2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Vuam hauv hom tsis siv neeg lossis semi-automatic feem ntau siv qhov chaw siv cov khoom siv xws li flux-cored hlau. Ib qho ntawm nws cov txiaj ntsig tseem ceeb yog lub peev xwm txuag roj, uas yuav siv los tiv thaiv oxidation.

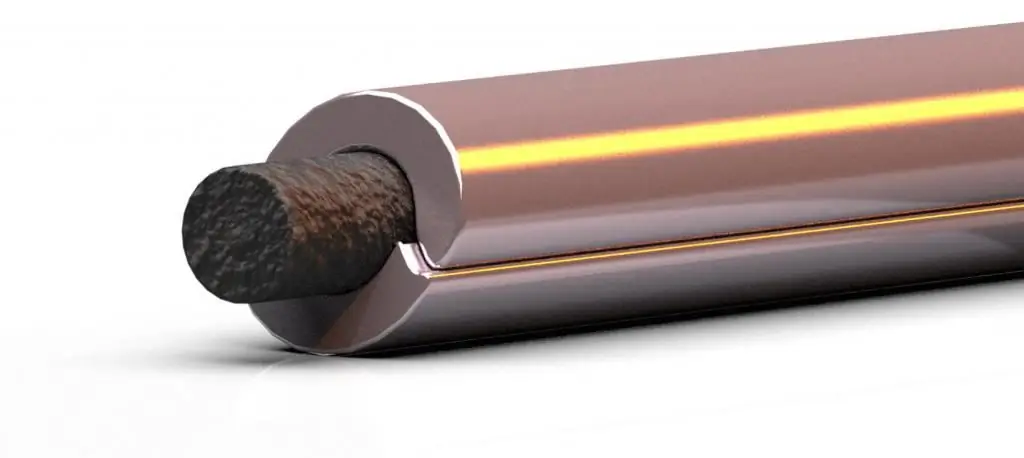

Wire description

Kev siv ntau tshaj plaws ntawm cov xaim hluav taws xob yog thaum nws tsim nyog ua haujlwm nrog cov hlau xws li tooj liab, titanium thiab txhuas. Lwm qhov tshwj xeeb cuam tshuam qhov vuam seam. Nws puv tawm heev du thiab heev check. Feem ntau, lub ntsiab tivthaiv yog granular flux. Txawm hais tias qhov no tsis yog ib txwm muaj, muaj cov xwm txheej thaum oxide, ntsev cov khoom siv. Tsis tas li ntawd, qee zaum, ib qho kev sib xyaw ua ke ntawm ntsev oxide puag yog siv.

Key Benefits

Nws tsim nyog pib nrog qhov tseeb tias cov xaim flux-cored muaj qib siab ntawm melting. Qhov no tso cai rau nws siv rau kev ua haujlwm nrog cov ntaub ntawv refractory. Tsis tas li ntawd, thaum lub sij hawm ua hauj lwm, lub siab vuam ceev yog guaranteed,thiab kev ua hauj lwm arc yog yam ntxwv ntawm stability thiab softness. Lub arc kuj kub nyhiab tusyees, uas yog vim li cas lub seam hloov mus ua tus txawm. Ib qho ntawm qhov zoo tshaj plaws yog tias tom qab vuam nrog cov xaim flux-cored, nws txaus los tshem tawm cov slag txheej los ntawm vuam.

Ntxiv rau qhov zoo tshaj plaws saum toj no, muaj ntau yam ntxiv:

- zoo vuam cheeb tsam tiv thaiv;

- kev ua haujlwm siab ceev yog nrog rau kev ua haujlwm;

- melting tuaj yeem nqa mus rau qhov tob loj txaus, thiab tsis muaj qhov tawg thaum ua haujlwm;

- thaum lub sijhawm ua haujlwm tsis muaj cov tshuaj tsis haum tshuaj raug tso tawm;

- koj tuaj yeem tswj cov pa oxygen uas muaj nyob hauv qhov vuam;

- Kev siv cov flux-cored hlau vuam tshuab pab txhim kho cov qauv vuam zoo.

