2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

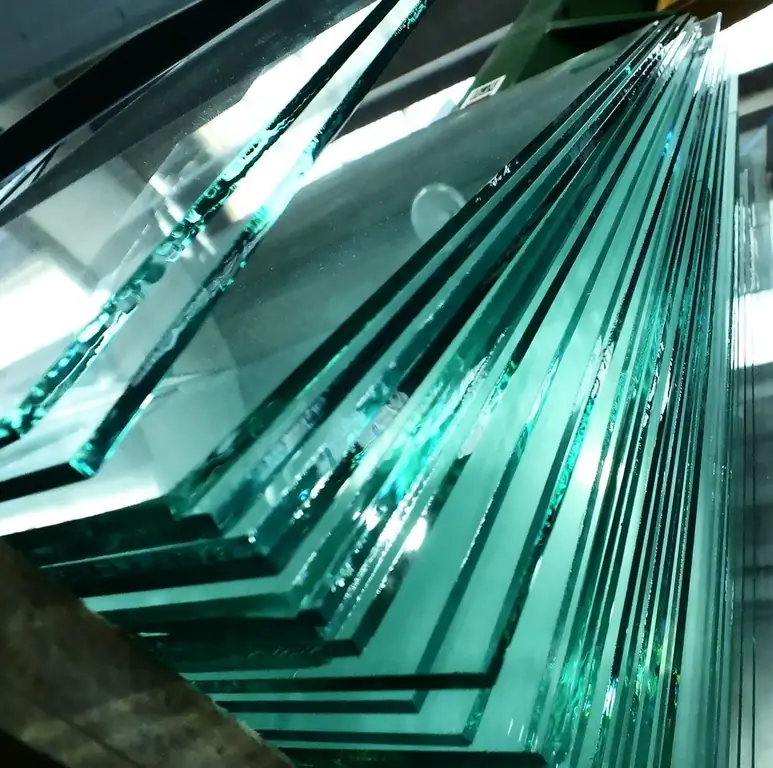

Hnub no, tib neeg nquag siv iav rau ntau lub hom phiaj. Cov txheej txheem glassmaking nws tus kheej yog melting ntawm raw cov ntaub ntawv los yog nqi. Cov iav melting rauv yog siv los yaj cov khoom. Lawv tuaj nyob rau hauv ntau hom thiab muab faib raws li ob peb yam.

Tus nqi yog dab tsi?

Nws yog ib qho tseem ceeb kom nco ntsoov ntawm no tias cov txheej txheem iav melting yog ib qho ntawm cov theem kawg ntawm kev tsim khoom. Tus nqi tuaj raws li cov khoom siv rau kev tsim khoom yog twb enriched raw khoom. Ntawm cov ntsiab lus tseem ceeb, qhov no suav nrog quartz xuab zeb, dej qab zib, limestone. Dyes, illuminators lossis darkeners yog siv los ua impurities ntxiv. Tsis tas li ntawd, tus nqi nkag mus rau hauv lub qhov cub muaj qhov feem pua ntawm cov dej noo, qhov yuav tsum tau muaj kev sib xws thiab qhov sib xws.

