2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2024-01-02 13:55

Tsis tshua muaj, tab sis tib lub sijhawm tseem ceeb heev hauv ntau qhov kev lag luam, cov hlau - zirconium - tau raug cais tawm thawj zaug hauv xyoo 1824. Txawm li cas los xij, nws tseem muaj qee feem pua ntawm lwm cov ntsiab lus. Tsuas yog nyob rau hauv lub xyoo pua 20th nws muaj peev xwm tau txais cov zirconium ntshiab, dawb los ntawm ntau yam impurities. Alloys raws li nws tau ntse siv rau kev tsim cov refractories, abrasives, ceramic xim, sandpaper, textiles, deodorants thiab dag pob zeb. Ntawm chav kawm, ib tug yuav tsum tsis txhob hnov qab txog lub siab tseem ceeb ntawm no hlau nyob rau hauv cov tshuaj. Kawm paub ntxiv txog nws.

Kev txhim kho ntawm metallurgy

Zirconium yog cov khoom tseem ceeb ntawm cov alloys rau nuclear fais fab engineering. Tab sis rau qhov no nws yog tsim nyog hais tias nws yuav tsum huv si li sai tau los ntawm ntau yam impurities. Qhov tseeb yog hais tias nyob rau hauv zirconium ores tsis tsuas yog xws li ib tug tsawg lub ntiaj teb lub caij xws li hafnium, tab sis kuj nitrogen, carbon thiab oxygen. Thiab xws li cov khoom tsis yog hlau tsis huv yog qhov txaus ntshai heev thiab tuaj yeem suav nrog hauv cov khoom siv hauv cov khoom siv rau cov tshuab hluav taws xob nuclear nyob rau hauv tus nqi tsis ntau tshaj lab ntawm ib feem pua. Yog li ntawd, tau txais cov ntshiab zirconium thiab alloys ntawmnws lub hauv paus yog ib qho kev ua haujlwm ntev thiab ua haujlwm hnyav. Ua ntej, cov concentrate yog qhib, ces nws yog enriched, pliaj impurities thiab hafnium raug cais.

Ntshiab zirconium zoo li cov hlau raug. Nyob rau hauv tsos, nws zoo ib yam li steel, tab sis nyob rau tib lub sij hawm ntau check thiab ductile. Ntawm chav kawm, nyob rau hauv alloys raws li nws, nws cov yam ntxwv yuav txawv ho nyob ntawm seb tus nqi ntawm lwm yam ntsiab. Piv txwv li, oxygen (ntau dua 0.6%) yuav ua rau zirconium nkig. Tab sis kuj tseem muaj qhov tsis zoo: cov dioxide ntawm cov hlau no (ZrO2) muaj qhov melting point ntawm 2680 °C.

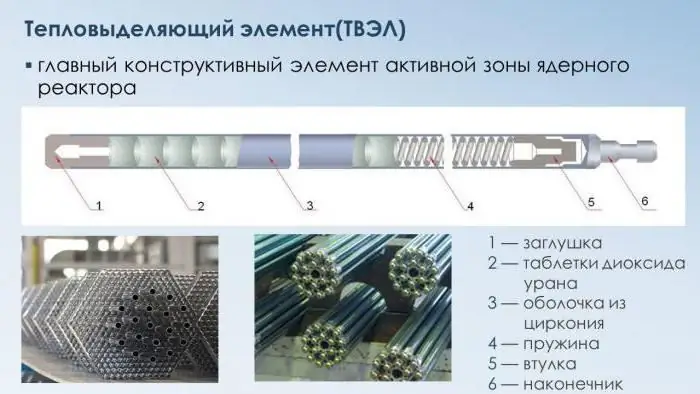

khoom siv tseem ceeb

Raws li tau hais ua ntej, thaj chaw dav tshaj plaws uas zirconium thiab nws cov alloys siv yog kev lag luam nuclear. Lawv lub ntsiab kom zoo dua yog tias lawv muaj me me thermal neutron ntes hla ntu (tsuas yog 0.18 barn), cov khoom zoo corrosion thiab siab melting point. Yog li, TVEL yog qhov tseem ceeb ntawm cov roj hluav taws xob ntawm thaj chaw ua haujlwm ntawm lub tshuab hluav taws xob nuclear, nyob rau hauv uas cov roj hluav taws xob tau muab tso rau. Nws yog nyob rau hauv nws tias lub fission ntawm hnyav nuclei tshwm sim, uas txhais tau hais tias cov roj yam yuav tsum tau ua los ntawm cov feem ntau ruaj thiab refractory hlau, thiab nws yuav tsum tsis txhob hloov tus cwj pwm ntawm neutron absorption nyob rau hauv lub reactor.

