2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

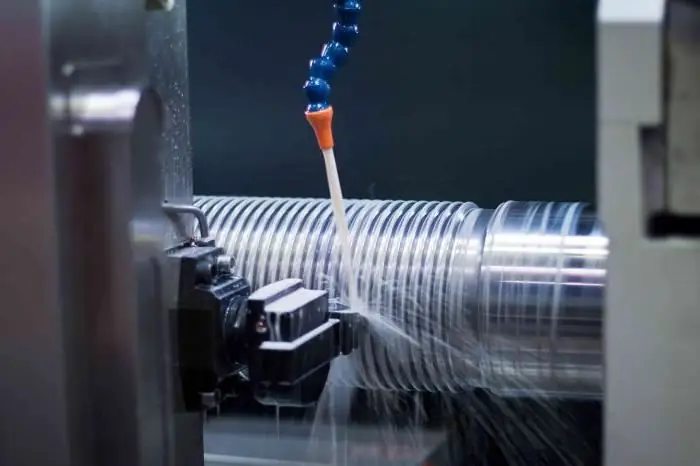

Cov txheej txheem hlau ua haujlwm yog qhov muaj feem cuam tshuam nrog kev sib txhuam muaj zog uas tshwm sim ntawm cov khoom ua haujlwm thiab cov cuab yeej. Qhov no tshwj xeeb tshaj yog tshwm sim nyob rau hauv txoj kev tig thiab milling, thaum lub cutter kub heev, thaum lub sij hawm txias extrusion, thiab high-speed multi-txoj hauj lwm nqe lus. Kev sib txhuam hnyav ua rau cov cuab yeej hnav ntxov ntxov, yas deformation ntawm cov khoom ua haujlwm, thiab kev hloov pauv ntawm cov khoom hlau vim overheating. Ib qho tshwj xeeb txiav kua (coolant) yuav tsum tau txo qis kev sib txhuam thiab qis kub.

Kev faib cov tsis muaj kev txiav cov kua dej

Kev faib tawm dav dav ntawm kev txiav cov kua dej yog ua raws li ob peb yam tseem ceeb:

- Raws li keeb kwm ntawm cov khoom. Roj coolants yog tsim, uas yog raws li cov roj av, tsiaj los yog zaub rog.

- Raws li txoj kev teeb tsa. Emulsol yog cov khoom tiav nrog lub neej ntev ntev lossis cov khoom ua kom txias tau npaj tam sim ua ntej siv los ntawm kev mloog zoo raws li GOST.

- pokev lag luam ntawm daim ntawv thov. Ntau hom coolants yog tsim rau txawv kev ua hauj lwm ntawm daim ntawv thov. Synthetic tej kua rau cov yas deformation ua hauj lwm, coolant rau tig los yog milling tshuab.

- Raws li lub cev thiab cov khoom siv tsis tau - viscosity, acid naj npawb, flash point. Cov yam ntxwv tom kawg txiav txim siab siv cov roj coolants rau kub stamping.

Kev faib cov kua dej los ntawm kev sib xyaw

Cov hom dej txias hauv qab no yog qhov txawv ntawm qhov sib xyaw:

- Roj - cov khoom sib xyaw uas tsis sib xyaw nrog dej. Lub hauv paus ntawm cov roj coolants yog paraffin, ntxhia lossis roj av (60-95%). Txhawm rau txhim kho kev ua tau zoo ntawm kev hnav, kev sib txhuam, corrosion, ntau yam additives thiab inhibitors muaj nyob rau hauv muaj pes tsawg leeg. Roj coolants muaj zoo lubricating zog. Siv rau cov hlau mos hauv kev siv yooj yim.

- Mineral - lub hauv paus yog tsim los ntawm cov roj los ntawm catalytic hydrogenation. Txhawm rau kom ua tau zoo, cov tshuaj ntxiv los ntawm cov rog, chlorine, sulfur, phosphorus tebchaw yog suav nrog hauv cov muaj pes tsawg leeg. Cov khoom sib xyaw no yog siv rau hauv cov khoom siv hlau xws li: txiav steel, aluminium, tooj dag, threading, milling ua haujlwm ntawm alloy steels.

- Dej miscible - ntxhia-raws li aqueous tov. Cov tebchaw no muaj cov khoom ua kom txias txias thiab tsis muaj toxicity, tab sis tib lub sij hawm tsis tshua muaj lubricating yam ntxwv. Scope ntawm daim ntawv thov - lub teeb thiab nruab nrab tig ntawm tooj liab thiab bronze, milling thiab drilling ntawm txhua hom tsis-ferroushlau, sib tsoo thiab steel stamping.

