2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Txhawm rau npog cov ntaub ntawv hauv peb lub sijhawm, tag nrho cov thev naus laus zis sib txawv yog siv. Muaj cov thev naus laus zis thev naus laus zis, hluav taws xob-proton hluav taws xob, qhov kub thiab txias fusion thiab ntau lwm yam.

Txheej steel nrog titanium nitride

Nyob hauv lub ntiaj teb niaj hnub no, "gilded" cov hniav nyiaj hniav kub thiab cov khoom lag luam tau dhau los ua neeg nyiam. Hauv kev lag luam, qhov no yog hardening (sputtering) ntawm cov cuab yeej thiab qhov chaw nrog titanium nitride. Cov khoom siv tshuaj no muaj ob qho tib si sab nrauv zoo nkauj thiab muaj txiaj ntsig ua haujlwm zoo - siab hardness, tsis kam thiab tshuaj inertness. Hauv kev lag luam, titanium nitride txheej yog nqa tawm:

- Nqus tsev deposition method. Nws yog siv nyob rau hauv ntau txoj kev - ion deposition, plasma theem condensation system thiab sputtering nyob rau hauv magnetron installations: PVD (Lub cev Vapor Deposition), los yog FOP technology.

- Tshuaj Vapor Deposition Method: CVD (Chemical Vapor Deposition), lossis CVD thev naus laus zis.

- Plasma txau hauv microwave plasma torches.

- SHS thev naus laus zis (nws tus kheej nthuav tawm qhov kub thiab txias).

Txheej steel nrog titanium nitride los ntawm txoj kev tso nyiaj muab cov txiaj ntsig zoo, tab sis yuav tsum muaj kev sib koom ua ke (nqus, ncu-gas) hauv kev lag luam. Tsis tas li ntawd, nws yuav tsum muaj cov cuab yeej tshwj xeeb, cov khoom siv thiab cov khoom siv roj (xws li nitrogen). Tsis tas li ntawd, cov pov tseg tshuaj lom yog tsim nyob rau hauv cov khw electroplating.

Plasma kev teeb tsa. Txheej txheem

Hauv plasma-hom kev teeb tsa, titanium nitride txheej yog nqa los ntawm electro-plasma sprayers siv cov hmoov av npaj ua hmoov (titanium nitride hauv cov hmoov hmoov). Plasmatrons rau kev txau yog qhov yooj yim, cov txheej txheem yog nqa tawm muaj yam tsis muaj lub tshuab nqus tsev thiab qhov chaw tshwj xeeb gaseous. Tab sis txhawm rau txo cov oxidation ntawm titanium nitride los ntawm oxygen, argon yog siv los tsim cov ntshav. Nws muaj inert zog. Nitrogen yog siv nyob rau hauv lub microwave plasma torch. Cov txheej txheem hmoov txheej no tuaj yeem siv rau hauv cov chav me me, xws li kev lag luam ntiag tug.

Qhov tsis zoo ntawm txoj kev txau ntshav plasma

Hauv kev teeb tsa plasma, titanium nitride txheej tshuab muaj qhov tsis zoo hauv qab no:

- tsis muaj adhesion. Txheej adhesion lub zog yog qis dua rau PVD lossis CVD txoj kev, tshuaj tsuag zoo li khom;

- zaj duab xis npog qhov chaw tsis sib xws;

- dab ntxwg nyoog cov yeeb yaj kiab uas tsis zoo;

- sputtering dhau ib lub sijhawm ntawm lub sijhawm tuaj yeem ua tau ntau zaus, yog li cov khoom lag luam nquag hnav.

Pom tseeb, yog tias titanium nitride txheej yog nqa tawm hauv chav me me, tsis zoo, qhov tshwm sim muaj qhov tsis zoo. Cov txheej no tsuas yog siv rau kev kho kom zoo nkauj xwb. Piv txwv li, qhov zoo no yog yuav tsum tau nyob rau hauv kev tsim cov khoom souvenir, rooj tog fittings, hniav nyiaj hniav kub, thiab lwm yam.

Hluav taws xob tshuab

Hauv qhov kub-kub synthesis, titanium nitride yog coated nyob rau hauv kaw reactors siv cua sov ntawm cov khoom tiav. Nyob rau hauv xws li installation, lub txheej yog tau huv si thiab uniform. Nws surpasses paub cov ntaub ntawv sib xyaw hauv lub zog, hardness thiab refractoriness.

Cua sov lub reactor kom kub kub tshwm sim vim cov txheej txheem exothermic. Raws li qhov tshwm sim ntawm cov tshuaj tiv thaiv ntawm ntau yam tshuaj, ib feem yog tsim. Qhov kub nce mus txog 4000 degrees. Txoj kev no koj tuaj yeem tau txais cov nitride zoo heev, diborite ntawm titanium, silicon thiab txhuas thiab lwm yam ntaub ntawv nrog cov txheej tiav. Cov txheej txheem ntawm txheej nrog titanium nitride nyob rau hauv variants ntawm high-temperature hmoov synthesis yuav nqa tawm ntxiv. Hauv SHS reactors tshiab, txhua yam khoom hloov pauv mus rau qhov txawv txav thiab zoo nkauj zoo nkauj.

