2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Vises yog cov khoom siv thoob ntiaj teb tsim los tuav cov khoom ua haujlwm thaum lub sijhawm phau ntawv (qhov no, lub vise tau teeb tsa rau ntawm lub rooj zaum ua haujlwm) lossis siv tshuab (tshwj xeeb tshuab vise yog siv) ua.

Cov neeg tsim khoom ntawm cov cuab yeej siv tshuab muaj ntau yam kev pabcuam ntawm ntau hom. Txhua hom muaj tej yam ntxwv thiab muaj ntau yam nta. Yog li, raws li cov yam ntxwv ntawm cov txheej txheem thev naus laus zis thiab cov khoom siv muaj, peb tuaj yeem txiav txim siab tias qhov kev xaiv ntawm lwm tus yog ib txoj haujlwm nyuaj. Yuav ua li cas xaiv txoj cai thiab kev pom zoo, coj mus rau hauv tus account lub dav hlau uas twb muaj lawm ntawm metalworking tshuab? Kab lus no muab cov lus teb rau qhov no, nrog rau lwm cov lus nug uas yuav tshwm sim thaum npaj thiab yuav khoom siv rau koj tus kheej rhiav.

Cov khoom siv dab tsi yog cov khoom siv ua los ntawm

Vise lub cev yog ua los ntawm hlau lossis grey cam khwb cia hlau. Cam khwb cia hlau rooj yog feem ntau. Qhov no yog vim lub fact tias cam khwb cia hlau muaj zoo heev casting zoo (lub yaj solidifies heevntev thiab tswj kom sau tag nrho cov pwm) thiab pheej yig dua li hlau. Nyob rau tib lub sijhawm, cov khoom siv hluav taws xob ntawm cov hlau alloy nrog cov ntsiab lus siab ua kom txaus siab rau cov khoom siv rau kev tsim khoom ntawm ob phau ntawv thiab tshuab vices.

Lub khw muaj cov khoom siv los ntawm Tuam Tshoj, Europe thiab Asmeskas. Cov teb chaws no tau tsim thiab siv lawv tus kheej cov qauv. Raws li rau Lavxias teb sab Federation, kev tsim cov khoom siv ntawm nws thaj chaw yog nruj me ntsis tswj los ntawm GOST 16518-96.

Tus yam ntxwv tseem ceeb tshaj plaws ntawm lub vise

Thaum xaiv ib lub cuab yeej tshwj xeeb, koj yuav tsum ua tib zoo nyeem nws cov kev ntsuas thiab peev xwm. Ua ntej tshaj plaws, txhawm rau kom tsis txhob muab cov nyiaj pov tseg, koj yuav tsum paub seb cov cuab yeej siv tshuab zoo li cas lawv tau npaj rau kev teeb tsa (milling, nto sib tsoo, npaj, broaching, drilling lossis lwm yam tshuab).

Tom qab ntawd nws yuav tsum tau kuaj xyuas seb qhov dav ntawm lub puab tsaig ua haujlwm puas txaus, lossis seb lawv nqaim dhau lawm thiab yuav nias nyuaj rau ntawm qhov chaw ua haujlwm, tawm hauv cov dents hauv nws. Lub zog clamping kuj tseem ceeb. Qhov ntev stroke tso cai rau koj los txiav txim siab qhov siab tshaj plaws linear qhov ntev ntawm lub workpiece ntsia hauv lub vise.

Nyob rau hauv cov xwm txheej uas lwm tus neeg yuav khoom rau lub tshuab ua haujlwm me me tau teeb tsa hauv chav nres tsheb lossis hauv qab daus ntawm chav tsev, lossis txawm nyob rau ntawm lub sam thiaj (muaj qhov zoo li no!), Tom qab ntawd qhov tseem ceeb tsis zoo, tau kawg, yog lawv qhov hnyav. Kev txwv qhov hnyav ntawm cov khoom yuav tsum tau nruab rau ntawm lub tshuab ua haujlwm me me yuav tsum tsis txhob dhau, vim tias cov khoom siv ntawm lub tshuab yuav ua tsis tau sai.

Hom thiab ntau yam ntawm vise rau hlau ua haujlwm

- Ua raws li tus qauv teev tseg, kev lag luam tsim cov kev ua haujlwm ntawm qhov raug, nce qhov tseeb thiab siab-precision, nruab nrog phau ntawv lossis tsis siv neeg (hydraulic, pneumatic, hluav taws xob) tsav.

- Raws li lub hom phiaj, lub vise muab faib ua phau ntawv, lub rooj zaum, tshuab, tshwj xeeb (nrog rau kev tsav tsheb).

- Raws li hom tsav, tshuab vices txawv nrog phau ntawv clamping, nrog hydraulic tsav, nrog lub tawb (los yog eccentric clamp), nrog lub caij nplooj ntoos hlav clamp.

