2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Lub ntsiab melting unit nyob rau hauv steel kev lag luam yog lub qhib-hearth rauv. Nws yog npaj rau smelting steel ntawm ib tug muab tshuaj muaj pes tsawg leeg thiab nrog tej yam lub cev thiab txhua yam yam ntxwv. Lub qhov cub qhib-hearth, uas tau muaj sia nyob ntau qhov kev lag luam thiab thev naus laus zis hloov pauv, ua rau nws muaj peev xwm smelt cov qib steel nyuaj tshaj plaws, suav nrog cov alloyed.

Lub qhov qhib-hearth hom melting rauv yog lub tshuab hluav taws xob hluav taws xob rov ua dua tshiab, suav nrog cov qauv hauv qab no:

- Chaw ua haujlwm suav nrog sab nraub qaum thiab pem hauv ntej phab ntsa thiab vault.

- Lub taub hau nrog txoj kab ntsug los ntawm kev sib xyaw roj thiab cua nkag rau hauv chav ua haujlwm thiab cov khoom siv hluav taws xob raug tshem tawm ntawm nws.

- Roj thiab cua slag tso tsheb hlau luam tsim los sau thiab sau cov feem loj ntawm cov hmoov av smelting.

- Regenerators los xyuas kom meej qhov ntsuas kub tsis tu ncua los ntawm cua sov cov roj thiab cov cua sib xyaw nrog cov cua sov ntawm cov khoom siv hluav taws xob seem uas tawm hauv chav ua haujlwm.

- Ib qho kev hloov pauv hloov pauv hloov pauv tswj li qub tsim los hloov cov kev taw qhia ntawm cov khoom siv roj thiab cua sib xyaw rau qhov chaw ua haujlwm, nrog rau tshem tawm cov khoom sib txuas los ntawm nws.

- dej rov qab boiler.

- Kimney.

Open-hearth cub tawg yog ib chav symmetrical, uas txhais tau hais tias tib tus qauv tsim ntawm nws txoj cai thiab sab laug qhov txheeb ze rau txoj kab ntsug. Kev thauj khoom ntawm cov khoom siv raw yog nqa tawm los ntawm kev qhib tshwj xeeb - sau cov qhov rais kaw nrog li qub, uas yog cov phaj tuab tuab. Ntawm phab ntsa tom qab ntawm chav tsev muaj qhov hluav taws xob uas cov hlau ua tiav tau nchuav rau hauv lub ladle. Thaum lub sij hawm melting, lub qhov hluav taws xob yog clogged nrog low-caking refractory av nplaum, uas yog khob tawm thaum lub tiav lawm melted.

Open-hearth rauv tuaj yeem tsim yuav luag txhua hom carbon steels thiab ntau qib ntawm cov hlau alloy. Tab sis kev siv ntau yam khoom siv uas tsim nyog rau txoj kev qhib-hearth saturates cov hlau molten nrog ib qho tseem ceeb ntawm cov teeb meem impurities. Txawm tias ib feem me me ntawm cov khoom ntxiv xws li sulfur, phosphorus, arsenic thiab lwm yam khoom ua rau muaj kev puas tsuaj rau lub cev thiab tshuaj lom neeg ntawm cov hlau, txo cov yas zoo ntawm cov hlau, thiab ua rau nws nkig heev.

Lub tshuab hluav taws xob arc yog npaj rau smelting qib steel zoo. Tag nrho cov keeb kwm ntawm txoj kev loj hlob ntawm mechanical engineering thiab metallurgy yog txo mus rau kev tawm tsam rau cov yam ntxwv zoo ntawm cov hlau, kev txhim kho ntawm lawv cov khoom siv kho tshuab, lub cev thiab tshuaj lom neeg. Thiab qhov zais cia ntawm qhov zoo tshaj plaws ntawm cov hlau nyob hauv nws cov tshuaj purity. Electrometallurgy pab kom tau cov tshuaj dawb huv, thiab yog li cov hlau zoo thiab cov hlau. Feem ntau ntawm cov hlau zoo alloyed yog smelted nyob rau hauv hluav taws xob arc rauv.