- Synthetic thiab semi-synthetic - sib tov dej, surfactants, dej-soluble polymers, anti-foam thiab antibacterial additives, corrosion inhibitors. Anti-coj additives kuj tau ntxiv rau cov khoom siv hluavtaws los ua kom lubricity.

- Emulsions yog cov muaj pes tsawg leeg nrog cov ntsiab lus siab ntawm cov khoom tawg. Txo cov cuab yeej thiab cov cuab yeej hnav hauv txhua qhov kev ua haujlwm hlau.

qauv thiab txheej txheem ntawm kev ua kom txias

Kev siv dav dav ntawm cov dej txias hauv cov txheej txheem hlau ua haujlwm yog vim muaj kev sib cais zoo ntawm kev sib tsoo ntawm qhov chaw ua haujlwm thiab cov cuab yeej thiab txo lawv qhov kub thiab txias. Cov kua txiav ua tau zoo tshaj plaws yuav suav nrog cov khoom hauv qab no:

- Raws li roj hluavtaws lossis tsiaj rog.

- Cov khoom ntxiv uas ua rau muaj kev sib txhuam thiab kev ua haujlwm siab heev.

- Cov khoom uas tiv thaiv kev sib cais ntawm qhov sib xyaw thaum lub sijhawm khaws cia.

- Cov khoom ntxiv uas tiv thaiv corrosion thiab kev puas tsuaj.

- Cov khoom siv uas txo cov npuas dej thiab txhim kho qhov ntub dej ntawm cov chaw hauv cov hlau ua haujlwm.

Daim ntawv thov kom txias

Cov kua dej txias yog siv los lubricate thiab txias qhov chaw ua haujlwm hauv kev ua haujlwm hlau. Coolant zog ua kom nws muaj peev xwm txo tau kev sib txhuam ntawm qhov chaw ua haujlwm, yog li txo cov cuab yeej siv, ua kom cov khoom zoo, txhim kho kev siv thev naus laus zis.txheej txheem thiab, yog li ntawd, tag nrho productivity.

Vim lawv cov khoom lubricating, coolants zoo txo qhov kev sib txhuam quab yuam ntawm qhov chaw ntawm lub workpiece thiab ntug ntawm cov cuab yeej txiav, kev sib txhuam sab hauv hauv cov txheej hlau txiav. Cov khoom siv sib cais muaj cov khoom siv tshuaj lom neeg uas pab txo qis tsis yog kev sib txhuam quab yuam, tab sis kuj yog lub zog txiav. Feem ntau cov coolants yog surfactants nrog siab adsorption zog. Lawv muaj peev xwm tsim tau ib zaj duab xis ruaj khov ntawm cov hlau nto, uas txo cov kev sib txhuam. Qee qhov tshwj xeeb nto-ua haujlwm additives muaj "kab laug" cuam tshuam rau cov hlau. Cov elongated molecules ntawm xws li additives poob rau hauv microcracks ntawm cov hlau nto, zoo li ib tug wedge, yog li ua rau tsis muaj zog ntawm cov khoom ntawm cov khoom. Yog li, lub coolant "pab" cov cuab yeej ua haujlwm los txiav tawm cov txheej txheem los ntawm cov hlau puag.

ntau lub tshuab cuab yeej coolants

Cov kua dej hauv qab no yog tsim los rau kev ua haujlwm hlau ntawm kev tig thiab milling tshuab:

- Emulsols raws li cov ntxhia thiab roj av.

- Emulsifiers nrog hluavtaws fatty acids.

- Tig thiab milling kev ua haujlwm nrog kev ua haujlwm siab ceev ntawm stainless thiab alloy steels tau ua raws li GOST 38.01445-88. Rau cov hom phiaj no, cov khoom siv hluavtaws yog muab, uas yog raws li cov roj siab, cov dej cawv siab atomic, triethanolamine.

- Sulfofresols yog cov khoom sib xyaw ntawm cov roj purified heev thiab cov tshuaj sulfur-muaj cov tshuaj. Tsis yogmuaj dej, alkalis, acids. Xws li coolants rau cov cuab yeej siv tau zoo txo kev sib txhuam thiab tsis ua rau corrosion.

