2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Polymeric cov ntaub ntawv yog cov tshuaj lom neeg cov tshuaj molecular uas muaj ntau yam me me-molecular monomers (units) ntawm tib cov qauv. Feem ntau, cov khoom siv monomeric hauv qab no yog siv rau kev tsim cov polymers: ethylene, vinyl chloride, vinyl dechloride, vinyl acetate, propylene, methyl methacrylate, tetrafluoroethylene, styrene, urea, melamine, formaldehyde, phenol. Hauv tsab xov xwm no, peb yuav txiav txim siab kom meej tias cov ntaub ntawv polymeric yog dab tsi, lawv cov khoom siv tshuaj thiab lub cev yog dab tsi, kev faib tawm thiab hom.

Hom ntawm polymers

Ib yam ntawm cov molecules ntawm cov khoom no yog qhov hnyav molecular, uas sib haum rau cov nqi hauv qab no: М>5103. Cov tshuaj uas muaj qis dua ntawm qhov ntsuas no (M=500-5000) yog hu ua oligomers. Nyob rau hauv cov sib txuas uas tsis muaj molecular hnyav, qhov loj yog tsawg dua 500. Cov nram qab no hom ntawm polymeric cov ntaub ntawv yog txawv: hluavtaws thiab ntuj. Cov tom kawg suav nrog cov roj hmab ntuj, mica, ntaub plaub, asbestos, cellulose, thiab lwm yam. Txawm li cas los xij, qhov chaw tseem ceeb yog nyob ntawm cov khoom siv hluavtaws polymers, uas tau txais los ntawm cov txheej txheem tshuaj synthesis los ntawm cov khoom siv qis-molecular-qhov hnyav. nyob ntawmlos ntawm cov txheej txheem ntawm kev tsim cov khoom siv molecular siab, cov polymers yog qhov txawv, uas yog tsim los ntawm polycondensation los yog los ntawm ib qho ntxiv cov tshuaj tiv thaiv.

YPolymerization

txheej txheem no yog kev sib xyaw ntawm cov khoom hnyav molecular rau hauv siab molecular hnyav kom tau txais cov saw ntev. Cov theem ntawm polymerization yog tus naj npawb ntawm "mers" nyob rau hauv lub molecules ntawm ib tug muab muaj pes tsawg leeg. Feem ntau, cov ntaub ntawv polymeric muaj los ntawm ib txhiab mus rau kaum txhiab ntawm lawv cov units. Cov khoom siv hauv qab no tau txais los ntawm polymerization: polyethylene, polypropylene, polyvinyl chloride, polytetrafluoroethylene, polystyrene, polybutadiene, thiab lwm yam.

Polycondensation

txheej txheem no yog cov tshuaj tiv thaiv ib ntus, uas muaj nyob rau hauv kev sib txuas nrog ntau tus monomers ntawm tib hom, lossis ib khub ntawm pawg sib txawv (A thiab B) rau hauv polycapacitor (macromolecules) nrog rau kev tsim ib txhij ntawm cov hauv qab no. by-products: methyl cawv, carbon dioxide, hydrogen chloride, ammonia, dej, thiab lwm yam. Polycondensation tsim silicones, polysulfones, polycarbonates, amino plastics, phenolic plastics, polyesters, polyamides thiab lwm yam ntaub ntawv polymeric.

polyaddition

txheej txheem no tau nkag siab tias yog kev tsim cov polymers los ntawm cov tshuaj tiv thaiv ntawm ntau qhov sib ntxiv ntawm cov khoom siv monomeric uas muaj kev txwv kev sib xyaw ua ke rau cov monomers ntawm cov pab pawg tsis muaj zog (cov voj voog ua haujlwm lossis ob daim ntawv cog lus). Tsis zoo li polycondensation, cov tshuaj tiv thaiv polyaddition tshwm sim yam tsis muaj cov khoom lag luam. Cov txheej txheem tseem ceeb tshaj plaws ntawm cov thev naus laus zis no yog kho cov epoxy resins thiab tsim cov polyurethanes.

