2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Kev kos duab ntawm kev kho cua sov ntawm cov hlau tau paub rau noob neej ntev. Cov craftsmen koom nrog hauv kev tsim cov cuab yeej, thiab tshwj xeeb tshaj yog riam phom, mastered nws ntawm lawv tus kheej, los yog kawm tau ntau xyoo nrog rau lwm yam kev paub tshwj xeeb. Cov lus zais tau khaws cia tsis pub leejtwg paub, uas, tau kawg, ua rau qeeb ntawm kev sib kis ntawm cov thev naus laus zis, tab sis nce kev sib tw ntawm cov chaw tsim khoom tshwj xeeb ntawm cov khoom siv rau lub hom phiaj tshwj xeeb. Ib qho ntawm cov txheej txheem ntawm cov cuab yeej cuab tam medieval yog qhov tawv tawv, uas muab cov npoo txiav thiab cov ntsiab lus ntawm rab ntaj thiab sabers ib qho tshwj xeeb hardness, ua ke nrog kev yooj yim ntawm cov hniav. Niaj hnub no, cov khoom zoo li no tsis ua rau leej twg xav tsis thoob, thev naus laus zis tau dhau los ua qhov loj thiab dav.

Vim li cas tib neeg thiaj paub txhua yam no?

Cov kab lus no rau cov kws tshaj lij hauv kev ua haujlwm thermal feem ntau yuav zoo li cov txheej txheem platitudes thiab paub qhov tseeb. Tsis tas li ntawd, lawv yuav pom qee qhov tsis raug hauv cov lus siv. Cov ntaub ntawv nthuav tawm tsis yog rau lawv, nws yog hais rau cov neeg uas nyob deb ntawm metallurgy, amateurs,cov neeg uas xav paub yuav ua li cas ib lub rooj zoo tib yam los yog folding riam sib txawv ntawm lub zog los ntawm ib tug zoo hniav, nto hardening los ntawm ntim hardening, thiab cov teeb meem zoo sib xws. Thaum yuav ib lossis lwm yam khoom xav tau hauv tsev, tus neeg siv khoom tau ntsib nrog tus nqi sib txawv. Tus neeg muag khoom tsis tuaj yeem piav qhia txog qhov tsim nyog thiab nkag siab tias yog vim li cas ib lub cuab yeej (piv txwv li tus ciaj ntswj) kim dua li lwm qhov uas muaj qhov sib xws sab nraud. Nws, feem ntau yuav, yuav sim "hmoov nws lub hlwb" nrog cov ntsiab lus thiab cov ntsiab lus uas tsis nkag siab rau qhov nruab nrab layman. Txhais ua hom lus zoo tib yam, cov lus piav qhia no yuav txhais tau hais tias tus ciaj ntswj kho tau yuav tsis tawg lossis siv sijhawm ntev dua, thiab kev sib tsoo yuav tsum tau tsawg dua (yog tias tus neeg siv khoom xav yuav riam). "Nto hardening!" - tus neeg muag khoom yuav qhia tsis meej txog qhov laj thawj, dov nws lub qhov muag nrog kev xav zoo siab. Dab tsi yog?

Cov khoom sib txawv hauv ib yam khoom

Raws li tau hais meej los ntawm cov kab lus, qhov no tsuas yog cov txheej nyias nyias ntawm cov khoom raug rau kev kho cua sov. Qhov tseeb tias steel yuav tsum tau hardening yog vaguely guessed los ntawm txhua leej txhua tus, txawm cov neeg uas tsis paub dab tsi nws yog nyob rau hauv tag nrho cov. Qhov no yog qhov nws txawv ntawm ib txwm "daim hlau", mos thiab nkig. Tab sis yog vim li cas nws yog qhov superficial uas nyiam qhov kev hwm zoo li no? Hardening yog siv los hloov cov khoom ntawm cov hlau, thiab tsis yog rau lub hom phiaj ntawm qee yam kev txhim kho, raws li feem ntau tshaj tawm. Kev ua tau zoo, muaj txiaj ntsig zoo hauv qee kis, ua teeb meem rau lwm tus. Cov ntaub ntawv yog ib qho nyuaj, vim hais tias nws yog ib qho yooj yim rau lawv ua hlau, txhuas los yog tooj dag, tab sis yog tias koj sim khoov nws.los yog ntaus nws nrog rauj, nws yuav tawg. Tib yam siv rau cov hniav hacksaw, uas feem ntau tawg ntawm lub kaum sab xis tsis raug. Txhawm rau muab cov hardness ua ke nrog kev yooj yim lossis ductility, nto hardening yog siv. Tom qab nws, cov khoom ntawm cov khoom tuaj yeem muab cov khoom zoo, qee zaum rov qab, cov yam ntxwv ntawm cov qauv siv lead ua sib txawv. Tam sim no peb yuav tsum delve rau hauv qee cov ntaub ntawv tshawb fawb cov ntsiab lus.