- Nyob ntawm cov khoom raug ua tiav thiab nws cov khoom siv kho tshuab, lub puab tsaig ntawm qhov sib txawv hardness thiab nrog cov ntawv sib txawv tuaj yeem ntsia tau rau ntawm lub vise.

Lub ntsiab tseem ceeb ntawm lub vise

Cov tshuab niaj hnub vices yog cov qauv sib txawv ntawm cov khoom siv classic. Txawm li cas los xij, lub hauv paus ntsiab lus ntawm kev ua haujlwm thiab kev ua haujlwm tseem tsis hloov pauv, thiab cov khoom tseem ceeb hauv qab no tuaj yeem paub qhov txawv: lub cev, txav tau thiab ruaj khov lub puab tsaig, kov, lub zog ntsia hlau nrog trapezoidal thrust xov, kov.

Txoj kev ntawm lub vise mounted ntawm lub rooj ntawm lub tshuab milling

Machine milling vices muaj, tej zaum, ntawm txhua qhov chaw ua haujlwm. Thiab yog tias, nyob rau hauv cov xwm txheej ntawm kev tsim khoom loj, lawv siv zog ua cov cuab yeej tshwj xeeb rau kev kho cov khoom ua haujlwm ntawm lub rooj ua haujlwm ntawm lub tshuab, tom qab ntawd hauvCov xwm txheej ntawm ib qho kev tsim khoom, nrog rau kev kho ntau lawm, tsis hais txog qhov chaw nres tsheb rhiav, xws li vise tsuas yog ib qho tseem ceeb tshaj plaws.

Rau cov cuab yeej siv tshuab vises, qhov tawv nqaij yog qhov tseem ceeb thiab qhov tseem ceeb tshaj plaws. Yog hais tias tus tsim tsis muab rigidity, ces thaum lub sij hawm ua, ib tug tsis kaj siab thiab irritating lub rooj sib hais ntawm ib tug neeg yuav tshwm sim, ib tug nrov screech ntawm hlau. Hauv qhov no, lub cutter yuav rattle. Yog li ntawd, ua tsis tiav ntxov ntxov ntawm cov cuab yeej kim heev thiab tsis txaus siab roughness ntawm machined nto. Qee zaum ib feem tseem yuav mus pov tseg, uas txhais tau tias kev poob nyiaj ntxiv.

Yog tias cov sponges ntawm universal locksmith vice muaj tus yam ntxwv corrugated nto, ces nyob rau lwm yam rau cov cuab yeej tshuab lawv yuav tsum ib txwm du. Tsis tas li ntawd, ib qho ntxhib uas tsis tau kho kom zoo tom qab casting tsis raug tso cai. Cov sponges no tau ua tiav nrog cov cuab yeej txiav (cutter lossis cutter), thiab tom qab ntawd hauv av rau saum npoo kom ua tiav qhov xav tau roughness thiab geometric duab.

Rotary tshuab vise

Cov kev pabcuam zoo li no tau teeb tsa rau ntawm lub tshuab hluav taws xob tshwj xeeb. Nws tsis muaj kev txwv thiab tuaj yeem tig mus rau txhua lub kaum ntse ntse. Ua kom tig, nws yog ib qho tsim nyog yuav tsum tau ntxuav ob lub txiv ntoo ntawm lub hauv paus. Tom qab qhov xav tau lub kaum sab xis tau teeb tsa, cov txiv ntseej tau nruj nrog lub ntsej muag qhib qhov kawg nrog lub zog ntau li ntau tau.

Tsis muaj livise yog qhov tsis muaj rigidity. Tab sis lub hauv paus pivot tuaj yeem raug tshem tawm, thiab tom qab ntawd nws yuav yog ib txwm jig.

Machine vise rau cov tshuab drilling

Vise mounted rau ntawm tus ncej ntawm ntsug drilling tshuab yuav tsum muab qhov ua tau ntawm kev hloov lub workpiece nyob rau hauv ob txoj kev nyob rau hauv lub kab rov tav dav hlau. Cov nqe lus no tsis muaj tseeb rau cov tshuab radial drilling, txij li lub spindle nws tus kheej txav mus rau lawv nrog lub laum nruab rau hauv nws. Feem ntau, tshuab vices rau drilling units muaj tsawg dua rigidity dua milling vices, raws li lawv muaj ntau qib ntawm kev ywj pheej.

