2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2024-01-02 13:55

cam khwb cia hlau yog ib qho nyuaj, corrosion-resistant, tab sis nkig hlau-carbon alloy nrog cov ntsiab lus C ntawm 2.14 txog 6.67%. Txawm hais tias muaj cov yam ntxwv tsis zoo, nws muaj ntau hom, khoom, kev siv. Ductile hlau yog dav siv.

History

Cov khoom no tau paub txij li xyoo pua 4 BC. e. Nws cov hauv paus hniav Suav yog nyob rau hauv lub xyoo pua VI. BC e. Nyob rau hauv cov teb chaws Europe, thawj hais txog kev lag luam ntawm cov alloy hnub rov qab mus rau lub 14th, thiab nyob rau hauv Russia - mus rau lub xyoo pua 16th. Tab sis lub tshuab rau zus tau tej cov hlau ductile yog patented nyob rau hauv Russia nyob rau hauv lub xyoo pua puv 19. Tom qab tsim los ntawm A. D. Annosov.

Vim tias grey cam khwb cia hlau raug txwv rau kev siv vim tsis muaj cov khoom siv kho tshuab, thiab cov hlau tsis tshua muaj zog thiab tsis muaj zog thiab ua haujlwm ntev, cov lus nug tshwm sim ntawm kev tsim cov hlau ruaj khov, ruaj khov, tawv tawv, tib lub sijhawm muaj zog ntxiv. thiab tej yam yas.

Forging cam khwb cia hlau tsis tuaj yeem ua tau, tab sis vim nws cov yam ntxwv ductile, nws qiv nws tus kheej rau qee hom kev kho siab (piv txwv, stamping).

Production

Txoj kev tseem ceeb -smelting nyob rau hauv blast furnaces.

Feedstock rau blast furnace processing:

- Batch - hlau ore muaj hlau nyob rau hauv daim ntawv ntawm ferum oxides.

- Roj - coke thiab natural gas.

- Oxygen - txhaj los ntawm cov lances tshwj xeeb.

- Fluxes yog tshuaj tsim los ntawm manganese thiab (lossis) silicon.

theem ntawm qhov cub tawg:

- Kev rov qab los ntawm cov hlau ntshiab los ntawm cov tshuaj tiv thaiv ntawm cov hlau ore nrog oxygen muab los ntawm lances.

- Kev sib xyaw ntawm coke thiab tsim cov carbon oxides.

- Carburization ntawm cov hlau ntshiab hauv kev cuam tshuam nrog CO thiab CO2.

- Saturation of Fe3C nrog manganese thiab silicon, nyob ntawm seb cov khoom tsim tawm.

- Txiav cov hlau tiav rau hauv pwm los ntawm cov cam khwb cia hlau tapholes; slag tawm los ntawm slag tapholes.

Thaum kawg ntawm lub voj voog ua haujlwm, cov tshuab hluav taws xob tawg tau txais npua hlau, slag thiab tawg-qhov cub gases.

Blast Rauv Hlau Khoom

Nyob ntawm qhov txias txias, microstructure, saturation nrog carbon thiab additives, nws muaj peev xwm tau txais ntau hom cam khwb cia hlau:

- Yuav (dawb): cov pa roj carbon monoxide, thawj cementite. Lawv yog siv los ua raw khoom rau smelting ntawm lwm yam hlau-carbon alloys, ua. Txog li 80% ntawm tag nrho cov blast furnace alloy tsim.

- Foundry (grey): carbon nyob rau hauv daim ntawv ntawm tag nrho los yog ib nrab dawb graphite, uas yog nws daim hlau. Siv rau kev tsim khoom ntawm lub luag haujlwm qis hauv lub cev. Txog li 19% ntawm cov khoom tawg-qhov cub castings.

- Tshwj xeeb: nplua nuj hauv ferroalloys. 1-2% ntawm qhov kev txiav txim siab ntau lawm.

Cov hlau yog tau los ntawm kev kho cua sov ntawm npua hlau.

Txoj kev xav ntawm hlau-carbon qauv

Carbon nrog ferum tuaj yeem tsim ntau yam sib txawv ntawm cov alloys raws li hom siv lead ua lattice, uas tau tso tawm ntawm qhov kev xaiv microstructure.

- Tshuaj tshuaj nkag mus rau hauv α-hlau - ferrite.

- Solid solution nkag mus rau γ-hlau - austenite.