Kev faib tawm ntawm cov polymers

Cov khoom sib xyaw ntawm tag nrho cov ntaub ntawv polymeric muab faib ua inorganic, organic thiab organoelement. Thawj ntawm lawv (silicate iav, mica, asbestos, ceramics, thiab lwm yam) tsis muaj atomic carbon. Lawv ua raws li cov oxides ntawm txhuas, magnesium, silicon, thiab lwm yam Organic polymers tsim cov chav kawm dav tshaj plaws, lawv muaj carbon, hydrogen, nitrogen, sulfur, halogen thiab oxygen atoms. Organoelement polymeric cov ntaub ntawv yog cov tebchaw uas nyob rau hauv lub ntsiab chains muaj, ntxiv rau cov teev, atoms ntawm silicon, txhuas, titanium thiab lwm yam khoom uas yuav ua ke nrog organic radicals. Xws li kev sib xyaw ua ke tsis tshwm sim hauv qhov xwm txheej. Cov no tsuas yog hluavtaws polymers xwb. Cov neeg sawv cev ntawm cov pab pawg no yog organosilicon-based compounds, cov saw tseem ceeb uas yog tsim los ntawm oxygen thiab silicon atoms.

Kom tau txais cov khoom siv polymers nrog cov khoom tsim nyog, thev naus laus zis feem ntau siv tsis yog "ntshiab" tshuaj, tab sis lawv cov kev sib txuas nrog cov organic lossis inorganic Cheebtsam. Ib qho piv txwv zoo yog cov khoom siv hauv tsev: hlau-yas, yas, fiberglass, polymer pob zeb.

qauv ntawm polymers

Qhov peculiarity ntawm cov khoom ntawm cov ntaub ntawv no yog vim lawv cov qauv, uas, nyob rau hauv lem, muab faib ua cov nram qab no hom: linear-branched, linear, spatialnrog cov pawg loj molecular thiab cov qauv geometric tshwj xeeb, nrog rau cov ntaiv. Cia peb los piav me ntsis txog lawv txhua tus.

Polymeric cov ntaub ntawv nrog ib tug linearly branched qauv, ntxiv rau cov saw tseem ceeb ntawm molecules, muaj sab ceg. Cov polymers no suav nrog polypropylene thiab polyisobutylene.

Cov khoom siv nrog cov qauv linear muaj ntev zigzag lossis kauv chains. Lawv cov macromolecules feem ntau tshwm sim los ntawm kev rov ua dua ntawm qhov chaw hauv ib pawg txheej txheem ntawm kev sib txuas lossis tshuaj lom neeg ntawm cov saw hlau. Polymers nrog ib tug linear qauv yog txawv los ntawm lub xub ntiag ntawm heev ntev macromolecules nrog ib tug tseem ceeb sib txawv nyob rau hauv cov xwm ntawm bonds raws cov saw thiab nruab nrab ntawm lawv. Qhov no yog hais txog kev sib txuas lus sib txuas thiab tshuaj lom neeg. Cov macromolecules ntawm cov ntaub ntawv no yog hloov tau yooj yim. Thiab cov cuab yeej no yog lub hauv paus ntawm cov saw hlau polymer, uas ua rau cov yam ntxwv tshiab zoo: siab elasticity, nrog rau qhov tsis muaj brittleness hauv lub xeev kho.

Thiab tam sim no cia saib seb dab tsi yog cov ntaub ntawv polymeric nrog cov qauv spatial. Cov tshuaj no tsim, thaum macromolecules ua ke nrog ib leeg, muaj zog chemical bonds nyob rau hauv txoj kev transverse. Yog li ntawd, ib tug mesh qauv yog tau, uas muaj ib tug non-uniform los yog spatial hauv paus ntawm lub mesh. Polymers ntawm hom no muaj ntau dua tshav kub tsis kam thiab rigidity tshaj linear sawv daws yuav. Cov ntaub ntawv no yog lub hauv paus ntawm ntau yam khoom tsis yog xim hlau.

Molecules ntawm cov ntaub ntawv polymer nrog tus qauv ntaiv muaj xws li ib khub ntawm cov saw hlau uas txuas nrog cov tshuaj lom neeg. Cov no suav nrogorganosilicon polymers, uas yog tus cwj pwm los ntawm kev nce rigidity, kub tsis kam, ntxiv rau, lawv tsis cuam tshuam nrog cov kuab tshuaj organic.