Cov tswv yim yooj yim tshaj plaws txog polymorphism ntawm cov hlau

Cov hlau tib yam tuaj yeem, nyob ntawm seb cov duab ntawm cov siv lead ua lattice, muaj cov khoom sib txawv ntawm lub cev (hardness, viscosity, ductility, flexibility, elasticity, etc.) Qhov no muaj peev xwm hloov pauv cov khoom siv tsis zoo hu ua polymorphism. Lub sijhawm ntev dhau los, thaum ua riam phom qub, tib neeg pom tias ib lossis lwm rab ntaj lossis cleaver tau ua tiav zoo dua, nws khaws nws cov ntse ntev dua thiab tsis tawg. Yog lawm, peb cov poj koob yawm txwv tsis tau paub txog cov qauv molecular ntawm cov hlau, lawv tuaj rau txhua yam intuitively thiab empirically. Yog li, empirically, lawv pom tias yog lub taub hau yog rhuab, ces nws qhov kub thiab txias nyob ntawm qhov ntxoov ntxoo ntawm lub ci. Nrog ceev txias, ib yam dab tsi hloov nyob rau hauv cov hlau, nws yuav nyuaj los yog hloov tau ntau dua. Yog hais tias nws yog reheated, nws yuav zoo li qub, thiab tej zaum kuj tseem phem. Los ntawm lub sijhawm ntawd, cov tswv yim tshwj xeeb tau tsim txog dab tsi, piv txwv li, rab riam tua tsiaj zoo tshaj yuav tsum yog. Nto hardening kuj tau siv thaum ntawd, tab sis ntau zauslub npe hu ua hauv zos tau siv, uas yog, ib qho ntawm qhov taw tes yog khoom, nruab nrab ntawm cov hniav yog hloov tau, thiab ib feem ntawm cov hniav uas nyob ib sab ntawm tus kov yog yas (cia nws khoov me ntsis, tab sis tsis tawg).

Yuav ua li cas rau hauv

Yog tsis nkag mus rau hauv cov ntsiab lus tshwj xeeb, nws yuav tsum raug sau tseg tias cov qauv ntawm cov hlau tawv tawv yog ntawm peb hom tseem ceeb: martensitic, troostite thiab sorbitic. Cov yam ntxwv txhua yam nyob ntawm qhov piv ntawm cov crystalline formations. Nyob rau hauv cov ntaub ntawv no, nws tsis muaj teeb meem dab tsi ntawm lawv thiab yuav ua li cas cuam tshuam lub hardness. Qhov tshwm sim nyob ntawm seb cov hlau kub npaum li cas thiab nws txias npaum li cas. Yog li, qhov tawv tawv tuaj yeem tshwm sim nrog qhov nce ntawm qhov kub ntawm txheej txheej sab saud thiab tom qab txias, los ntawm kev hloov pauv mus rau qhov chaw sab nraud (kua, feem ntau yog roj, dej thiab brine, cua lossis lwm yam khoom siv), lossis vim rau nws ib nrab khiav mus rau hauv cov khoom. Nyob rau hauv cov ntaub ntawv no, polymorphic transformations tshwm sim nyob rau hauv cov khaubncaws sab nraud povtseg, nyob ntawm seb lub degree ntawm ncav cuag qhov tseem ceeb kub, uas muaj feem xyuam rau lub tsim ntawm ib tug tshiab siv lead ua qauv.

Vim li ntawd, muaj qhov hloov pauv hauv thaj chaw hauv qab no:

- Upper hardened.

- Nruab nrab, ib nrab hardened. Nws tseem yog hu ua tshav kub cuam tshuam.

- Cheeb tsam ntawm txo qhov nyuaj.

- Tsis hloov kho sab hauv.