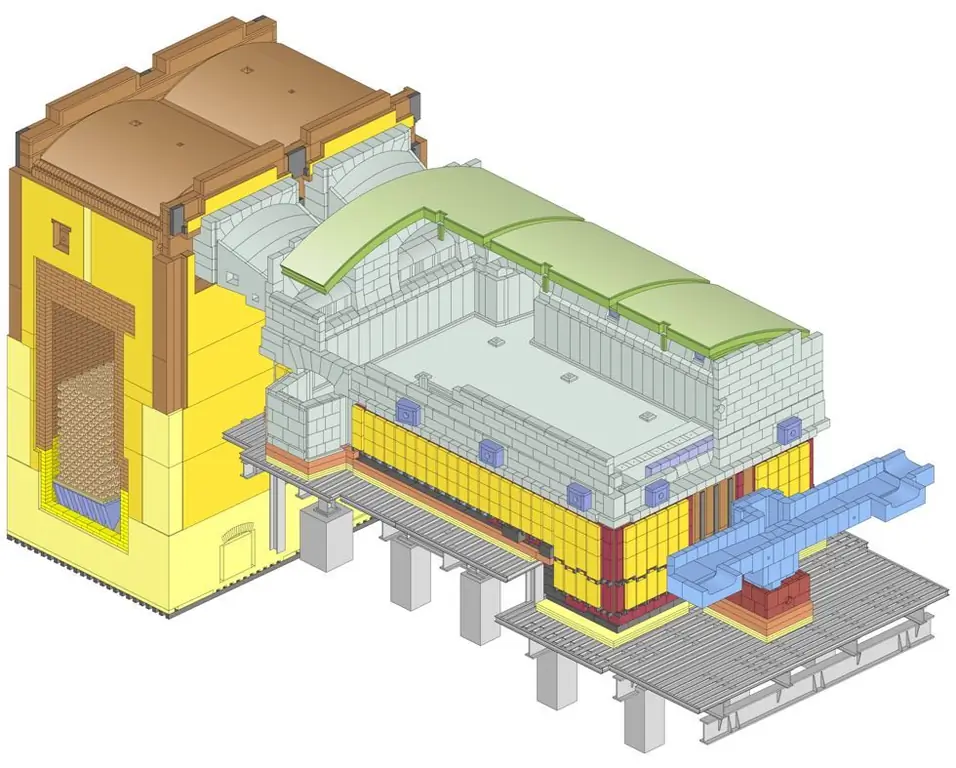

Ntse thiab cov cuab yeej ntawm lub qhov cub. Pool

iav melting rauv yog ib yam khoom tshwj xeeb tsim los rau yaj nqi. Cov roj tuaj yeem siv tau los ua roj, cov roj hluav taws xob tuaj yeem hlawv, thiab tseem muaj hluav taws xob rauv taws. Tus nqiNws yuav tsum raug sau tseg tias txawm tias muaj ntau hom, txhua qhov cub tawg muaj kwv yees li tib lub cuab yeej. Lub ntsiab tseem ceeb ntawm cov iav melting rauv yog lub pas dej ua ke, vault thiab qhov chaw nplaim taws.

pas dej ua ke muaj hauv qab thiab sab. Nws nqa tawm batch ua noj, cov txheej txheem qhia cov khoom, txias, thiab ncaj qha tsim cov iav loj. Yog tias peb tham txog kev faib cov iav furnaces raws li kev teeb tsa ntawm lub pas dej ua ke, ces muaj cov tshuab nrog lub pas dej ua ke. Lawv tsis muaj kev faib ua ntau thaj chaw. Kuj tseem muaj cov kev npaj pas dej ua ke tag nrho nrog cov seem demarcated kom meej. Cov da dej zoo li no muaj ib cheeb tsam uas ua noj ua haus thiab teeb pom kev ua haujlwm, thiab nws yog hu ua cua sov. Thaj chaw uas muaj cua txias thiab ua haujlwm tawm yog hu ua ua haujlwm tawm.