Nws yog ib qho tsim nyog sau cia tias qhov kev tiv thaiv ntawm qhov chaw vuam yog ua tau raws li qhov tseeb tias cov hlau muaj flux. Vim li no, atmospheric gases tsis ncav cuag qhov chaw vuam, thiab yog li ntawd tsis oxidize cov khoom welded. Nws yog ib nqi sau cia hais tias vim muaj xws li ib tug xov tooj ntawm zoo, lub flux hlau rau semi-automatic yog siv tsis tau tsuas yog los ntawm amateurs rau vuam, tab sis kuj los ntawm cov tub txawg.

Main Applications

Feem ntau, lub tshuab vuam uas ua haujlwm siv cov hlau no yog siv los koom nrog cov ntaub ntawv xws li cov hlau tsis muaj hlau, hlau alloy thiab lwm yam khoom siv high-alloy.

Nyob ntawm seb puas yogdab tsi raws nraim yog yuav tsum tau welded, muaj pes tsawg leeg ntawm flux yuav hloov. Piv txwv li, yog tias nws yog ib qho tsim nyog los txuas ua ke cov khoom uas yog cov pab pawg ntawm cov hlau tsis tshua muaj hlau, ces oxide flux yuav tsum tau siv. Yog tias koj yuav tsum ua haujlwm nrog cov hlau uas tsis yog-ferrous, ces cov flux-cored vuam hlau yuav tsum muaj cov ntsev ntsev. Rau cov hlau alloyed, kev sib xyaw ua ke ntawm oxide thiab ntsev yog siv.

Dhau li ntawm, lwm qhov tseem ceeb ntawm cov xaim, txoj kab uas hla, kuj tseem yuav hloov. Qhov ntsuas no hloov pauv hauv qhov dav dav, los ntawm 0.6 hli mus rau 8 hli. Ntawm chav kawm, qhov tuab ntawm cov vuam hlau, ntev nws yuav siv sij hawm rau nws kom yaj. Thiab qhov no yuav nyob ntawm tus nqi pub. Vim yog cov xwm txheej no, nws hloov tawm tias yog tias cov thickness ntawm cov khoom yog tsawg los yog nws muaj pes tsawg leeg yog yooj yim rau welding, ces siv ib tug tuab hlau yog yooj yim unprofitable.

Xaiv hlau los ntawm kab

Raws li tau piav qhia saum toj no, thaum welding nrog flux-cored hlau, ib qho khoom siv nrog lub cheeb ntawm 0.6 txog 8 hli. Ntxiv nrog rau tus nqi pub, qhov ceev ntawm nws melting kuj nyob ntawm qhov ntsuas no. Ob peb yam no tseem ceeb heev thiab yuav tsum tau coj mus rau hauv tus account thaum xaiv.

Cia peb hais tias kom tau txais qhov siab tshaj plaws txawm tias seam, nws yog qhov tsim nyog kom cov hlau ntev. Piv txwv li, yog tias nws yuav tsum tau welding ib tug txaus refractory khoom ua ke, thiab lub seam yuav tsum muaj zog thiab tuab, ces lub thickness ntawm electrode yuav tsum tau loj. Yog hais tias nws yog tsim nyog los ua hauj lwm nrog txaus moshlau nyob rau hauv cov nqe lus ntawm vuam, tsis tas yuav siv cov hlau tuab.

Yog tias txoj kab uas hla tau raug xaiv kom raug thiab tag nrho cov kev cai rau kev ua haujlwm tau raug soj ntsuam, tom qab ntawd vuam nrog cov xaim flux-cored tsis muaj roj tuaj yeem muab cov vuam zoo, cov npoo siab ntawm kev nyab xeeb thiab tsim kev sib txuas uas yuav yog resistant rau atmospheric influences. Peb yam no ua rau nws muaj peev xwm siv cov qauv kev sib txuas hauv txoj kev no txawm tias nyob rau hauv qhov chaw uas muaj huab cua phem, piv txwv li, nyob rau hauv ib cheeb tsam uas muaj zog ntxiv.

Flaws

Txawm tias muaj ntau qhov zoo, zoo ib yam li lwm yam, cov hlau muaj nws qhov tsis zoo.