Phase muaj pes tsawg leeg ntawm polymers

Cov ntaub ntawv no yog cov tshuab uas muaj cov cheeb tsam amorphous thiab crystalline. Thawj ntawm lawv pab txo qhov tawv nqaij, ua rau cov polymer elastic, uas yog, muaj peev xwm ntawm loj reversible deformations. Cov theem crystalline pab txhawb lawv lub zog, hardness, elastic modulus, thiab lwm yam tsis, thaum txo cov molecular yooj ntawm cov khoom. Qhov piv ntawm qhov ntim ntawm tag nrho cov cheeb tsam no rau tag nrho cov ntim yog hu ua degree ntawm crystallization, qhov siab tshaj plaws (txog 80%) muaj polypropylene, fluoroplasts, high-density polyethylene. Polyvinyl chlorides, tsawg ntom polyethylene muaj qis dua ntawm crystallization.

Raws li cov ntaub ntawv polymer coj li cas thaum rhuab, lawv feem ntau muab faib ua thermosetting thiab thermoplastic.

thermoset polymers

Cov ntaub ntawv no feem ntau muaj cov qauv kab. Thaum rhuab, lawv soften, tab sis raws li ib tug tshwm sim ntawm cov tshuaj tiv thaiv tshwm sim nyob rau hauv lawv, cov qauv hloov mus rau ib tug spatial, thiab cov tshuaj hloov mus rau hauv ib tug khoom. Nyob rau hauv lub neej yav tom ntej, qhov zoo no yog khaws cia. Polymer composite cov ntaub ntawv yog tsim los ntawm txoj cai no. Lawv cov cua kub tom qab tsis soften cov khoom, tab sis tsuas yog ua rau nws decomposition. Qhov sib xyaw thermoset tiav tsis yaj lossis yaj, yog li ntawdtsis pub rov siv dua. Cov khoom no muaj xws li epoxy silicone, phenol-formaldehyde thiab lwm yam resins.

YThermoplastic polymers

Cov ntaub ntawv no, thaum cua sov, ua ntej muag muag thiab tom qab ntawd yaj, thiab tom qab ntawd tawv thaum txias. Thermoplastic polymers tsis hloov tshuaj lom neeg thaum lub sijhawm kho. Qhov no ua rau cov txheej txheem thim rov qab. Cov khoom ntawm hom no muaj ib txoj kab-txheej lossis kab qauv ntawm macromolecules, nruab nrab ntawm cov quab yuam me me thiab tsis muaj tshuaj lom neeg kiag li. Cov no suav nrog polyethylene, polyamides, polystyrenes, thiab lwm yam. Cov thev naus laus zis ntawm cov khoom siv thermoplastic-hom polymeric muab rau lawv cov khoom los ntawm kev txhaj tshuaj molding hauv dej-txias pwm, nias, extrusion, tshuab, thiab lwm yam.

tshuaj muaj zog

Polymers tuaj yeem nyob hauv cov xeev hauv qab no: khoom, kua, amorphous, crystalline theem, nrog rau cov elasticity, khov thiab iav deformation. Kev siv ntau ntawm cov ntaub ntawv polymeric yog vim lawv qhov kev tiv thaiv siab rau ntau yam kev tawm tsam, xws li cov kua qaub thiab alkalis. Lawv tsis raug rau electrochemical corrosion. Tsis tas li ntawd, nrog kev nce hauv lawv qhov hnyav molecular, solubility ntawm cov khoom hauv cov kuab tshuaj organic txo. Thiab cov polymers, uas muaj cov qauv peb sab, feem ntau tsis cuam tshuam los ntawm cov kua tau hais.

Lub cev muaj zog

Feem ntau cov polymers yog cov insulators, ntxiv rau, lawv yog cov khoom tsis sib nqus. Ntawm tag nrho cov txheej txheem cov ntaub ntawv siv, tsuas yog lawv muaj qhov qis tshaj thermal conductivity thiab lub siab tshaj plaws tshav kub muaj peev xwm, nrog rau thermal shrinkage (txog nees nkaum npaug tshaj li ntawm cov hlau). Yog vim li cas rau qhov poob ntawm nruj ntawm ntau yam sealing cov rooj sib txoos nyob rau hauv tsis tshua muaj kub tej yam kev mob yog lub thiaj li hu ua iav hloov ntawm cov roj hmab, nrog rau cov ntse sib txawv ntawm cov coefficients expansion ntawm hlau thiab roj hmab nyob rau hauv lub vitrified lub xeev.

