2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Linear low-density polyethylene yog tam sim no siv dav vim muaj cov khoom zoo xws li lub zog, ductility thiab saj zawg zog. Kev siv cov khoom siv no yog qhov xav tau vim tias nws tuaj yeem ua tiav cov txiaj ntsig siab ntawm tus nqi qis.

YProperties of polymers

Cov khoom ntawm cov khoom siv kab tso cai rau nws siv tsis yog hauv kev lag luam, tab sis kuj nyob rau hauv lub neej txhua hnub. Ntawm cov yam ntxwv tseem ceeb yog cov hauv qab no:

- Cov khoom xws li vapor barrier thiab waterproofing yog zoo haum rau lub sij hawm ntev cia cov zaub mov tsis poob noo noo nyob rau lub sij hawm no.

- Cov khoom zoo kawg nkaus zam cov teebmeem ntawm yuav luag txhua cov kuab tshuaj organic. Qhov cuam tshuam ntawm qee qhov sib xyaw ua tau tsuas yog nyob rau hauv qee qhov xwm txheej, piv txwv li, ntawm qhov kub ntawm 60 degrees Celsius thiab siab dua.

- Vim qhov elasticity siab ntawm linear polyethylene, nyias thiab txawm tias ultra-thin films tuaj yeem tsim los ntawm nws.

- zoo UV tiv tausrays.

- High impact resistance.

- Txawm tias muaj kev ua haujlwm siab, nws muaj tus nqi qis.

Lwm yam khoom

Muaj lwm hom linear polyethylene - siab siab. Cov yam ntxwv ntawm ob hom ntawm ib qho khoom siv zoo sib xws, tab sis qhov thib ob muaj lub zog ntau dua. Tsis tas li ntawd, nws kuj zoo dua tiv thaiv cov neeg kho tshuab loads, nrog rau cov teebmeem ntawm cov organic kua thiab kub kub. Txawm li cas los xij, nyob rau tib lub sijhawm, nws kuj muaj qhov tsis zoo, uas nyob hauv qhov tsawg dua plasticity ntawm polyethylene. Lwm feature ntawm high-density linear polyethylene yog tias nws yog tsim nyob rau hauv multilayer, thiab qhov no zoo heev tsub kom lub zog ntawm cov khoom tiav. Vim li no, nws tuaj yeem siv rau hauv qhov chaw muaj zog.

Muaj qhov tsis zoo me ntsis uas siv rau ob hom khoom - qhov no yog qhov yuav luag tiav ntawm kev decomposition. Vim li no, koj yuav tsum pov tseg cov khoom siv koj tus kheej.

Cov yam ntxwv dav dav

Tus yam ntxwv tseem ceeb ntawm linear polyethylene yog nws qhov ntom. Nws yog tus yam ntxwv no uas cuam tshuam rau cov qauv ntawm cov khoom, thiab yog li qhov kev siv ntawm nws daim ntawv thov. Yog tias qhov ntom ntawm cov khoom sib txawv, ces nws cov qauv kuj txawv heev. Ib lub polymer uas muaj qhov ntom ntom dua yuav kuj muaj cov qauv denser lattice. Kev nce hauv qhov ntom ntawm cov lattice yuav ua rau kom muaj zog ntawm cov khoom, tab sis tib lub sij hawm kom txo qisyam ntxwv ntawm optical hom. Qhov ntom ntawm linear polyethylene tuaj yeem tsis tsuas yog qis, tab sis kuj siab.

khoom siv

Hais txog kev siv cov linear polyethylene, nws feem ntau siv hauv kev lag luam, vim nws cov tshuaj tiv thaiv siab heev. Feem ntau, cov thawv sib txawv yog tsim los ntawm cov khoom siv no. Niaj hnub no, peb hom LDL ntau lawm yog siv.

- thawj txoj kev hu ua suspension polymerization. Nyob rau hauv cov ntaub ntawv no, cov txheej txheem tsim yuav siv sij hawm qhov chaw nyob rau hauv ib tug tej yam kev ncua, uas yog ntxiv catalysts. Nyob rau hauv cov ntaub ntawv no, nws yog tsim nyog los mus tas li do lub muaj pes tsawg leeg. Nyob rau hauv rooj plaub no, koj tuaj yeem tau txais ib qho kev sib xyaw uas yuav muaj cov qauv zoo ib yam nkaus, tab sis tib lub sijhawm nws yuav muaj cov stabilizer residues.

- Hom thib ob yog hom tshuaj polymerization. Ib qho tshwj xeeb ntawm txoj kev no yog linear polyethylene yog tsim thaum tswj qhov kub ntawm 60 txog 130 degrees Celsius. Yog li ntawd, koj tuaj yeem tau txais cov khoom siv uas yuav tiv taus kev puas tsuaj thiab muaj cov ductility siab. Txawm li cas los xij, muaj teeb meem nrog kev xaiv cov catalyst, txij li thaum kub siab ntau yam tshuaj pib nkag mus rau hauv cov tshuaj tiv thaiv.

