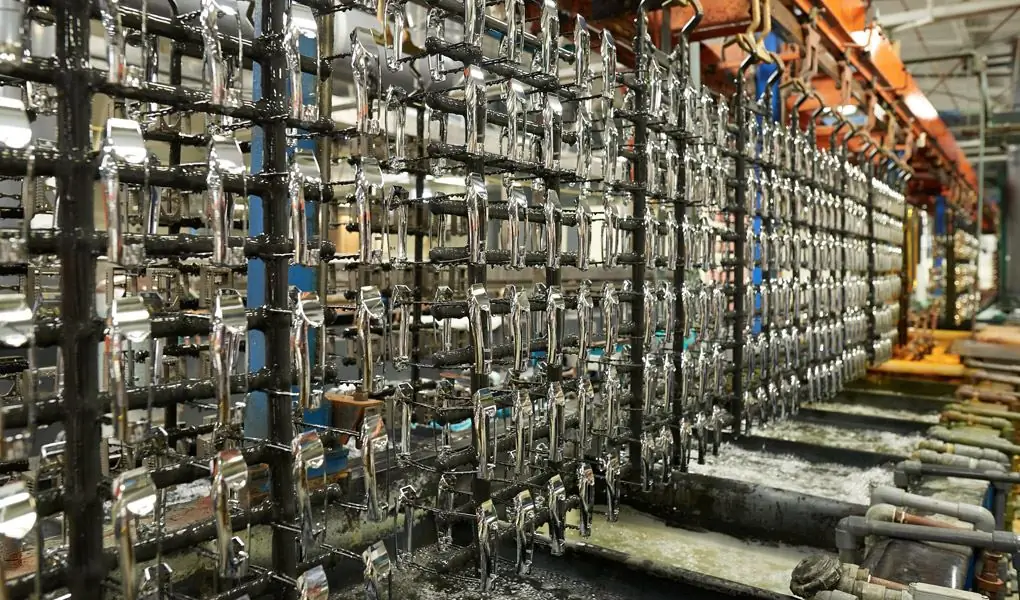

Chrome plating qhov chaw. Chrome qhov chaw hauv Moscow. Chrome qhov chaw hauv St. Petersburg

Chrome plating ntawm qhov chaw yog lub sijhawm los muab lawv lub neej tshiab thiab ua rau lawv txhim khu kev qha thiab ua haujlwm zoo

Hom, nta ntawm kev teeb tsa thiab kev siv cov khoom siv rau chromium plating

Cov kab lus tau mob siab rau cov khoom siv chromium plating. Cov yam ntxwv ntawm cov khoom siv no, cov txheej txheem chrome plating, thiab lwm yam

Tshuaj nickel plating - nta, thev naus laus zis thiab cov lus pom zoo

Technologies rau metallization ntawm qhov chaw thiab cov qauv yog dav nyob rau hauv ntau qhov chaw ntawm kev lag luam thiab kev tsim kho. Ib txheej txheej ntxiv tiv thaiv qhov chaw los ntawm kev puas tsuaj sab nraud thiab cov yam ntxwv uas ua rau muaj kev puas tsuaj tag nrho ntawm cov khoom. Ib qho ntawm cov kev kho mob zoo li no yog cov tshuaj npib tsib xee plating, cov yeeb yaj kiab muaj zog uas yog qhov txawv ntawm cov neeg kho tshuab thiab corrosion kuj thiab muaj peev xwm tiv taus qhov kub ntawm qhov kev txiav txim ntawm 400 ° C