2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2024-01-02 13:55

Yuav kom tig ib qho dawb paug rau hauv qhov tsim nyog rau lub tshuab, tig, milling, sib tsoo thiab lwm yam tshuab siv. Yog tias milling tsim nyog rau kev tsim khoom ntawm ntau qhov chaw, piv txwv li, lub zog, txiav splines, ces tig yog siv los tsim cov khoom yooj yim thiab muab cov duab tsim nyog rau lawv (lub khob hliav qab, lub tog raj kheej, kheej kheej). Cov xwm txheej ntawm kev tig yog ib qho tseem ceeb heev, vim hais tias, piv txwv li, rau cov hlau nkig, nws yog ib qho tsim nyog yuav tsum siv lub zog qis dua li cov hlau muaj zog.

Txoj kev tig

Yuav kom tig ib qho kev nthuav dav ntawm lub tshuab dhos, raws li txoj cai, siv cov cutters. Lawv tuaj nyob rau hauv ntau yam kev hloov kho thiab raug cais raws li hom kev ua, pub kev taw qhia thiab lub taub hau zoo li. Tsis tas li ntawd, cov cutters yog ua los ntawm ntau yam ntaub ntawv: alloy steel, carbon steel, cuab yeej steel, high-speed txiav, tungsten,carbide.

Kev xaiv ntawm ib lossis lwm qhov yog nyob ntawm cov khoom ntawm lub workpiece, nws cov duab thiab txoj kev tig. Txiav tej yam kev mob rau tig yuav tsum coj mus rau hauv tus account tag nrho cov nuances. Thaum tig, lub workpiece yog tsau nyob rau hauv spindle, nws ua lub ntsiab rotational txav. Cov cuab yeej rau kev ua haujlwm yog ntsia rau hauv lub caliper, thiab pub mov txav tau ncaj qha los ntawm nws. Nyob ntawm lub tshuab siv, ob qho tib si me me thiab qhov loj tuaj yeem ua tau machined.

Basic elements

Dab tsi ntawm kev txiav cov ntaub ntawv tuaj yeem siv los hloov? Txawm hais tias tig tsis yog ib txwm ua haujlwm yooj yim, nws cov ntsiab lus tseem ceeb yog ceev, pub, qhov tob, dav thiab tuab. Tag nrho cov ntsuas no nyob ntawm qhov feem ntau ntawm cov khoom ntawm lub workpiece thiab qhov loj me. Rau qhov me me, piv txwv li, xaiv qhov kev txiav qis tshaj plaws, vim tias txawm tias 0.05 millimeters uas raug txiav tawm tuaj yeem ua rau tsis lees paub tag nrho ib feem.

Ntxiv rau, cov ntsuas tseem ceeb heev uas qhov kev xaiv ntawm kev txiav cov xwm txheej thaum lub sijhawm tig yog nyob ntawm theem uas nws tau ua. Xav txog cov ntsiab lus tseem ceeb thiab theem ntawm kev txiav hlau kom ntxaws.

Roughing, semi-tiav thiab tiav

Tig ib qho chaw ua haujlwm rau hauv qhov tsim nyog yog txheej txheem nyuaj thiab siv sijhawm. Nws muab faib ua tej theem: roughing, semi-finishing thiab xov. Yog hais tias ib feem yog qhov yooj yim, ces qhov nruab nrab (semi-tiav) theem, raws li txoj cai, tsis raug coj mus rau hauv tus account. Hauv thawj theem (draft), cov ntsiab lus tau muab cov duab tsim nyog thiab kwv yees qhov ntev. Nyob rau tib lub sijhawm, cov nyiaj pub dawb yuav tsum tau tso tseg rau theem tom ntej. Piv txwv li, muab ib lub workpiece: D=70 mm thiab L=115 mm. Nws yog tsim nyog los tshuab ib feem ntawm nws, thawj qhov loj ntawm uas yuav yog D1 =65 mm, L1 =80 mm, thiab thib ob - D2 =40mm, L2=20mm.

Roughing yuav muaj raws li hauv qab no:

- Txiav kawg 14mm.

- Tig txoj kab uas hla ntawm tag nrho qhov ntev ntawm 66 mm

- Tig ob txoj kab D2 =41 mm mus rau qhov ntev ntawm 20 mm.

Nyob rau theem no, peb pom tias qhov tsis tau ua tiav, tab sis ze li sai tau rau nws cov duab thiab qhov loj me. Thiab qhov nyiaj pub rau tag nrho qhov ntev thiab rau txhua qhov diameters yog 1 mm.

Siav ntu no yuav ua raws li hauv qab no:

- Ua qhov kawg txiav nrog qhov xav tau roughness.

- Tig 80mm ntev mus rau 65mm txoj kab uas hla.

- Ua zoo tig los ntawm qhov ntev ntawm 20mm mus rau txoj kab uas hla ntawm 40mm.

Raws li peb tuaj yeem pom, kev ua tiav yuav tsum muaj qhov siab tshaj plaws, vim li no, kev txiav ceev yuav qis dua hauv nws.

