2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Tshuab thiab tshuab cuab yeej, khoom siv thiab khoom siv hauv tsev - tag nrho cov txheej txheem no muaj ntau cov ntsiab lus hauv lawv cov qauv tsim. Lawv cov kev sib txuas zoo yog qhov lav ntawm kev ntseeg tau thiab kev nyab xeeb thaum ua haujlwm. Hom kev sib txuas twg muaj? Cia wb mus saib lawv cov yam ntxwv, qhov zoo thiab qhov tsis zoo.

Kev faib tawm

Ntau hom kev sib txuas tuaj yeem muab faib ua ob pawg loj. Thawj qhov, raws li lub hauv paus ntsiab lus ntawm kev ua:

- Txiv. Cov khoom tuaj yeem txav mus rau ib leeg.

- Nyob twj ywm. Ob qho tib si ntawm ib feem yog rigidly tsau rau ib leeg.

Thiab, txhua hom kev faib tawm yav dhau los tuaj yeem ua tau ob txoj hauv kev sib txuas:

- Detachable. Nws yog siv thaum lub sij hawm hloov ntawm qhov chaw, sib dhos thiab disassembly ntawm lub mechanism raws li ib tug tag nrho. Cov no yog cov kev sib txuas hauv qab no: threaded (siv bolts khiav), toothed, keyed, thiab lwm yam.

- Ib thooj. Cov kev sib txuas no tsuas yog dismantled siv txhua yam kev txiav txim, uas rhuav tshem cov mating qhov chaw. Cov hom kev sib txuas no yog dab tsi? Ntawm lawv yog vuam, gluing, riveting, flaring, crimping, cuam tshuam haum, stitching, xuas nrig ntaus, thiab lwm yam.

Yog li, cia peb saib ze dua ntawm hom kev sib txuas ntawm qhov chaw.

xov xwm txheej

Ib qho qub thiab ntev-kuaj mounting xaiv. Cov khoom hauv qab no yog siv rau nws: bolts, screws, studs, ntsia hlau ties thiab lwm yam. Fastening yog nqa tawm vim xov ntawm lub fastener thiab nyob rau hauv lub qhov ntawm ib feem.

Kauv protrusions ntawm tus pas nrig thiab hauv lub qhov thev naus laus zis ntawm cov khoom yog hu ua xov. Xav txog lub ntsiab fasteners:

- A bolt yog ib tug threaded pas nrig nrog kho lub taub hau ntawm ib kawg. Nws cov duab yog hexagonal, square, round, thiab lwm yam.

- Cov ntsia hlau txawv ntawm cov khoom dhau los hauv qhov uas muaj qhov (slot) rau lub hau ntswj ntawm lub taub hau. Nws tuaj yeem ua hexagonal, ncaj, hla, thiab lwm yam. Raws li hom lub taub hau, cov khoom lag luam yog countersunk, cylindrical, semicircular, semi-secret.

- Stud yog ib txoj hlua khi ntawm ob qho kawg. Tsis zoo li cov kev xaiv yav dhau los, nws tsis muaj lub taub hau.

- Tus pin qhov chaw yog slotted ntawm ib kawg.

- Nut - lub prism nrog lub qhov los yog ntsaws rau ntawm ib sab.

Washers yog tsim rau cov khoom siv no: tiaj, caij nplooj ntoos hlav, deformable. Qhov kev kho no yog siv rau txhua qhov chaw.

Keyed

Keys kho cov ncej nrog cov khoom uas xa cov kev sib hloov thiab kev co. Kev tsim cov ntsiab lus no tuaj yeem yog prismatic,wedge, ntu, tangential. Xws li fasteners tsim hom kev sib txuas hauv qab no:

- Tsis muaj kev ntxhov siab yog tsim los ntawm cov yuam sij prismatic segmental. Tsis muaj kev ntxhov siab thaum sib dhos.