Mechanical Properties

Polymeric cov ntaub ntawv muaj ntau yam ntawm cov yam ntxwv, uas yog nyob ntawm lawv cov qauv. Ntxiv nrog rau qhov ntsuas no, ntau yam sab nraud tuaj yeem muaj kev cuam tshuam zoo rau cov khoom siv kho tshuab ntawm cov khoom. Cov no suav nrog: qhov kub thiab txias, zaus, lub sijhawm lossis tus nqi thauj khoom, hom kev ntxhov siab, lub siab, qhov xwm txheej ntawm ib puag ncig, kev kho cua sov, thiab lwm yam. Ib qho tshwj xeeb ntawm cov khoom siv hluav taws xob ntawm cov khoom siv polymeric yog lawv lub zog muaj zog ntawm cov rigidity tsawg heev (piv. rau hlau).

Polymers feem ntau yog muab faib ua cov khoom, cov qauv elastic uas sib haum rau E=1-10 GPa (fibers, films, plastics), thiab cov khoom muag muag heev, cov elastic modulus uas yog E=1– 10 MPa (roj hmab). Cov qauv thiab cov txheej txheem ntawm kev puas tsuaj ntawm ob qho tib si txawv.

Polymeric cov ntaub ntawv yog tus cwj pwm los ntawm kev hais tawm anisotropy ntawm cov khoom, nrog rau kev txo qis ntawm lub zog, kev loj hlob ntawm creep nyob rau hauv lub sij hawm ntev loading. Ua ke nrog qhov no lawvmuaj kev qaug zog heev. Piv nrog rau cov hlau, lawv txawv nyob rau hauv ib tug sharper dependence ntawm mechanical zog ntawm kub. Ib qho ntawm cov yam ntxwv tseem ceeb ntawm cov ntaub ntawv polymeric yog deformability (pliability). Raws li qhov ntsuas no, nyob rau hauv ntau qhov kub thiab txias, nws yog ib txwm ua los ntsuas lawv cov haujlwm tseem ceeb thiab cov khoom siv thev naus laus zis.

cov ntaub ntawv polymer flooring

Tam sim no cia peb xav txog ib qho ntawm cov kev xaiv rau kev siv cov khoom siv polymers, nthuav tawm tag nrho cov khoom siv no. Cov tshuaj no tau siv dav hauv kev tsim kho thiab kho thiab ua tiav cov haujlwm, tshwj xeeb hauv kev ua hauv pem teb. Qhov nrov loj yog piav qhia los ntawm cov yam ntxwv ntawm cov khoom hauv nqe lus nug: lawv tiv taus kev puas tsuaj, muaj cov thermal conductivity tsawg, tsis tshua muaj dej nqus, muaj zog thiab tawv, thiab muaj cov xim zoo nkauj thiab cov kua roj vanish. Kev tsim cov ntaub ntawv polymeric tuaj yeem muab faib ua peb pawg: linoleums (dov), cov khoom siv pobzeb thiab cov khoom sib xyaw rau kev teeb tsa ntawm cov plag tsev tsis sib haum. Cia wb mus saib ib leeg tam sim no.

Linoleums yog tsim los ntawm ntau hom kev muab tub lim thiab polymers. Lawv kuj tseem muaj xws li plasticizers, kev pab cuam thiab cov xim xim. Nyob ntawm seb hom khoom siv polymer, polyester (glyphthalic), polyvinyl chloride, roj hmab, colloxylin thiab lwm yam txheej txheej yog txawv. Tsis tas li ntawd, raws li cov qauv, lawv tau muab faib ua lub hauv paus thiab nrog lub suab thiab cua sov insulating puag, ib txheej thiab ntau txheej, nrog ib tug du, fleecy.thiab corrugated nto, nrog rau ib leeg thiab ntau xim.

Cov ntaub ntawv pob zeb ua los ntawm cov khoom siv polymer muaj kev puas tsuaj tsawg heev, tshuaj tiv thaiv thiab kav ntev. Raws li cov khoom siv raw, hom khoom polymer no tau muab faib ua coumarone-polyvinyl chloride, coumarone, polyvinyl chloride, roj hmab, phenolite, bituminous vuas, nrog rau chipboard thiab fiberboard.

Cov khoom siv rau cov plag tsev seamless yog qhov yooj yim tshaj plaws thiab huv si siv, lawv muaj lub zog siab. Cov khoom sib xyaw no feem ntau muab faib ua cov cement, polymer pob zeb thiab polyvinyl acetate.