Yog li, zirconium alloys yog siv los ua nws lub plhaub. Cov kev cai rau lawv yog nruj heev. Yog li, alloying ntsiab yuav tsum tsis txhob ua phem rau nws cov yam ntxwv. Tshwj xeeb, qhov no cuam tshuam rau qhov me me hla ntu rau kev ntes ntawm thermal neutrons. Zirconium yog alloyed nyob rau hauv thiaj li yuavinhibit qhov teeb meem ntawm nitrogen thiab txhim kho nws cov khoom corrosion. Ntau lub ntsiab lus ntawm lub caij nyoog ntawm Mendeleev tsis haum, vim lawv txo qee yam ntxwv.

Cov hlau nto moo tshaj plaws siv los ua cov roj rods yog zircaloy. Nws cov ntsiab lus alloying yog tin, thiab cov khoom pabcuam yog hlau, chromium thiab npib tsib xee. Nyob rau hauv Russia, niobium feem ntau yog siv rau alloying zirconium. Nws kuj muaj qhov qis thermal neutron capture hla ntu, txo cov hydrogen uptake, thiab cov ntaub ntawv tsuas yog cov kev daws teeb meem. Thiab qhov no, nyob rau hauv lem, muab alloys nrog siab ductility.

Zirconium alloying

Qhov kev tiv thaiv corrosion siab ntawm cov hlau no piav qhia vim li cas nws feem ntau siv los ua cov khoom siv hlau hauv ferrous thiab non-ferrous metallurgy. Tsis tas li ntawd, nws yog insoluble nyob rau hauv hydrochloric thiab nitric acids thiab alkalis. Yog li, multicomponent alloys ntawm zirconium nrog magnesium yog nrov heev. Tsis tas li ntawd, alloying nrog cov hlau no ua rau cov kua qaub ua haujlwm ntawm titanium. Alloys ntawm zirconium nrog tooj liab muaj zog thiab hluav taws xob conductivity. Feem ntau nws kuj yog siv los ua ib qho ntxiv hauv kev tsim cov qib steel ntau. Qhov no tso cai rau koj tshem tawm sulfur, nitrogen thiab oxygen ntawm lawv.

Kev lag luam kho mob

Xav txog zirconium thiab nws cov alloys, ib tus tsis tuaj yeem hais txog ib qho ntxiv ntawm lawv qhov kev siv. Hauv kev lag luam kho mob, lawv nyob deb ntawm qhov chaw kawg. Tsis ntev los no, steel thiabtitanium alloys. Txawm li cas los xij, qee zaum, lub cev tsis lees txais cov hlau no, tawm tsam qhov kev tsis haum tshuaj tshwm sim. Cov tshuaj niaj hnub siv zirconium thiab titanium alloys rau kev tsim cov staples, phaj, cog, hniav hniav thiab lawv fixation mechanisms.

Vim tias cov hlau no thiab nws cov khoom sib txuas tsis ua rau cov pob txha thiab cov ntaub so ntswg ib puag ncig, nws tau siv los ua cov hniav nyiaj hniav kub. Piv txwv li, zirconium qhwv ntsej tsis ua rau muaj kev tsis haum tshuaj thiab kho qhov txhab ntawm pob ntseg kom tsis txhob mob hnyav dua li kub.

siv zog

Alloy ntawm txhuas thiab zirconium muaj ntau yam zoo thiab yog li siv tau zoo hauv kev lag luam hluav taws xob. Qhov tseeb yog tias cov hlau thiab tooj liab hlau hnyav hnyav heev, thiab feem ntau cov kev txhawb nqa qub tsis tuaj yeem tiv taus xws li kev thauj khoom. Xyoo 1960, hauv Nyij Pooj, ib pab pawg kws tshawb fawb tau tsim cov alloys ntawm txhuas thiab zirconium. Lawv tau txiav txim siab tias cov khoom siv no tuaj yeem siv rau lub sijhawm ntev ntawm qhov kub thiab txias (150-230 ° C) thiab tib lub sijhawm nws yuav ci heev. Qhov no tso cai rau nws los siv rau kev tsim cov hlau kub kub. Qhov no ua rau kom muaj kev ntseeg siab thiab ua haujlwm ntawm cov khoom siv hluav taws xob.

