2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Qhov cuam tshuam ntawm hluav taws xob arc ntawm cov qauv ntawm cov khoom siv yog ib txoj hauv kev qub tshaj plaws kom tau txais kev sib txuas ntawm cov hlau ua haujlwm. Thawj cov txheej txheem thev naus laus zis rau txoj kev vuam no muaj ntau qhov tsis zoo cuam tshuam nrog lub porosity ntawm vuam thiab tsim cov kab nrib pleb hauv qhov chaw ua haujlwm. Txog niaj hnub no, cov tuam ntxhab ntawm cov cuab yeej siv thiab cov cuab yeej pabcuam tau ua kom zoo dua rau txoj kev siv hluav taws xob arc vuam, nthuav dav qhov kev siv.

Technology overview

Tus qauv yog tsim los ntawm MMA (Kev Taw Qhia Hlau Arc), uas tuaj yeem txiav txim siab raws li phau ntawv nplaum electrode vuam. Kev ua haujlwm yog ua raws li kev tswj hwm ntawm cov hluav taws xob tam sim no nkag mus rau thaj chaw lub hom phiaj los ntawm qhov chaw tshwj xeeb txuas nrog lub network. Tam sim no yog nkag mus rau qhov chaw yuav tsum tau welded los ntawm ob cables ntawm txawv polarity. Qhov tseeb, kaw ntawm hluav taws xob Circuit Court thiab provokes tsim ntawm arc,Cov nyhuv thermal ntawm cov hlau melts thiab tsim ib lub pas dej ua ke.

Tom qab qhov kawg ntawm kev kub ntxhov, thaj chaw ua haujlwm txias, thiab nws cov qauv crystallizes. Ib qho tseem ceeb ntawm kev siv tshuab hluav taws xob arc vuam yog cov electrode. Raws li txoj cai, qhov no yog ib tug steel pas nrig muab ib txheej nrog ib tug tej yam tshuaj muaj pes tsawg leeg. Raws li cov hluav taws xob arc siv, cov qauv ntawm lub bar kuj yaj thiab poob rau hauv qhov chaw ua haujlwm, tsim cov khoom siv nrog ib qho qauv nrog cov khoom ua haujlwm.

Ignition ntawm arc raws li thawj kauj ruam ua haujlwm

Raws li twb tau hais lawm, qhov pib ntawm thermal raug tshwm sim los ntawm kev kaw ntawm hluav taws xob hluav taws xob. Lub arc nws tus kheej, nyob ntawm qhov siv tam sim no, tuaj yeem ua tau los ntawm kev maj mam dipping, steeply dipping, los yog lub zog tam sim no-voltage. Nws tshwm sim los ntawm kev siv tam sim no rau lub electrode thiab qhov chaw ntawm lub workpiece. Tam sim no dhau los ntawm ob yam khoom, tom qab uas muaj hluav taws xob arc tsim ntawm lawv.

Qhov kev zoo siab heev ntawm cov txheej txheem tshwm sim nyob rau hauv ntau txoj kev. Nyob rau hauv ib rooj plaub, arc vuam yog pib los ntawm luv luv kov lub workpiece nrog ib tug ceev breakaway nrog lub bar. Thiab nyob rau hauv lwm yam, striking touches yog ua nrog tib sib cais ntawm tej yam nyob deb. Nyob rau hauv cov ntaub ntawv no, kev ruaj ntseg ntawm vuam yuav nyob ntawm qhov tseeb ntawm kev tswj qhov kev ncua deb ntawm cov electrode thiab lub workpiece. Yog tias qhov kev ncua deb dhau mus, lub arc yuav nres. Hloov pauv, tso tus pas nrig dhau los ze rau ntawm qhov yuav tsum tau welded tuaj yeem ua rau cov ntaub ntawv lo ua ke. Kev xaivQhov kev pom kev deb nyob ntawm qhov degree ntawm elasticity ntawm lub arc nws tus kheej, uas kuj yog txiav txim los ntawm qhov tam sim no-voltage chaw ntawm cov cuab yeej. Cov kws ua haujlwm paub txog tuaj yeem kho qhov kev ncua deb ntawm qhov kev tso cai, yog li cuam tshuam rau ob qho tib si kev ua haujlwm ntawm cov yaj thiab qhov nkag mus ntawm cov hlau.