Ua ntej, tus nqi ntawm cov khoom siv no yog qhov siab heev, uas txhais tau hais tias kev vuam nrog flux-cored hlau tsis yog ib txwm muaj txiaj ntsig ntawm cov nqi lossis cov nqi. Qhov thib ob, nrhiav cov khoom siv hluav taws xob zoo li no yog qhov nyuaj dua li lwm yam. Thib peb, nws kuj tshwm sim tias txawm tias nrog kev pab los ntawm cov khoom siv flux nws tsis tuaj yeem daws qhov teeb meem ntawm cov khoom siv weldability tsis zoo thiab koj yuav tsum siv nyiaj rau kev ntsuas ntxiv, uas ua rau tus nqi ntxiv ntawm cov txheej txheem.

Type of wire

Hnub no nws tseem ceeb heev uas yuav tsum xav txog tsis yog tsuas yog lub thickness thiab txoj kab uas hla, tab sis kuj yuav tsum tau ua haujlwm nrog.

Piv txwv li, hais txog cov hlau, koj tsis tuaj yeem siv tib lub xaim nrog tib qhov tsis zoo rau txhua yam khoom, vim lawv tuaj yeem yog los ntawm ntau pawg, piv txwv li, los ntawm qib ntawm alloying ntawm cov khoom sib xyaw. Ib sabKuj tseem muaj cov khoom siv xws li stainless hlau. Raws li kev siv tooj liab, nws yog ib qho tsim nyog yuav tsum siv cov khoom siv nrog lub cheeb ntawm 0.8 hli, uas yog tsim tshwj xeeb rau kev siv tooj liab. Cov hlau zoo li no yuav pab txhim kho qhov zoo ntawm cov seam thaum vuam ntawm qhov kub thiab txias.

Raws li cov ntsiab lus tseem ceeb thiab lawv lub ntsiab lus, lawv muaj raws li hauv qab no:

- lub zog kawg yog 480-580 MPa;

- yield zog ntawm 400 txog 490 MPa;

- txheeb ze elongation thaj tsam li ntawm 22 txog 27%;

- ua cov roj tiv thaiv, yog tias tsim nyog, carbon dioxide tuaj yeem siv.

Powder Material

Hnub no, cov xaim flux-cored kuj tseem siv tau. Nws yog ib lub raj nyob rau hauv uas yog muab tso rau ib tug vuam flux muaj hlau hmoov raws li ib tug additive. Nws kuj muaj nws tus yam ntxwv thiab siv tau rau ntau lub hom phiaj, tab sis nyob rau hauv kev xyaum nws yog feem ntau tsuas yog siv rau vuam tsawg alloy steel los yog tsis muaj zog carbon steel.

Muaj ntau ntau yam yuav tsum tau ua rau kev ua haujlwm nrog xws li khoom siv.

Ua ntej, cov hmoov flux yuav tsum muaj qhov ruaj khov arc, nrog rau qhov yooj yim uas nws yuav tshwm sim. Thib ob, thaum melting, yuav tsum tsis muaj spattering ntawm cov khoom thiab uniformity ntawm melting. Lawm, nws yog tsim nyog hais tias qhov kawg tshwm sim, uas yog, lub seam, tsis muaj flaws. Thaum lub sij hawm vuam, slag yuav tsim ntawm txheej, uas tom qabtxias yuav tsum yooj yim tev tawm ntawm qhov chaw.