- Kev ntxhov siab yog tsim los ntawm tangential thiab ntu cov yuam sij. Thaum sib dhos, mounting kev ntxhov siab tshwm. Siv rau cov txheej txheem nyuaj.

Toothed (splined) txuas

Mounting tshwm sim vim cov hniav protruding ntawm ncej thiab qhov chaw so hauv qab lawv hauv hub.

Qhov ntau thiab tsawg yog kho los ntawm cov qauv. Txoj kev no yog siv rau kev txav mus los thiab ruaj khov.

Ntawm no, muaj peb txoj hauv kev los kho qhov tawv nqaij: lub teeb, nruab nrab, siab. Qhov txawv yog nyob rau hauv tus naj npawb thiab qhov siab ntawm cov hniav. Nws nyob hauv thaj tsam ntawm 6-20 daim. Cov hniav zoo:

- Daim duab peb sab yog qhov xav tau me me. Siv rau cov ncej me me thiab lub zog qis.

- Squamous. Nruab nrab ntawm sab ntsej muag, ntawm sab hauv thiab sab nraud.

- Involute. Haum rau cov ncej loj.

Cov hom no siv qhov twg? Lub hom phiaj ntawm kev sib txuas ntawm cov phiaj xwm zoo li no yog kev sib kis ntawm torque. Daim ntawv thov nto moo tshaj plaws yog cov cuab yeej hluav taws xob.

Peb tau saib cov mountable detachable. Tom ntej no, peb yuav kawm txog yam tseem ceeb ntawm kev sib txuas mus tas li.

vuam

Dab tsi ua rau lawv tshwj xeeb? Cov hom pob qij txha no yog tsim los ntawm cua sov thiab fusing cov khoom ntawm qhov txuas taw tes los ua ib qho kev sib txuas. Qhov no clutch yog suav hais tias yog ib qho ntawm feem ntaucommon.

Muaj ntau txoj kev xaiv rau vuam. Cov neeg nyiam tshaj plaws:

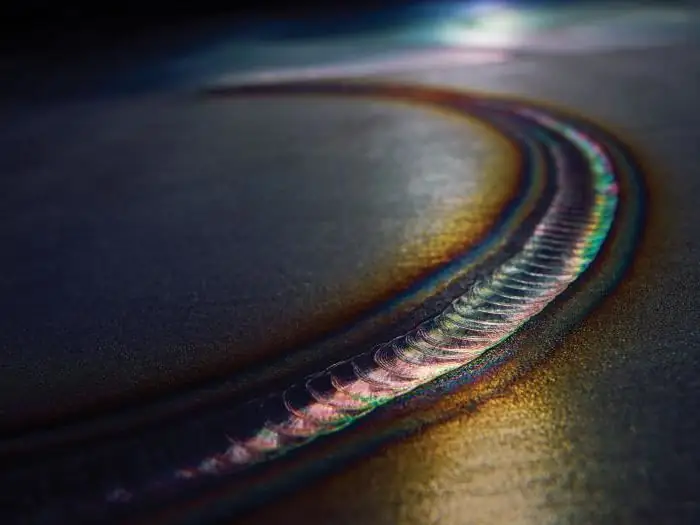

- Arc vuam. Peb lub ntsiab subtypes tuaj yeem paub qhov txawv: tsis siv neeg submerged arc (qhov txawv los ntawm kev tsim khoom siab thiab zoo, siv hauv ntau lawm), semi-automatic submerged arc (siv rau luv luv intermittent welds), phau ntawv (txo cov khoom lag luam ceev, zoo nyob ntawm qhov kev paub ntawm tus welder).

- Hu rau vuam. Siv nyob rau hauv loj ntau lawm rau nyias daim hlau. Lub seam yog overlapped.

Ib qho kev xaiv mounting nrov tau pom hauv daim duab.

Feem ntau siv hauv kev tsim kho suburban.