Pom zoo:

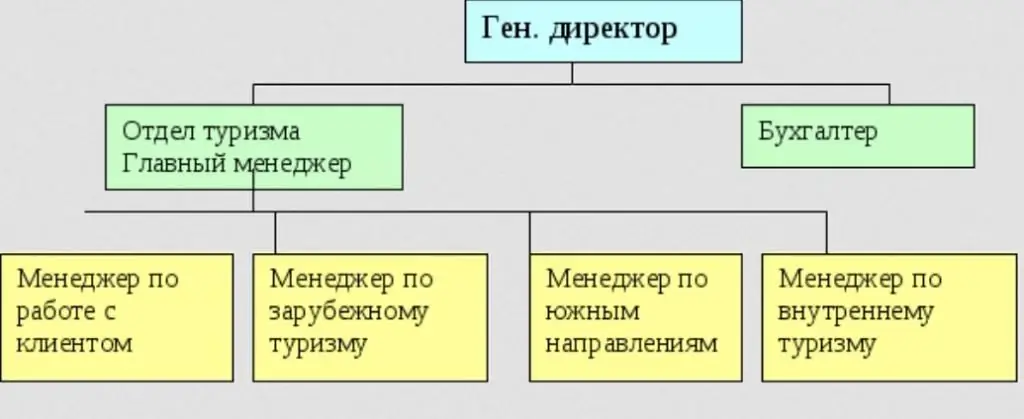

Hom kev ncig xyuas thiab lawv cov yam ntxwv. Kev ua haujlwm thiab cov yam ntxwv ntawm cov haujlwm ntawm cov neeg ncig xyuas ncig xyuas

Tus neeg ncig xyuas muab ntau yam kev pabcuam mus ncig thiab ua kom yooj yim rau kev tshwj tseg cov kev pabcuam hauv lwm lub nroog thiab lub tebchaws, ua haujlwm rau cov haujlwm no. Nyob rau hauv lub tshav pob ntawm tourism kev pab cuam, nws occupies ib tug tshwj xeeb niche. Hauv tsab xov xwm peb yuav txiav txim siab txog hom kev ua ub no ntawm cov neeg ncig xyuas

Italian geese: piav qhia ntawm hom, nta ntawm kev saib xyuas, kev yug me nyuam, yam ntxwv nta, kev cai ntawm kev khaws cia thiab cov txiaj ntsig

Qhia kev yug me nyuam yog ib txoj hauv kev zoo kom tau nyiaj rau tus neeg ua liaj ua teb. Lawv yog unpretentious nyob rau hauv kev saib xyuas, sai sai nce qhov hnyav thiab nyob rau hauv kev thov ntawm cov pejxeem. Dawb Italian geese yuav tsis tsuas yog coj cov nyiaj tau los zoo, tab sis kuj kho lub tshav puam nrog lawv cov tsos. Cov noog yoog tau zoo rau cov xwm txheej sib txawv ntawm kev kaw, lawv tuaj yeem raug bred nyob rau hauv txhua qhov chaw huab cua. Italian geese - ib tug godsend rau ib tug neeg ua liaj ua teb ua lag luam

Txoj kev tsheb ciav hlau yog Txhais, tswvyim, yam ntxwv thiab qhov ntev. Tsheb ciav hlau qhov ntev thiab cov yam ntxwv ntawm cov chaw khiav haujlwm

Kev mus los ntawm tsheb ciav hlau hla lub nroog thiab cov nroog, koj tuaj yeem kawm ntau yam nthuav thiab lom zem txog lub ntiaj teb ntawm txoj kev tsheb ciav hlau. Ntau tshaj ib zaug, cov neeg taug kev tau nug lawv tus kheej cov lus nug txog qhov twg qhov no lossis txoj kev tsheb ciav hlau coj mus? Thiab tus engineer uas tswj lub tsheb ciav hlau xav li cas thaum lub tsheb ciav hlau pib tawm lossis tuaj txog ntawm qhov chaw nres tsheb? Yuav ua li cas thiab los ntawm qhov twg cov tsheb hlau txav thiab txoj hauv kev ntawm cov khoom dov yog dab tsi?

Cov yam ntxwv thiab cov yam ntxwv ntawm cov kev pabcuam hauv tsev so, tshwj xeeb thiab cov ntsiab lus

Kev lag luam tsev so yog ib ceg ntawm kev tos txais qhua. Cov ntsiab lus thiab cov yam ntxwv ntawm cov kev pabcuam hauv tsev so raws li cov khoom lag luam ntawm lub tsev so yog vim muaj kev lag luam zoo ntawm cov lag luam kev lag luam uas xav tau ntawm cov neeg siv khoom uas xav tau cov xwm txheej tsim nyog rau kev pab thiab khoom noj

Dorper yog ib hom yaj. Kev piav qhia, yam ntxwv thiab cov yam ntxwv ntawm cov ntsiab lus

Dorper - ib hom ntawm yaj yog unpretentious heev thiab nyob rau tib lub sij hawm thaum ntxov thiab tsim tau. Nws nrov heev nrog cov neeg ua liaj ua teb txawv teb chaws. Hauv peb lub tebchaws, nws tseem nyuaj heev los yuav cov yaj no. Txawm li cas los xij, qee qhov chaw ua liaj ua teb tseem muag cov tsiaj me ntawm cov tsiaj no