Nyob rau saum npoo tawv

Tsim ib txheej sab saum toj nrognce hardness, nyob rau hauv ntau txoj kev. Railroad tsheb springs tsuas yog tua nrog me me hlau pob (steev) uas tsim ib tug deg foob, thaum lub internal ntim ntawm cov hlau tseem yas txaus los tiv thaiv lub sij hawm ntev mechanical kev nyuaj siab. Txoj kev qub tshaj plaws yog suav tias yog qhov cua kub ceev ntawm ib qho khoom ntawm qhov qhib hluav taws, nrog rau kev txau lossis dav hlau ntws. Nws yog los ntawm cov thev naus laus zis no uas ib txwm siv riam oriental nkhaus (karambit) yog tsim. Nto hardening tuaj yeem ua tau los ntawm kev ua kom txias txias. Gas-plasma, induction, laser thiab lwm txoj kev kuj paub. Ib txhia yeej tsim nyog nyob.

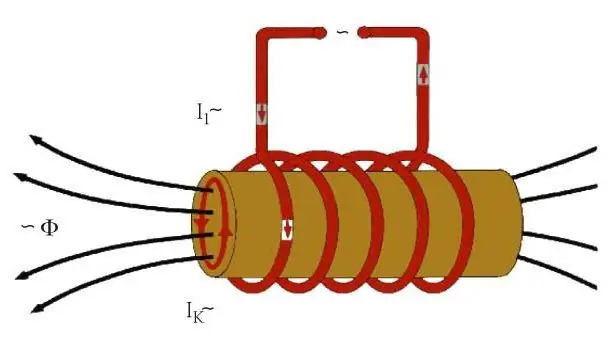

HDTV

Nyob rau hauv nruab nrab-1930s, tus kws tshawb fawb Soviet V. P. Vologdin tau tsim ib txoj hauv kev rau kev muab cov qauv molecular uas tsis yog-khaus rau cov khoom loj uas siv cov hluav taws xob ntau zaus. Kev tsim kho tshuab tsim kho sai, kev lag luam xav tau cov thev naus laus zis uas ua kom muaj kev tsim khoom loj yam tsis muaj kev txi zoo. Nto hardening ntawm HDTV yog raws li qhov tshwm sim ntawm induction. Lub peculiarity ntawm txoj kev nyob rau hauv lub dependence ntawm lub thickness ntawm lub rhuab txheej ntawm lub zaus thiab qhov loj ntawm lub tam sim no nyob rau hauv lub radiating voj. Nyob rau hauv cov ntaub ntawv no, qhov tshwm sim yog kwv yees nrog ib tug high degree ntawm probability, yog li ntawd, kev tswj zoo yog heev yooj yim. Tsis tas li ntawd, txoj kev no muaj feem xyuam rau kev ua tiav ntawm tag nrho cov khoom thiab cov khoom sib dhos, xws li crankshafts thiab lwm yam khoom loj uas tuaj yeem txav tau raws li inductor, raws li cov khoom sib txuas.nthuav tawm tag nrho qhov ntev. Nrog rau cov cuab yeej no, nws yog ib qho nyuaj rau xaiv qhov tsis ua haujlwm rau cov khoom me me thiab tiaj tus, xws li riam. Nto hardening nrog high zaus tam sim no muaj feem xyuam rau cov khoom loj heev, lub zog thiab hnav tsis kam uas nyob ntawm seb cov khoom siv ntawm cov txheej txheem saum toj kawg nkaus.

Txoj kev siv HDTV txoj kev

Cov txheej txheem tau tsim nyob rau hauv cov xwm txheej ntawm kev loj hlob sai ntawm lub tshuab tsim kev lag luam, qhov tseem ceeb rau kev tiv thaiv lub peev xwm ntawm USSR, uas tau tshwm sim hauv qhov tshwj xeeb ntawm nws daim ntawv thov. Qhov tseem ceeb tshaj plaws ntawm cov tsheb laij teb, tso tsheb hlau luam, tsheb lossis dav hlau tsis loj txaus los muab tso rau hauv tus ncej ntawm cov khoom siv hluav taws xob, nws kim heev los tsim cov khoom siv rau lawv txhua tus, thiab yog tias nws tau ua raws li qhov loj tshaj plaws, ces cov nqi hluav taws xob tau loj heev. Txawm li cas los xij, cov ntaub ntawv induction hardening yog siv rau txhua yam khoom, los ntawm me me mus rau cov loj loj. Piv txwv li, cov iav raug nthuav tawm rau HDTV ua ntu zus, tig cov hniav los ntawm cov hniav. Cov ntsiab lus ntawm cov crankshafts thiab cardan shafts yog txuas mus ntxiv thiab ua ntu zus, txav mus rau hauv cov thav duab ruaj khov ntawm cov inductor, thaum lub tshuab txias (sprayer) suav nrog hauv cov txheej txheem thev naus laus zis tam sim ntawd tom qab nws. Thaum kawg ntawm lub tshuab, lub workpiece yog tam sim ntawd txau nrog dej (li no lub npe, consonant nrog "txhaj").