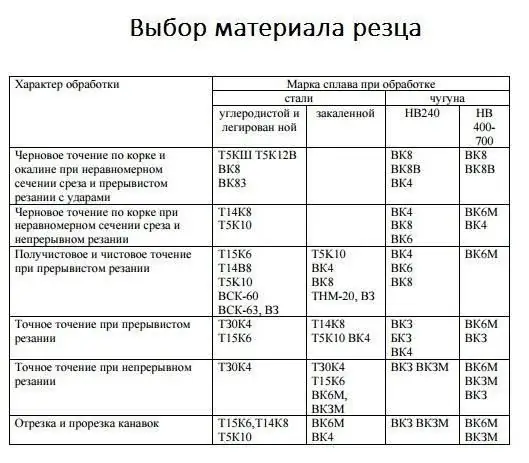

pib qhov twg los suav

txhawm rau xam cov kev txiav, koj yuav tsum xub xaiv cov khoom ntawm lub tshuab txiav. Nws yuav nyob ntawm seb cov khoom ntawm lub workpiece, hom thiab theem ntawm kev ua. Tsis tas li ntawd, incisors nyob rau hauv uas txiav ib feem yog tshem tau yog xam tau tias yog siv tau. Hauv lwm lo lus, nws tsuas yog tsim nyog los xaiv cov khoom ntawm kev txiav ntug thiab kho nws hauv cov cuab yeej txiav. Hom txiaj ntsig tshaj plaws yog qhov uas tus nqi ntawm cov khoom tsim tawm yuav yog qhov qis tshaj. Raws li, yog tias koj xaiv cov cuab yeej txiav tsis raug, nws yuav ua rau tawg, thiab qhov no yuav ua rau poob. Yog li yuav ua li cas koj txiav txim siab lub cuab yeej thiab txiav cov xwm txheej rau kev tig? Cov lus hauv qab no yuav pab koj xaiv qhov zoo tshaj plaws incisor.

Txiav txheej thickness

Raws li tau hais ua ntej, txhua tus txheej txheem ua tiav yuav tsum muaj qee qib ntawm qhov tseeb. Cov ntsuas no tseem ceeb heev kom meej meej thaum xam lub thickness ntawm txheej txheej. Txiav cov ntaub ntawv rau txoj siav guarantees xaiv qhov zoo tshaj plaws qhov tseem ceeb rau txoj siav. Yog tias lawv tsis saib xyuas thiab tsis suav nrog, ces ob lub cuab yeej txiav thiab qhov nws tus kheej tuaj yeem tawg.

Yog li, ua ntej ntawm tag nrho, koj yuav tsum xaiv qhov tuab ntawm txheej txheej. Thaum lub cutter hla cov hlau, nws txiav ib feem ntawm nws. Qhov tuab lossis qhov tob ntawm kev txiav (t) yog qhov kev ncua deb uas lub cutter yuav tshem tawm hauv ib qho dhau los. Nws yog ib qho tseem ceeb uas yuav tau xav txog tias rau txhua qhov kev ua haujlwm tom ntej nws yog ib qho tsim nyog yuav tsum tau ua ib qho kev suav ntawm txoj kev txiav. Piv txwv li, koj yuav tsum ua sab nraud tig ntawm ib feem D =33.5 mm rau ib txoj kab uas hla ntawm D1=30.2 mm thiab boring ntawm lub qhov d=3.2 hli rau d2=2 mm.

Rau txhua qhov kev ua haujlwm, kev suav ntawm kev txiav thaum lub sijhawm tig yuav yog tus kheej. Txhawm rau xam qhov tob ntawm kev txiav, nws yog ib qho tsim nyog los rho tawm txoj kab uas hla ntawm lub workpiece los ntawm txoj kab uas hla tom qab ua tiav thiab faib los ntawm ob. Hauv peb qhov piv txwv, nws yuav tig tawm:

t=(33.5 - 30.2) / 2=1.65mm

Yog tias qhov sib txawv ntawm txoj kab uas hla loj dhau, piv txwv li 40 hli, raws li txoj cai, nws yuav tsum muab faib los ntawm 2, thiab tus lej tshwm sim yuav yog tus lej hla, thiab qhov tob yuav sib npaug rau ob. millimeters. Nrog txoj kev ntxhib, koj tuaj yeem xaiv qhov tob ntawm 1 mus rau 3 hli, thiab ua tiav - los ntawm 0.5 mus rau 1 hli. Yog tias txiav qhov kawg nto ua tiav, ces qhov tuab ntawm cov khoom raug tshem tawm yuav yog qhov tob ntawm kev txiav.

Setting the feed amount

Kev xam ntawm kev txiav thaum lub sijhawm tig tsis tuaj yeem xav txog yam tsis muaj qhov txav ntawm cov cuab yeej txiav hauv ib lub kiv puag ncig ntawm ntu - pub (S). Nws txoj kev xaiv nyob ntawm qhov xav tau roughness thiab qib ntawm qhov tseeb ntawm lub workpiece, yog tias nws tiav. Thaum roughing, nws tso cai rau siv qhov siab tshaj plaws pub, raws li lub zog ntawm cov khoom thiab lub rigidity ntawm nws installation. Koj tuaj yeem xaiv cov khoom noj uas xav tau siv lub rooj hauv qab no.