Yam hlau rau hmoov vuam

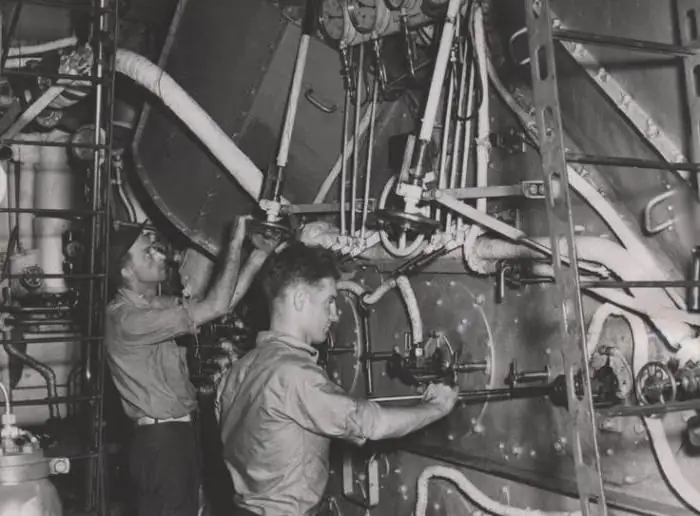

Ntxiv mus, nws tsim nyog hais tias muaj ntau txoj hauv kev siv thiab tiv thaiv los ntawm kev cuam tshuam sab nraud. Raws li ob txoj hauv kev no, cov xaim flux-cored tau muab faib ua gas-shielded thiab self-shielded.

Raws li thawj hom, nws yog siv nyob rau hauv rooj plaub uas yuav tsum tau ua hauj lwm nyob rau hauv tsis siv neeg los yog semi-automatic hom, thiab low-alloy steel los yog low-carbon steel ua raws li cov txheej txheem. Thaum lub sijhawm ua haujlwm, carbon dioxide thiab qee zaum nws cov khoom sib xyaw nrog argon kuj siv. Yog tias koj xaiv cov hmoov flux zoo, koj tuaj yeem txhim kho qee qhov kev sib txuas. Piv txwv li, koj tuaj yeem ua kom nrawm nrawm ntawm txoj hlua vuam los yog txhim kho cov khoom siv zog ntawm cov hlau tawv tawv.

Raws li kev siv cov tshuab vuam no, nws yog qhov tseem ceeb rau kev tsim cov sib tshooj, nrog rau ntawm cov ces kaum ntawm cov qauv lossis ntawm cov pob qij txha. Raws li tau hais ua ntej, nws tuaj yeem siv tau ob qho tib si hauv hom vuam tsis siv neeg thiab hauv hom semi-automatic.

tiv thaiv tus kheej hom xaim

Feature of self-shielded wire is that it was made in form of an electrode that is "tig" in out. Lub peculiarity ntawm daim ntawv thov nyob rau hauv lub fact tias vuam nrog xws li ib tug consumable yuav siv tau nyob rau hauv ntau yam thiab txawm huab cua kub. Tsis tas li ntawd, nws raug tso cai ua haujlwm hauv cua daj cua dub thiab lwm yam huab cua zoo sib xws.

Tsim nyog qhia ob peb ntxivcov txiaj ntsig ntawm kev tiv thaiv tus kheej flux-cored hlau.

- tso cai rau vuam hauv txhua txoj haujlwm;

- vim lub arc nyob rau hauv rooj plaub no yog ib hom qhib, uas yog, muaj peev xwm maj mam txav cov hlau ua tiav;

- hlau yog coated nrog cov khoom tshwj xeeb uas ua rau kom muaj zog tiv thaiv;

- nws muaj peev xwm tswj tau cov tshuaj muaj pes tsawg leeg, uas txhais tau tias koj tuaj yeem tau txais qee yam muaj pes tsawg leeg ntawm cov slag yog tias tsim nyog.

Powder Welding Benefits and Reviews

Raws li qhov zoo uas cov hmoov vuam muaj, cov no yog tag nrho cov ntsiab lus hais txog kev qhib thiab semi-automatic. Hauv lwm lo lus, tsis muaj teeb meem zoo li hauv cov ntaub ntawv ntawm cov roj ntws los tiv thaiv, uas tuaj yeem ua rau cua daj cua dub.

Yog peb tham txog lub ntsiab kom zoo dua ntawm vuam nrog cov xov hlau los ntawm pawg no, qhov no yog qhov tsis xav tau kev npaj ua haujlwm ntev.

Kev tshuaj xyuas txog cov xaim xaim thiab ua haujlwm nrog nws zoo heev, tab sis kuj muaj qhov phem. Cov kab hauv qab yog tias rau kev ua haujlwm me me, cov xaim haum zoo kawg nkaus thiab nws raug nqi tsawg dua lub raj mis roj. Txawm li cas los xij, nyob rau hauv qhov kev tshwm sim uas yuav tsum tau ua noj ntau, ces tas li yuav xws li cov khoom siv yuav kim heev, qhov no yog qhov teeb meem tseem ceeb. Yuav tsim nyog yuav hlau yog tias koj tsis tas ua noj ntau dhau.