- Tshuaj tsim Fe3C (lub xeev khi) - cementite. Lub hauv paus yog tsim los ntawm kev ua kom txias sai ntawm cov kua yaj. Secondary - qis qis qis, los ntawm austenite. Tertiary - maj mam txias, los ntawm ferrite.

- Kev sib xyaw ntawm cov nplej ntawm ferrite thiab cementite - perlite.

- Kev sib xyaw ntawm cov nplej ntawm perlite lossis austenite thiab cementite - ledeburite.

Cam khwb cia hlau muaj qhov tshwj xeeb microstructure. Graphite tuaj yeem nyob rau hauv daim ntawv khi thiab tsim cov qauv saum toj no, lossis nws tuaj yeem nyob hauv lub xeev dawb hauv daim ntawv ntawm ntau yam kev suav. Cov khoom yog cuam tshuam los ntawm ob qho tib si tseem ceeb nplej thiab cov formations. Graphite feem hauv cov hlau yog daim hlau, flakes lossis pob.

Cov duab lamellar yog yam ntxwv ntawm grey hlau-carbon alloys. Nws ua rau lawv tsis yooj yim thiab tsis ntseeg.

Flake-like inclusions muaj malleable cam khwb cia hlau, uas muaj txiaj ntsig zoo rau lawv cov tshuab ua haujlwm.

Cov qauv kheej kheej ntawm graphite yog ntau duatxhim kho qhov zoo ntawm cov hlau, cuam tshuam rau qhov nce hauv hardness, kev ntseeg tau, raug rau cov khoom tseem ceeb. High-strength cam khwb cia hlau muaj cov yam ntxwv no. Malleable cam khwb cia hlau txiav txim siab nws cov khoom los ntawm ferritic lossis pearlitic hauv paus nrog lub xub ntiag ntawm flaky graphite inclusions.

Kev tsim cov ferritic ductile hlau

Nws yog tsim los ntawm npua dawb hypoeutectoid low-carbon alloy los ntawm annealing ingots nrog cov pa roj carbon ntsiab lus ntawm 2.4-2.8% thiab muaj cov khoom siv ntxiv rau lawv (Mn, Si, S, P). Lub thickness ntawm cov phab ntsa ntawm cov annealed qhov chaw yuav tsum tsis txhob ntau tshaj 5 cm. Rau castings ntawm tseem ceeb thickness, graphite muaj daim ntawv ntawm daim hlau thiab cov khoom uas xav tau yog tsis tiav.

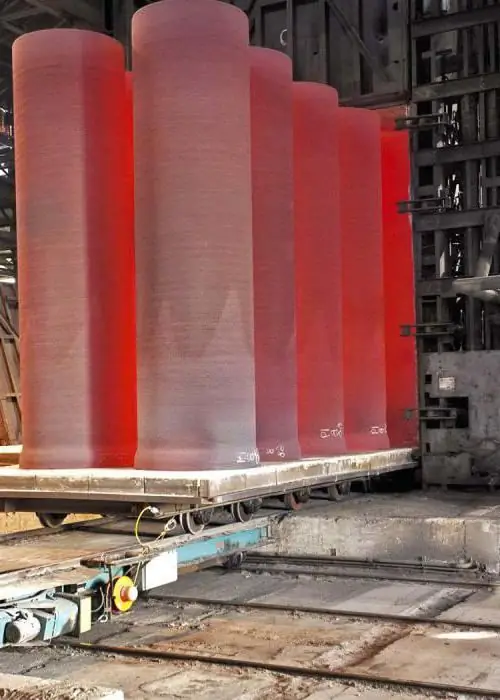

Kom tau cov hlau nplaum nrog lub hauv paus ferritic, cov hlau muab tso rau hauv cov thawv tshwj xeeb thiab nphoo nrog xuab zeb. Tightly kaw ntim tau muab tso rau hauv cov cua sov rauv taws. Ua raws li cov kev ua hauv qab no thaum lub sij hawm annealing:

- Cov qauv yog rhuab rau hauv qhov cub kom kub txog 1,000 ˚C thiab sab laug kom sawv ntawm qhov cua sov tas li rau 10 mus rau 24 teev. Yog li ntawd, thawj cementite thiab ledeburite disintegrate.

- Cov hlau yog txias rau 720 ˚С ua ke nrog rau qhov cub.

- Ntawm qhov kub ntawm 720 ˚С lawv khaws cia ntev: los ntawm 15 mus rau 30 teev. Qhov ntsuas kub no ua kom cov decomposition ntawm cov cementite thib ob.