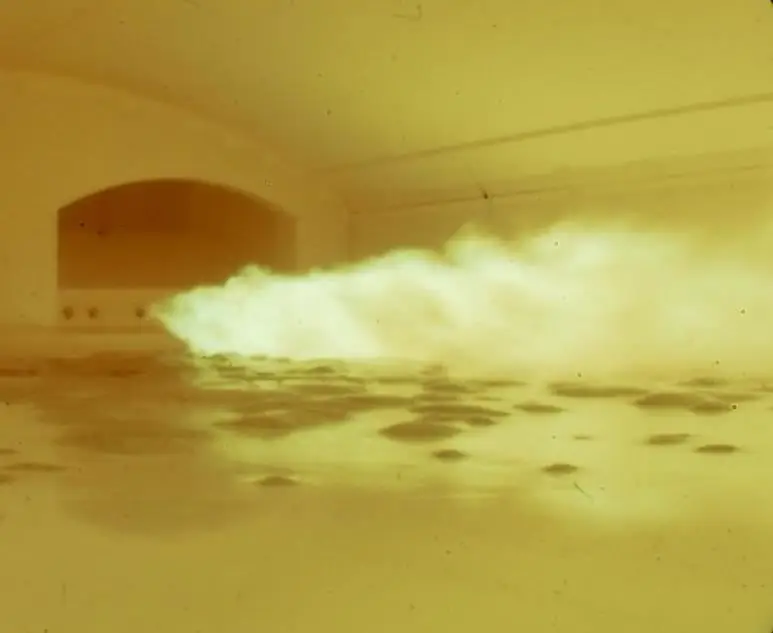

Nyob rau hauv qhov cua sov ntawm chav da dej ntawm cov iav melting rauv, muaj qhov chaw kub kub nyob nruab nrab ntawm cov phab ntsa thiab lub vault. Nws yog tus cwj pwm los ntawm qhov muaj qhov rau cov khoom siv roj thiab cua, nrog rau kev tshem tawm cov roj kub kub uas tshwm sim thaum lub sij hawm combustion ntawm roj.

da dej tso thiab ceev faj

Thaum lub tsev iav melting furnaces, tshwj xeeb yuav tsum tau them rau lub vault ntawm da dej. Nws yuav tsum tau ua los ntawm ib tug tshwj xeeb refractory cib hu ua dynas.

Ib qhob cib tsim nyog tsuas yog ib qho uas tsawg kawg 93% tsim los ntawm cov khoom xws li silica. Lub thickness ntawm phab ntsa ntawm da dej yuav tsum yog 500-600 hli, thiab lub thickness ntawm lub vault 300-450 mm.

Vim qhov tseeb ntawm kev ua nojtsub rau hauv iav furnaces dhau los ntawm qhov kub siab heev, tom qab ntawd thaum lub sijhawm txheej txheem no muaj ntau yam tshuaj tiv thaiv yuav tshwm sim, nrog rau kev tso tawm ntawm cov pa phem. Qhov no tau coj mus rau qhov tseeb tias ib qho ntawm cov kev ceev faj tseem ceeb yog ua kom tiav sealing ntawm sab hauv ntawm lub qhov cub. Tsis tas li ntawd, nyob rau hauv cov khw muag khoom uas cov khoom siv iav nyob, yuav tsum tau nruab ib lub qhov cua tshwj xeeb kom tshem tawm tag nrho cov teeb meem impurities thiab lwm yam khoom ntawm cov roj combustion los ntawm huab cua.

Hais txog lub tshuab ua pa, nws yuav tsum tau muab sau tseg tias cov pa hluav taws xob zoo sib xws yuav tsum tau muab tso rau hauv qhov cub nws tus kheej. Qhov sib txawv ntawm cov pa cua thiab modular qhov cua yuav tsuas yog hais tias lub modular ib qho yog tsim los tswj cov huab cua nyob rau hauv cov khoom siv.

Kev piav qhia dav dav ntawm hom qhov cub

Ntawm no yog tsim nyog pib nrog qhov tseeb tias muaj 2 qhov kev faib tawm ntawm qhov cub.

Thawj ntawm lawv faib tag nrho cov koob yees duab ua ob pawg nyob ntawm lub cuab yeej ntawm lub koob yees duab ua haujlwm. Cov no tuaj yeem yog lub lauj kaub iav los yog cov dab da dej.

Raws li txoj kev faib thib ob, ntawm no yog cov txheej txheem tseem ceeb ntawm cov iav cua sov. Hauv qhov no, muaj peb yam tseem ceeb - nplaim taws, hluav taws xob thiab roj hluav taws xob txoj kev.

khoom siv potting tam sim no suav tias tsis muaj txiaj ntsig. Qhov no yog vim li no qhov cubhais txog cov khoom siv sib cuam tshuam. Vim li no, muaj cua sov ntau, thiab yog li roj, thawj zaug mus rau qhov cub nws tus kheej, thiab tsuas yog tom qab ntawd kom yaj tus nqi.

chav dej iav melting rauv, tsis zoo li lub lauj kaub rauv, yog cov khoom siv tas mus li. Lawm, cov txheej txheem txuas ntxiv ua tiav daws qhov teeb meem ntawm kev nkim cov peev txheej ntawm lub sijhawm ua kom sov lub qhov cub, siv roj tsuas yog rau cov khoom siv smelting.