- Hom thib peb yog txoj kev tsim khoom qub tshaj plaws, hu ua roj-theem polymerization siv diffusion. Siv cov qauv no, koj tuaj yeem tau txais cov khoom siv uas yuav txawv ntawm nws qhov kev coj dawb huv, tab sis tib lub sijhawm nws yuav tsis muaj qhov sib xws.muaj pes tsawg leeg, uas yuav ua rau muaj kev sib txawv nyob rau hauv ntau qhov chaw, mus rau tib lub composition.

Nws tsim nyog sau cia tias nrog txhua txoj hauv kev, LDL tau txais hauv granules. Kev kho cua sov ntawm cov khoom siv los muab nws cov duab kawg.

YHigh density polyethylene

High-density polyethylene yog tsim los ntawm kev siv tshuab sib txawv. Ntawm no, ib txoj hauv kev yog siv los ua polymerize cov khoom xws li ethylene hauv autoclave lossis hauv reactor. Txhawm rau ua tiav cov txheej txheem no, nws yog qhov yuav tsum tau ua kom sov ethylene mus rau qhov kub ntawm 700 degrees Celsius, tom qab ntawd, nyob rau hauv lub siab ntawm 25 MPa, nws yuav tsum tau pub rau thawj feem ntawm lub reactor. Hauv qhov no, yuav tsum muaj cov pa oxygen thiab qhov pib pib. Nyob rau hauv thawj feem ntawm lub reactor, cov khoom heats ntau tshaj, mus txog 1800 degrees Celsius.

Tom qab ncav cuag qhov ntsuas kub no, cov khoom nkag mus rau qhov thib ob ntawm lub reactor, qhov twg qhov kub poob mus rau 190-300 degrees, thiab lub siab nce mus rau 130-250 MPa. Nws nyob ntawm no, nyob rau hauv tej yam kev mob, uas polymerization tshwm sim. Nws yog ib qho tseem ceeb uas yuav tsum tau ntxiv tias feem pua me me ntawm qhov pib yuav muaj nyob rau hauv cov khoom kawg.

Type of LDL

Hnub no, cov polyethylene tsawg-density yog siv dav heev thiab feem ntau siv rau kev tsim cov yeeb yaj kiab ntau yam. Ntau hom khoom raug paub.

- Moulded polyethylene. Nws yog tsuas yog siv rau ntim cov zaub mov kub. Qhov no yog yooj yim los ntawm high plasticity, siabtiv taus noo noo thiab kub.

- Zaj duab xis polyethylene. Qhov ntau yam no feem ntau yog siv los ua cov hnab sib txawv, uas muaj cov yam ntxwv ntawm elasticity siab.

- Rotational polyethylene. Siv los ua cov tso tsheb hlau luam uas muaj cov tshuaj tsis zoo.

Linear polyethylene LLDPE

Qhov no cov khoom uas tsis tshua muaj siab, uas yog tus cwj pwm los ntawm qhov tseeb tias nws cov qauv muaj ntau ntawm cov ceg luv luv. Lub hauv paus tseem ceeb ntawm kev tau txais cov tshuaj no yog cov txheej txheem ntawm copolymerization ntawm ethylene thiab olefin.

Lub luag haujlwm tseem ceeb ntawm hom polyethylene yog cov yeeb yaj kiab uas muaj qhov me me thiab nruab nrab ntawm kev nyab xeeb. Ib qho tshwj xeeb yog tias cov khoom siv no tshwj xeeb tsim los rau kev ua haujlwm hauv qhov chaw kub thiab txias nrog kev ua haujlwm siab. Qhov ntsuas kub uas cov khoom tsim los ntawm cov yeeb yaj kiab tuaj yeem tiv taus yog los ntawm -20 txog +60 degrees Celsius. Nws kuj muaj kev tiv thaiv siab Frost thiab tuaj yeem siv rau kev ntim khoom noj.

Linear expansion

Ntawm cov yam ntxwv ntawm polyethylene, kev nthuav dav kab kuj tseem ua lub luag haujlwm tseem ceeb heev. Piv txwv li, yog tias peb sib piv cov coefficients rau hlau thiab polyethylene, ces rau qhov thib ob nws yuav siab dua 14 npaug. Yog hais tias qhov saum npoo ntawm ib hom convex yog them nrog ib zaj duab xis ntawm polyethylene, ces vim qhov sib txawv ntawm qhov coefficient, adhesion yuav hloov tau zoo heev, nws yuav nce.

Summing tag nrho cov saum toj no, nws yuav pom tseeb tias polyethylene nyob rau hauvtau dhau los ua ntau thiab nrov tsis ntev los no. Qhov no yog kev txhawb nqa los ntawm qhov tseeb tias cov nyiaj tsawg yog siv rau nws cov khoom tsim, uas yog vim li cas nws cov nqi qis dua li cov hlau, piv txwv li, tab sis tib lub sijhawm nws qhov kev ua tau zoo heev. Tsis tas li ntawd, nws tseem tuaj yeem siv los tsim ntau lub thawv uas tuaj yeem siv rau hauv kev lag luam thiab hauv kev lag luam khoom noj.

