2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Tshuaj etching ntawm hlau txhais tau tias tshem tawm cov flux lossis oxide residues ntawm nws qhov chaw. Cov txheej txheem zoo li no suav nrog kev siv cov tshuaj chloride ntsev, alkali lossis kua qaub. Txawm hais tias siv cov tshuaj phem npaum li cas, hlau etching yuav tsum tau ceev faj heev thiab raug los ntawm ib tug neeg, vim hais tias cov tshuaj no yog heev txaus ntshai thiab yuav ua rau cov tshuaj burns yog hais tias lawv mus rau ntawm daim tawv nqaij. Txawm li cas los xij, nrog kev npaj kom raug, cov txheej txheem no tuaj yeem nqa tawm hauv tsev. Hlau etching tso cai rau koj rov tsim dua ib qho kev piav qhia, ntawv nyeem, qhov tob lossis kev kho kom zoo nkauj ntawm yuav luag txhua qhov chaw hlau. Cov khoom tau txais txiaj ntsig tiag tiag siv sijhawm los kawm txog cov thev naus laus zis no.

Lub ntsiab ntawm txheej txheem

Txhim kho cov hlau tuaj yeem ua tiav, uas feem ntau yog siv los ntxuav yooj yim, lossis ib nrab, uas feem ntau siv los kho cov khoom. Thaum kawgHauv qhov no, txhawm rau tiv thaiv thaj chaw uas yuav tsum tsis txhob raug kev kho mob zoo li no, siv lub npe hu ua tiv thaiv. Pickling ntawm cov hlau tuaj yeem ua tau tshuaj lom neeg lossis galvanically. Nyob rau hauv thawj rooj plaub, cov khoom yog immersed nyob rau hauv ib tug tov. Lub sijhawm ua haujlwm yog nyob ntawm qhov xav tau qhov tob etch thiab hom khoom nws tus kheej. Tom qab rho tawm, cov hlau yog ntxuav kom huv si nrog dej txias, uas qee zaum ntxiv cov kua dej qab zib. Ua tsaug rau qhov no, koj tuaj yeem paub tseeb tias cov kua qaub yuav tsis lwj qhov tshwm sim.

kos duab hlau etching

Nws tau siv nyob rau hauv Nruab Nrab Hnub nyoog los kho cov riam phom thiab cuab yeej cuab tam. Nyob rau hauv cov nqe lus ntawm lawv kev zoo nkauj, xws li cov khoom yog feem ntau tsis inferior mus rau lub creation ntawm txhais tes ntawm txawj jewelers. Rau hom kev kho hlau saum npoo no, txoj kev thib ob, uas yog, txoj kev galvanic, yog qhov zoo tshaj plaws. Txoj kev no zam kev tso tawm cov pa roj uas tsim kev puas tsuaj rau tib neeg, uas tshwm sim thaum lub sijhawm ua tshuaj lom neeg, thiab muaj txiaj ntsig zoo dua, vim nws ua rau nws tuaj yeem ua rau cov npoo ntawm cov qauv etched ntau qhov txawv.

Kev xyaum ua haujlwm

txhawm rau qhia koj lub peev xwm thiab pib cov txheej txheem no hauv tsev, thawj qhov koj yuav tsum tau ua yog nrhiav DC qhov chaw, qhov hluav taws xob uas yog kwv yees li ntawm 4-7 Volts. Qhov kev xaiv zoo tshaj plaws yog lub tsev siv hluav taws xob siv hluav taws xob nrog kev hloov pauv. Tom qab ntawd koj yuav tsum tau da dej ntawm cov khoom siv insulating, uas yuav muaj cov electrolyte. Raws li yav tas los, ib qho kev daws teeb meem ntawm cov ntsev zoo tib yam tuaj yeem siv tau, tab sis feem ntau yog rau qhov noCov hom phiaj siv ib qho kev daws teeb meem ntawm vitriol. Hlau yog siv rau hlau thiab hlau, thiab tooj liab yog siv rau tooj liab, tooj dag thiab tooj.

Hlau billet yuav tsum tau degreased ua ntej. Ua li no, solder ib tug tooj liab xaim rau nws, tuav nyob rau hauv uas nws yog txo rau 5 feeb rau hauv ib tug tov ntawm caustic sodium, rhuab mus rau ib tug kub ntawm 50 ° C. Tom qab ntawd lub workpiece raug xa mus rau ob peb feeb rau hauv cov kua nrog 15% sulfuric acid cov ntsiab lus, tom qab ntawd nws yog huv si ntxuav nrog dej kub. Qhov kev npaj kawg yog qhov kev npaj ntawm mastic. Nyob rau hauv ib lub thawv, sib tov var, rosin thiab ciab nyob rau hauv ib tug ratio ntawm 4: 2: 3 thiab yaj kom txog thaum ib homogeneous loj tau txais. Thaum nws txias lawm, qhwv nws nyob rau hauv ib tug muaj zog, nyias daim ntaub thiab khiav tshaj lub rhuab me ntsis workpiece kom txog rau thaum nws yog them nrog ib tug nyias txheej. Tom qab tag nrho cov no tau hardened, siv cov qauv xav tau nrog cov xim dej thiab txhuam tawm cov mastic nrog rab riam qhov twg cov indentations yuav tsum yog. Tam sim no muab nws tso rau hauv electrolyte los ntawm kev sib txuas ntawm lub davhlau ya nyob twg nrog tus ncej zoo rau nws, thiab dai ib qho khoom siv hlau los ntawm cov hlau nrog lub cim rho tawm thiab tseem txo qis rau hauv electrolyte. Tom qab ua tiav cov pickling, desolder cov hlau, yaug lub resulting masterpiece nrog turpentine thiab ua qhov kawg finishing (sib tsoo thiab polishing).