- Thaum kawg, lawv tau txias dua ua ke nrog lub qhov cub ua haujlwm rau 500 ˚С, thiab muab tshem tawm mus rau saum huab cua.

Cov thev naus laus zis annealing yog hu ua graphitizing.

Tom qab ua haujlwm tiav, cov khoom siv microstructure yogferrite nrog flaky graphite nplej. Hom no hu ua "dub-hearted" vim kev tawg yog dub.

Kev tsim cov pearlitic ductile hlau

Qhov no yog ib hom hlau-carbon alloy, uas kuj yog los ntawm hypoeutecoid dawb, tab sis cov ntsiab lus carbon hauv nws tau nce: 3-3.6%. Yuav kom tau txais castings nrog pearlite puag, lawv muab tso rau hauv lub thawv thiab sprinkled nrog crushed hmoov hlau ore los yog nplai. Cov txheej txheem annealing nws tus kheej yog yooj yim.

- Qhov kub ntawm cov hlau yog nce mus rau 1,000 ˚C, tuav rau 60-100 teev.

- Designs txias nrog qhov cub.

Vim languor nyob rau hauv lub zog ntawm tshav kub, diffusion tshwm sim nyob rau hauv cov hlau ib puag ncig: lub graphite tso tawm nyob rau hauv lub cementite decay ib feem ntawm lub nto txheej ntawm lub annealed qhov chaw, nyob rau saum npoo ntawm cov ore los yog nplai. Lub softer, ntau ductile thiab ductile sab sauv txheej ntawm "dawb-hearted" ductile hlau nrog ib tug nyuaj chaw yog tau.

Cov kev xav zoo li no hu ua tsis tiav. Nws xyuas kom meej qhov tawg ntawm cementite thiab ledeburite rau hauv lamellar perlite nrog cov graphite sib xws. Yog hais tias granular pearlitic ductile hlau yuav tsum muaj kev cuam tshuam ntau zog thiab ductility, ntxiv cua sov ntawm cov khoom mus txog 720 ˚С yog siv. Qhov no ua rau tsim cov pearlite nplej nrog flaky graphite inclusions.

Khoom, cim thiab kev siv ntawm Ferritic Ductile Iron

Ntev "ntxias" ntawm cov hlau nyob rau hauv lub cub tawg ua rau ua tiav kev lwj ntawm cementite thiab ledeburite rau hauv ferrite. Ua tsaug rauKev siv thev naus laus zis, cov hlau alloy nrog cov ntsiab lus siab carbon tau txais - cov qauv ferritic yam ntxwv ntawm cov hlau tsis tshua muaj carbon. Txawm li cas los xij, carbon nws tus kheej tsis ploj mus qhov twg - nws dhau los ntawm lub xeev khi rau hlau mus rau lub xeev dawb. Cov nyhuv kub hloov pauv cov duab ntawm graphite suav nrog rau flaky.

Ferritic qauv ua rau txo qis hauv hardness, nce hauv qhov muaj zog, muaj cov yam ntxwv xws li cuam tshuam lub zog thiab ductility.

Kev kos npe ntawm cov hlau nplaum ntawm ferritic chav kawm: KCh30-6, KCh33-8, KCh35-10, KCh37-12, qhov twg:

KCh - ntau hom npe - malleable;

30, 33, 35, 37: σv, 300, 330, 350, 370 N / mm2 - siab tshaj plaws tias nws tuaj yeem tiv taus yam tsis muaj kev sib tsoo;

6, 8, 10, 12 - txheeb ze elongation, δ, % - ductility Performance index (tus nqi siab dua, ntau cov hlau tuaj yeem ua tiav los ntawm kev siab).

Hardness - txog 100-160 HB.

Cov khoom siv no, hais txog nws qhov kev ua tau zoo, nyob nruab nrab ntawm txoj haujlwm xws li hlau thiab grey hlau-carbon alloy. Ductile cam khwb cia hlau nrog lub hauv paus ferritic tsis zoo rau pearlitic nyob rau hauv cov nqe lus ntawm hnav tsis kam, corrosion thiab qaug zog zog, tab sis siab dua nyob rau hauv cov nqe lus ntawm mechanical endurance, ductility, thiab casting yam ntxwv. Vim nws tus nqi qis, nws tau siv dav hauv kev lag luam rau kev tsim khoom ntawm cov khoom siv qis thiab nruab nrab: lub zog, crankcases, rear qag, kav dej.