Lub dab da dej los ntawm qhov cub nws tus kheej yog lub pas dej loj loj uas muaj cov tin molten. Vim lub fact tias qhov ceev ntawm lub iav loj yuav txo qis dua qhov ceev ntawm cov hlau no, lawv yuav tsis sib tov nrog ib leeg, nyob rau hauv tib lub thawv. Tin nws tus kheej yog siv nyob rau hauv furnaces rau maj mam txias ntawm iav loj los ntawm ib tug kub ntawm 1600 degrees Celsius mus rau 600. Cov qauv no thiab cov khoom raug xaiv vim lub fact tias thaum lub sij hawm txias txoj kev no tsis tsim nyob rau hauv cov kev ntxhov siab nyob rau hauv lub loj. Lawv qhov tshwm sim yuav ua rau tsis zoo rau qhov zoo ntawm cov khoom tiav, thiab yog li ntawd lawv yuav tsum tau zam. Nws tseem tsim nyog sau cia ntawm no tias cov iav loj tau muab faib sib npaug, tso cai rau koj kom tau txais ib daim ntawv zoo kawg nkaus.

Lwm qhov zoo ntawm kev siv cov tin yog cov txheej txheem thermal polishing thaum txias. Cov txheej txheem no txhim kho lub zog thiab pom tseeb.

Nplaim Smelting Furnaces

Lub tshuab hluav taws xob no yog suav tias yog thawj zaug thiab hauv nws cov iav melting yog ua los ntawm kev hlawv roj. Nws yuav tsum tau muab sau tseg ntawm no hais tias lub generated cua sov yuav siv tsis tau tsuas yog rau cua sov tus nqi, tab sis kuj boilers rau ua noj ua haus, ces tus coefficient.kev ua tau zoo yuav tsawg. Cov nplaim taws muaj qhov ua tau zoo ntawm 25-30%.

khoom siv hluav taws xob

Yog tias peb tham txog kev ua haujlwm zoo, hnub no thawj kab yuav nyob hauv lub tshuab hluav taws xob. Lawv cov kev ua tau zoo nce mus txog 60%, uas yog suav tias yog tus lej siab tshaj plaws rau hnub tim. Qhov no yog ua tiav vim qhov tseeb tias hluav taws xob yuav raug xa ncaj qha mus rau iav loj nws tus kheej, cua sov nws. Yog li, nws muaj peev xwm zam kom tsis txhob muaj qhov tsis tsim nyog pov tseg ntawm lub zog rau cua sov boilers thiab lwm yam.

Lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm cov cuab yeej no yog raws li qhov tseeb tias ntawm qhov kub kub iav tuaj yeem ua hluav taws xob. Nyob rau hauv no hais txog, nyob ntawm tus txheej txheem ntawm tshav kub hloov mus rau qhov loj, peb hom hluav taws xob furnaces txawv: induction, arc, ncaj thiab indirect kuj.

Txawm li cas los xij, hom khoom siv no muaj qhov tsis zoo, uas yog qhov xav tau rau qhov kev ntseeg siab thiab tsis tu ncua ntawm cov hluav taws xob pheej yig.

Electrodes yog siv los hloov hluav taws xob hluav taws xob mus rau lub pas dej uas tus nqi melting nyob. Nws yog vim qhov sib txawv ntawm kev tiv thaiv uas cov cua sov tshwm sim, thiab tom qab ntawd cov iav loj melting. Raws li rau cov electrodes lawv tus kheej, lawv feem ntau yog ua los ntawm graphite. Cov khoom no tsis tshua muaj kev cuam tshuam rau kev deformation nyob rau hauv kev cuam tshuam ntawm qhov kub thiab txias.