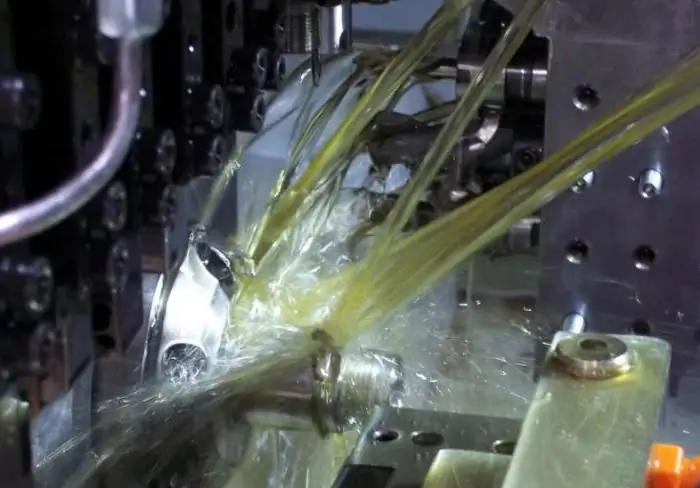

Siv cov dej txias rau kev ua hlau

Txoj kev no ntawm kev ua hlau yog nrog los ntawm cov kev tshwj xeeb tshwj xeeb thiab kev cuam tshuam ntawm cov khoom ua haujlwm thiab cov cuab yeej. Cov coolants siv nyob rau hauv xws li cov txheej txheem thev naus laus zis yuav tsum muaj viscosity ntau dua. Cov yam ntxwv tseem ceeb ntawm cov hlau sib txuas yog:

- Ntau viscosity.

- Resistant rau pob txha thiab delamination nyob rau hauv qhov kub thiab txias.

- Cov dej graphite yog siv nrog kev suav nrog cov nplua-flake graphite raws li cov roj raug tshem tawm.

Txoj kev siv cov kua dej txiav

Yuav kom siv cov dej txias kom zoo dua, muaj ob peb txoj cai yooj yim kom nco ntsoov.

- Tus nqi qis kawg nkaus, txawm tias nws yog cov tshuaj aqueous lossis emulsion, yog 10-15 l / min.

- Nws yog ib qho tseem ceeb heev uas cov khoom siv coolant yog nqa tawm nyob rau hauv qhov chaw uas cov cua sov siab tshaj plaws yog generated. Hauv kev tig, qhov no yog thaj chaw uas cov chips cais tawm ntawm lub workpiece.

- Coolant yuav tsum muab tam sim ntawd. Thaum cov dej txias tau thov tom qab qee lub sijhawm, lub tshuab txiav kub kub yuav txias sai heev, uas yuav ua rau muaj cov kab nrib pleb hauv nws.

- Coolant tsis haum rau tig cov hlau nkig (bronze, cam khwb cia hlau, thiab lwm yam). Thaum tig cov ntaub ntawv no,chips me me, uas, tov nrog coolant, tuaj yeem txhaws cov chav ua haujlwm ntawm lub tshuab (carriage, caliper, coj txaj), uas ua rau hnav ntxov ntxov thiab tawg ntawm cov units.

Kev tsim khoom thiab khaws cia cov kua txiav

Ntxiv rau cov khoom tsim tau npaj rau lub sijhawm ntev, cov concentrates thiab cov khoom siv rau kev npaj cov kua ua kom haum rau cov xwm txheej ntawm ib lub lag luam tshwj xeeb yog tsim. Coolant, coolant, tus nqi ntawm uas feem ntau yog nyob ntawm cov muaj pes tsawg leeg uas ua tau raws li ib tug tej yam kev ua hauj lwm, yog muag nyob rau hauv lub niaj hnub khw rau 70-160 rubles / liter rau tiav formulations ntawm domestic manufacturers thiab 105-290 rubles / liter ntawm txawv teb chaws ntau lawm. Tus nqi nruab nrab ntawm cov concentrate yog 240 rubles / liter. Ua ntej siv cov kua, cov txheej txheem hauv qab no tau ua:

- Kev sib xyaw ntawm cov khoom siv yog ua raws li qhov ntsuas kub tau teev tseg rau cov khoom xyaw thiab hom (60-110 0С).

- Kev tshuaj xyuas ntawm qhov muaj pes tsawg leeg rau kev ua raws li GOST.

- Cov khoom xyaw npaj tau khaws cia rau hauv cov thawv tshwj xeeb uas tso cai rau lub sijhawm cua sov, sib tov.

- Thaum npaj lub coolant, nws muaj peev xwm ua kom paub cov additives, uas yog nqa tawm ntawm zoo emulsification vibrators.

- Refilling nruam feeders.

- Hauv kev siv, cov khoom sib xyaw ua paug. Coolant ntxuav tshuab los ntawm cov hlau seem yog muab. Cov khoom pov tseg uas tsis tuaj yeem ntxuav tau zoo yuav tsum muab pov tseg.