Khoom, cim thiab kev siv ntawm Pearlitic Ductile Iron

Vim tsis tiav annealing, thawj, theem nrab cementites thiab ledeburite muaj sij hawm kom yaj tag rau hauv austenite, uas ntawm qhov kub ntawm 720 ˚С hloov mus ua pearlite. Cov tom kawg yog kev sib xyaw ua ke ntawm cov nplej ntawm ferrite thiab tertiary cementite. Qhov tseeb, ib feem ntawm cov pa roj carbon tseem nyob rau hauv daim ntawv khi, txiav txim siab tus qauv, thiab ib feem yog "tso tawm" rau hauv flaky graphite. Hauv qhov no, perlite tuaj yeem yog lamellar lossis granular. Yog li pearlitic ductile hlau yog tsim. Nws cov khoom yog vim nws saturated, nyuaj thiab tsawg pliable qauv.

Cov no, piv nrog ferritic, muaj ntau dua los tiv thaiv corrosion, hnav-resistant zog, lawv lub zog yog ntau dua, tab sis qis casting yam ntxwv thiab ductility. Lub pliability rau txhua yam kev nyuaj siab yog nce superficially, thaum tuav lub hardness thiab viscosity ntawm cov tub ntxhais ntawm cov khoom.

Kev kos npe ntawm malleable cam khwb cia hlau pearlitic chav kawm: KCh45-7, KCh50-5, KCh56-4, KCh60-3, KCh65-3, KCh70-2, KCh80-1, 5.

thawj tus lej yog lub zog tsim: 450, 500, 560, 600, 650, 700 thiab 800 N / mm2 raws.

Thib ob - lub npe ntawm plasticity: elongation δ,% - 7, 5, 4, 3, 3, 2 thiab 1, 5.

Perlitic malleable cam khwb cia hlau tau siv rau hauv kev tsim kho tshuab thiab kev ntsuas rau cov qauv ua haujlwm hauv cov khoom hnyav - ob qho tib si zoo li qub thiab dynamic: camshafts, crankshafts, clutch qhov chaw, pistons, txuas rods.

kev kho cua sov

Cov khoom tau txais los ntawm kev kho cua sov, uas yog annealing, tuaj yeem rov ua duayuav raug kub influences. Lawv lub hom phiaj tseem ceeb yog ua kom muaj zog ntxiv, hnav tsis kam, tiv thaiv corrosion thiab laus.

- Hardening yog siv rau cov qauv uas xav tau siab hardness thiab toughness; ua los ntawm cua sov mus txog 900 ˚С, cov khoom yog txias ntawm qhov nruab nrab ntawm li 100 ˚С / sec siv cov roj tshuab. Nws ua raws li kev kub ntxhov siab nrog cua sov txog 650˚С thiab cua txias.

- Normalization yog siv rau qhov nruab nrab qhov yooj yim los ntawm cua sov hauv qhov cub rau 900 ˚С, tuav ntawm qhov ntsuas kub no rau 1 mus rau 1.5 teev thiab tom qab ntawd txias hauv huab cua. Muab troostite granular perlite, nws hardness thiab kev ntseeg tau ntawm kev sib txhuam thiab hnav. Nws yog siv los tiv thaiv kev sib txhuam malleable cam khwb cia hlau nrog pearlitic puag.

- Annealing yog rov ua dua nyob rau hauv kev tsim khoom ntawm kev sib txhuam: cua sov - txog li 900 ˚С, tuav lub sij hawm ntev ntawm qhov cua sov no, txias ua ke nrog lub cub tawg. Lub ferritic lossis ferritic-pearlitic qauv ntawm kev sib txhuam ductile hlau yog muab.

Cov khoom cua sov ntawm cov khoom siv hlau tuaj yeem nqa tawm hauv zos lossis ua ke. Rau kev siv hauv zos, cov khoom siv hluav taws xob ntau lossis cov nplaim hluav taws xob acetylene (hardening). Rau complex - cua sov furnaces. Nrog rau cov cua sov hauv zos, tsuas yog cov txheej sab saud yog hardened, thaum nws hardness thiab lub zog nce, tab sis cov yas thiab viscosity ntawm cov tub ntxhais tseem nyob.

Nws yog ib qho tseem ceeb uas yuav tsum tau taw qhia ntawm no tias forging cam khwb cia hlau tsis tuaj yeem tsis tsuas yog vim tsis muaj kev siv tshuab txausCov yam ntxwv, tab sis kuj vim nws qhov kev nkag siab zoo rau qhov kub thiab txias poob, uas yog qhov kev zam tsis tau thaum hardening nrog dej txias.