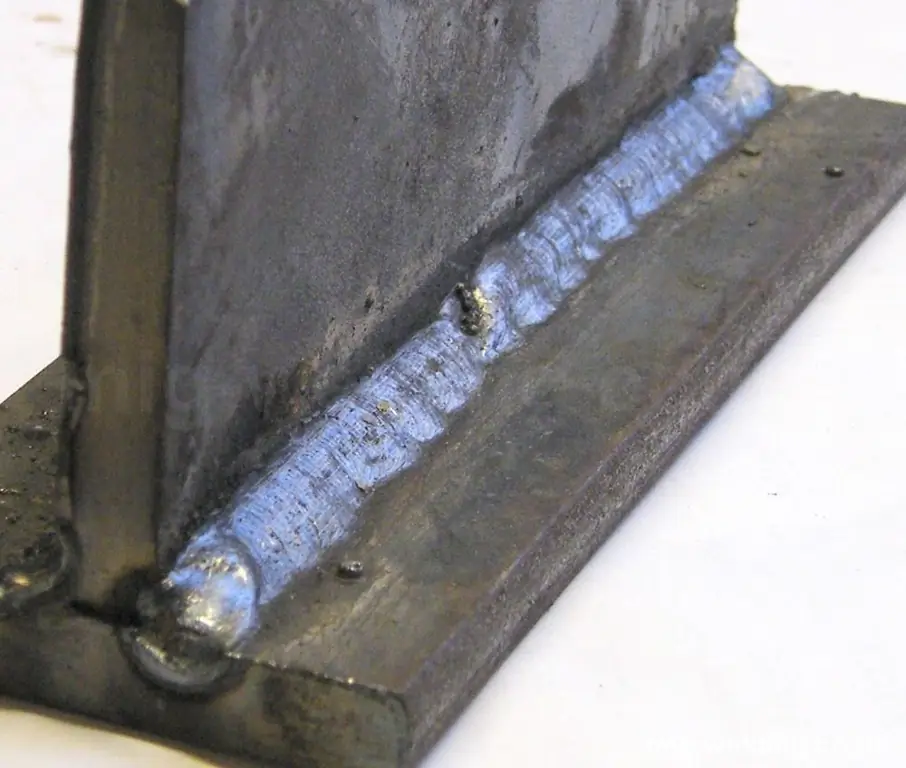

txheej txheem vuam

Qhov uas twb tau hais lawm tam sim no yog koom nrog hauv kev ua haujlwm, hom uas yuav raug txiav txim siab cais, thiab ob lub cables nrog cov polarity sib txawv. Ib tug cable xaus nrog ib tug electrode tuav, thiab lwm yam nrog ib tug davhlau ya nyob twg clamp, uas yog tsau rau ntawm lub workpiece. Raws li qhov tshwm sim ntawm thermal nyhuv ntawm qhov pib arc, cov hlau melts nyob rau hauv lub pas dej ua ke. Raws li cov txheej txheem no ua tiav, kev hloov pauv ntawm cov tee ntawm cov khoom siv hluav taws xob kuj tau ua tiav - me me thiab poob loj. Ntawm no nws yog ib qho tsim nyog los qhia txog qhov tseem ceeb ntawm cov txheej txheem bar. Cov tshuaj muaj pes tsawg leeg ntawm cov txheej yog txiav txim siab tsis ntau los ntawm cov kev xav tau rau kev cuam tshuam nrog hluav taws xob arc, tab sis los ntawm kev cuam tshuam ntawm cov qauv ntawm cov seam, uas yuav txais cov khoom ntawm cov txheej los ntawm cov tee melting.