Zoo, cov khoom lag luam nrog lub ntsej muag me me tau muab tso rau hauv qhov inductor tag nrho thiab txias tib yam.

Laser

Cov khoom siv nonyob rau hauv peb lub sij hawm, siv heev dav nyob rau hauv ntau yam teb ntawm tib neeg kev ua si, tau pom daim ntawv thov nyob rau hauv metalworking. Cov txheej txheem tsis tas yuav tsum tau ua kom txias tom qab, vim tias qhov cuam tshuam ntawm lub nqaj yog luv luv thiab nws cuam tshuam rau cov txheej txheem saum toj kawg nkaus ntawm cov hlau, ua rau qhov xav tau ntawm cov qauv siv lead ua. "Laser sharpening" tiag tiag xyuas kom meej tias tsis tas yuav ua kom cov cuab yeej txiav ntev ntev (nws yog siv rau lawv), yog tias txoj kev no yog siv tiag tiag hauv nws cov khoom siv. Txawm li cas los xij, nws yuav tsum nco ntsoov tias nyob rau hauv peb lub hnub nyoog cuav, cov ntawv sau rau ntawm cov khoom tsis yog ib txwm sib haum rau qhov tseeb. Qee lub sij hawm qee qhov pheej yig "npauj npaim" riam muag ntawm ib lub khw muag khoom kuj tau dai kom zoo nkauj nrog cov khoom zoo li no. Deg hardening nrog ib tug laser beam yog ib tug kim technology, nws tsuas yog muaj rau cov tuam txhab ua lag luam.

Coj

Lub hauv paus ntawm lub cev ntawm txoj kev yog qhov kev tshawb pom ntawm qhov tshwm sim ntawm kev ua kom tawv nqaij ntawm cov hlau vim yog kev hloov pauv ntawm cov qauv austenitic mus rau martensitic thaum lub sij hawm sib sib zog nqus khov. Qhov saum npoo hardening yog ua raws li txoj kev tsim los ntawm A. P. Gulyaev, N. A. Minkevich thiab S. S. Shtenberg nyob rau hauv lub USSR. Nws muaj feem xyuam rau cov pa roj carbon (muaj ntau dua 0.5 feem pua C) thiab cov hlau alloy rau lub hom phiaj tshwj xeeb, xws li cov khoom siv rau kev tsim cov tshuab hluav taws xob ceev thiab lwm yam khoom siv tshwj xeeb.

hluav taws xob cua sov

Feem ntau, nws yog tsim los ntawm tib lub hauv paus ntsiab lus xws li induction hardening, nrog rau qhov sib txawv tsuas yog qhov cua sov yog tiv taus, vimdhau tam sim no ntawm cov nqi loj thiab qhov tsis kam ntawm ib feem. Qhov zaus ntawm qhov input voltage nyob rau hauv tib txoj kev cuam tshuam rau qhov tob ntawm rhuab txheej, thiab qhov siab dua nws yog, qhov thinner nws yog. Qhov saum npoo ntawm qhov tawv tawv tuaj yeem nyob ntawm feem ntawm ib millimeter mus rau ob peb ntawm nws cov units. Nws nyob ntawm qhov yuav tsum tau ua rau cov khoom thiab nws qhov ntev. Muab piv rau HDTV, txoj kev electroresistive muaj ntau yam ntawm cov tam sim no, qhov kub thiab txias, thiab txheej txheej tob. Nrog kev pab los ntawm nws, piv txwv li, xws li ib tug loj heev thiab yuav tsum tau tshwj xeeb zoo yam khoom raws li ib tug tub rog lub bayonet-riam yuav ua tau. Kev ua kom tawv nqaij los ntawm hluav taws xob cua sov yuav tsum muaj kev ntsuas kev ntsuas cua txias hauv cov roj, dej lossis lwm yam khoom siv cua sov.