Pom zoo:

Kev txhim kho kev tshaj lij hauv kev tiv thaiv kev ua haujlwm: nta, kev xav tau thiab cov lus pom zoo

Muaj tus kws tshaj lij tiv thaiv kev ua haujlwm hauv txhua qhov khoom. Tus neeg no yuav tsum tsim kom muaj kev ua haujlwm zoo, nrog rau kev kuaj xyuas kev ua raws li cov cai tswj kev nyab xeeb. Thiab qhov no txhais tau hais tias kev tsim nyog yuav tsum tau hloov kho tas li

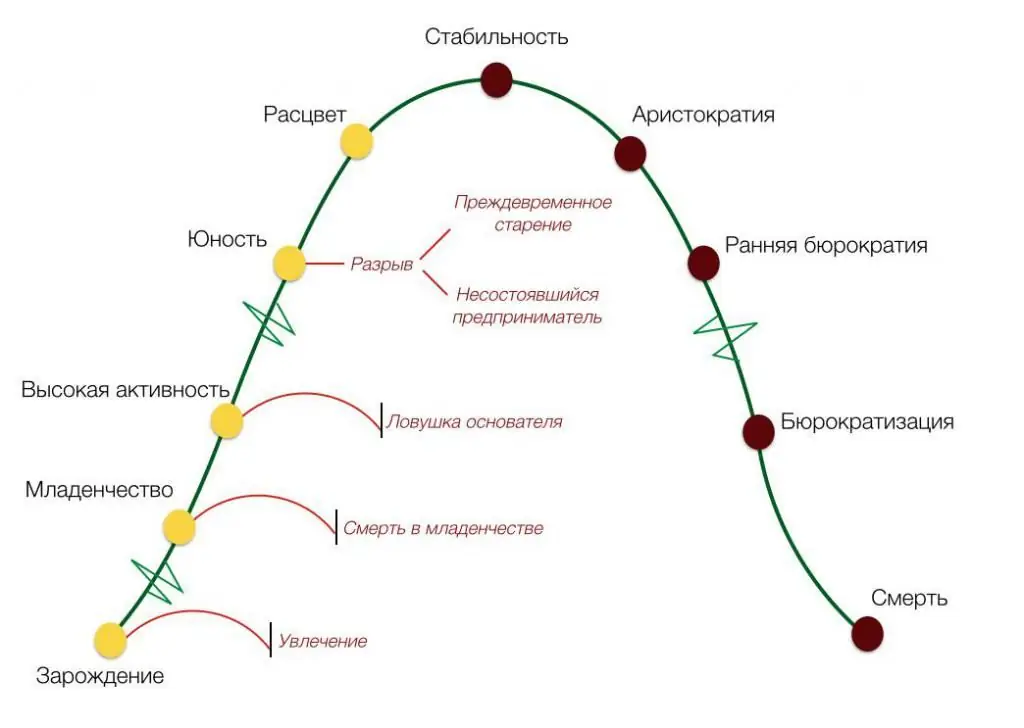

Kev txhim kho vaj tsev thiab nws lub luag haujlwm hauv kev txhim kho kev lag luam. Lub tswvyim, hom, cov hauv paus ntsiab lus thiab lub hauv paus ntawm txoj kev loj hlob

Nyob rau hauv lub moj khaum ntawm kab lus no, peb yuav txiav txim siab lub koom haum ntawm kev txhim kho vaj tse thiab nws lub luag haujlwm hauv kev txhim kho kev lag luam. Cov ntsiab lus tseem ceeb, hom thiab cov hauv paus ntsiab lus ntawm lub koom haum ntawm txoj kev txhim kho yog txiav txim siab. Cov yam ntxwv nta ntawm lub system nyob rau hauv Lavxias teb sab tej yam kev mob yog xam

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Kev npaj phiaj xwm yog Cov theem thiab cov yam ntxwv ntawm cov txheej txheem, kev txhim kho thiab kev npaj ntawm kev npaj

Thaum lub sijhawm npaj, kev txiav txim siab zoo thiab ntau npaum li cas los ua kom tiav cov hom phiaj ntawm lub koom haum nyob rau lub sijhawm ntev. Ntxiv mus, nyob rau hauv cov chav kawm ntawm xws li kev ua hauj lwm, nws muaj peev xwm mus txiav txim precisely lub zoo txoj kev. Kev npaj qhov project yog qhov kev nthuav dav ntawm cov txheej txheem meej raws li qhov kev txhim kho ntawm lub koom haum yuav ua tiav. Qhov no tso cai rau koj los xav txog tag nrho cov ntsiab lus, xaiv txoj hauv kev los daws cov teeb meem thiab ua tiav koj lub hom phiaj. Yuav ua li cas cov hauj lwm zoo li no yuav tau tham hauv qab no

Txhim kho phau ntawv zoo: txheej txheem kev txhim kho, nta, cov xwm txheej thiab cov cai

Kev tswj kom zoo, kev txhim kho phau ntawv zoo - niaj hnub no cov haujlwm tseem ceeb tshaj plaws hauv kev tswj xyuas cov khoom lossis cov kev pabcuam zoo. Nws yog ib qho tsim nyog los txheeb xyuas qhov teeb meem no kom ntxaws ntxiv, txhawm rau txiav txim siab txhua yam ntawm nws tus kheej