Pom zoo:

Daim ntawv thov rov qab los ntawm kev tuav pov hwm qiv nyiaj: piv txwv, cov cai ntawm daim ntawv thov, lub sijhawm xa tawm

Nyob rau hauv tus txheej txheem ntawm tau txais cov nyiaj qiv, cov tsev txhab nyiaj muaj peev xwm qiv nyiaj los xaus daim ntawv cog lus pov hwm. Yog tias tus neeg siv tsis tuaj yeem them cov nuj nqis, lub luag haujlwm kaw nws mus rau lub txhab nyiaj yog nrog lub tuam txhab pov hwm. Tab sis hauv kev xyaum, qhov xwm txheej tsis sib xws feem ntau tshwm sim, thiab cov neeg them nyiaj siab xav tau xav txog qhov muaj peev xwm rov qab tau txais kev pov hwm qiv nyiaj thaum them rov qab ntxov. Tab sis yuav tau txais ntau npaum li cas? Thiab leej twg yuav tsum muab cov nyiaj - tus tuav pov hwm lossis lub txhab nyiaj?

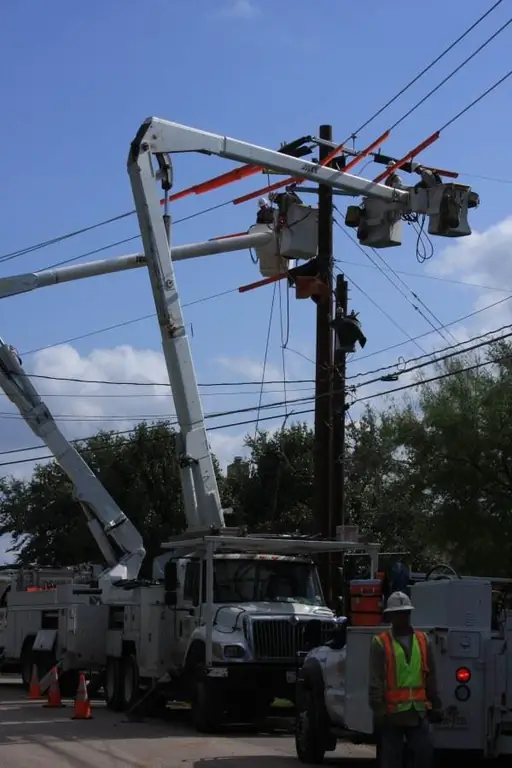

Thermal imaging tswj ntawm cov khoom siv hluav taws xob: lub tswv yim, lub hauv paus ntsiab lus ntawm kev ua haujlwm, hom thiab kev faib tawm ntawm thermal imagers, nta ntawm daim ntawv thov thiab kev txheeb xyuas

Kev ntsuas cua sov ntawm cov khoom siv hluav taws xob yog ib txoj hauv kev zoo los txheeb xyuas qhov tsis xws ntawm cov khoom siv hluav taws xob uas kuaj pom yam tsis tau kaw lub tshuab hluav taws xob. Nyob rau hauv qhov chaw ntawm kev sib cuag tsis zoo, qhov kub thiab txias nce, uas yog lub hauv paus ntawm cov txheej txheem

Kev faib hluav taws xob: chaw nres tsheb, khoom siv tsim nyog, kev faib khoom, daim ntawv thov, accounting thiab tswj cov cai

Txhua tus paub tias lub zog hluav taws xob tau muab rau qhov chaw ntawm nws cov khoom siv los ntawm qhov chaw ncaj qha. Txawm li cas los xij, cov peev txheej zoo li no tuaj yeem nyob ntawm qhov deb ntawm cov neeg siv khoom. Vim li no, kev faib hluav taws xob thiab nws cov khoom xa tuaj yog txheej txheem nyuaj

Coal: kev faib tawm, hom, qib, yam ntxwv, combustion nta, qhov chaw rho tawm, daim ntawv thov thiab qhov tseem ceeb rau kev lag luam

Coal yog ib qho chaw sib txawv thiab ntau yam. Vim nws peculiarity ntawm tsim nyob rau hauv lub plab hnyuv ntawm lub ntiaj teb, nws muaj peev xwm muaj ntau yam txawv. Yog li ntawd, nws yog txoj cai los faib cov thee. Yuav ua li cas qhov no tshwm sim yog piav nyob rau hauv tsab xov xwm no

Cov cua kub siab qis: txhais, lub hauv paus ntawm kev ua haujlwm, cov yam ntxwv ntawm kev ua haujlwm, kev faib tawm, tsim, kev ua haujlwm nta, daim ntawv thov hauv kev lag luam

Cov cua kub siab qis (LPH) tam sim no siv heev. Muaj ob hom tseem ceeb uas yog tsim los ntawm cov nroj tsuag sib txawv. Lawm, lawv kuj txawv ntawm lawv cov kev ua tau zoo