Nyob rau hauv cov txheej txheem ntawm hluav taws xob arc vuam, txheej txheej ntawm cov electrode kuj raug kub hnyiab, uas ua rau muaj cov khoom tiv thaiv gaseous. Kev tsim cov huab uas tsis tso cai rau cov teeb meem cuam tshuam los ntawm ib puag ncig yog qhov sib txawv ntawm qhov niaj hnub mus rau MMA vuam. Tom qab qhov hluav taws xob arc nres, cov txheej txheem ntawm solidification thiab crystallization ntawm cov tsim compound pib.

Nyob ntawm seams tsim

Muaj ntau qhov kev faib tawm ntawm cov seams uas tuaj yeem tau txais hauv cov txheej txheem ntawm qhov vuam no. Piv txwv li, qab nthab, ntsug thiab kab rov tav kev sib txuas yog qhov txawv ntawm txoj hauj lwm. Nyob rau hauv lem, ntsug seams txawv nyob ntawm qhov kev taw qhia - downhill thiab uphill. Kab rov tav pob qij txha yog kab tias qhov nyuaj tshaj plaws, txij li cov hlau yuav poob los ntawm qhov chaw vuam mus rau sab qis ntawm lub workpiece. Vim tib yam, lub sab saum toj yuav raug txiav.

Kev sib txuas tsis tu ncua thiab tsis tu ncua yog qhov txawv ntawm lawv qhov ntev. Cov qub tau siv ntau heev vim tias lawv txuag cov peev txheej thiab sijhawm. Cov khoom sib txuas ntawm hluav taws xob arc vuam yog siv nyob rau hauv rooj plaub uas nws yog ib qho tsim nyog los xyuas kom meej qhov siab ntawm kev ntseeg siab thaum sib koom ua ke ob qhov tseem ceeb. Kev sib txuas sib txuas tsis tshua muaj zog, tab sis hauv qee qhov xwm txheej nws ua rau nws tus kheej.

Tseem muaj kev faib tawm los ntawm convexity. Qhov ntsuas no nyob ntawm qhov ntim ntawm cov hlau tso. Muaj convex, ib txwm thiab concave seams. Nyob rau tib lub sijhawm, ib tus yuav tsum tsis txhob cia siab tias qhov muaj ntau ntawm cov overlay xws li ua kom lub zog thiab kav ntev ntawm kev sib txuas. Nyob rau hauv qhov kev txiav txim siab loads thiab vibrations, xws li seam poob rau kev sib koom ua ke ntawm ib txwm qauv.

Transformers rau MMA vuam

Qhov no yog qhov chaw thoob ntiaj teb thiab hloov pauv ntawm cov hluav taws xob tam sim no, uas kuj yog siv hauv cov vuam flux thiab cov ntshav plasma ntawm cov hlau. Cov cuab yeej zoo li no yooj yim hauv kev tsim, unpretentious hauv kev saib xyuas thiab txhim khu kev qha. Management txawmcov qauv niaj hnub no feem ntau yog siv tshuab. Cov khoom siv ntawm cov khoom siv yog lub kauj nrog lub qhov txhab hlau - lub hauv paus uas hloov cov hluav taws xob tam sim no rau hauv qhov hluav taws xob tsim nyog rau cov haujlwm tshwj xeeb. Nws yog ib qho tseem ceeb kom nco ntsoov tias kev ua hauj lwm nrog hluav taws xob arc vuam nyob rau hauv transformer fais fab mov yuav tsum tau siv cov alternating tam sim no, uas yuav tsum tau kev txawj ntse los ntawm tus neeg teb xov tooj.

Inverter devices

Cov thev naus laus zis tshaj plaws, siv tau yooj yim thiab siv tau los txhawb kev vuam niaj hnub. Nws muab kev khiav hauj lwm hauv DC tej yam kev mob, ua rau kom muaj feem tau txais ib tug du thiab huv seam txawm rau ib tug beginner. Qhov tseem ceeb tshaj, hluav taws xob arc vuam nrog lub inverter tso cai rau koj siv lub tsev network rau lub zog yog tias nws muaj peev xwm muab tam sim no los ntawm 16 A txog 25 A. Feem ntau, qhov no yog qhov kev daws teeb meem zoo tshaj plaws rau kev xav tau ntiag tug thaum tsim nyog los ua cov khoom siv. nyob rau hauv ib lub chaw nres tsheb, nteg hlau txheej, thiab lwm yam e. Cov kws tshaj lij kuj tuaj yeem siv cov khoom siv inverter rau argon-arc vuam, nthuav dav cov khoom siv ua haujlwm.