Tsis zoo li vuam, thaum lub sij hawm soldering, cov hlau nto tsis kub mus txog qhov kub thiab txias. Lub luag hauj lwm ntawm lub binder yog ua los ntawm molten solder, uas muaj ib tug qis melting point.

Txoj kev clutch no yog siv rau qhov me me. Qhov no yog vim qhov kev txwv ntawm qhov sib txawv ntawm qhov chaw ntawm qhov chaw.

Adhesive joints

Qhov kev txuas no tsis tas yuav tsum tau ua kom sov.

Rau txhua hom hlau, nws tus kheej cov kua nplaum raug xaiv, uas yuav muab kev tuav nruj. Cov khoom yog npaj rau cov haujlwm zoo li no. Qhov saum npoo yog polished, degreased, ib qho tshwj xeeb primer yog siv, tom qab uas lub gluing ua haujlwm. Cov khoom sib xyaw siv tau txawv los ntawm cov khoom siv ntxiv thiab adhesion rau ntau qhov chaw.

Riveted fixation

Txoj kev sib txuas no yog siv los txuas cov ntawv hlau thiab cov duab zoo li tus. Lub qhov technologies nyob rau hauv qhov chaw yog nqa tawm los ntawm drilling, ces lub riveting yog tso.

Vim yog kev ua haujlwm, tus pas nrig thiab lub taub hau yog deformed, sau thiab kho lub qhov. Qhov kev ua haujlwm no yog ua tiav manually thiab mechanically. Rivets kho cov khoom uas tsis tuaj yeem ua rau vuam, soldering, gluing, thiab rau qhov chaw uas nws tsim nyog los ncua kev puas tsuaj.

Kev sib koom tes

Tsim los ntawm kev haum lub rooj zaum ntawm qhov chaw. Lub coupling tshwm sim vim lub zog ntawm kev sib txhuam. Yeej, hom no suav hais tias yog ib qho. Tab sis qhov no yog conditional. Hauv kev xyaum, lawv tseem rhuav tshem thiab hloov qhov chaw.

Qhov zoo, qhov tsis zoo ntawm hom kev sib txuas

Txhua tus fastener muaj nws tus yam ntxwv. Xav txog txhua qhov kev xaiv ntawm qhov zoo thiab qhov tsis zoo:

- xov. Withstands hnyav loads, txhim khu kev qha tuav, ntau yam khoom, yooj yim ntawm installation thiab dismantling, muaj peev xwm siv mechanization, tsawg tus nqi. Qhov tsis zoo: nce qhov kev ntxhov siab ntau ntxiv, txo qhov tsis kam.

- Keyed. Yooj yim tsim, yooj yim installation thiab dismantling. Qhov tsis zoo: qhov zawj rau cov veneer tsis muaj zog rau lawv los ntawm kev txo qis ntawm cov ncej thiab hub. Nws kuj tshwm sim vim qhov concentration ntawm torsional kev nyuaj siab thiabkhoov. Labor-intensive fastener manufacturing process.

- Toothed. Tsim kom muaj kev tuav zoo thiab raug kev taw qhia ntawm axial txav, xa cov torque ntau dua, tsawg qhov chaw, kev ntseeg siab nyob rau hauv reversible thiab dynamic loads, tsis muaj zog ncej, txo qhov ntev ntawm lub hub. Disadvantages: nce nqi, complex ntau lawm technology.

- vuam. Tus nqi qis ntawm kev ua haujlwm, kev sib txuas yog kaw thiab nruj, kev siv cov txheej txheem automated, muaj peev xwm ua haujlwm nrog cov ntaub ntawv tuab. Qhov tsis zoo: nyob rau hauv phau ntawv welding, qhov zoo yog nyob ntawm qhov tsim nyog ntawm tus neeg ua haujlwm, deformation ntawm qhov chaw ntawm qhov chaw thaum rhuab, tsis tshua muaj kev ntseeg siab thaum vibration thiab shock.