Pom zoo:

Cov ntaub ntawv xa tuaj: tus kheej xaj, daim ntawv them nqi, daim ntawv xaj, cov ntaub ntawv xa khoom thiab cov chaw xa khoom xa tuaj

Kev ua haujlwm hauv kev xa khoom yog nrov heev niaj hnub no, tshwj xeeb tshaj yog cov tub ntxhais hluas muaj siab nyiam. Tus neeg xa xov tsis yog ib tus neeg xa khoom xwb, tab sis yog tus kws tshaj lij uas muaj kev txawj ntse thiab tuaj yeem nqa parcel los yog xa mus rau qhov chaw nyob uas tau teev tseg nrog cov khoom zoo thiab sai

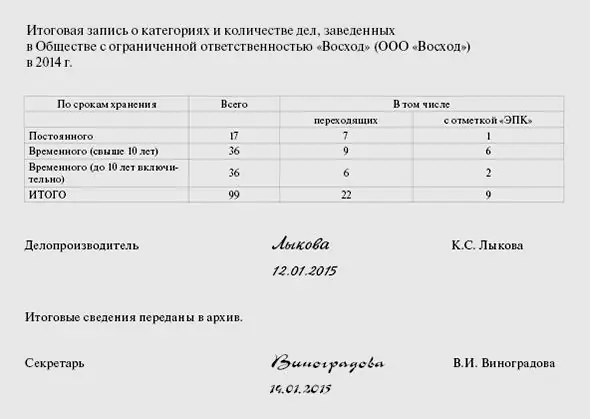

Cov ntaub ntawv sau nyiaj yog Lub tswv yim, cov cai rau kev sau npe thiab khaws cov ntaub ntawv sau nyiaj. 402-FZ "Rau Accounting". Tshooj 9. Cov ntaub ntawv sau nyiaj txiag tseem ceeb

Kev ua tiav ntawm cov ntaub ntawv sau nyiaj tau zoo yog qhov tseem ceeb heev rau cov txheej txheem ntawm kev tsim cov ntaub ntawv nyiaj txiag thiab txiav txim siab txog se. Yog li ntawd, yuav tsum tau kho cov ntaub ntawv nrog kev saib xyuas tshwj xeeb. Cov kws tshaj lij ntawm cov kev pabcuam nyiaj txiag, cov neeg sawv cev ntawm cov lag luam me uas khaws cov ntaub ntawv ywj pheej yuav tsum paub txog cov ntsiab lus tseem ceeb rau kev tsim, tsim, txav, khaws cov ntaub ntawv

Kev sib cog lus ntawm cov koom haum: kos daim ntawv cog lus, cov ntaub ntawv tsim nyog, cov ntaub ntawv thiab cov cai rau kev sau cov piv txwv

Kev sib pauv kev lag luam (offsets thiab kev sib cog lus) ntawm cov chaw lag luam yog qhov muaj ntau hauv kev ua lag luam. Qhov tshwm sim ntawm cov haujlwm no yog kev txiav tawm ntawm kev sib nrig sib cai thiab kev lav phib xaub ntawm cov neeg koom nrog kev sib raug zoo hauv pej xeem

Cov ntaub ntawv rau kev txiav tawm cov cuab yeej: cov ntaub ntawv dav dav, cov ntaub ntawv xav tau thiab cov ntawv

Kev sau npe ntawm kev txiav tawm cov cuab yeej yog txheej txheem uas ntau tus pej xeem hauv Lavxias xav tau. Kab lus no yuav qhia koj yuav ua li cas kom tau nws. Yuav tsum npaj dabtsi? Raws li cov xwm txheej twg thiab qhov twg ib tus tuaj yeem thov qhov kev txiav tawm ntawm cov cuab yeej?

Ntoo shavings: hom, ntau lawm technology thiab daim ntawv thov nta

Ntoo shavings raws li kev lag luam, ntim thiab cov khoom siv zoo nkauj. Hom thiab yam ntxwv ntawm chips, sib txawv ntawm chips thiab sawdust. Daim ntawv thov nyob rau hauv lub teb chaws, nyob rau hauv cov tsiaj ua liaj ua teb, nyob rau hauv kev tsim kho, raws li ib tug rhaub, cov khoom dai kom zoo nkauj thiab muab tub lim thaum ntim khoom plig thiab cov khoom tawg yooj yim