Gas-electric ncu

hom khoom siv no ua ke nrog lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm ob qho dhau los. Gas yog siv los ua kom sov lub chamber thiab thawj melting ntawm tus nqi; kua roj yog siv ntau tsawg zaus. Yuav kom sov thiab yaj lub iav loj nws tus kheej, nws yuav siv taulub hauv paus ntsiab lus ntawm hluav taws xob tsis kam. Feem ntau, cov tshuab hluav taws xob zoo li no tau siv yog tias xav tau los ua kom muaj txiaj ntsig zoo ntawm lub qhov cub hluav taws xob, tab sis tsis muaj qhov pheej yig thiab hluav taws xob tas li.

Thaum kawg ntawm kev faib tawm, nws tsim nyog ntxiv tias muaj cov iav zoo li lub qhov cub. Kev taw qhia ntawm nplaim taws txav hauv cov khoom siv no yuav txawv, thiab ntawm lub hauv paus no muaj peb pawg me me ntawm cov cuab yeej siv, uas suav nrog cov khau zoo li tus nees. Lawv peculiarity yog tias lawv siv thaum tsim nyog los tsim cov ntxhia thiab iav ntaub plaub.

khoom kho

Hauv kev tsim cov iav, cov tshuab hluav taws xob tau raug hnav ntau heev, thiab yog li qhov teeb meem ntawm lawv cov txij nkawm yog qhov tseem ceeb heev. Kev kho iav rauv tuaj yeem yog peb hom: tam sim no, kub thiab overhaul.

Raws li kev kho tam sim no, nws yooj yim heev thiab muaj nyob rau hauv kev hloov qee cov nodes thiab qee cov ntsiab lus ntawm chav da dej.

hom kev kho kub yog ua tiav yam tsis tso tseg cov txheej txheem tsim khoom. Ua ntej pib ua haujlwm nrog nws tus kheej, nws yog ib qho tsim nyog yuav tsum tau tso tseg cov khoom siv hluav taws xob rau lub rhuab chamber. Tom qab ntawd, nws tuaj yeem hloov tau ntau lub ntsiab lus uas thawj cov cim ntawm kev puas tsuaj tshwm sim. Qhov no tso cai rau koj kom lub sijhawm siv ntau ntxiv.

Txias, nws tseem yog qhov kev kho dua tshiab, ua tiav nyob rau lub sijhawm teev tseg hauv cov phiaj xwm tsim khoom. Nws tau txais nws lub npe vim qhov tseeb tias nws tsuas yog nqa tawm tom qab ua tiav ntawm cov khoom siv, kev tso tseg ntawm cov khoom siv cua sov thiabtshem tag nrho cov iav los ntawm da dej.

kho loj

Ua ntej, koj yuav tsum tau tso tseg cov khoom them nqi. Tsis txhob muab cov khoom siv raw rau lub pas dej ua rau cov iav yaj yuav tsum yog 8-10 teev ua ntej nws nres. Tom qab ntawd, iav loj yog qhia, rhuab mus rau 1500 degrees Celsius (qhov no nce nws fluidity), thiab tshem tawm los ntawm tshwj xeeb raws. Cov iav yaj no dhau los ntawm cov txheej txheem granulation thiab tuaj yeem siv los ua cov khoom siv rov ua dua yav tom ntej. Ceev faj heev thaum tua cov burners. Qhov kub thiab txias yuav tsum tau hloov maj mam, vim nws qhov kev poob qis tuaj yeem ua rau kev puas tsuaj ntawm koov. Kev kho yog pib tsuas yog tom qab tag nrho cov kev ua no thiab tsuas yog tom qab lub qhov cub txias mus rau 100-150 degrees Celsius.

Feem ntau thaum lub sij hawm kho qhov loj, tag nrho cov khoom ua vaj tse puas raug tshem tawm, refractory tuav thiab cib raug hloov raws li xav tau. Thaum lub sijhawm kho dua, lub ru tsev ntawm lub tshuab hluav taws xob rov ua dua kuj raug kho.