Lwm daim ntawv thov rau zirconium compounds thiab alloys

Nyob hauv ntau cov tshuaj tua kab mob, koj tuaj yeem pom cov khoom xws li Aluminium Zirconium Tetrachlorohydrex. Nws yog ib qho tshuaj lom neeg uas absorbs hws thiab nws tsw. Cov kws tshawb fawb tau pom tias tsis yogabsorbed rau hauv daim tawv nqaij, thiab yog li ntawd, tsis tuaj yeem ua rau mob hnyav. Txawm li cas los xij, aluminium-zirconium-tetrachlorohydrexglycine raug txwv hauv EU thiab Asmeskas.

Zirconium oxide yog siv los ua electrocorundum. Nws yog tau los ntawm smelting nyob rau hauv tilting hluav taws xob furnaces. Zirconium electrocorundum hloov tawm kom muaj zog heev thiab tso cai rau cov khoom siv nrog lub zog loj clamping. Feem ntau nws yog siv rau kev sib tsoo thiab ntxhib.

Feem ntau, nws yuav tsum tau muab sau tseg tias zirconium thiab nws cov alloys muaj lub siab melting point, tshuaj tsis kam, thiab qis coefficient ntawm thermal expansion. Nws yog vim li no nws thiaj li tau siv ntau yam.

Pom zoo:

Tshav kub-resistant alloys. Tshwj xeeb steels thiab alloys. Kev tsim khoom thiab siv cov khoom siv hluav taws xob kub-resistant

Kev lag luam niaj hnub tsis tuaj yeem xav txog yam tsis muaj cov khoom siv hlau. Peb ntsib nws ntawm yuav luag txhua qhov tig. Los ntawm kev qhia ntau yam tshuaj nyob rau hauv nws cov muaj pes tsawg leeg, nws muaj peev xwm txhim kho cov khoom siv kho tshuab thiab kev ua haujlwm zoo

Ua haujlwm raws li tus kws tshawb fawb yog kev ua haujlwm nyuaj raws li kev paub tob thiab kev paub dhau los

Ua haujlwm raws li tus kws tshawb fawb txog qhov loj tshaj yog nyob ntawm tus neeg thiab nws qhov kev paub. Ua tsaug rau kev kawm txuj ci, ntau yam khoom siv thiab khoom siv tau tshwm sim uas pab txhawb tib neeg txoj haujlwm

Kev tswj hwm kev ua haujlwm zoo ntawm kev lag luam raws li kev lees paub ntawm kev txhim kho kev vam meej

Kab lus no yuav qhia koj txog qhov txiaj ntsig zoo uas qhia txog kev tswj hwm kev lag luam zoo yuav muaj thiab yuav tsum ua li cas rau qhov no

Kev ntsuas hluav taws xob siab: lub hom phiaj, algorithm, kev sim, cov qauv, raws tu qauv thiab ua raws li cov cai kev nyab xeeb

Kev ua haujlwm ntawm cov khoom siv hluav taws xob suav nrog ntau qhov kev ntsuas hluav taws xob siab, lawv tseem ceeb heev rau kev ua haujlwm raug ntawm cov cuab yeej. Lawv lub hom phiaj. cov algorithm rau kev coj ua, cov qauv thiab ua raws li cov cai kev nyab xeeb tau piav qhia hauv cov lus qhia no

Unified methodology rau xam kev puas tsuaj raws li OSAGO. Kev sib koom ua ke ntawm kev suav ntawm kev puas tsuaj raws li OSAGO

Nyob rau xyoo 2014, ib txoj hauv kev tshiab rau kev soj ntsuam kev puas tsuaj tom qab muaj kev huam yuaj tshwm sim. Txoj haujlwm thiab cov ntsiab lus ntawm kev daws teeb meem ua ntej kev sib cav tau tsim los ntawm Ministry of Transport hauv 2003, tab sis rau 11 xyoo lawv tsis tau siv. Cov tuam txhab tuav pov hwm txhua lub sijhawm no suav cov kev puas tsuaj ntawm lawv tus kheej txoj kev. Tab sis, thaum lub rooj sib tham ntawm Lub Tsev Hais Plaub Siab tau txuas ntxiv txoj cai "Rau Kev Tiv Thaiv Cov Neeg Siv Khoom" rau OSAGO, lawv txiav txim siab rov qab cov ntaub ntawv