Anti-friction ductile irons

Qhov ntau yam no siv tau rau ob qho tib si malleable thiab alloyed sawv daws yuav, lawv yog grey (ASF), malleable (ASC) thiab high-strength (ACS). Ductile hlau yog siv rau zus tau tej cov ACHK, uas yog annealed los yog normalized. Cov txheej txheem tau ua tiav txhawm rau txhawm rau txhim kho nws cov khoom siv kho tshuab thiab tsim cov yam ntxwv tshiab - hnav tsis kam thaum sib txhuam nrog lwm qhov chaw.

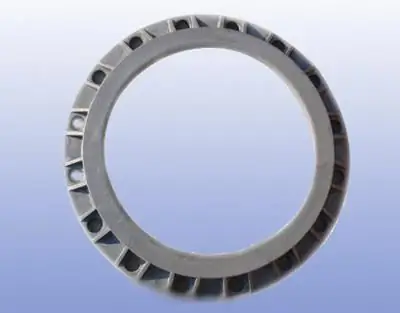

Kos npe: AChK-1, ACHK-2. Nws yog siv rau kev tsim cov crankshafts, zog, bearings.

Kev cuam tshuam ntawm cov khoom ntxiv ntawm cov khoom

Ntxiv rau cov hlau-carbon puag thiab graphite, lawv kuj muaj lwm yam khoom uas tseem txiav txim siab cov khoom ntawm cam khwb cia hlau: manganese, silicon, phosphorus, sulfur, thiab qee cov ntsiab lus alloying.

Mangan ua kom cov kua hlau ua kua dej, tiv thaiv corrosion thiab hnav tsis kam. Nws pab ua kom tawv thiab lub zog, sib txuas cov pa roj carbon nrog hlau hauv cov tshuaj Fe3C, tsim cov granular perlite.

Silicon kuj muaj txiaj ntsig zoo ntawm cov kua dej ua kua, txhawb kev decomposition ntawm cementite thiab tso tawm ntawm graphite inclusions.

Sulfur yog ib qho tsis zoo tab sis tsis muaj kev cuam tshuam. Nws txo cov khoom siv thiab tshuaj lom neeg, txhawb kev tsim cov kab nrib pleb. Txawm li cas los xij, qhov sib piv ntawm nws cov ntsiab lus nrog lwm cov ntsiab lus (piv txwv li, nrog manganese) tso caicov txheej txheem microstructural raug. Yog li, ntawm Mn-S piv ntawm 0.8-1.2, perlite yog khaws cia txhua lub sijhawm ntawm qhov kub thiab txias. Thaum qhov sib piv tau nce mus rau 3, nws tuaj yeem tau txais cov qauv tsim nyog, nyob ntawm qhov kev txwv tsis pub dhau.

Phosphorus hloov fluidity rau qhov zoo dua, cuam tshuam lub zog, txo qhov cuam tshuam lub zog thiab ductility, cuam tshuam rau lub sijhawm ntawm graphitization.

Chromium thiab molybdenum cuam tshuam kev tsim cov graphite flakes, hauv qee cov ntsiab lus lawv pab tsim cov granular perlite.

Tungsten txhim kho kev hnav tsis kam hauv qhov chaw kub.

Aluminium, npib tsib xee, tooj liab pab txhawb rau graphitization.

Los ntawm kev kho tus nqi ntawm cov tshuaj uas tsim cov hlau-carbon alloy, nrog rau lawv qhov sib piv, nws muaj peev xwm cuam tshuam cov khoom kawg ntawm cam khwb cia hlau.

Qhov zoo thiab qhov tsis zoo

Cov hlau nplaum yog cov khoom siv dav siv hauv engineering. Nws cov txiaj ntsig tseem ceeb:

- siab hardness, hnav tsis kam, lub zog nrog rau fluidity;

- ib txwm toughness thiab ductility yam ntxwv;

- kev tsim khoom hauv kev tsim, tsis zoo li grey cam khwb cia hlau;

- ntau yam kev xaiv rau kev kho cov khoom rau ib feem los ntawm txoj kev kho cua sov thiab tshuaj lom neeg;

- nqi qis.

Qhov tsis zoo suav nrog tus kheej tus yam ntxwv:

- fragility;

- muaj graphite suav nrog;

- kev ua haujlwm tsis zoo;

- hnyav hnyav ntawm castings.