Tom qab S tau raug xaiv, nws yuav tsum tau teev nyob rau hauv lub tshuab daim ntawv hla tebchaws.

txiav nrawm

Txiav ceev (v) thiab spindle ceev (n) yog qhov tseem ceeb heev uas cuam tshuam rau kev txiav cov kev hloov hauv kev tig. Rauxam tus nqi thawj zaug siv tus qauv:

V=(π x D x n) / 1000, qhov twg π yog Pi sib npaug 3, 12;

D - qhov siab tshaj qhov kab;

n yog spindle ceev.

Yog tias tus nqi kawg tseem tsis hloov pauv, ces qhov kev sib hloov ceev yuav ntau dua, qhov loj dua ntawm txoj kab uas hla ntawm lub workpiece. Cov mis no tsim nyog yog tias lub spindle ceev paub, txwv tsis pub koj yuav tsum siv cov mis:

v=(Cvx Kv)/ (Tm x t x S),

qhov twg t thiab S twb xam qhov tob ntawm kev txiav thiab pub, thiab Cv, Kv, T yog coefficients nyob ntawm txhua yam cov khoom thiab cov qauv ntawm cov khoom siv. Lawv cov txiaj ntsig tuaj yeem raug coj los ntawm cov ntaub ntawv txiav.

Cutting Data Calculator

Leej twg tuaj yeem pab koj suav cov xwm txheej thaum tig? Cov kev pabcuam online ntawm ntau qhov kev pabcuam hauv Is Taws Nem tiv nrog txoj haujlwm no tsis muaj qhov phem dua li tus neeg.

Nws tuaj yeem siv cov khoom siv ob qho tib si ntawm lub khoos phis tawj desktop thiab hauv xov tooj. Lawv xis nyob heev thiab tsis xav tau kev txawj tshwj xeeb. Koj yuav tsum nkag mus rau qhov yuav tsum tau muaj nyob rau hauv cov teb: pub, qhov tob ntawm kev txiav, cov khoom ntawm lub workpiece thiab txiav cov cuab yeej, raws li zoo raws li tag nrho cov tsim nyog qhov ntev. Qhov no yuav tso cai rau koj kom tau txais cov lus qhia ntxaws thiab nrawm ntawm txhua cov ntaub ntawv tsim nyog.

Pom zoo:

Usinskoye teb: cov yam ntxwv tseem ceeb thiab cov yam ntxwv ntawm thev naus laus zis

Usinskoye teb: thaj chaw thaj chaw, piav qhia, kwv yees hydrocarbon reserves. Nta ntawm cov roj thiab geological qauv ntawm cov deposit. Keeb kwm ntawm discovery thiab kev tshawb fawb ntawm cov deposit. Roj ntau lawm technology

Loj hlob nceb hauv tsev cog khoom: thev naus laus zis, yam ntxwv ntawm kev ua haujlwm, cov xwm txheej tsim nyog thiab cov kws tshaj lij cov lus qhia

Kev cog nceb hauv tsev cog khoom yog ib txoj hauv kev zoo kom tau cov qoob loo huv si rau koj tus kheej lossis muag. Nws tsis tuaj yeem hais tias thev naus laus zis ntawm cov txheej txheem no nyuaj heev, tab sis ntau txoj haujlwm yuav tsum tau nqis peev

Kev tsim cov ntoo: cov yam ntxwv thiab cov txheej txheem thev naus laus zis

Kev tsim cov ntoo niaj hnub suav nrog kev siv cov cuab yeej siv thev naus laus zis los tsim cov ntoo zoo

Vuam hauv qhov chaw tiv thaiv roj: ua haujlwm thev naus laus zis, txheej txheem piav qhia, cov txheej txheem ua tiav, cov khoom tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib ntus thiab cov lus qhia kws tshaj lij

Vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Versatility tau ua vuam nyob rau hauv ib puag ncig tiv thaiv roj ib qho tseem ceeb ntawm kev tsim khoom. Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv ib puag ncig tiv thaiv yog maj mam hloov cov tsoos electrode vuam

Kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab ntog: cov txheej txheem thiab cov txheej txheem ntawm kev kho dua tshiab, nta, txheej txheem thev naus laus zis

Vuam thiab surfacing thev naus laus zis ua rau nws ua tau zoo los kho cov hlau seem, muab cov qib siab ntawm kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom. Qhov no tau lees paub los ntawm kev xyaum siv cov txheej txheem no thaum ua haujlwm kho hauv ntau qhov chaw - los ntawm kev kho tsheb mus rau kev tsim cov hlau dov. Hauv tag nrho cov nyiaj ua haujlwm ntawm kev kho cov qauv hlau, kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam thiab surfacing yuav siv li 60-70%