Pom zoo:

Kev tswj cov ntaub ntawv hluav taws xob: qhov zoo thiab qhov tsis zoo, qhov tseem ceeb ntawm qhov system, txoj hauv kev siv

Cov kab lus nthuav tawm qhov zoo ntawm kev tswj cov ntaub ntawv hluav taws xob, thiab tseem teev cov kauj ruam tseem ceeb los siv nws hauv kev ua haujlwm ntawm txhua lub lag luam. Qhov tsis txaus ntawm qhov system no tau qhia, nrog rau cov teeb meem tseem ceeb uas cov tswv ntawm cov tuam txhab yuav tsum tau ntsib

Lub hom phiaj tseem ceeb ntawm kev siv nyiaj txiag. Lub tswv yim, qhov tseem ceeb ntawm cov txheej txheem thiab cov dej num ntawm kev siv nyiaj txiag

Lub hom phiaj tseem ceeb ntawm kev siv nyiaj txiag yog dab tsi? Vim li cas qhov txheej txheem no tshwm sim? Vim li cas thiaj xav tau? Cov hauj lwm twg raug ua? Dab tsi yog qhov tseem ceeb ntawm txoj kev no? Yuav ua li cas yog lub zuag qhia tag nrho system? Cov no, nrog rau ntau cov lus nug, yuav raug teb rau hauv lub moj khaum ntawm tsab xov xwm

Yam khoom ntawm se: cov ntsiab lus tseem ceeb thiab qhov tseem ceeb ntawm nws lub ntsiab lus

Cov khoom ntawm kev them se yog cov npe ntawm cov ntaub ntawv raug cai uas txiav txim siab lub luag haujlwm ntawm lub tuam txhab lag luam kom them se rau kev siv cov khoom muag. Tsis tas li ntawd, cov khoom lag luam se suav nrog kev xa khoom mus rau hauv thaj chaw Lavxias, muaj cov khoom ntiag tug ntawm tus kheej, tau txais cov khoom qub txeeg qub teg thiab cov nyiaj tau los yooj yim

Txoj kev tseem ceeb. Txoj kev tseem ceeb - nws yog dab tsi?

Txoj Kev Tseem Ceeb yog cov cuab yeej tswj hwm qhov project tseem ceeb siv los txiav txim siab hnub ua tiav qhov project thiab nyiaj pub dawb rau cov haujlwm tshwj xeeb. Cov kab lus muab ib qho algorithm rau kev xam lub network teem sij hawm ntawm tej yaam num siv txoj kev tseem ceeb

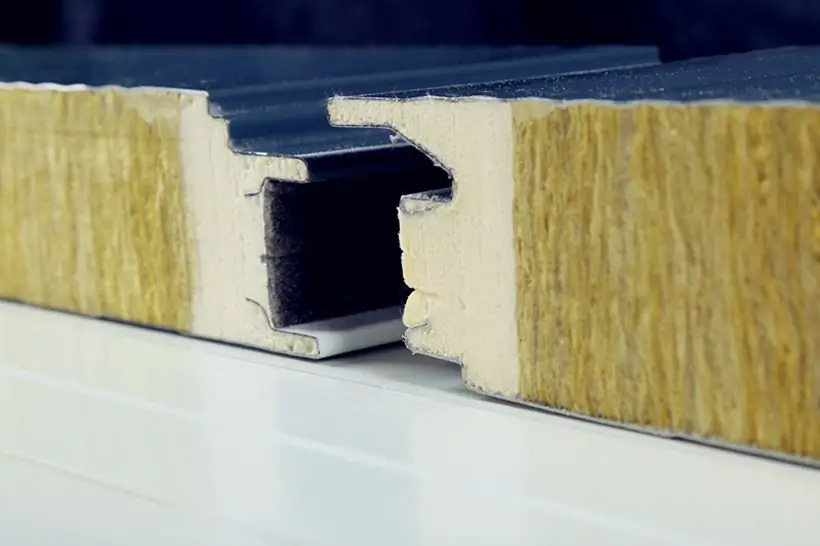

Thermal conductivity ntawm sandwich panels: lub tswv yim, cov yam ntxwv tseem ceeb, qhov ntev, tuab, thermal conductivity coefficient, kev teeb tsa kev cai, qhov zoo thiab qhov tsis zoo ntawm kev ua haujlwm

Cov thermal conductivity ntawm sandwich panels yuav qis tshaj yog tias polyurethane ua npuas ncauj yog lub hauv paus. Cov parameter raws li kev xav ntawm no txawv ntawm 0.019 txog 0.25. Cov khoom muaj zog, ntom thiab lub teeb. Nws yog tshuaj resistant thiab tsis nqus noo noo. Cov nas tsuag tsis zoo rau polyurethane ua npuas ncauj, fungi thiab pwm tsis tsim nyob rau hauv nws. Ua haujlwm kub txog +160 ˚С