Arc Vuam Rectifiers

Cov khoom siv zoo li no tau siv los hloov cov khoom siv tam sim no los ntawm AC rau DC, kuj tseem ua rau kev siv cov seams zoo. Qhov sib txawv tseem ceeb ntawm cov khoom siv tam sim no yog kev sib txuam nrog ntau hom electrodes. Nrog rau qhov kev txhawb nqa no, arc vuam tshuab tuaj yeem siv rau kev ua haujlwm hauv kev tiv thaiv roj av - piv txwv li, yog tias tus pas nrig yog ua los ntawm cov hlau lossisnon-ferrous hlau. Qhov tsis zoo ntawm rectifiers muaj xws li qhov loj me, loj loj thiab, vim li ntawd, kev nyuaj rau kev thauj mus los. Yog li ntawd, cov chaw tsim khoom, ua ib qho ntxiv, muab cov platform khiav nrog lub log kom yooj yim txav ntawm lub cuab yeej.

Pros of thev naus laus zis

Qhov kev teeb tsa ntawm txoj kev vuam no tiv thaiv keeb kwm yav dhau los ntawm ntau txoj hauv kev yuav zoo li qub thiab tsis muaj txiaj ntsig, txawm li cas los xij, nyob rau hauv lub moj khaum ntawm lub tswv yim no, nws muaj peev xwm los npaj qhov ua tau yuav luag txhua hom hlau. Versatility yog lub ntsiab kom zoo dua ntawm MMA txoj kev. Kuj tseem muaj qhov ntxiv rau ntawm lub cev ergonomics ntawm kev ua haujlwm. Qhov no tsis yog hais tias phau ntawv arc vuam yog qhov yooj yim, tab sis lub peev xwm ua haujlwm hauv txhua txoj haujlwm thiab hauv qhov chaw kaw yog qhov tseem ceeb heev.

Cais, nws tsim nyog hais txog kev ywj pheej ntawm sab nraud atmospheric thiab kub ntawm kev ua haujlwm. Cov txheej txheem tuaj yeem teeb tsa hauv tsev thiab sab nraum zoov. Yog tias peb tab tom tham txog kev xav tau ntau ntxiv rau qhov zoo ntawm qhov vuam, tom qab ntawd cov cuab yeej tso cai rau kev siv cov xov xwm tiv thaiv kom tsis txhob muaj cua nkag mus rau hauv lub pas dej weld, uas txo qhov kev pheej hmoo ntawm qhov tsis xws luag.

Cons of thev naus laus zis

Txoj kev pheej yig heev ntawm lub koom haum, uas tsis tuaj yeem tab sis ua rau muaj ntau yam tsis zoo. Piv txwv li, tsis suav nrog cov txheej txheem niaj hnub ntawm cov txheej txheem automation thiab kev tswj hluav taws xob ntawm tus kheej ntawm cov khoom siv hluav taws xob hloov lub luag haujlwm rau qhov zoo ntawm cov seam rau tus neeg teb xov tooj. Los ntawm nws cov txuj cicov yam ntxwv ntawm cov qauv tsim ntawm cov compound yuav nyob ntawm ntau dua. Yooj yim hauv kev ua tiav, hluav taws xob arc vuam ntawm cov hlau kuj tsis tuaj yeem hu ua. Qhov nyuaj yog nyob rau hauv cov txheej txheem ntawm arc ignition, uas, dua, yog tswj los ntawm tus neeg siv "los ntawm qhov muag" tsis muaj auxiliary systems. Yog hais tias peb piv cov qauv nrog semi-automatic vuam, ces yuav muaj ib tug tsis muaj productivity.