- Tshuaj. Tsis muaj deformation ntawm qhov chaw ntawm qhov chaw, siab raug, muaj peev xwm ntawm desoldering. Qhov tsis zoo: Cov txheej txheem kev npaj tsis yooj yim, kev tshem tawm yam tsawg kawg nkaus yuav tsum tau khaws cia.

- Kaw. Tus nqi qis, tsis muaj qhov tsis muaj zog ntawm qhov ua haujlwm, muaj peev xwm ua ke nrog lwm hom fasteners, nruj ntawm kev sib koom ua ke, ua rau kom muaj kev tiv thaiv corrosion ntawm seam, tiv taus dej, tshuaj, kub hloov, yooj yim. ntawm kev siv technology. Qhov tsis zoo: ua tib zoo npaj ntawm lub hauv paus, yog tias cov khoom sib xyaw raug xaiv tsis raug, cov yam ntxwv ntawm lub zog yuav txo qis.

- Riveting. Yuav siv tau rau cov ntaub ntawv uas tsis yog weldable, txhim khu kev qha, tiv thaiv kev qaug zog tawg. Disadvantages: laboriousness, khoom siv, thaum lub sij hawm tus txheej txheem deformation ntawm qhov chaw ntawm seem tshwm vimMechanical impact.

- Kev cuam tshuam kev sib txuas. Cov qauv tsim yog yooj yim heev, kev npaj zoo ntawm cov khoom sib txheeb rau ib leeg, withstands hnyav loads. Disadvantages: nyuaj rau assemble, lub zog dissipates nyob rau hauv lub cuam tshuam ntawm kev co thiab vibrations.

Raws li koj tuaj yeem pom, txhua hom muaj nws qhov zoo thiab qhov tsis zoo. Muab cov xwm txheej no, xaiv qhov zoo tshaj plaws ntawm cov fasteners nyob rau hauv txhua rooj plaub. Xav txog qhov twg siv ntau yam sib xyaw.

Hom kev sib txuas. Piv txwv daim ntawv thov

Threaded, glued, welded kev sib txuas muaj nyob txhua qhov chaw hauv kev lag luam. Piv txwv li, kev tsim kho, rooj tog zaum, kev lag luam hnyav thiab lwm yam. Keyed thiab slotted fixings yog dav siv nyob rau hauv cov cuab yeej fais fab, khoom siv, mechanical engineering. Kev cuam tshuam kev sib txuas yog ntsia rau ntawm lub shafts ntawm iav rings, worm log. Soldering feem ntau yog siv nyob rau hauv cov tshuab hluav taws xob uas yuav tsum tau muaj qhov siab tshaj plaws. Riveting yog siv rau stitching nplooj ntawv ntawm nyias hlau. Txawm li cas los xij, raws li pom nyob rau hauv daim duab kawg, cov channel loj loj tuaj yeem txuas nrog rivets. Nov yog ib daim ntawv teev npe me me rau cov kev xaiv mounting rau tus kheej.

Nws tuaj yeem hais tau tias nrog kev txhim kho thev naus laus zis, clutch thev naus laus zis tau txhim kho sai, uas txhais tau hais tias hom tshiab ntawm qhov sib txuas yuav tshwm sim. Lub ntiaj teb niaj hnub no muaj cov khoom sib sau ua ke, tshuab thiab cov tshuab. Qhov zoo thiab kev pabcuam lub neej ntawm cov khoom yog nyob ntawm seb cov khoom ruaj khov li cas. Nws tseem yog ib qho tseem ceeb uas qhov kev sib txuas tsis cuam tshuam cov duab ntawm cov khoom thiab tsis qhia txog kev hloov pauv ntxiv hauvkev tsim kho. Yog li ntawd, nws yuav tsum ua raws li cov txheej txheem thev naus laus zis. Yog tias lawv tau pom, cov xwm txheej kub ntxhov ntawm cov lag luam yuav raug txo qis, thiab cov chav nyob lawv tus kheej yuav kav ntev heev.

Yog li, peb pom tias hom kev sib txuas muaj dab tsi.