Pom zoo:

Daim ntawv thov rov qab los ntawm kev tuav pov hwm qiv nyiaj: piv txwv, cov cai ntawm daim ntawv thov, lub sijhawm xa tawm

Nyob rau hauv tus txheej txheem ntawm tau txais cov nyiaj qiv, cov tsev txhab nyiaj muaj peev xwm qiv nyiaj los xaus daim ntawv cog lus pov hwm. Yog tias tus neeg siv tsis tuaj yeem them cov nuj nqis, lub luag haujlwm kaw nws mus rau lub txhab nyiaj yog nrog lub tuam txhab pov hwm. Tab sis hauv kev xyaum, qhov xwm txheej tsis sib xws feem ntau tshwm sim, thiab cov neeg them nyiaj siab xav tau xav txog qhov muaj peev xwm rov qab tau txais kev pov hwm qiv nyiaj thaum them rov qab ntxov. Tab sis yuav tau txais ntau npaum li cas? Thiab leej twg yuav tsum muab cov nyiaj - tus tuav pov hwm lossis lub txhab nyiaj?

High density low pressure polyethylene: yam ntxwv, piav qhia, daim ntawv thov

HDPE yog cov thermoplastic polymer. Nws muab ntau yam zoo uas tso cai rau nws siv rau hauv ntau yam kev lag luam. Nws tuaj yeem ua tiav ob qho tib si rau kev ntim cov yeeb yaj kiab thiab kev tsim cov kav dej sib txuas

Tshaj tawm ntawm phab ntsa daim ntawv qhia hnub: hom, xaiv cov ntsiab lus ntawm daim ntawv qhia hnub, nuances ntawm kev tsim thiab luam ntawv

Daim ntawv qhia hnub yog ib qho tseem ceeb ntawm txhua qhov chaw ua haujlwm. Thiab txawm tias muaj pes tsawg tus neeg siv khoom thiab cov neeg muag khoom pub dawb rau lawv, lawv tseem ua khawv koob los ntawm lub tuam txhab cov chaw ua haujlwm uas tsis koom nrog kev sib txuas lus nrog cov neeg cog lus. Cias muab, daim ntawv qhia hnub yog qhov tseem ceeb tshaj plaws ntawm cov ntaub ntawv tshaj tawm uas ib txwm mus nrog lub suab nrov

Lub hnab ntawv qhia: piav qhia, xav tau kev teeb tsa, daim ntawv thov, kev siv lub tswv yim

Qhov ntsuas lub hnab ntawv yog cov cuab yeej siv los txiav txim siab qhov txwv sab saud thiab qis ntawm kev ua lag luam. Daim duab qhia txog tus nqi ua haujlwm qhia ob kab, ib qho, ntawm ib qho kev ncua deb ntawm tus tub luam, rov ua qhov nruab nrab txav saum toj no, thiab lwm qhov hauv qab nws. Nrog rau kev lag luam ntau, cov cuab yeej tshuaj ntsuam xyuas no feem ntau yog siv los txheeb xyuas cov khoom lag luam overbought thiab oversold kev lag luam

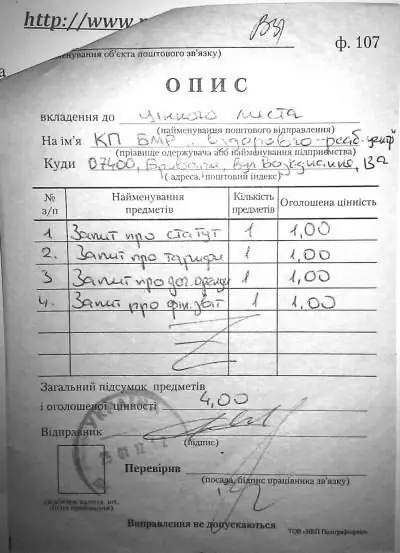

Daim ntawv sau npe nrog cov lus piav qhia txuas ntxiv. Cov txheej txheem xa ib tsab ntawv sau npe nrog cov lus piav qhia ntawm qhov txuas

Nyob hauv lub hnub nyoog ntawm computer technology, tib neeg sau ntawv rau ib leeg tsawg thiab tsawg. Tej zaum nws yuav zoo li tias nyob rau yav tom ntej xws li lub koom haum raws li lub chaw xa ntawv feem ntau yuav dhau los lawm. Tab sis nyob rau hauv kev muaj tiag no yog deb ntawm rooj plaub. Feem ntau, nws yooj yim ua tsis tau yam tsis muaj kev xa ntawv xa mus. Hauv tsab xov xwm no, peb yuav xav txog cov txheej txheem rau xa ib tsab ntawv sau npe nrog cov lus piav qhia txuas ntxiv. Wb kuj tham txog tias tsab ntawv yuav siv sij hawm ntev npaum li cas, thiab tus nqi pabcuam li cas