Qhov zoo ntawm titanium nitride coated cov ntaub ntawv

Cov no suav nrog:

- tseem ceeb tiv thaiv kev puas tsuaj;

- ntau yam xim txheej;

- functional durability;

- sustainability ntawm kev tsim tawm tshiab;

- kev yooj yim thiab yooj yim ntawm kev siv;

- yog siv ntau qhov chaw ntawm kev tsim khoom, los ntawm kev kho kom zoo nkauj (gilding) ntawm lub tsev teev ntuj domes mus rau kev tsim khoom plig.

Nws tuaj yeem sib cav tias tus nqi ntawm titanium nitride plating hauv kev tsim khoom yog qis dua li lwm qhov kev lag luam uas yuav tsum tau plating kub. Piv txwv li, ib square meter ntawm ib daim ntawv stainless hlau nrog "gilding" yuav raug nqi kwv yees li 2.5 txhiab rubles. TiN txheej tsis tarnish thiab tiv thaiv cov khoom los ntawm xeb. Lub neej kev pab cuam ntawm titanium nitride plhaub yog ntev dua. Qhov kev sib txuas no tiv taus qhov kub ntawm 800 degrees.

Zaj lus

Kev pab them nqi ua haujlwm muaj ntau yam nta. Nitride txheej yog siv nyob rau hauv kev tsim khoom ntawm kev sib koom ua ke vim tias cov khoom siv no yog ob qho tib si tus neeg xyuas pib thiab cov insulator. Cov tshuaj tsuag muab qhov chaw sib txawv paj, cov khoom lag luam zoo nkauj dua. Nws yog xim kub, burgundy, ntsuab thiab xiav, nrog rau nyiaj thiab crimson Tag nrho cov ntawm lawv ruaj khov, tsis txhob ploj los yog ntxuav tawm.

Pom zoo:

Tshuab rau fertilization. Kev faib cov tshuab, cov txheej txheem ntawm fertilization

Cov tshuab ua chiv yog tsim los hloov tib neeg kev siv zog hauv kev ua haujlwm no. Nyob rau hauv kev sib raug zoo nrog cov ntxhia chiv, cov tshuaj tua kab thiab cov noob qoob loo nrog cov chiv seeders yog siv. Aggregates kuj tseem siv los ua cov hauv cov kua dej

Tsis siv neeg tshuab dhos thiab nws cov yam ntxwv. Tsis siv neeg tshuab dhos ntau spindle longitudinal tig nrog CNC. Manufacturing thiab processing ntawm qhov chaw ntawm tsis siv neeg lathes

Tsis siv neeg tshuab dhos yog cov cuab yeej siv niaj hnub siv feem ntau hauv kev tsim khoom ntau. Muaj ntau ntau yam ntawm cov tshuab xws li. Ib hom nrov tshaj plaws yog longitudinal tig lathes

Abrasive hmoov: ntau lawm, noj. Yuav siv cov hmoov abrasive qhov twg?

Abrasive hmoov yog siv los ntxuav cov hlau los ntawm xeb. Feem ntau, rau lub hom phiaj no, nws ntau yam xws li cooper slag thiab nickel slag yog siv. Pob zeb diamond hmoov yog siv los ua abrasive pastes thiab sib tsoo cov cuab yeej

Tus nqi zoo tshaj plaws credit card nrog lub sijhawm zoo. Txheej txheem cej luam ntawm credit cards nrog lub sij hawm zoo

Daim npav rho nyiaj nrog lub sijhawm zoo, cov khoom lag luam tau txais txiaj ntsig los ntawm ntau lub tuam txhab nyiaj txiag hauv tebchaws Russia

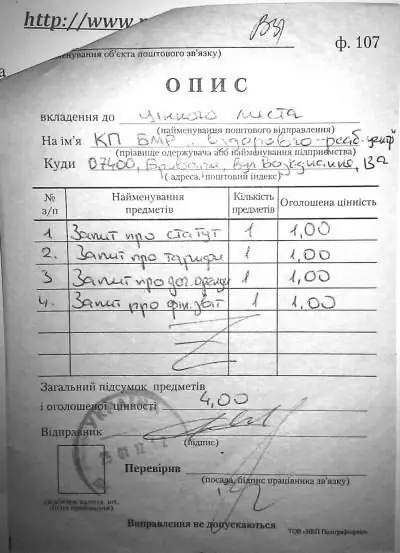

Daim ntawv sau npe nrog cov lus piav qhia txuas ntxiv. Cov txheej txheem xa ib tsab ntawv sau npe nrog cov lus piav qhia ntawm qhov txuas

Nyob hauv lub hnub nyoog ntawm computer technology, tib neeg sau ntawv rau ib leeg tsawg thiab tsawg. Tej zaum nws yuav zoo li tias nyob rau yav tom ntej xws li lub koom haum raws li lub chaw xa ntawv feem ntau yuav dhau los lawm. Tab sis nyob rau hauv kev muaj tiag no yog deb ntawm rooj plaub. Feem ntau, nws yooj yim ua tsis tau yam tsis muaj kev xa ntawv xa mus. Hauv tsab xov xwm no, peb yuav xav txog cov txheej txheem rau xa ib tsab ntawv sau npe nrog cov lus piav qhia txuas ntxiv. Wb kuj tham txog tias tsab ntawv yuav siv sij hawm ntev npaum li cas, thiab tus nqi pabcuam li cas