Pom zoo:

Kev sib koom tes zoo yog kev pom zoo ntawm ob lossis ntau lub tuam txhab ywj pheej los koom tes kom ua tiav qee lub hom phiaj kev lag luam. Cov qauv thiab cov piv txwv ntawm kev sib koom tes thoob ntiaj teb kev sib tw

Cov kev sib koom tes zoo yog qhov kev pom zoo ntawm ob lossis ntau lub tog kom ua tiav cov hom phiaj pom zoo thaum tswj hwm kev ywj pheej ntawm cov koom haum. Lawv zoo li poob qis ntawm kev cai lij choj thiab kev koom tes nrog kev koom tes. Cov tuam txhab tsim kev sib koom tes thaum lawv txhua tus muaj ib lossis ntau dua cov cuab yeej ua lag luam thiab tuaj yeem sib koom ua lag luam kev paub rau ib leeg

Lub chaw tshaj tawm kev tshaj tawm: yuav qhib li cas, pib qhov twg, npaj cov ntaub ntawv tsim nyog, teeb tsa lub phiaj xwm kev lag luam, lub hom phiaj, lub hom phiaj thiab theem ntawm kev txhim kho

Kev thov rau cov kev pabcuam tshaj tawm muaj zog thoob plaws hauv lub xyoo, tsis hais qhov tseeb tias kev ua lag luam tau sawv cev los ntawm ntau lub tuam txhab muab cov kev pabcuam zoo li no. Yog li ntawd, thaum npaj yuav ua li cas qhib ib lub koom haum tshaj tawm, tshwj xeeb yuav tsum tau them nyiaj rau kev txheeb xyuas kev lag luam. Qhov no yuav tso cai rau koj los ntsuas qhov kev cia siab tiag tiag ntawm niche, nrog rau tsim cov qauv kev lag luam zoo nrog cov txiaj ntsig siab

Kev sib txuas lus lag luam. Cov lus ntawm kev lag luam kev sib txuas lus. Kev sib txuas lus kev lag luam

Cov ntaub ntawv ntawm kev sib txuas lus lag luam muaj ntau haiv neeg hauv lub neej niaj hnub. Ob lub koom haum kev lag luam ntawm qee hom kev ua tswv cuab thiab cov pej xeem zoo tib yam nkag mus rau hauv kev lag luam thiab kev lag luam kev sib raug zoo

Piv txwv ntawm kev tsis sib haum xeeb ntawm kev tshaj lij thiab lawv txoj kev daws teeb meem. Hom kev tsis sib haum xeeb

Kev tshawb fawb txog kev sib raug zoo qhia tias txhua yam kev sib raug zoo cuam tshuam nrog kev tsis sib haum xeeb. Qhov no yog li cas lub ntiaj teb no ua hauj lwm: dab tsi zoo rau ib tug Lavxias teb sab yog kev tuag rau ib tug German. Raws li kev tsis sib haum xeeb ntawm kev cia siab, lub hom phiaj thiab kev nyiam, kev tsis pom zoo thiab kev tsis sib haum xeeb tshwm sim. Yuav ua li cas kom tau tawm ntawm cov xwm txheej zoo li no nrog kev poob qis? Puas yog kev tsis sib haum xeeb ib txwm phem?

Kev sib txuas lus: hom, kev faib tawm, txoj hauv kev thiab kev tso, lub hom phiaj ntawm kev sib txuas lus

Kev sib txuas lus yog ib theem tseem ceeb tshaj plaws hauv kev tsim kho, piv txwv li, ntawm lub tsev tshiab. Txog niaj hnub no, muaj ntau ntau txoj kev sib txawv ntawm kev txhim kho kev sib txuas lus. Lawv cov yam ntxwv, nrog rau qhov zoo thiab qhov tsis zoo, tau coj mus rau qhov tseeb tias ib tus neeg txoj kev xaiv rau txhua rooj plaub