Kev tswj hwm

Rau qhov cub da dej nws yog ib qho tseem ceeb heev uas yuav tsum muaj cov iav yaj tas li, vim tias lawv yog cov khoom siv tas mus li. Qib hloov pauv yuav cuam tshuam tsis zoo rau qhov zoo ntawm cov khoom tiav, nrog rau ua rau qee yam kev puas tsuaj. Vim li no, nws yog ib qho tsim nyog rau nruab cov cuab yeej uas tswj cov ntsuas no. Raws li kev ntsuas cov cuab yeej, koj tuaj yeem nruab ntab, pneumatic, kho qhov muag ntsuas ntsuas los tswj thiab tswj cov qib.iav loj nyob rau hauv ib lub khob melting rauv. Kev teeb tsa hluav taws xob ntawm cov khoom siv yuav tsum tsuas yog ua los ntawm cov kws tshaj lij tsim nyog.

Pom zoo:

Yuav ua li cas iav? iav ntau lawm technology. iav khoom

Iav yog paub rau sawv daws. Tab sis cov txheej txheem ntawm kev ua nws yog qhov zoo siab heev. Txhua theem yog qhov tseem ceeb thiab cuam tshuam rau qhov zoo ntawm cov khoom kawg. Lub hauv paus yog xuab zeb, dej qab zib, txiv qaub. Cov txheej txheem yog yuav luag tag nrho automated. Kuj ceeb tias, iav tuaj yeem ua tau hauv tsev

Iav sandblasting: iav ua cov lus piav qhia, khoom siv, daim ntawv thov, duab

Ntawm ntau qhov kev hloov pauv ntawm kev kho kom zoo nkauj sab hauv, sandblasting ntawm iav los yog iav nto occupies ib qho chaw tshwj xeeb. Cov cuab yeej no suav nrog kev nthuav tawm cov ntaub ntawv rau cov xuab zeb lossis lwm yam abrasive nrog lub dav hlau ntawm cov cua compressed tso rau hauv siab. Raws li qhov tshwm sim, qhov chaw hloov pauv thiab ua matte, ntxhib, velvety lossis pleev xim nrog cov qauv. Nyob rau hauv tsab xov xwm peb yuav xav txog dab tsi yog sandblasting iav

Kev tsim cov khoom siv roj: cov txheej txheem thev naus laus zis, khoom siv thiab khoom siv

Hnub no, muaj ntau yam khoom siv hauv tsev uas nrov. Ib qho kev tsim kho tshiab yog kev tsim cov khoom siv roj av, uas yog cov pob zeb ntawm tes. Ntawm cov no, nws muaj txiaj ntsig tsis yog los tsim ib lub tsev ntiag tug xwb, tab sis kuj tsim khoom muag

Yam koj yuav tsum tau ua haujlwm hauv tsheb tavxij: cov ntaub ntawv tsim nyog thiab cov cai, cov cai thiab kev cai lij choj. Cov lus teb thiab cov lus qhia los ntawm cov neeg tsav tsheb tavxij, cov neeg siv khoom thiab cov neeg xa khoom

Raws li ntau tus neeg caij tsheb, txoj haujlwm ntawm tus tsav tsheb tavxij yog qhov yooj yim tshaj plaws. Koj zaum, mloog suab paj nruag zoo nkauj thiab tsav tsheb rov qab los. Thiab lawv muab nyiaj rau koj. Tab sis qhov no tsuas yog sab nraud ntawm lub npib. Qhov rov qab yog ntau dua rosy. Peb yuav tham txog nws hauv kab lus no. Thiab peb tseem yuav qhia txog yam koj xav tau ua haujlwm hauv tsheb tavxij

Qhov twg tau txais txiaj ntsig kom tau txais qiv nyiaj rau cov neeg siv khoom xav tau? Cov xwm txheej zoo tshaj plaws rau cov neeg siv khoom siv credit

Cov nyiaj qiv siv tam sim no muaj rau yuav luag txhua tus. Lub hom phiaj ntawm cov neeg qiv nyiaj yog xaiv qhov kev pom zoo. Cov tsev txhab nyiaj muab nyiaj qiv nrog ntau yam xwm txheej. Qhov twg nws tau txais txiaj ntsig los qiv nyiaj rau cov neeg siv khoom xav tau yuav tau tham hauv kab lus