Zaj lus

Vim nws muaj ntau yam, MMA thev naus laus zis tau txais thiab tuav ntau daim ntawv thov. Hauv tsev neeg, hauv kev cob qhia thiab kev pabcuam tsheb, hauv kev lag luam thiab hauv kev tsim kho, hluav taws xob arc vuam pom nws qhov chaw, tso cai rau koj ua ntau yam seams. Raws li cov kev txwv, lawv tsuas yog txiav txim siab los ntawm ergonomics. Lwm lub tswv yim rau kev vuam semi-automatic, vim lawv txoj kev yooj yim, kuj yog qhov xav tau zoo, hauv qee qhov chaw hloov cov ntsiab lus ntawm MMA. Ntawm qhov tod tes, arc welding outperforms ntau yam kev sib tw technologies vim muaj zog ntawm cov tsim seam thiab tsawg peev peev peev nyob rau hauv lub koom haum ntawm kev ua hauj lwm.

Pom zoo:

Yuav them nqi hluav taws xob li cas hauv Is Taws Nem? Kev them nyiaj hluav taws xob ntawm tus kheej tus account hauv Internet

Tom qab Is Taws Nem tau ruaj khov thiab sib koom ua ke rau hauv kev muaj tiag Lavxias, kev lag luam nyiaj txiag hauv online tau tso tseg tsis yog ib qho khoom tshwj xeeb rau tib neeg. Kev ua haujlwm them nyiaj online, txawm tias rau tus neeg siv PC tsis muaj kev paub, yog qhov yooj yim heev. Hauv kab lus no koj tuaj yeem pom cov lus qhia ntxaws txog yuav ua li cas koj tuaj yeem them hluav taws xob siv Is Taws Nem

Cov roj hluav taws xob hluav taws xob: cov npe, khoom thiab daim ntawv thov

Cov pa roj carbon monoxide - hydrocarbons tsim nyob rau hauv lub ntiaj teb crust los ntawm thermal decomposition ntawm organic residues. Lawv yog cov roj siv hluav taws xob zoo heev

Yuav ua li cas ua noj cam khwb cia hlau los ntawm hluav taws xob vuam: ua hauj lwm technology thiab cov khoom tsim nyog

Lub ntsiab muaj pes tsawg leeg thiab hom cam khwb cia hlau. Qhov nyuaj thiab nta ntawm vuam cam khwb cia hlau cov khoom. Cam khwb cia hlau welding txoj kev. Kev npaj ua haujlwm ua ntej vuam. Yuav ua li cas ua noj cam khwb cia hlau los ntawm hluav taws xob vuam nyob rau hauv ib txoj kev txias thiab kub, nrog rau cov khoom siv roj. Cov yam ntxwv ntawm cov electrodes siv rau vuam cam khwb cia hlau. Kev ntsuas kev nyab xeeb thaum vuam

Kev them nqi hluav taws xob hauv Is Taws Nem. Yuav them cov nqi hluav taws xob li cas hauv online

Tsis tas yuav hais ntau qhov tseeb tias mus rau lub txhab nyiaj them nqi hluav taws xob yog qhov dhuav heev. Thiab muaj cov laj thawj zoo heev rau qhov no. Tab sis koj tuaj yeem them nqi hluav taws xob hauv Internet. Hauv qhov kev tshuaj xyuas no, qhov no yog qhov tseeb uas yuav tau tham txog

Yuav siv cov tshuaj tua hluav taws dab tsi los tua hluav taws xob thaum muaj hluav taws kub?

Hluav taws xob thaiv hluav taws xob yog qhov txaus ntshai heev. Yog li ntawd, cov tshuaj tua hluav taws yuav tsum muaj txiaj ntsig txaus los tua nws. Cov ntsiab lus no yog qhov tseem ceeb rau txhua lub koom haum lossis kev lag luam uas muaj cov khoom siv hluav taws xob. Cov cai tswj kev nyab xeeb hluav taws xav tau cov tshuaj tua hluav taws. Lawv yuav tsum yog dab tsi? Xav txog yam kev tua hluav taws uas koj tuaj yeem tua hluav taws xob, suav nrog lawv cov yam ntxwv thiab lub xeev tam sim no ntawm daim phiaj hluav taws xob