Cov Lus Qhia

Yog li, lub luag haujlwm tseem ceeb ntawm kev ua kom tawv nqaij yog qhov kev faib tawm ntawm cov qauv siv lead ua hauv cov khoom, uas muaj ntau yam sorbite lossis troostite nyob hauv nws, thiab txheej ntawm martensite yog tsim sab nraud. Qhov no tuaj yeem ua tiav los ntawm ntau txoj hauv kev, los ntawm qhov yooj yim tshaj plaws thiab qub tshaj plaws mus rau cov thev naus laus zis tshaj plaws thiab niaj hnub. Nyob rau hauv txhua rooj plaub, high-zoo hardening steel yuav tsum tau muaj peev xwm thiab raug nyob rau hauv ua raws li cov kev cai ntau lawm. Ib qho khoom lag luam ua raws li txhua txoj cai tsis tuaj yeem pheej yig. Vim li no, ob qho tib si chav ua noj riam zoo thiab karabit yog kim. Nto hardening nrog lub laser beam feem ntau tsuas yog rau cov cuab yeej txiav.

Pom zoo:

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Kev ntsuas ntawm cov chaw muab kev pabcuam hauv St. Petersburg: cov npe ntawm cov chaw muab kev pabcuam zoo tshaj plaws, cov nqi se thiab cov kev pabcuam, cov neeg siv khoom tshuaj xyuas

Ib txoj hauv kev zoo tshaj plaws los xaiv ISP thiab nrhiav seb lub sijhawm twg lub tuam txhab kev sib txuas lus muab yog los saib qhov ntsuas. Kev ntsuam xyuas ntawm cov chaw muab kev pabcuam hauv St. Petersburg - cov ntaub ntawv tshiab txog cov kev pabcuam zoo ntawm cov tuam txhab muab kev pabcuam hauv Internet, TV thiab hauv nroog

Txoj kev tsheb ciav hlau yog Txhais, tswvyim, yam ntxwv thiab qhov ntev. Tsheb ciav hlau qhov ntev thiab cov yam ntxwv ntawm cov chaw khiav haujlwm

Kev mus los ntawm tsheb ciav hlau hla lub nroog thiab cov nroog, koj tuaj yeem kawm ntau yam nthuav thiab lom zem txog lub ntiaj teb ntawm txoj kev tsheb ciav hlau. Ntau tshaj ib zaug, cov neeg taug kev tau nug lawv tus kheej cov lus nug txog qhov twg qhov no lossis txoj kev tsheb ciav hlau coj mus? Thiab tus engineer uas tswj lub tsheb ciav hlau xav li cas thaum lub tsheb ciav hlau pib tawm lossis tuaj txog ntawm qhov chaw nres tsheb? Yuav ua li cas thiab los ntawm qhov twg cov tsheb hlau txav thiab txoj hauv kev ntawm cov khoom dov yog dab tsi?

Dab tsi yog qhov nyiaj thiab kev pov hwm ib feem ntawm cov nyiaj laus? Lub sij hawm rau kev hloov ntawm cov nyiaj tau los ntawm cov nyiaj laus. Qhov twg ntawm cov nyiaj laus yog kev tuav pov hwm thiab qhov twg yog nyiaj

Hauv tebchaws Russia, kev hloov pauv nyiaj laus tau siv sijhawm ntev, me ntsis dhau kaum xyoo. Txawm li cas los xij, ntau tus pej xeem ua haujlwm tseem tsis tuaj yeem nkag siab tias qhov nyiaj tau los thiab kev pov hwm ntawm cov nyiaj laus yog dab tsi, thiab yog li ntawd, qhov kev nyab xeeb npaum li cas tos lawv thaum laus. Txhawm rau kom nkag siab txog qhov teeb meem no, koj yuav tsum tau nyeem cov lus qhia hauv kab lus

Passivation yog Cov txheej txheem ntawm passivation ntawm hlau txhais tau tias tsim cov yeeb yaj kiab nyias ntawm qhov chaw txhawm rau tiv thaiv corrosion

Txoj kev niaj hnub ntawm kev tiv thaiv cov hlau los ntawm corrosion yog tsawg thiab tsawg dua yuav ua tau raws li cov kev cai uas siv rau kev ua tau zoo ntawm cov qauv thiab cov khoom tseem ceeb. Beams nyob rau hauv lub tsev thav duab, cov kav dej thiab cov hlau claddings tsis tuaj yeem ua yam tsis muaj kev tiv thaiv xeb ib leeg thaum nws los txog rau kev siv cov khoom mus ntev. Ib txoj hauv kev zoo dua rau kev tiv thaiv corrosion yog txoj kev electrochemical thiab tshwj xeeb passivation