Txawm hais tias muaj qhov tsis zoo uas twb muaj lawm, cov hlau nplaum muaj lub luag haujlwm hauv metallurgy thiab engineering. Xws li qhov tseem ceeb xws li crankshafts, nres nres qhov chaw, iav log, pistons, txuas rods yog tsim los ntawm nws. Muaj ntau yam tsis tseem ceeb ntawm cov qib, ductile hlau occupies ib tus neeg niche hauv kev lag luam. Nws siv yog ib yam rau cov loads uas siv lwm yam ntaub ntawv tsis zoo li.

Pom zoo:

Lub luag haujlwm tseem ceeb ntawm kev txhim kho cov neeg ua haujlwm subsystem yog: ua haujlwm nrog cov neeg ua haujlwm khaws cia, rov cob qhia thiab kev cob qhia cov neeg ua haujlwm siab, npaj thiab saib xyuas cov haujlwm ua lag luam

Lub luag haujlwm tseem ceeb ntawm kev txhim kho cov neeg ua haujlwm subsystem yog cov cuab yeej ua haujlwm zoo uas tuaj yeem txhim kho cov kev tsim nyog ntawm cov neeg ua haujlwm zoo rau ib tus neeg sab hauv, tus tswv, txoj cai, tus cob qhia. Nws yog nyob rau hauv lub koom haum ntawm xws li kev loj hlob ntawm cov neeg ua hauj lwm uas cov txuj ci ntawm ib tug txias neeg ua hauj lwm neeg ua hauj lwm dag. Nws yog ib qho tseem ceeb rau nws thaum lub ntsiab lus "xav rau cov neeg ua haujlwm tau zoo" yog ntxiv los ntawm lub hom phiaj sib sib zog nqus kev paub txog cov txheej txheem ntawm cov neeg ua haujlwm, uas tau tsim thiab tswj kom ntxaws

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Yam koj yuav tsum tau ua haujlwm hauv tsheb tavxij: cov ntaub ntawv tsim nyog thiab cov cai, cov cai thiab kev cai lij choj. Cov lus teb thiab cov lus qhia los ntawm cov neeg tsav tsheb tavxij, cov neeg siv khoom thiab cov neeg xa khoom

Raws li ntau tus neeg caij tsheb, txoj haujlwm ntawm tus tsav tsheb tavxij yog qhov yooj yim tshaj plaws. Koj zaum, mloog suab paj nruag zoo nkauj thiab tsav tsheb rov qab los. Thiab lawv muab nyiaj rau koj. Tab sis qhov no tsuas yog sab nraud ntawm lub npib. Qhov rov qab yog ntau dua rosy. Peb yuav tham txog nws hauv kab lus no. Thiab peb tseem yuav qhia txog yam koj xav tau ua haujlwm hauv tsheb tavxij

REMIT Meat Processing Plant LLC: tawm tswv yim los ntawm cov neeg siv khoom thiab cov neeg ua haujlwm, cov khoom tsim thiab cov khoom zoo ntawm cov nqaij

REMIT tshuaj xyuas yog qhov txaus siab rau cov neeg siv khoom uas xav txog kev xaiv rau kev koom tes nrog lub tuam txhab no, thiab cov neeg ua haujlwm uas xav tias yuav tau txais txoj haujlwm zoo thiab ruaj khov. Nyob rau hauv tsab xov xwm no, peb yuav tham txog qhov no nqaij ua cov nroj tsuag, dab tsi cov khoom nws tsim, seb nws zoo sib xws rau ib tug tshaj tawm, dab tsi nws cov neeg ua hauj lwm thiab cov neeg koom tes hais txog lub enterprise

Gazpromneft: kev tshuaj xyuas cov neeg ua haujlwm, cov haujlwm ua haujlwm, cov haujlwm ua haujlwm thiab cov nyiaj hli

Russia paub thoob plaws ntiaj teb ua ib qho ntawm cov khoom lag luam loj tshaj plaws ntawm cov zaub mov, yog li muaj ntau lub tuam txhab koom nrog hauv kev tsim cov nyiaj tso cia thiab kev ua haujlwm ntxiv ntawm cov khoom tsim tawm. Ib lub koom haum loj tshaj plaws hauv kev lag luam no yog Gazpromneft, cov lus tawm tswv yim los ntawm cov neeg ua haujlwm ntawm kev lag luam txhawb cov tub ntxhais hluas kom tau txais kev kawm hauv cov lus qhia no