Pom zoo:

Container type diesel generator set: hom, specifications, ua hauj lwm hauv paus ntsiab lus thiab daim ntawv thov

Kev piav qhia ntawm kev tsim qauv dav dav ntawm DGS thiab lub hauv paus ntsiab lus ntawm lawv txoj haujlwm. Kev faib tawm ntawm kev teeb tsa los ntawm kev txav mus los. Dab tsi yog lub thawv-hom diesel generator teeb rau? Kev piav qhia ntawm cov ntim khoom thiab cov khoom siv, cov yam ntxwv. Nta ntawm FGWilson diesel generator teeb. Yuav ua li cas yog DGUs ntsia? Cov cai tseem ceeb ntawm kev ua haujlwm. Kev xaiv rau cov khoom siv ntxiv raws li kev thov. Locomotive installations

Tshaj tawm ntawm phab ntsa daim ntawv qhia hnub: hom, xaiv cov ntsiab lus ntawm daim ntawv qhia hnub, nuances ntawm kev tsim thiab luam ntawv

Daim ntawv qhia hnub yog ib qho tseem ceeb ntawm txhua qhov chaw ua haujlwm. Thiab txawm tias muaj pes tsawg tus neeg siv khoom thiab cov neeg muag khoom pub dawb rau lawv, lawv tseem ua khawv koob los ntawm lub tuam txhab cov chaw ua haujlwm uas tsis koom nrog kev sib txuas lus nrog cov neeg cog lus. Cias muab, daim ntawv qhia hnub yog qhov tseem ceeb tshaj plaws ntawm cov ntaub ntawv tshaj tawm uas ib txwm mus nrog lub suab nrov

Nqus txoj kev tshuab: hom, chaw tsim tshuaj paus, specifications, ua hauj lwm hauv paus ntsiab lus thiab daim ntawv thov

Hnub no, tib neeg nquag siv cov thawv yas. Rau kev tsim cov khoom zoo li no nrog cov duab sib txawv thiab nyuaj, lub tshuab nqus tsev yog siv. Cov khoom tsim los ntawm cov tshuab zoo li no tau nquag siv tsis yog hauv lub neej txhua hnub, tab sis kuj yog khoom noj khoom haus, kev lag luam teeb, thiab kev lag luam tsheb

Boiler tsev fireman: hauj lwm piav qhia, lub luag hauj lwm, txoj cai, lub luag hauj lwm

Cov ntaub ntawv tseem ceeb uas tus neeg ua haujlwm yuav tsum tau nyeem ua ntej pib ua haujlwm hauv tuam txhab yog cov lus piav qhia txog haujlwm. Boiler tsev stokers saib xyuas kev ua haujlwm raug thiab txhim khu kev qha ntawm boilers, muab tso rau hauv kev ua haujlwm, nrog rau kev tswj xyuas kev nyab xeeb thaum siv. Thaum ntiav, cov yam ntxwv tshwj xeeb ntawm tus kheej raug coj mus rau hauv tus account, suav nrog lub qhov muag ntse, hnov lus, thiab tus kws tshaj lij yuav tsum tau saib xyuas, sau thiab qhuab qhia

Flux rau vuam: lub hom phiaj, hom vuam, flux muaj pes tsawg leeg, cov cai ntawm kev siv, GOST cov cai, qhov zoo thiab qhov tsis zoo ntawm daim ntawv thov

Qhov zoo ntawm cov vuam yog txiav txim siab tsis yog los ntawm lub peev xwm ntawm tus tswv los npaj lub arc kom raug, tab sis kuj los ntawm kev tiv thaiv tshwj xeeb ntawm thaj chaw ua haujlwm los ntawm kev cuam tshuam sab nraud. Tus yeeb ncuab tseem ceeb ntawm txoj hauv kev los tsim kom muaj kev sib txuas ntawm cov hlau uas muaj zog thiab ruaj khov yog cov huab cua puag ncig ntuj. Lub vuam yog cais tawm los ntawm cov pa oxygen los ntawm cov flux rau vuam, tab sis qhov no tsis yog nws txoj haujlwm xwb